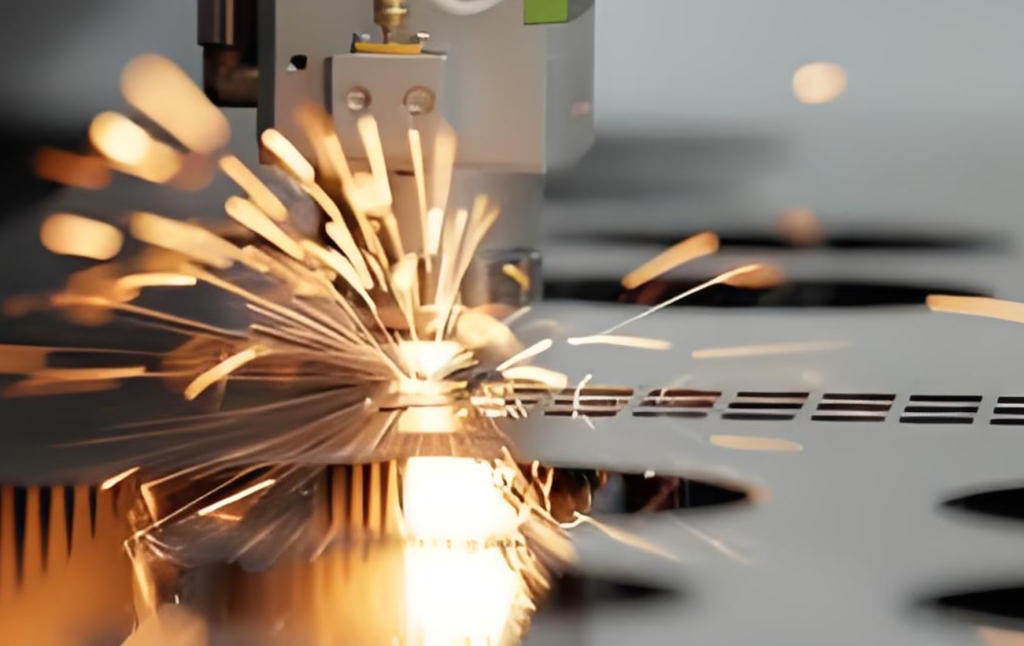

Laser cutting is a high-precision technology that uses concentrated laser beams to cleanly cut a wide range of materials—from metals and plastics to wood and acrylic. The results depend on factors like material type, thickness, and laser power. In this guide, we explore 12 of the most common and suitable materials for laser cutting. Read on.

12 Common Materials That a Laser Can Cut

1. Acrylic (PMMA)

Acrylic (PMMA), a high-performance engineering plastic, has become the cost-effective material of choice in fields such as advertising decoration, optical components, and industrial design. With a light transmittance of 92%, which is close to traditional glass yet it only has half of its weight, acrylic offers decent clarity and portability. In addition, it’s easy to dye, laser cut, thermoform, and engrave, making it the great choice in many areas.

Here, we will introduce two common types of acrylic: cast and extruded. Cast acrylic, compared to extruded, is much more suitable for laser cutting because it is harder and thus can endure laser beams. On the other hand, extruded acrylic, which soft and easy to bend, is more appropriate for thermoforming.

User tips:

Please note that laser cutting acrylic will release harmful gases. So make sure you have proper ventilation to avoid toxic fumes. Also, wear a respirator when you are laser cutting the acrylic.

2. Plywood

Unlike solid wood, plywood is made up of multiple thin layers of wood stuck together. It is more durable, lightweight, and stable than solid wood. Thus, plywood is usually used in decoration, furniture manufacturing, packaging logistics, DIY, and so on. Today, laser cutting of plywood can achieve high-precision cutting, which is suitable for those who require a high degree of precision.

User Tips:

Laser cutting plywood has high requirements for its material. Poor quality plywood is prone to carbonization of the edges when cut with a laser. In addition, since plywood cutting releases harmful gases such as formaldehyde and phenol, ventilation is necessary.

3. MDF

MDF (Medium-density fiberboard) board is also one of the materials for laser cutting. Similar but denser than plywood, MDF board is also a man-made wood material consisting of wood fiber, resin and wax. Common usages of MDF includes flooring, roofing, decorating, etc.

User Tips:

Pay attention to ventilation, and fire prevention, and wear a gas mask.

4. Cardboard

Cardbord is one of the ideal materials to laser cut. Made from paper pulp, cardboard is light, cheap, and eco-friendly and thus, it has become a popular choice in packaging and logistics. Most of the time, it is known as corrugated cardboard.

User Tips:

Basic ventilation and fire prevention are needed.

5. POM

POM (Polyoxymethylene) is an engineering plastic. It is often used for making precision parts. These parts include gears, zippers, and other components that need high accuracy. In some cases, POM can replace metals.

User Tips:

If you need to cut POM with a laser, choose a fiber laser and equip it with powerful exhaust facilities. Avoid CO₂ laser cutting because POM releases formaldehyde (a dangerous toxic gas) after high-temperature decomposition. A better processing alternative is CNC machining, which is the safest and most efficient way to process POM. It is non-toxic and has a clean edges and good surface finish after cutting.

6. Foam

Foam is a lightweight and soft material which is filled with tiny air pockets. In addition, foam has good heat insulation. It can also be shaped easily. For these reasons, foam is widely used in both daily life and industrial applications. Most foam materials can usually be laser cut, but laser cut PVC Foam is strictly forbidden as it will release deadly chlorine at high temperatures.

User Tips:

Most foam materials release harmful fumes cut by a laser. Therefore, please make sure good ventilation during the operation.

7. Metal

Metal is a shiny material. It is electrically conductive and generally hard. Examples include iron, aluminum, copper, and so on. Most metals are good for laser cutting.

User Tips:

The laser beam can easily cut stainless steel and carbon steel with high temperature. However, copper and aluminum are not recommended for laser cutting.

8. Leather

Leather is a durable material. It is made from animal skin through chemical treatment, like tanning. With the features of softness and wear resistance, leather becomes the perfect material for making bags, shoes, etc.

User Tips:

Cutting leather will produce smoke and odor, so ventilation is required. In addition, CNC machining is more recommended for leather that is too thick (usually >5mm).

9. Plastic

Plastic is a synthetic polymer material. This material can be easily changed into a new shape by external forces (such as heat and pressure) and retains its new shape. Because plastic is light and inexpensive, its use covers almost every aspect of daily life.

User Tips:

Some plastics like Acrylic (PMMA) and ABS are suitable for laser cutting, but PVC is not.

10. Cork

Cork, unlike plastics, is an environmental-friendly material made from the bark of oak trees. It is lightweight, squishy but springs back and can be used to make good wine stoppers.

User Tips:

Pay attention to selecting different laser cutting parameters according to the thickness and purpose of the cork.

11. Textiles

Textiles are any type of cloth or fabric made by weaving, knitting, or pressing fibers together. They’re the soft, flexible materials used to make clothes, curtains, carpets, etc.

User Tips:

Laser-cutting works on many (e.g., denim, felt), but melts stretchy fabrics like Lycra.

12. Paper

Paper is a thin, flat material made mainly from wood pulp. Thin and soft, paper is perfect for laser cutting. Laser cutting paper allows for detailed shapes, clean edges, and fast results. It is widely used for custom cards, invitations, and creative decorations.

User Tips:

When laser cutting paper, use low power to avoid burning.

Summary

In this article, we have detailed 12 common materials for laser cutting, ranging from durable metals and engineered wood products to delicate plastics and natural fabrics. But material knowledge alone isn’t enough. To ensure success, you need a laser cutting service that combines expertise with precision, delivering clean cuts and high-quality results every time. Choose wisely—your project depends on it.

Fecision has been committed to providing customers with professional laser cutting services and CNC machining services for years. From design to production, Fecision offers customized solutions for each project. We can handle both small orders (without minimum order quantity) and large projects. If you are looking for laser cutting services or would like to learn more about laser cutting materials, feel free to visit Fecision or contact our representative for a fast, free quote now.