Did you know that reverse engineering is used in various industries, from software development to manufacturing, to analyze and understand the design and components of existing products? This process has become a crucial tool in modern engineering, allowing companies to improve product design, reduce production costs, and enhance overall quality.

As an engineer, you understand the importance of analyzing and improving product design. Reverse engineering involves a systematic process of analyzing existing products or systems to comprehend their functionality, design, and components. By bridging the gap between physical objects and digital representations, reverse engineering enables the extraction of valuable information from existing products, facilitating innovation and improvement.

This introductory section will provide a comprehensive overview of the fundamental concepts and importance of reverse engineering in modern engineering and product development.

What is Reverse Engineering?

When you reverse engineer a product, you’re essentially working backward to understand how it was designed and built. This process involves analyzing the product’s structure, function, and operation to extract valuable design information.

Definition and Basic Concepts

Reverse engineering is the method of extracting knowledge or design information from anything man-made to understand its functionality and reproduce it. The fundamental concepts behind reverse engineering include analyzing the structure, function, and operation of objects or systems. This process allows you to comprehend the underlying design principles and operational mechanisms, enabling you to recreate or improve the product.

The Purpose and Objectives of Reverse Engineering

The primary objectives of reverse engineering are multifaceted, focusing on cost reduction, information recovery, and product enhancement. Organizations and engineers use reverse engineering to achieve these goals, ultimately driving innovation and competitiveness.

Reducing Development Costs

Reverse engineering helps reduce development costs by identifying cost-effective alternatives for components or systems. This approach enables companies to leverage existing designs, minimizing the need for new, costly designs from scratch.

Recovering Lost Information

Lost or inaccessible information can be recovered through reverse engineering. This is particularly valuable for retrieving design specifications, source code, or documentation that has been lost or was never properly documented.

Analyzing and Improving Existing Products

By analyzing existing products, reverse engineering facilitates the identification of design flaws and areas for improvement. This process enhances product performance and extends product lifecycles, contributing to overall business efficiency.

Key Goals of the Reverse Engineering Process

Reverse engineering is a multifaceted process with several primary goals, including managing complexity, detecting side effects, and facilitating component reuse. By achieving these goals, engineers can gain a deeper understanding of complex systems and improve their design, functionality, and performance.

Managing System Complexity

You can use reverse engineering to break down intricate systems into more manageable components, making it easier to analyze and modify them. This process helps engineers understand the system’s architecture, relationships, and design patterns, ultimately reducing complexity and improving maintainability.

Detecting Side Effects and Dependencies

Reverse engineering allows you to identify unintended implications, dependencies, and interactions within a system or component. By analyzing these side effects, engineers can better understand the system’s behavior and make informed decisions about its design and functionality.

Facilitating Component Reuse

Through reverse engineering, you can identify reusable parts or modules within existing systems, which can be repurposed in new designs. This approach saves time and resources, as it eliminates the need to recreate existing components from scratch.

By achieving these key goals, reverse engineering can provide significant benefits for engineering teams working on complex systems or legacy products, ultimately leading to improved design, reduced costs, and enhanced overall performance.

Essential Reverse Engineering Tools and Software

To effectively reverse engineer a product or system, engineers utilize a range of sophisticated tools and software. These tools enable the analysis and recreation of existing products, facilitating the understanding of their design and functionality.

3D Scanning Technologies

3D scanning technologies, including laser scanners, structured light scanners, and photogrammetry, capture the geometry of physical objects with precision, converting them into digital point clouds.

Tools like ZEISS INSPECT software create high-resolution point clouds, also known as STL meshes, from the scanned data.

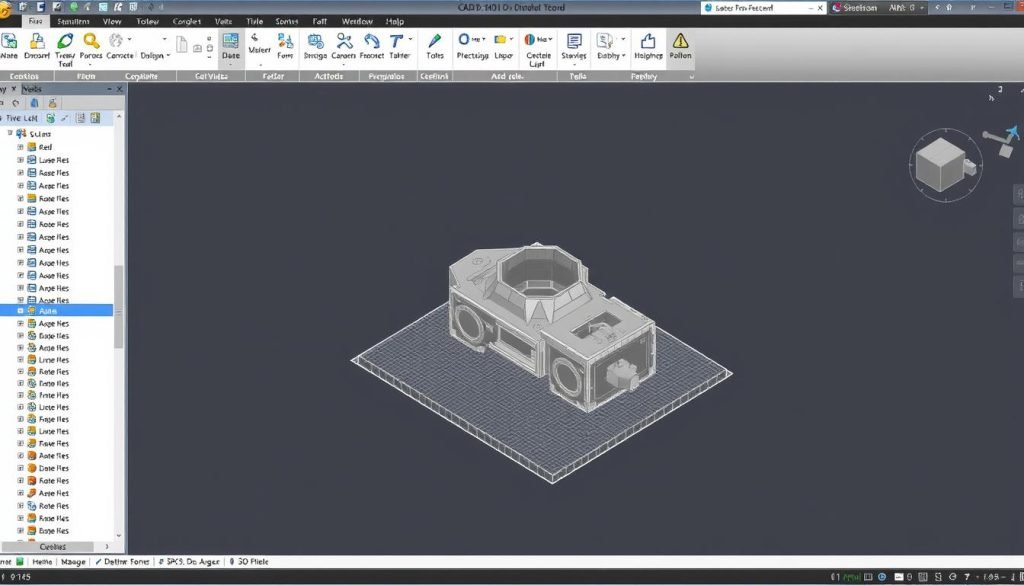

CAD Modeling Software

CAD modeling software, such as SolidWorks and Fusion360, converts scan data into usable 3D models through surface reconstruction techniques.

Specialized reverse engineering software further refines these models, making them suitable for various engineering applications.

Code Analysis and Decompilation Tools

Code analysis and decompilation tools, including Ghidra, IDA Pro, and Hex-Rays, allow engineers to convert compiled software back into readable source code or pseudocode.

These tools are essential for understanding the functionality and behavior of software systems.

The selection of appropriate tools depends on the specific reverse engineering application, whether it’s mechanical parts, electronic circuits, or software systems.

The Step-by-Step Reverse Engineering Process

The reverse engineering process involves a series of systematic steps that help in analyzing and understanding the structure and functionality of a product or system. This process is crucial for extracting valuable information and insights that can be used to improve existing products or develop new ones.

Information Collection and Preparation

The first step in the reverse engineering process is the collection and preparation of information. This involves gathering existing documentation, specifications, and background information about the product or system before beginning the physical or digital examination. You should collect all possible information, including source design documents, to get a comprehensive understanding of the system.

Examining and Analyzing the Target

Once the information is collected, the next step is to examine and analyze the target. This involves techniques for systematic inspection, including visual examination, functional testing, and preliminary measurements to understand the object’s purpose and operation. You will study the collected information to get familiar with the system and identify its key components.

Extracting Structural Information

Extracting structural information is a critical step in the reverse engineering process. This involves identifying the program structure in the form of a structure chart where each node corresponds to some routine. For physical objects, this may involve disassembly procedures, while for software, it involves code analysis.

Documentation and Knowledge Transfer

The final step is documentation and knowledge transfer. During this step, you record the processing details of each module of the structure using structured language like decision tables. It’s essential to thoroughly document your findings, create technical specifications, and effectively communicate the extracted knowledge to development teams.

By following these steps, you can ensure accurate and efficient reverse engineering results. Each step is crucial in understanding the product or system and extracting valuable information that can be used for future development or improvement.

Reverse Engineering Techniques for Different Domains

As you delve into the world of reverse engineering, you’ll discover that different domains require unique approaches. The techniques used in software reverse engineering differ significantly from those employed in hardware or mechanical parts reverse engineering.

Software Reverse Engineering

Software reverse engineering involves recovering the design and functionality of a software product from its compiled code.

Source Code Recovery

This process involves decompiling binaries to retrieve source code, allowing engineers to understand the software’s architecture and make necessary modifications.

Program Structure Analysis

Analyzing the program’s structure reveals its control flow, data structures, and overall architecture, even when the original source code is unavailable.

Hardware and Electronics Reverse Engineering

Hardware reverse engineering focuses on understanding the physical components and circuitry of electronic devices.

Circuit Board Analysis

This involves visually inspecting circuit boards, tracing signals, and using specialized equipment like logic analyzers to comprehend the device’s functionality.

Component Identification

Identifying components involves using reference designators, testing components, and consulting semiconductor code books to determine the specifications of unmarked or partially marked components.

Mechanical Parts and Product Reverse Engineering

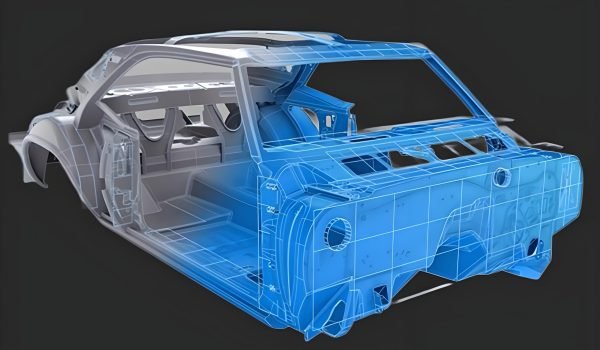

Mechanical parts reverse engineering involves recreating physical objects with precision using dimensional analysis, material testing, and 3D scanning techniques.

Understanding Data Through Reverse Engineering

Reverse engineering plays a crucial role in understanding complex data structures. By applying reverse engineering techniques, you can gain valuable insights into how data is organized, manipulated, and related within software applications and databases.

Internal Data Structure Analysis

Internal data structure analysis involves examining program code to identify abstract data types, record structures, and other organizational patterns. This helps you understand how data is organized and manipulated within software applications, including methods for identifying data types, relationships, and access patterns.

Database Schema Reverse Engineering

Database schema reverse engineering is the process of extracting and understanding database designs from existing implementations. This includes analyzing table structures, relationships, constraints, and business rules to build an initial object model and define generalizations. By doing so, you can migrate between different database paradigms, such as moving from flat file to relational or object-oriented database systems.

Reverse Engineering for Surface and 3D Model Creation

Using 3D scanning technology, reverse engineering enables the precise reconstruction of physical objects into digital models. The first step in this process is to use a 3D scanner, which allows for non-contact and full-field scanning of entire part surfaces.

Point Cloud Generation and Processing

The 3D scanner captures millions of measuring points to create a comprehensive digital representation of the physical object. Software like ZEISS INSPECT computes the 3D coordinates by creating a high-resolution point cloud, also known as an STL mesh.

This polygon mesh forms the basis for creating a CAD model as part of the surface reconstruction. Point cloud processing involves methods such as noise reduction, alignment, registration, and mesh generation to transform raw scan data into usable 3D models.

Converting Scan Data to CAD Models

The scan data is then converted into mathematically described curves (splines), freeform surfaces (NURBS surfaces), standard geometries (primitives), or solids. This process involves transforming polygon meshes into parametric CAD models through surface fitting, feature recognition, and geometric primitive extraction.

Engineers can export the data from the ZEISS INSPECT software as an STL mesh or ASCII point cloud, facilitating the creation of accurate CAD models. Validation techniques, such as deviation analysis, ensure the accuracy of the reverse-engineered CAD models by comparing them to the original scan data.

Advantages of Reverse Engineering

Reverse engineering is a powerful tool that can help you streamline product development, reduce costs, and enhance overall quality. By analyzing and optimizing existing products or components, reverse engineering can significantly impact your engineering processes.

Time and Cost Efficiency

One of the primary benefits of reverse engineering is its ability to deliver time and cost efficiency. By eliminating the need to design products from scratch and leveraging existing successful designs, you can reduce development cycles and lower production costs.

Product Quality Enhancement

Reverse engineering also enables you to improve product quality by identifying design flaws, optimizing performance characteristics, and implementing improvements based on detailed analysis of existing products. This results in enhanced product performance and reliability.

Knowledge Acquisition and Preservation

Furthermore, reverse engineering facilitates knowledge acquisition and preservation by capturing critical design information from products that may lack documentation or whose original designers are no longer available. This helps preserve valuable engineering knowledge and expertise.

Challenges and Limitations of Reverse Engineering

While reverse engineering offers numerous benefits, it also comes with its own set of challenges that engineers must navigate. The process involves a range of complexities, from technical intricacies to legal considerations.

Technical Complexity and Skill Requirements

Reverse engineering demands specialized knowledge and skills, particularly when dealing with intricate components or systems. Engineers must be proficient in using sophisticated engineering software and tools to analyze and interpret data accurately.

Data Accuracy and Reconstruction Issues

Inaccuracies can arise if methods and procedures are not correctly applied, or if the collected data lacks precision. Reconstruction errors can occur due to flawed analysis or incomplete data capture, undermining the reliability of reverse engineering.

Legal and Ethical Considerations

Reverse engineering is also subject to legal and ethical considerations, including intellectual property rights and varying legal frameworks across different countries and industries. Engineers must be aware of these factors to avoid potential legal issues.

Industry Applications of Reverse Engineering

By applying reverse engineering techniques, you can significantly improve product development and innovation. Reverse engineering is used in various sectors to analyze, enhance, or replicate products, systems, and parts.

Automotive and Aerospace

In the automotive sector, reverse engineering analyzes and refines existing components, such as enhancing car aerodynamics or producing spare parts for discontinued models. Similarly, in aerospace, it analyzes intricate components and systems, increasing safety and simplifying maintenance.

Manufacturing and Product Development

Reverse engineering facilitates competitive analysis, helps create improved product versions, and enables the production of compatible components or accessories, driving innovation in manufacturing and product development.

Software and Cybersecurity

In software development, reverse engineering analyzes program functionality, identifies bugs, and enhances security through code analysis and decompilation, contributing to vulnerability assessment and legacy system modernization.

Medical and Consumer Electronics

Reverse engineering enables the creation of custom medical devices, improves existing designs, and develops compatible accessories or replacement parts, benefiting both medical and consumer electronics industries.

Practical Examples of Successful Reverse Engineering Projects

Reverse engineering has been successfully applied in various projects across different domains. You can benefit from understanding how this technique has been used to drive innovation and improvement.

Legacy System Modernization

Organizations have used reverse engineering to modernize legacy systems, extracting business logic and data models to migrate to modern platforms without losing functionality. By recovering source code and system architecture, companies have successfully upgraded their systems while preserving essential business processes, saving time and resources.

Competitive Product Analysis

Companies have legally reverse engineered competitors’ products to understand their features, performance characteristics, and design approaches. This analysis has informed product development strategies, helped identify market opportunities, and led to the creation of improved or differentiated products, giving companies a competitive edge.

Conclusion

As we conclude our exploration of reverse engineering, it’s clear that this process plays a vital role in modern engineering practices. Reverse engineering is a systematic approach to understanding existing products, software, and systems, extracting valuable design information and knowledge. With diverse techniques and tools available across different domains, technological advancements have made these processes more accessible and accurate. While there are significant advantages, including cost savings and knowledge preservation, challenges such as technical complexity and legal considerations must be addressed. As a critical practice across industries, reverse engineering enables innovation and problem-solving, and its importance is expected to continue growing.