Have you ever wondered why some plastic items feel smooth while others are rough? The answer is injection mold textures. This entire process creates visual, tactile, and functional improvement to your product, which is an enhancement of product value in everything from car dashboards to household appliances.

This guide will introduce you to the mold texture. You will learn what they are, how they are made, and why their inclusion is important. In the end, you will be able to select a perfect finish that allows your products to be unique.

What is Surface Texture?

In manufacturing, surface texture refers to the intentional design of the mold’s finish so that the final plastic part’s appearance, feel, and performance are controlled. It can be broadly defined as the three-dimensional pattern on a surface – perfectly smooth, rough, or patterned. The surface finish becomes important for aesthetic reasons and grip, along with hiding imperfections on a product.

When discussing surface textures, you will come across a few terms, and these three elements together define the whole surface finish.

- Lay: The main direction of a surface pattern. It’s caused by the manufacturing process, like milling or grinding, and can be horizontal, vertical, or even random.

- Waviness: The larger, more spaced-out undulations on a surface. Think of it as soft, rolling hills caused by the vibration of a tool or tool movement across a wide area.

- Roughness: The fine irregularities of a surface texture that are more tightly packed. These micro-scale imperfections are the things that you can feel when you run your hand over a product.

Surface Texture Applications

Textures on plastic parts are more than just for looks; they provide a wide range of practical benefits and are used in countless industries to improve a product’s function and appeal.

Healthcare Equipment

Textures become important for hygiene and safety. Smooth textures are necessary to avoid bacterial buildup. They also help provide user comfort, which is vital for devices that are used consistently and for longer durations. For sensitive equipment, anti-slip textures can help avoid disengagement during handling of the device for safety purposes.

The Packaging Field

Textures on packaging can improve a product’s appeal and value immediately, helping to establish brand identity. They can help improve functionality in packaging items to make grabbing and handling easier. Meanwhile, textures can also help packaging withstand the hazards of damage during transport and display as well.

Automotive Sector

Within the automotive space, textures are more than just a visual appeal. They provide functional benefits, most notably better grip on steering wheels and dashboards, which in turn means a better handling experience. Textures have also been shown to improve the durability and wear resistance of both interior and exterior parts by making parts last longer physically while also being more aesthetically pleasing.

Household Devices

When it comes to home appliances, textures are essential to help them integrate into your home’s design. They improve usability and make buttons or handles easier and more comfortable to use. Textures also contribute to the durability of a product, deter scratches and wear on the surfaces of devices, and help it look new over the appliance’s life.

Consumer Electronics

Textures are key to creating a great user experience with electronics. They improve the tactile feel of devices for added comfort to hold, and assist premium aesthetics, making a product feel more advanced with polished and satin textures applied. They also provide a better grip with anti-slip textures that add a comforting function to prevent slipping.

Industrial and Commercial Products

When it comes to industrial and commercial products, surface textures serve the safety and durability functions. The increase of grip on tools and machinery surfaces ultimately leads to a reduction in accidents. Some textures also improve efficiency by reducing the friction on moving machine parts, thus increasing the service life and keeping the performance consistent for harsher working environments.

Advantages of Mold Surface Textures

Surface texture on a mold provides several benefits that go beyond just aesthetics. It improves a product – its function, its durability, and ultimately the overall value.

Enhancing Aesthetics

You can create a noticeably enhanced visual quality to a product by adding a texture to a mold. You can mask imperfections such as flow lines, weld lines, and other common molding defects. Adding texture to the part allows you to achieve a high-quality professional finish, without the added post-production time, making the final product more attractive to the consumer.

Improving Usability and Safety

Textures make products easier and safer to use by improving the grip on a part. Tool handles and many sporting equipment rely on textures to prevent parts from slipping from your hand to ensure security. Textures can also create a unique tactile feel to a part, improving the overall feel of the product.

Increasing Durability

Textures help protect products and increase their service life. By providing a layer of resistance to contact damage during shipping and handling, textured surfaces can resist smudges or fingerprints, keeping the product looking cleaner. They also offer better paint adhesion for products requiring a long-lasting painted finish.

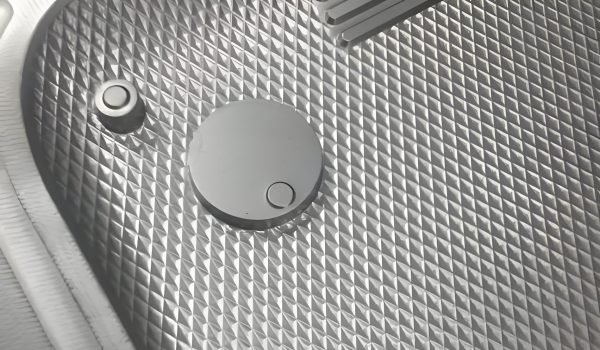

Different Types of Mold Surface Textures

Now that we have developed a good understanding of what surface texture is, let’s consider the methods of creating these unique finishes on injection molds.

Mold Surface Textures Made by Polishing

Polishing is a very common method to achieve smooth, mirror-like surfaces. The polishing process takes into account different grades of tools and compounds to create a reflective finish on the final plastic part. It is good for clear parts or products needing a high-end gloss, and the greater polish you receive, the more perfect the finish.

Mold Surface Textures Made by Sandpaper

To create a less reflective finish, sandpaper can be used to texture a mold. This technique involves different grits to form a consistent, matte finish. It’s used primarily for parts that require dull surfaces or for use with the intention of camouflaging minor surface flaws. The grade of the sandpaper will affect the final texture’s roughness.

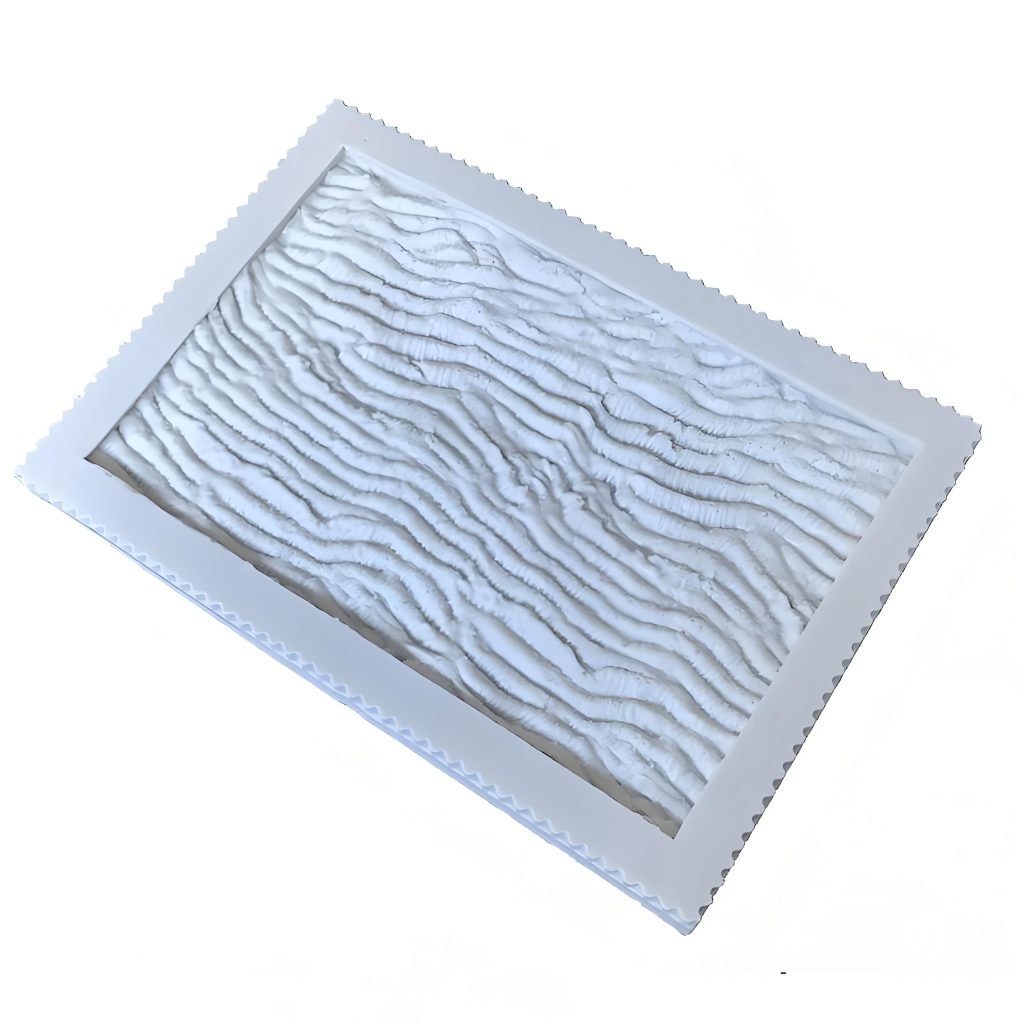

Mold Surface Textures Made by Blasting

Blasting uses an abrasive material (glass beads) that is shot at the mold during the process, and results in a mold tech texture with a slightly rough feel and matte finish. The injection mold texture is primarily determined by the size of the blasting media and the pressure used. This process is ideal for finishes where a non-slip surface or anti-glare is needed on products.

Mold Surface Textures Made with Satin

A satin finish provides a subtle sheen, but does not reflect as brightly as a polish. It is a mix of a few different techniques to create a clean, modern-looking finish. Satin finishes are typically popular in electronic devices and appliances because they hide imperfections and exhibit a soft, pleasing feel.

Mold Surface Textures Made with Grit Stone

Grit stones are used to create a uniform, specific plastic mold texture. It is made by rubbing or mechanically working an abrasive stone across the mold. This leaves a pattern of fine scratches which create a consistent matte finish. This method is often employed for a very precise, reproducible pattern that may be too difficult to achieve with other methods.

Mold Surface Textures Made with EDM

Electrical Discharge Machining (EDM) is also a high-tech precision texturing approach. Using electrical sparks to erode the mold surface, the EDM process can make detailed and deep patterns, with a greater degree of complexity. It can be used in hard-to-reach areas, and provides ground control over the rugged, final finish.

Injection Mold Texture Standards

The industry utilizes standard injection mold texture standards to produce consistent results as a common rule between designers, engineers, and mold makers. The two most utilized standards are:

- Mold-Tech Textured Finishes

Mold-Tech is a well-known mold texturing standard, commonly used for commercial products. It is broken up into four series – A, B, C, and D. The Series A finishes are the most applied and are classified from fine to coarse matte textures. These do not include advanced techniques such as laser cutting or masked chemical etching.

Because Mold-Tech textures are typically coarser, they necessitate a more pronounced draft angle. It is recommended to increase the draft by 1.5° for every 0.001″ of texture depth. This method provides many types for injection molding, with the mold tech textures grouped by series:

| Series | Texture Description | Common Applications |

| MT-11000 Series | Fine-grained, smooth finish | Consumer electronics, medical devices |

| MT-15000 Series | Moderate graininess | Automotive interior parts, household appliances, industrial equipment |

| MT-30000 Series | Medium to coarse grain | Automotive exterior components, power tools, agricultural machinery |

| MT-60000 Series | Deep and prominent textures; rugged or natural appearance | Off-road vehicle parts, outdoor equipment, furniture |

| MT-80000 Series | Highly defined and complex patterns | Luxury goods, specialty consumer products |

- VDI 3400 Surface Finish

The VDI 3400 surface finish is a standard developed by the Society of German Engineers. This mold texturing standard is primarily created through Electrical Discharge Machining (EDM) during the molding process. VDI is a globally recognized standard for achieving matte surfaces, offering textures from fine to coarse.

Unlike Mold-Tech, which can be applied using various methods like manual finishing or chemical etching, VDI mold surface textures are predominantly a result of the EDM process. While they are distinct standards, some injection mold surface textures may have similar appearances, such as the equivalence between VDI 33 and MT-11020.

The VDI 3400 standard is a global benchmark for classifying mold surface textures, most often created using EDM. The scale ranks from fine to coarse.

| VDI Code | Finish Type | Key Characteristics |

| VDI 0 | Glossy/Polished | Mirror-like, with minimal texture. |

| VDI 12 | Fine Stippled | Subtle matte finish with small, closely-spaced dots. |

| VDI 30 | Coarse Stippled | A pronounced, tactile texture from larger, more spaced dots. |

| VDI 33 | Orange Peel | A bumpy surface that effectively hides scratches and imperfections. |

| VDI 34 | Leather Grain | A textured surface with a pattern resembling leather. |

Factors to Consider While Deciding Mold Surface Textures

Once you have gained an understanding of the various types of textures, you can begin to consider the basic factors that will help you choose the right one for your product.

Aesthetic Requirements

The texture you choose sets the final look and feel of your product. You may want to hide some imperfections, lessen the glare, or create a more premium appearance. Don’t forget you have to apply an aesthetic choice that aligns with your brand. Rough, industrial mold surface textures may work for a power tool, but would be totally inappropriate for a delicate medical device.

Material Compatibility

Not every plastic responds similarly to textures. Some plastics, like ABS, hold a texture very well, while others, like polypropylene, may take a texture less effectively. The flow characteristics or shrink rate of the material can also make a difference in how a texture gets transferred. Just be mindful of the plastic compatibility when considering texture.

Part Functionality

Always think about usage. A tool handle needs a mold tech texture that provides a good level of grip. A car dash needs a texture that decreases glare but feels luxurious. The texture needs to always help your product fulfill its purpose and help a user enjoy the experience of using it, and serve its function better.

Cost and Time

The texturing option you choose can vastly impact your budget and timeline. An easy polish is less expensive and faster than a more complicated EDM texture, and, as a rule, blasting is more cost-effective than a hand-polished surface that requires custom finishing. Consider all of these options and make sure to consult with your manufacturer as you proceed to avoid a costly and unexpected delay.

Conclusion

Finding the best injection mold texturing process is a blend of engineering and artistry. The texture will affect not only how your product looks, but also the feel and the way your product performs. You will benefit from understanding standards like Mold-Tech and VDI. In addition, experienced manufacturers will apply the finish exactly as per your expectations and bring your product to life.

At Fecision, we offer you a perfect injection mold texturing experience. Our expertise ensures your choice of Mold-Tech and VDI textures can be perfectly applied to your molds, creating quality plastic parts with premium materials that meet your functional and aesthetic goals precisely. We understand the nuances of material behavior, draft angles, and design for manufacturability, so you can be confident in the final result.

Ready to put the perfect finish on your product? Contact Fecision today to start the discussion of your project.