Custom PP Injection Molding Service

PP injection molding (polypropylene injection molding) is a versatile manufacturing process that transforms polypropylene resin into precise, durable plastic components. Our engineering expertise, advanced manufacturing capabilities, and commitment to quality ensure your polypropylene parts perform as intended while optimizing costs and production efficiency.

Lightweight

Flexible

Chemical-resistant

Material Certifications

ISO 9001:2015 certified materials

FDA-compliant grades available

RoHS and REACH compliant options

UL-rated flame-retardant formulations

Medical-grade PP for healthcare applications

Material Customization

Custom color matching capabilities

Reinforced PP with glass or mineral fillers

UV-stabilized formulations for outdoor use

Antimicrobial additives available

Specialized grades for extreme environments

Engineering-Grade PP Material for Injection Molding

We utilize premium polypropylene injection molding materials that deliver exceptional performance across diverse applications. Our engineering-grade PP resins are carefully selected to match your specific requirements.

PP (Polypropylene) Properties for Injection Molding

| Property | Value Range | Benefit |

| Density | 0.895-0.92 g/cm³ | Lightweight components |

| Tensile Strength | 20-40 MPa | Durable under stress |

| Melting Point | 220-280°C | Thermal stability |

| Chemical Resistance | Excellent | Resistant to acids, bases, solvents |

| Moisture Absorption | Dimensional stability | |

| Electrical Insulation | High | Excellent electrical insulator |

PP Molding Specifications and Technical Capabilities

Our advanced PP injection molding equipment and expertise enable us to handle projects of varying complexity and scale.

We maintain tight tolerances while optimizing cycle times for cost-effective production.

Machine Capabilities

- Tonnage range: 25-1,500 tons

- Shot weight: 0.1g to 5kg

- Precision servo-driven systems

- Advanced process monitoring

Mold Specifications

- Single to 64-cavity molds

- Hot and cold runner systems

- Mold size up to 1000mm x 800mm

- In-house mold maintenance

Quality Parameters

- Tolerances: ±0.05mm possible

- Statistical process control

- 100% visual inspection

- Dimensional verification

Molding Benefits of Polypropylene

PP polypropylene injection molding offers numerous advantages that make it an ideal choice for a wide range of applications.

Understanding these benefits helps in making informed material selection decisions.

Advantages of PP Injection Molding

- Cost-Effective Production: Low material cost and fast cycle times reduce overall production expenses

- Design Flexibility: Excellent flow characteristics allow for complex geometries and thin walls

- Chemical Resistance: Withstands exposure to many acids, bases, and solvents

- Lightweight: Low density (0.895-0.92 g/cm³) creates lightweight yet durable components

- Recyclability: 100% recyclable material supports sustainable manufacturing

- Living Hinge Capability: Unique ability to create integral hinges that flex millions of times

Speak With Our Engineering Team

Discuss your specific application challenges with our specialists.

Why Choose Fecision for PP Injection Molding

Partner with Fecision for your PP injection molding services and experience the difference that expertise, advanced technology, and commitment to quality can make for your projects.

Technical Expertise

✅ 25+ years of specialized experience

✅ Dedicated material specialists

✅ Design for Manufacturing (DFM) support

✅ Process optimization experts

Quality Assurance

✅ ISO 9001:2015 certified facility

✅ Advanced inspection equipment

✅ Statistical process control

✅ Comprehensive quality documentation

Service Excellence

✅ Rapid quote response (24-48 hours)

✅ Flexible production scheduling

✅ Inventory management programs

✅ Global logistics capabilities

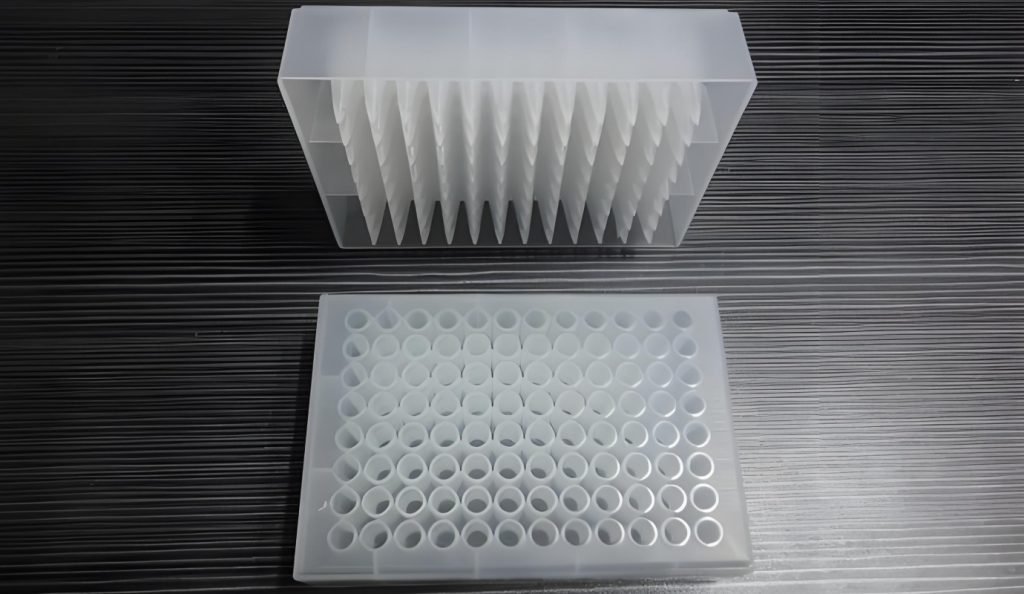

PP Injection Molding Applications

Industries We Serve

PP injection molding is utilized across numerous industries due to its versatility, durability, and cost-effectiveness.

Our expertise spans the full spectrum of polypropylene applications.

Automotive

Battery cases and covers

Fluid reservoirs and containers

Air intake components

Underhood protection parts

Consumer Goods

Household appliance housings

Furniture components

Toys and recreational products

Garden and outdoor equipment

Medical Devices

Laboratory consumables

Surgical instrument components

Drug delivery devices

Sterilizable medical containers

Packaging Solutions

Caps and closures

Hinged containers

Industrial packaging

Food-grade packaging

PP Injection Molding FAQs

Polypropylene injection molding can achieve various surface finishes, from high-gloss to textured matte. Common options include:

- High-gloss finish for aesthetic applications

- Textured surfaces for improved grip and scratch resistance

- Matte finishes to reduce glare

- Custom textures to match existing products

Lead times for PP plastic injection molding projects vary based on complexity, quantity, and tooling requirements:

- New tooling development: 4-6 weeks

- First article samples: 1-2 weeks after tool completion

- Production runs with existing tooling: 2-3 weeks

- Rush services available for time-critical projects

Need to discuss PP injection molding project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Discuss Your PP Injection Molding Project?

Contact our team today for expert guidance, design support, and competitive pricing on your next polypropylene project.