Did you know that nearly 30% of electrical equipment failures are caused by cable damage due to inadequate strain relief? This staggering statistic highlights the critical importance of proper cable management in ensuring the longevity and safety of electrical systems.

You can protect your cables from damage by using strain relief devices that secure them to equipment panels, thereby reducing mechanical stress on internal wiring. This not only prevents premature failure but also ensures electrical safety in various applications.

As we explore the concept of strain relief, we’ll delve into its definition, importance, and how it works, as well as the standards and regulations governing its use.

What is Strain Relief and Why It Matters

To protect your cables from stress and damage, it’s essential to understand the concept of strain relief and its significance. Strain relief refers to the methods or devices used to prevent cables from experiencing stress at the point where they connect to a device or another cable. This stress can lead to cable damage over time.

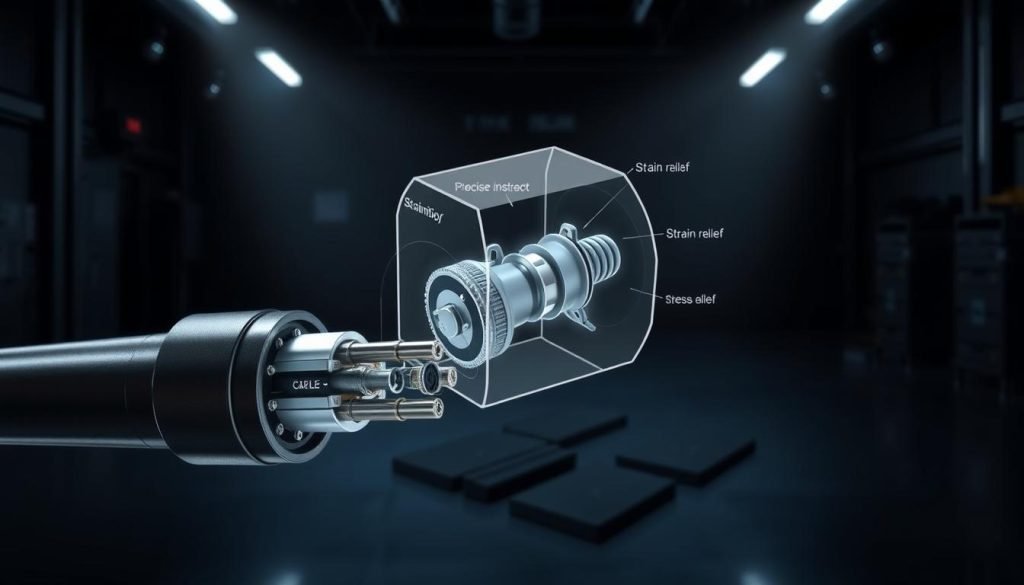

Definition and Basic Function

Strain relief mechanisms are designed to absorb or distribute the forces exerted on a cable, thereby reducing the risk of damage to the cable or its connector. By doing so, strain relief enhances the durability and safety of electrical connections. This is achieved through various products and designs that provide a secure and stable interface between the cable and the equipment it connects to.

The Consequences of Inadequate Cable Protection

Without proper strain relief, cables are susceptible to damage from repeated stress, leading to potential wire breakage, short circuits, and even complete device failure. The consequences of inadequate cable protection can be severe, including safety risks such as electrical shocks and fire hazards. Moreover, the cost implications of cable failures can be significant, encompassing not only repair expenses but also equipment downtime and potential safety incident costs.

The Science Behind Strain Relief

Understanding the science behind strain relief is crucial for protecting your cables from various damaging forces. Strain relief mechanisms are designed to absorb and distribute the forces exerted on cables, thereby preventing damage to the cable’s internal structure.

How Strain Relief Mechanisms Work

Strain relief mechanisms work by providing a secure grip on the cable, thus preventing it from being subjected to excessive tension, bending, or twisting. These mechanisms can be made from various materials and come in different designs, such as dome-style or flex-style strain reliefs, each suited to specific applications. By securing the cable effectively, strain relief mechanisms help to distribute forces along the cable’s length, reducing the risk of damage at any single point.

Forces and Stresses That Damage Cables

Cables are susceptible to various mechanical forces, including tension (pulling), compression, torsion (twisting), and flexion (bending). Exceeding a cable’s minimum bend radius can cause significant damage, particularly to fiber optic and high-performance electronic cables. Environmental stresses such as temperature fluctuations, UV exposure, and chemical exposure can compound mechanical stress, accelerating cable degradation. Different cable constructions respond differently to these stresses, underscoring the need for proper strain relief that accounts for the specific stresses a cable will encounter.

Common Types of Strain Relief Solutions

You have multiple options for strain relief, each designed to address specific cable protection challenges. The type of strain relief you choose depends on the application, cable type, and environmental conditions.

Dome Style Strain Reliefs

Dome style strain reliefs are a popular choice for many applications. They provide a secure grip on the cable, preventing strain and damage. These reliefs are often used in situations where the cable is subject to flexing or bending.

Flex Style Strain Reliefs

Flex style strain reliefs offer flexibility and are designed for cables that require a high degree of movement. They are typically made from flexible materials that can withstand repeated bending without compromising the cable’s integrity.

Strain Relief Plates with Cord Grip Function

Strain relief plates with cord grip function provide a robust solution for cable protection. They feature a cord grip mechanism that securely holds the cable in place, preventing strain and damage.

Conduit and Cable Gland Systems

Conduit and cable gland systems offer comprehensive protection for cables. Conduit, made from flame-retardant Nylon6/6, is highly flexible and corrugated, providing extra protection for wires and cables. These systems are particularly useful in harsh environments or areas with high mechanical abuse potential. They allow for future expansion by providing pathways for additional cables to be pulled through after initial installation.

Selecting the Right Strain Relief for Your Application

To ensure optimal performance and safety, it’s essential to choose a strain relief that meets your specific application needs. The right strain relief can protect your cables from damage and stress, ensuring the longevity and reliability of your connections.

Cable Size and Diameter Considerations

When selecting a strain relief, it’s crucial to consider the size and diameter of your cable. The strain relief should be compatible with your cable’s dimensions to provide effective protection. You should choose a strain relief that can accommodate your cable’s diameter, ensuring a secure and stable connection.

Environmental Factors and IP Ratings

Environmental factors such as temperature, humidity, and exposure to chemicals or dust can impact the performance of your strain relief. You should consider the IP (Ingress Protection) rating of your strain relief to ensure it can withstand the environmental conditions of your application. A higher IP rating indicates greater protection against environmental factors.

Mounting Methods and Installation Requirements

The mounting method and installation requirements of your strain relief are critical to its performance. You can choose from various mounting methods, including threaded connections, snap-fit designs, and panel mount options with lock nuts. Each method has its advantages and limitations, and you should consider factors such as installation time, security, and environmental sealing capabilities when making your selection.

Proper installation is also crucial to ensure the strain relief performs its intended function. You should follow the manufacturer’s instructions for installation, and consider factors such as panel thickness, hole sizing, and thread specifications. Additionally, you should ensure proper torque specifications when installing threaded strain relief components to prevent damage.

Standards and Regulations for Strain Relief

As you navigate the complexities of strain relief, it’s essential to be aware of the governing standards. Strain relief is subject to various regulations that ensure the safety and efficacy of electrical installations. These standards are crucial for manufacturers, installers, and users to understand and comply with.

DIN EN62444 Requirements

The DIN EN62444 standard outlines specific requirements for strain relief in electrical installations. This standard focuses on the protection of cables against mechanical stress and damage. To comply with DIN EN62444, strain relief solutions must be designed and installed to prevent cable damage, ensuring the longevity and reliability of electrical systems.

Key aspects of DIN EN62444 include the proper sizing of strain relief components for the cable diameter, the type of cable, and the environmental conditions in which they are used. By adhering to these requirements, you can ensure that your strain relief solutions meet the necessary safety and performance standards.

DIN VDE0100 Series and Other Applicable Standards

The DIN VDE0100 series of standards covers the installation of low-voltage electrical systems, including provisions for proper cable management and strain relief. This series applies to a wide range of applications and includes specific requirements for cable carriers and strain relief implementations. Beyond DIN VDE0100, other international standards such as IEC standards and UL requirements in North America also govern strain relief.

Industry-specific standards, such as those for medical equipment, marine applications, or railway systems, may impose additional requirements on strain relief beyond general electrical standards. Staying current with the latest requirements is crucial when designing or specifying strain relief solutions, as standards evolve over time. Compliance with these standards is not only a legal necessity but also a critical aspect of ensuring the safety and reliability of electrical installations.

Industries and Applications Requiring Strain Relief

Cable strain relief is essential across multiple industries, ensuring the longevity and reliability of electrical connections. Various sectors have unique requirements for strain relief due to differences in operating conditions, environmental factors, and equipment specifications.

Industrial Equipment and Manufacturing

In industrial settings, strain relief is crucial for protecting cables from mechanical stress and harsh environments. Manufacturing facilities often involve heavy machinery and equipment that can cause cable damage if not properly secured. Effective strain relief solutions help maintain production efficiency and reduce downtime.

Lighting and Electrical Installations

Lighting and electrical installations, both indoors and outdoors, require strain relief to safeguard against environmental factors such as moisture, temperature fluctuations, and physical stress. Proper strain relief ensures that electrical connections remain secure and functional.

Consumer Electronics and Home Applications

In consumer electronics and home applications, strain relief is used to protect cables from everyday wear and tear. This includes applications in home appliances, entertainment systems, and other domestic electronics where cable integrity is vital.

Specialized Applications in Harsh Environments

Specialized applications, such as those in marine environments, extreme temperatures, or hazardous locations, demand strain relief solutions that can withstand extreme conditions. Materials like PVDF are used in food processing equipment due to their resistance to chemicals and bacteria.

Other industries, including oil and gas, mining, and aerospace, also require specialized strain relief due to their unique operating conditions. The selection of appropriate materials and designs is critical to ensuring the reliability and safety of electrical systems in these environments.

Conclusion: Ensuring Long-Term Cable Protection with Proper Strain Relief

As we’ve explored throughout this article, strain relief plays a vital role in maintaining the integrity of electrical connections. Proper strain relief is essential for ensuring the longevity and reliability of cables across various applications.

When selecting strain relief, it’s crucial to consider factors such as cable specifications, environmental conditions, and mounting requirements. Investing in quality strain relief may seem like a small cost, but it significantly reduces the risk of equipment failure and safety incidents caused by cable damage.

A wide range of strain relief solutions is available to address different application requirements. By integrating strain relief into your design process from the outset, you can ensure compliance with relevant standards and enhance the overall safety and reliability of your electrical systems. Evaluate your current applications and ensure you’re using appropriate strain relief for optimal cable protection.

FAQ

What is the primary function of a strain relief cable?

The primary function of a strain relief cable is to protect cables from damage caused by stress, bending, and tension forces, ensuring long-term cable protection and safety.

What standards and regulations apply to strain relief products?

Strain relief products must comply with various standards, including DIN EN62444 and DIN VDE0100 series, to ensure they meet safety and performance requirements.

Can strain relief be used in harsh environments?

Yes, strain relief products are designed for use in various environments, including harsh conditions such as water exposure, extreme temperatures, and high-vibration applications.

How do I ensure the strain relief I choose meets my application’s requirements?

To ensure the strain relief meets your application’s requirements, consider factors such as IP ratings, material durability, and compatibility with your cable type and size.

Are there specific strain relief products designed for consumer electronics and home applications?

Yes, there are strain relief products designed for consumer electronics and home applications, such as cord grips and cable glands, that provide protection and safety for household cables.