Ever noticed how plastic bottle caps or toothbrush handles are perfectly formed with no excess material? That’s hot runner technology at work. These molds keep plastic molten in heated channels—like a thermos for liquid plastic—delivering just the right amount to shape everyday items precisely, while eliminating waste and saving energy in mass production. What is a hot runner mold indeed? Let’s read on!

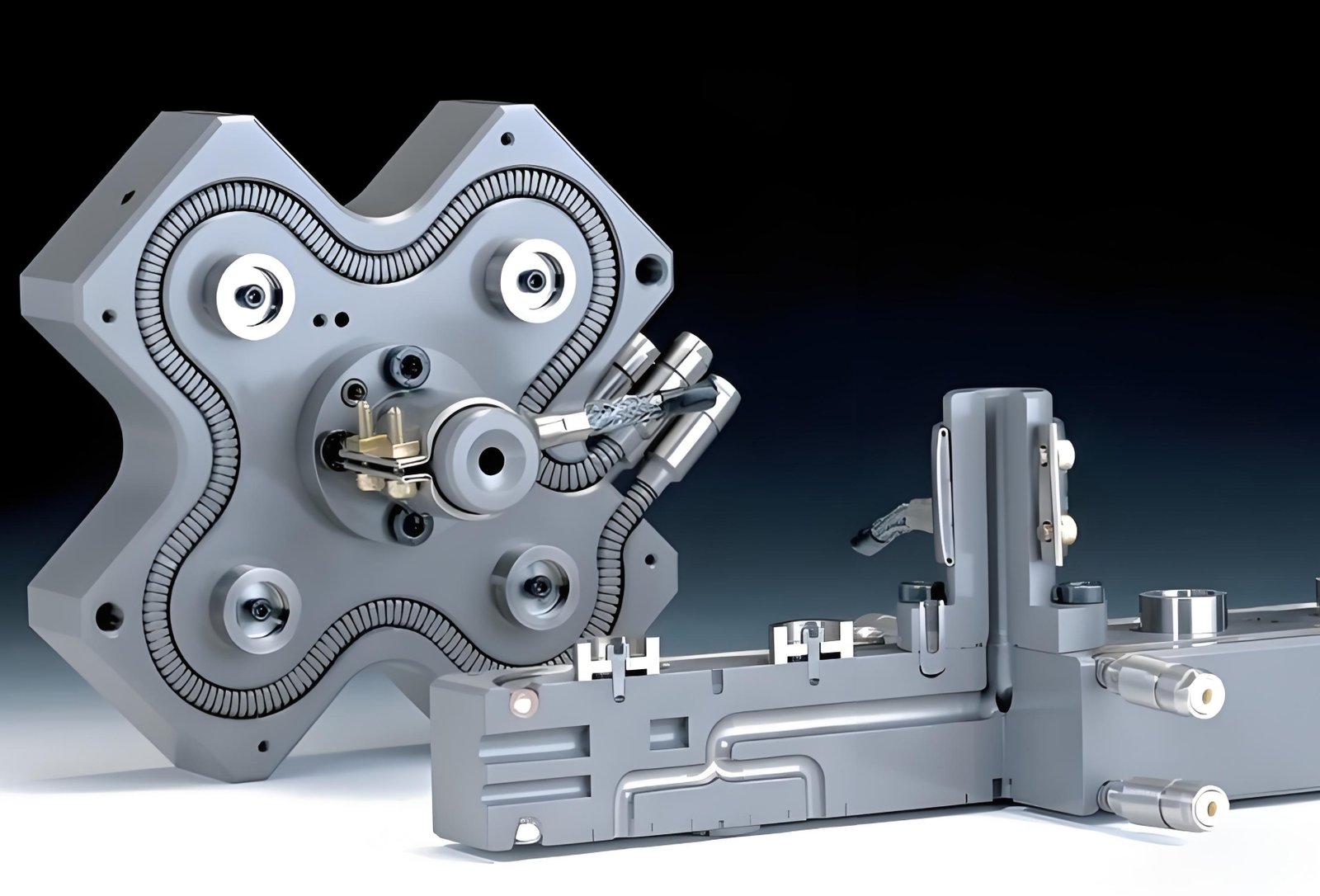

What Is a Hot Runner Mold?

A hot runner mold represents advanced injection molding technology designed to maintain plastic in a molten state throughout the runner system using integrated heating elements. This innovative system eliminates material waste and secondary processing issues associated with traditional cold runner molds.

Functioning as the heart of modern injection molding systems, the hot runner (or hot manifold) transports molten plastic directly from the injection nozzle to the mold cavities while preventing solidification. By maintaining optimal melt temperature continuously, it significantly reduces material waste and energy consumption.

Due to their precision and efficiency, hot runner systems have become essential for high-quality production, achieving over 60% adoption in precision industries like medical devices and electronic packaging. With proper selection and hot runner injection molding process optimization, manufacturers can typically recover their investment within just 6-12 months.

How Hot Runner Molds Work: A Step-by-Step Breakdown

1.Plastic Melting

Solid plastic pellets (e.g., ABS at 220–250°C) are melted in the injection molding machine’s screw barrel. The molten plastic is then injected into the temperature-controlled hot runner system.

2.Melt Conveying

- Manifold: Heated internally (e.g., PP maintained at 230°C±5°C) with layered channels to minimize heat loss (insulated outer layer, high-temperature alloy inner core).

- Nozzles: Each cavity has an independently heated nozzle (PID-controlled) to ensure consistent melt flow.

3.Injection & Filling

- Open Gate: Directly injects low-viscosity materials (e.g., PE)

- Valve Gate: Uses hydraulic/pneumatic valves (precision: 0.1s) to prevent drooling, ideal for high-viscosity materials (e.g., PA, PC).

4.Packing & Cooling

The melt remains fluid in the hot runner during packing to compensate for shrinkage, while only the product is cooled (20–120°C via mold temperature control).

5.Ejection & Reuse

Only the solidified product is ejected; the molten runner material is retained for the next cycle, eliminating waste.

Types of Hot Runner Mold (Insulated Hot Runners/Heated Hot Runners)

Now that you understand the basics of hot runner molds, let’s explore the two primary types of hot runner injection molding:

Heated Hot Runner Molds

The most widely used system, is known for its precise temperature control and stable melt delivery. Heating elements are installed on the mold (externally or internally) to maintain plastic in a molten state throughout the runner.

Insulated Hot Runner Molds

Features an extra-thick runner design. As molten plastic flows through, the outer layer cools and solidifies, forming a natural insulation barrier that reduces heat loss. This keeps the core molten, ensuring continuous material flow.

Key Differences:

Heated: Actively controlled, ideal for high-precision applications.

Insulated: Passive design, cost-effective for certain materials.

Pros and Cons of Hot Runner Injection Molding

| Pros | Cons |

| Cost savings: In the long run, it’s a more cost-efficient option as it offers reduced waste and better productivity. | Higher cost: It’s more expensive to buy than cold runners so be prepared to invest. |

| Reduced waste: There are no runners to remove after each cycle so waste is cut right down. | High maintenance: Looking after these systems takes a lot of time and effort. |

| Less chance of damage: It’s easy to reduce heat to the hot runner nozzle to prevent faulty parts. | Extra heating: To work, they need extra heating elements/sources, something that can also increase operating costs. |

| Faster production: Once the hot runner controller system heats up, it’s ready to go and doesn’t need any prep time for the next injection, so cycle times are brought down quite a bit. | |

| Less mold stress: It needs less force to inject the plastic into the mold, meaning less stress on the mold and the machine holding it. |

Applications of Hot Runner System Hot runner system

injection molding is used in many industries:

| Industry | Applications |

| Automotive | Interior and exterior parts, engine components |

| Packaging | Bottle caps, lids, closures, containers with minimal waste |

| Medical | Medical device parts, syringes, inhalers, surgical instruments, IV components |

| Consumer goods | Mass production of electronics, toys, household appliances |

| Industrial | Connectors, valves, gears, enclosures |

Tips on Choosing Hot Runner System

Material Compatibility: Match the system to your plastic’s melting point and flow behavior for optimal performance.

Precision Demands: Prioritize systems that ensure consistent product finish, tight tolerances, and uniform weight distribution.

Mold Integration: Verify the system aligns with your mold’s gate locations, cavity count, and structural design.

Cycle Time Optimization: Select configurations that maximize output without compromising part quality.

Total Cost Analysis: Consider both upfront investment and long-term operational/maintenance expenses.

Supplier Reputation: Partner with vendors offering robust technical support and proven system reliability.

Eco-Certifications: Choose energy-efficient systems meeting current sustainability regulations.

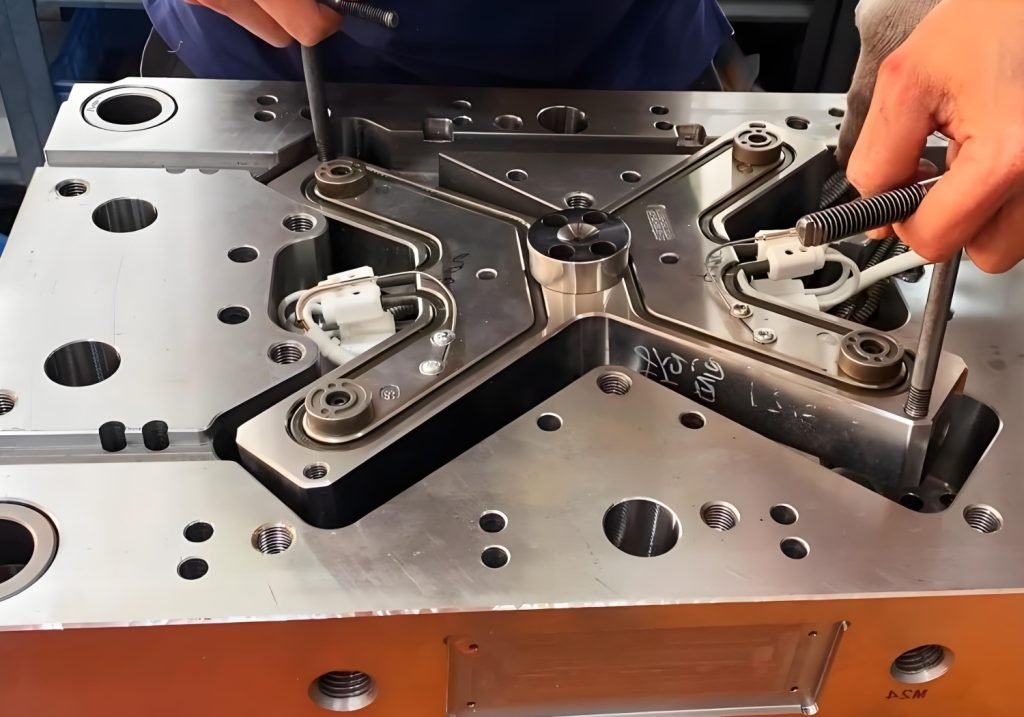

Fecision for Best Custom Injection Molding Services

Choosing the right injection molding partner demands careful evaluation of technical expertise, production experience, quality assurance, cost efficiency, and customer support—and Fecision excels in all these critical areas. As a leader in hot runner injection molding, we specialize in manufacturing high-precision plastic components through this advanced process, which injects molten material into molds to produce complex, consistent parts with exceptional efficiency.

Our advantages include:

✔ State-of-the-art molding equipment for superior precision

✔ Expert engineering team with decades of combined experience

✔ Rigorous quality control ensuring flawless output

✔ Competitive pricing without compromising standards

✔ Reliable on-time delivery for your production timeline

Trust Fecision to deliver high-performance plastic parts that meet your exact specifications, budget, and deadlines – contact us today for your custom molding needs.