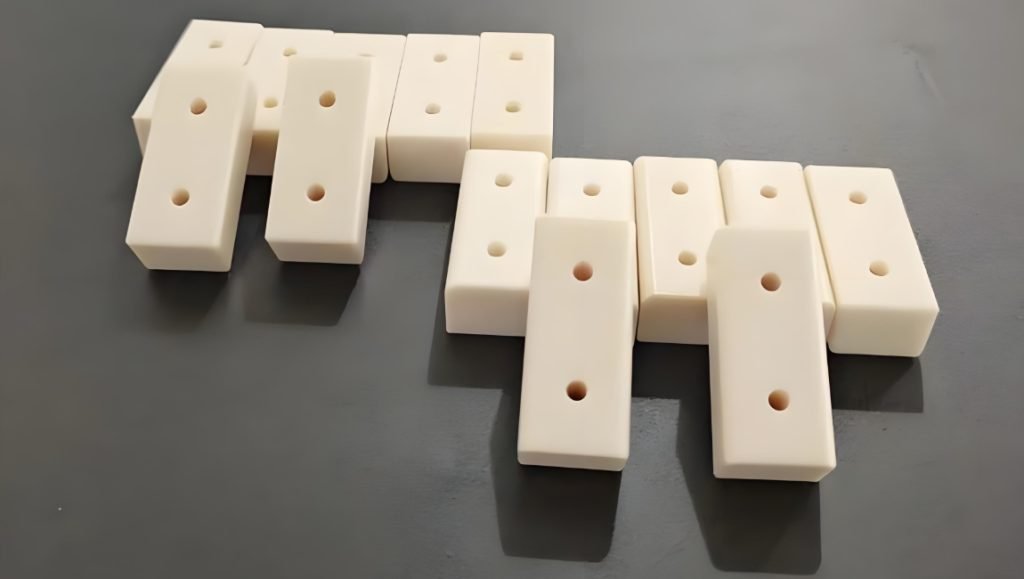

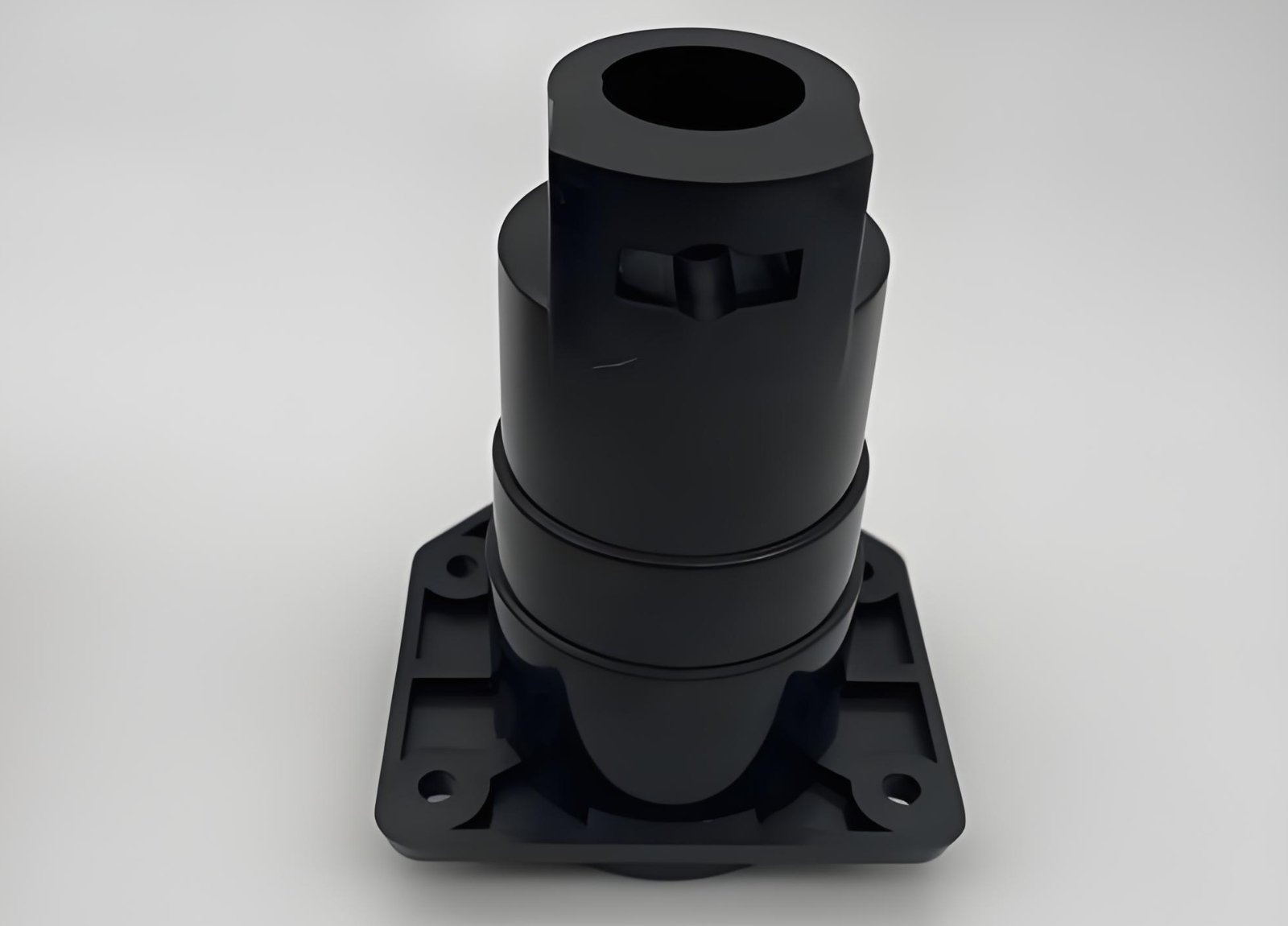

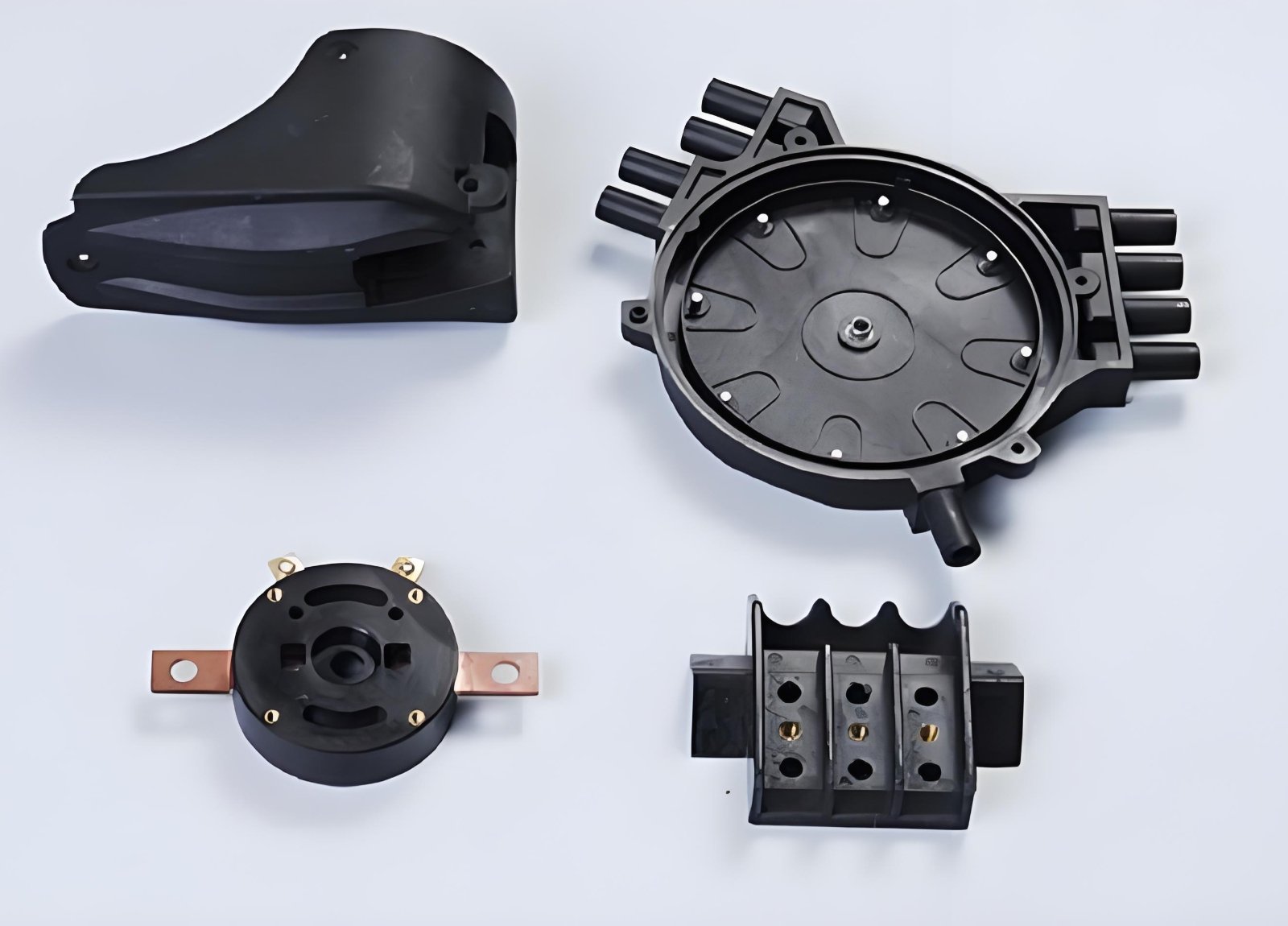

Custom ABS Injection Molding Service

ABS injection molding delivers exceptional durability, dimensional stability, and cost-effectiveness for manufacturing complex plastic components. Our comprehensive ABS injection molding services provide precision-engineered plastic parts with superior surface finish and consistent quality, helping you bring innovative products to market faster.

Durable

Impact-resistant

Machinable

What is ABS Plastic?

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer composed of three monomers, each contributing specific properties to the material. This unique composition creates a versatile plastic with an excellent balance of mechanical, thermal, and chemical properties.

The "A" in ABS provides chemical and heat resistance, enhancing the material's hardness and stability under various conditions.

The "B" component contributes toughness and impact resistance, allowing ABS parts to withstand physical stress and impacts.

The "S" element offers processability, strength, and a glossy surface finish that enhances the aesthetic appeal of molded parts.

Common ABS Plastic Grades

| Grade | Properties | Applications |

| ABS 757 | High impact resistance, good flow properties | Automotive components, consumer electronics |

| ABS 758 | Enhanced heat resistance, high gloss | Appliance housings, electronic enclosures |

| ABS FR | Flame retardant, UL 94 V-0 rated | Electronic housings, power tools |

| ABS/PC Blend | Improved heat resistance, impact strength | Automotive interiors, medical devices |

| ABS Medical Grade | Biocompatible, sterilizable | Medical equipment housings, diagnostic devices |

ABS Material Properties

ABS offers an excellent balance of mechanical, thermal, and chemical properties that make it ideal for a wide range of injection molded parts.

Mechanical Properties

- Tensile Strength: 40-50 MPa (5,800-7,250 psi)

- Impact Resistance: Excellent, especially at low temperatures

- Flexural Modulus: 2.1-2.4 GPa (305,000-348,000 psi)

- Hardness: Rockwell R105-R110

- Abrasion Resistance: Good to excellent

Thermal & Chemical Properties

- Heat Deflection Temperature: 90-105°C (194-221°F)

- Chemical Resistance: Good against alkalis, weak acids

- Water Absorption: 0.2-0.4% (24 hours)

- Shrinkage Rate: 0.4-0.7%

- Specific Gravity: 1.04-1.06

ABS Molding Specifications

Successful ABS injection molding requires precise control of processing parameters.

Our state-of-the-art equipment and experienced technicians ensure optimal processing conditions for consistent, high-quality parts.

| Parameter | Recommended Range | Notes |

| Melt Temperature | 210-270°C (410-518°F) | Higher temperatures for thin-walled parts |

| Mold Temperature | 40-80°C (104-176°F) | Higher temperatures for better surface finish |

| Injection Pressure | 60-100 MPa (8,700-14,500 psi) | Varies with part complexity and wall thickness |

| Drying Conditions | 80-85°C (176-185°F) for 2-4 hours | Essential to prevent surface defects |

| Minimum Wall Thickness | 1.14-3.56 mm (0.045-0.140 in) | Dependent on part geometry and flow length |

| Draft Angle | 0.5-1.0° | Required for proper part ejection |

Design Considerations for ABS Injection Molding

Wall Thickness

Maintain uniform wall thickness between 0.045" and 0.140" (1.14-3.56 mm) to prevent warping, sink marks, and other defects. Avoid abrupt transitions in wall thickness to ensure proper material flow and cooling.

Radii and Corners

Design with adequate radii at corners and transitions (minimum 25% of wall thickness) to reduce stress concentrations and improve material flow. Sharp corners can lead to stress concentration and potential part failure.

Pros and Cons of ABS Injection Molding

Advantages of ABS Injection Molding

- Excellent Impact Resistance: ABS provides outstanding toughness and impact strength, making it ideal for applications requiring durability.

- Dimensional Stability: ABS maintains its shape and dimensions over time, even under varying environmental conditions.

- Cost-Effectiveness: Relatively low material cost combined with efficient processing makes ABS economical for high-volume production.

- Surface Finish: ABS produces parts with excellent surface quality that can be easily painted, plated, or otherwise finished.

- Design Flexibility: ABS can be molded into complex geometries with fine details, thin walls, and various textures.

- Chemical Resistance: Good resistance to many chemicals, including weak acids, alkalis, and household cleaners.

- Recyclability: ABS can be recycled and reprocessed, supporting sustainable manufacturing practices.

Disadvantages of ABS Injection Molding

- UV Sensitivity: ABS degrades when exposed to prolonged sunlight, limiting outdoor applications without protective coatings.

- Temperature Limitations: Lower heat resistance compared to engineering plastics like polycarbonate or nylon.

- Moisture Sensitivity: Requires thorough drying before processing to prevent surface defects and property degradation.

- Flammability: Standard ABS is flammable and may require flame retardant additives for certain applications.

- Limited Chemical Resistance: Poor resistance to some solvents, including acetone and certain hydrocarbons.

- Warping Potential: Improper processing can lead to warping, especially in parts with uneven wall thickness.

- Fatigue Resistance: Not ideal for applications requiring repeated loading and unloading cycles.

ABS Injection Molding Applications

Industries We Serve

The versatility of ABS makes it suitable for a wide range of applications across multiple industries. Its combination of mechanical properties, processability, and cost-effectiveness has made it a preferred material for many products we use daily.

Automotive

Interior trim panels

Door handles and liners

Center console parts

Seat belt components

Consumer Electronics

Smartphone and tablet cases

Remote controls

Appliance housings

Gaming console components

Medical Devices

Laboratory instrument components

Medical device enclosures

Surgical tool handles

Monitoring equipment parts

Toys & Leisure

Action figures and dolls

Game pieces and controllers

Sporting equipment components

Recreational vehicle parts

ABS Injection Molding FAQs

Need to discuss ABS injection molding project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your ABS Injection Molding Project?

Contact our team today to discuss your requirements and receive a customized quote for your ABS injection molding needs.