Many industrial applications require distinct core and surface properties, which are unachievable with a single material. Overmolding—layering one material over another—solves this. But how does it work, and how are materials combined flexibly? This blog covers overmolding basics, the plastic overmolding process, and key injection molding tips.

What Is Overmolding in Injection Molding?

Overmolding is a specialized injection molding process where a pre-molded plastic part is placed into a second mold, and another material is molded over it. This technique combines different plastics for both functional and aesthetic benefits, such as layering soft plastic over hard plastic to improve grip. Unlike standard injection molding, overmolding creates multi-material parts with distinct properties in a single process.

Advantages

- Enhanced material flexibility

Overmolding enables the combination of multiple materials in a single plastic part, allowing for varied characteristics such as soft-touch grips, vibrant colors, or textured finishes. This enhances both functionality and aesthetic appeal.

- Eliminates the Need for Adhesives

By bonding materials directly during molding, overmolding removes the requirement for glue or secondary assembly. This not only strengthens part durability but also reduces production costs.

- Integrated Sealing Features

Overmolding can embed soft sealing elements (such as gaskets) directly into parts, improving waterproofing and dust resistance. For instance, electronic enclosures can achieve IP-rated protection without separate O-rings, ensuring a more economical and reliable seal.

Disadvantages of Overmolding

- Increased Process Complexity

Overmolding requires either multiple molding operations or specialized dual-shot injection systems, leading to longer production cycles and higher costs compared to single-material molding. However, it remains more efficient than manufacturing and assembling separate components, making it the preferred choice for integrated multi-material parts.

- Bonding Reliability Challenges

The process carries an inherent risk of delamination when joining dissimilar materials. This occurs when material compatibility is poor or process conditions are inadequate. In cases where thermal bonding proves insufficient, mechanical fasteners may be required to ensure structural integrity, adding to production complexity.

How Does Overmolding Work?

Overmolding employs a sequential manufacturing approach where a rigid substrate component – typically plastic or metal – forms the foundational layer. A secondary material is then precision-injected over this base, creating an inseparable bond while enabling innovative material synergies. This dual-phase process facilitates unprecedented design flexibility and functional enhancements in the final product.

Material Selection

Material selection is the most important step in the whole process. You need to choose the best material to comply with both the internal and external physical requirements of the product. Several types of overmolding injection molding materials are as below.

- Polycarbonate (PC)

Polycarbonate has excellent impact resistance and transparency. Its common application includes bulletproof glass and protective equipment. Besides stability and durability, it can also fade. However, polycarbonate is more easily scratched and degrades under sunlight.

- Polyethylene (PE)

Polyethylene has a wide range of applications, from plastic bags and high-strength containers. In the injection process, high-density polyethylene (HDPE) and low-density polyethylene (LDPE) offer several options, from stable form or softer parts.

- Polypropylene (PP)

Polypropylene has excellent chemical stability and mechanical durability. Its common application is concluding the automobile parts, consumer goods, and movable hinges that need to be repeatedly bent, etc. Its chemical stability is suitable for health-related applications. Polypropylene has relatively poor resistance to ultraviolet rays. When used outdoors, additives need to be added for stability treatment.

- Acrylonitrile Butadiene Styrene (ABS)

ABS is stable and widely applied in thermoplastics. It has outstanding impact resistance, excellent thermal stability, and a smooth surface texture. ABS is easier to form and layer, and is suitable for decorative effects.

- Silicone Rubber

Silicone rubber is an excellent material for rubber overmolding due to its outstanding heat resistance, flexibility, and electrical insulation properties. It is commonly used to create waterproof seals, insulated cables, and protective casings for electronic devices.

Additionally, silicone bonds well with metals and certain plastics, making it ideal for healthcare products and kitchenware (such as baking molds) that require high-temperature resistance and sterilization capabilities.

Mold Design and Setup

Mold design must account for material characteristics and thickness, which differ from standard molds. Key considerations include maintaining a wall thickness of no more than 4mm and incorporating a gate for pouring, typically positioned at the thickest wall section.

Unlike conventional injection molds, overmolding employs a CNC-machined mold made from durable metals such as steel or aluminum to withstand the high pressure and temperature of the injection molding process.

Injection Molding Setup

The setup is designed for multi-material molding and precise stacking sequences. For double-material overmolding, a specialized rotating mold system is used, allowing each injection unit to deliver the required material with precision.

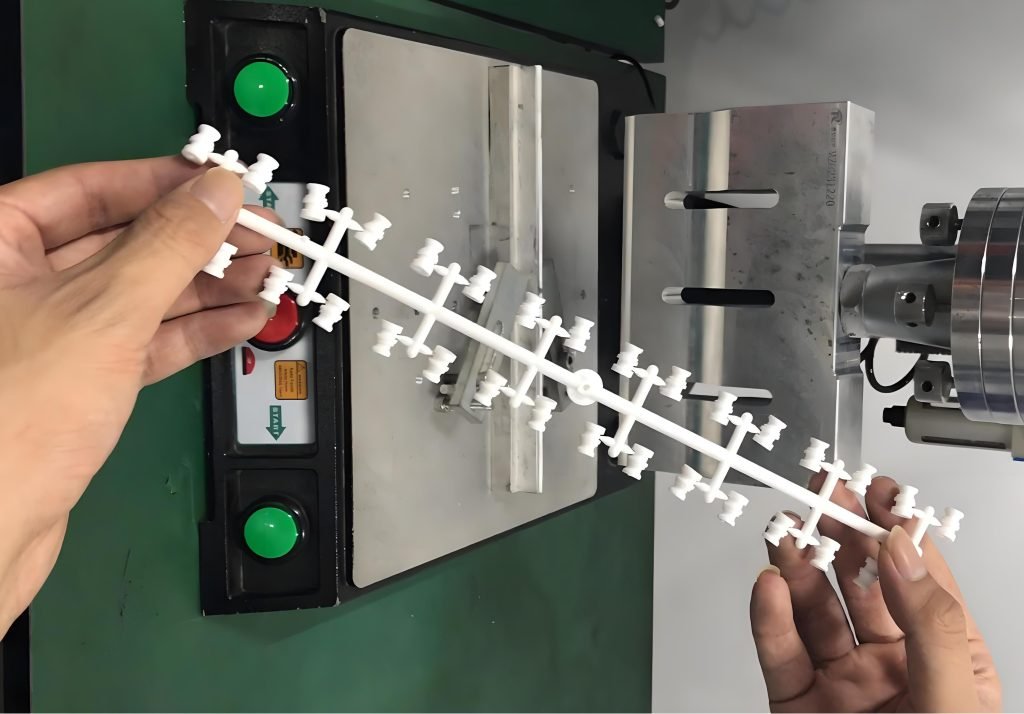

The process begins by injecting the base material. Once cooled, it forms a stable substrate for overmolding. A second material is then injected on top. In some cases, a single unit produces the initial part before applying elastomer materials in a subsequent step.

Ejection and Inspection

After forming, the parts are ejected from the mold and undergo a thorough defect inspection. Common issues include incomplete bonding, cavitation, and surface defects.

Post-Processing

The final part consists of a bonded multi-material structure but requires additional finishing. Post-processing may involve trimming excess material, polishing for better surface finish, or further curing to enhance material properties—ensuring the overmolded parts meet both functional and aesthetic requirements.

Overmolding Design Tips

Successful overmolding requires careful planning across several technical aspects. These fundamental design principles will help optimize your overmolding process:

Material Compatibility

Effective overmolding begins with thorough material evaluation. Key considerations include thermal properties (melting temperatures and expansion coefficients) and chemical compatibility between substrates. Select primary materials with higher melting points than secondary materials to prevent deformation, and account for differential shrinkage rates during cooling.

Part Geometry Optimization

Design molds to accommodate multiple injections while maintaining optimal wall thickness (2-4mm). Implement gradual transitions with minimum 0.5mm radii and incorporate 1° draft angles per inch to facilitate part ejection. Avoid sharp corners and deep ribs to minimize stress concentrations and ensure proper material flow.

Bonding Techniques

Effective bonding in overmolding requires multiple strategic approaches working in concert. Precise temperature control at material interfaces forms the foundation for reliable adhesion, while molecular-level chemical bonding should be prioritized where material compatibility allows. When chemical bonding proves insufficient, mechanical interlocking features and surface texturing of base materials provide alternative pathways to achieve strong, durable bonds between layers.

Manufacturing Efficiency

Manufacturing efficiency can be significantly improved through several integrated methods. Reducing subcomponents simplifies assembly, while advanced computational simulations enable accurate prediction of material flow and early identification of potential structural defects before physical tooling begins.

A practical example of this holistic approach can be seen in device handle manufacturing, where rigid ABS cores provide structural support while softer TPE overmolds deliver comfortable grip, demonstrating how material selection must balance functional requirements with bonding performance.

Plan for Post-Processing

Post-processing considerations should be incorporated early in the design phase to ensure final product quality. Common finishing techniques include surface polishing for aesthetic enhancement, UV stabilization for outdoor durability, and specialized treatments like flame-retardant applications for electrical components. Additional curing processes may also be employed to optimize material properties, ensuring the finished product meets all performance and appearance specifications.Get Your Best Injection Molding Services at Fecision

Overmolding is ideal for creating strong, multi-layered parts in a single process. But it’s not your only option—insert molding, LSR overmolding or standard injection molding may work better for your project.

At Fecision, we offer top-tier injection molding services with a wide material selection. Unsure which process fits your product best? Our experts bring decades of experience to guide your design choices and help you select the perfect molding solution.

Why Choose Fecision?

- Precision Manufacturing Expertise

- ISO 9001:2015 Certified – Guaranteed quality control at every production stage

- Advanced Injection Molding Machines – Handling projects from micro-components to large parts

- Tight Tolerances (±0.01mm) – Consistent accuracy for high-performance applications

2. Comprehensive Material Options

- Various Engineering-Grade Materials – Including ABS, PC, PP, Nylon, TPE, and custom blen

- Material Testing & Selection Support – Ensuring optimal performance for your application

3. End-to-End Service

- Design for Manufacturability (DFM) Analysis – Expert feedback to optimize part design and reduce costs

- Prototyping to Mass Production – Seamless scaling from 1,000 to 1,000,000+ units annually

- Secondary Operations – Painting, ultrasonic welding, assembly, and more

4. Industry-Proven Experience

- Rich Experience in Plastic Injection Molding – Serving automotive, medical, consumer electronics, and industrial sectors

- Thousands of Successful Projects – Delivering on time with rigorous quality standards

5. Cost-Effective Solutions

- Competitive Pricing – Optimized processes to minimize waste and reduce unit costs

- Global Logistics Support – Reliable shipping and warehousing options