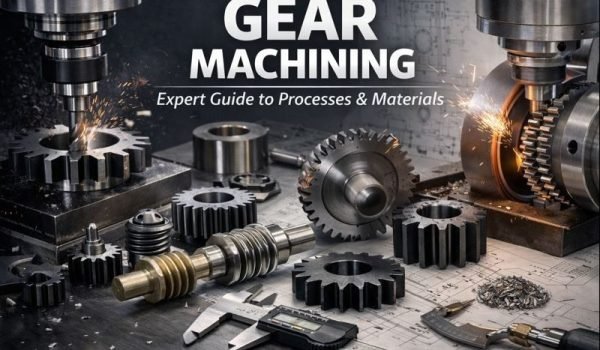

Gear machining is one of the most important processes in modern manufacturing. Gears are used in almost every machine that transfers power or motion, from cars and industrial equipment to robots and aerospace systems. The quality of a gear directly affects how smoothly, quietly, and reliably a machine operates. In recent years, demand for high-precision gears has grown rapidly.

Manufacturers must now meet stricter requirements for accuracy, durability, noise control, and efficiency. This is why professional gear machining and experienced gear manufacturers play such a critical role in industries. This article explains what gear machining is, the main manufacturing processes, commonly used materials, and why working with a professional gear manufacturer matters.

What Is Gear Machining?

Gear machining involves the manufacturing procedures employed to create gear teeth having accurate geometry on a gear blank. In contrast to general machining, gear machining is concerned with very precise tooth profiles, spacing (pitch), alignment, and surface finish to permit smooth meshing of mating gears.

Even minute variations at the micron scale may lead to undesirable noise, vibration, load imbalance, or early gearing breakup. To this end, gear machining will need special equipment, expert process design, and rigorous inspection procedures.

Modern gear machining generally comprises:

- Cutting and finishing controlled by the CNC.

- Gear design and simulation using CAD/CAM.

- Heat treatment to enhance hardness and fatigue resistance.

- Closed-loop quality control and advanced inspection.

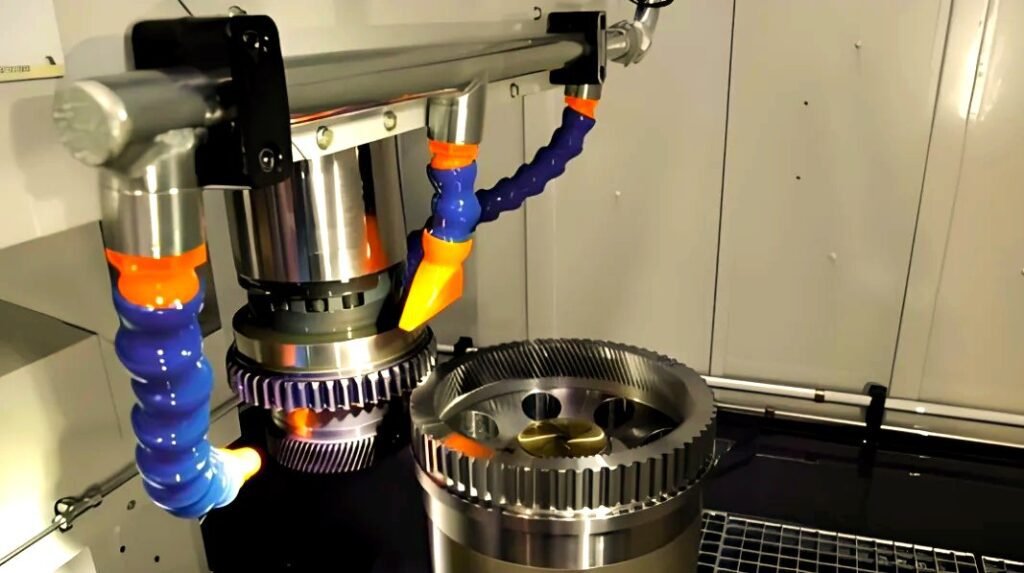

Professional gear manufacturers operate specialized machinery, including gear hobbing machines, shaping machines, grinding centers, and power skiving machines to provide high precision and repeatability.

Understanding Gear Types and Their Applications

Gears are the workhorse of mechanical power transmission systems. It enables machines to operate with accuracy and efficiency. The choice of the right type of gears significantly influences the performance of the system in different industrial applications.

Spur, Helical, Bevel, and Worm Gears

- Spur gears have straight teeth that are perpendicular to the axis of the gear and are therefore suitable in parallel shaft applications. Although they are simple and easy to manufacture, they cause more noise at high speeds than other types.

- Helical gears have angled teeth of helical gears engage slowly, thereby minimizing noise and vibration even at high speeds. They are designed to permit greater loads than spur gears, but produce axial thrust which necessitates thrust bearings. These gears perform well in automotive ratios of 3:2 to 10:1.

- Bevel gears are used to transmit movement between intersecting shafts at an angle. They can be used in systems that need to redirect power because of their shape, which enables them to alter the rotation direction. There are also bevel gears in various forms, based on the smoothness and efficiency required.

- Worm gears are characterised by a screw-like worm and a worm wheel. They offer plenty of speed reduction in a small area and can lock to themselves, which improves their use in lifting applications.

How Gear Type Affects Machining Method

The manufacturing process of gears differs quite considerably depending on the type of gears. The ISO, DIN, JIS, or AGMA-specified precision class defines tolerances of pitch error and the general quality. The significance of teeth grinding to performance optimizes the noise properties and force transmission capability.

Choosing the Right Gear for Your System

The need to choose the right gears involves careful examination of system requirements. Helical or spiral bevel gears are better in noise-sensitive applications. Additionally, worm gears are useful in applications that require high torque but have a small size, even though they are less efficient.

The Design-Material-Process Approach in Gear Machining

Successful gear manufacturing relies on an integrated approach rather than treating design, materials, and processes as isolated steps. The core problem in gear failure typically stems from systemic “mismatch” with other transmission components, not the gear’s individual quality.

1. Design Collaboration Based on Load and System Needs

Effective gear design starts with thorough analysis of real working conditions. This includes the assessment of transient impact loads, thermal cycles of deformation, and life cycle objectives.

Proposed gear models are exhaustively co-simulated in virtualized transmission systems before being physically manufactured. This computer-based prototyping combines the multi-body dynamics and finite element analysis to determine the possible failure points.

2. Material Selection for Strength and Fatigue Resistance

During material selection, load capacity is important because gears are always under pressure. In addition to simple material choice, the exact alloy composition and optimum proportions of chromium, molybdenum, and nickel reinforce the matrix, and harden the core. Controlled atmosphere heat treatment with precise carbon potential ensures even distribution of carbon, producing high-hardness and wear-resistant surfaces.

3. Process Planning for Precision and Repeatability

Achieving higher accuracy requires specialized tools appropriate to the material being machined. The processes of production should give rise to the achievement of designed tooth profiles and optimal use of materials.

The manufacturing method selection depends on the size of the gears, precision needs, complexity, and the volume of production. In large industrial gears, casting and forging are appropriate; smaller high-volume production may use powder metallurgy.

Key Gear Machining Processes Explained

Modern gear manufacturing uses different machining methods. Each method is chosen based on the gear type, the required accuracy, and the production speed.

Step 1: Gear Hobbing and Shaping

Gear hobbing creates teeth by an endless generation process where the hob and the gear blank are rotated simultaneously until the teeth are cut. The main strength of this technique is in the production of external gear, in which the benefits are a lower overall cost, higher cutting speeds, and a longer life of the tool.

Alternatively, gear shaping involves the use of a pinion-shaped cutter that rotates and reciprocates to shape teeth without the need to tilt the axes with the workpiece. Shaping is especially good at making internal gears and components positioned near flanges or other obstructive surfaces.

Step 2: Broaching and Milling

Broaching involves machining (removing material) sequentially with a set of cutting teeth, each of which steadily increases in diameter and effectively roughs, semi-finishes, and finishes in a single cut. This incredibly quick and accurate process is capable of cycle times as short as 6 seconds based on tooth depth.

Milling, in contrast, removes material with rotating cutters, but generates a large amount of heat transfer that necessitates that successive teeth are not milled in series. Milling is also slower, but it provides the flexibility of producing complex gear geometries.

Step 3: Grinding, Honing, and Lapping

An abrasive wheel is used in grinding, whereby material is removed to give high dimensional accuracy and surface finish. Honing then applies the fine abrasive stones against the surface of the gear to remove defects and correct slight mistakes in the tooth shape. Lapping is a lighter process, where a combination of abrasives and oil between the gear and a lapping tool is used to reach mirror-like finishes.

Step 4: EDM and Skiving for Complex Profiles

Electrical discharge machining (EDM) is a material removal process that is performed by electrical current discharges between electrodes with tolerances into the thousandths of an inch.

EDM is ideal when working with complex shapes of gear and hard materials, which are difficult to work with conventional techniques. Power skiving integrates both shaping and milling with a better surface finish and the capability to cut complex geometries such as internal gears and splines.

Materials Used in Gear Manufacturing

Material selection is a critical factor in determining gear performance, durability, and the manufacturing approach. Each material introduces its unique properties that influence wear resistance, strength, noise attributes, and cost-effectiveness.

1) Carbon Steel

The most common gear material is carbon steel. Medium-carbon steels have a balanced strength and toughness, whereas high-carbon steels are harder and more resistant to wearing. Such materials are frequently carburized or induction hardened on a surface.

2) Alloy Steel

Alloy steel is a mixture that has additional elements like chromium, molybdenum and nickel to enhance strength and toughness. These gears are capable of carrying heavier loads and can withstand fatigue as compared to carbon steel. High performance and industrial gear systems are often made with heat-treated alloy steels.

3) Stainless Steel

Stainless steel gears are prized because of corrosiveness and cleanliness. These are found in food processing, medical devices and the seas. There are also some grades that provide precision applications with good machinability and strength.

4) Cast Iron

Cast iron gears are very vibration damping and offer good wear resistance. They are commonly applied on large gears and low speed applications. Nodular cast iron is stronger than gray cast iron.

5) Brass and Bronze

The use of bronze gears has been extensive due to their superior wear resistance property and smoothness in operation. Phosphor bronze is the choice of worm gears because it is strong and has low friction. Brass gears can be used in light-load and low-speed applications.

6) Engineering Plastics

Plastic gears are light, noisy, and do not corrode. Common materials include nylon, POM, and polycarbonate. Reinforced plastics are more powerful and resist heat, thus suitable in moderate mechanical load.

Common Industries Served by Professional Gear Manufacturers

The professional gear manufacturers serve diverse industries with specialized components tailored to unique operational demands. These precision components form the backbone of critical systems across multiple sectors.

- Automotive: Gears are used in the transmissions of the automotive industry, steering systems, and differentials. Cars, trucks and motorcycles are dependent on gears to run smoothly, transfer power more efficiently, and achieve better fuel economy. With the rise of electric vehicles, gear manufacturers are now designing compact and low-noise gear systems specifically for EVs.

- Industrial Machinery: Gears used in machines are powerful gears in factories and construction machines like conveyors, presses, and CNC machines. These gears are designed to carry large loads and operate over a long duration without failure.

- Robotics: Robotics involves small and low-precision gears to move and control with precision. These gears are typically employed in automated production systems and robotic arms, and they assist in enhancing speed and accuracy.

- Aerospace: Gears are used in the aerospace industry in aircraft engines, landing gear, and control systems. Such gears need to be of high quality in terms of strength, weight and reliability to operate safely in harsh operating conditions.

The Pros and Cons of Gear Manufacturing

The manufacturing of gears has both strengths and weaknesses that should be addressed by manufacturers.

Advantages: Gear manufacturing offers high precision, strength, and durability. Well-made gears handle heavy loads, work efficiently with minimal power loss, and improve machine performance. The process is versatile, allowing for the production of different gear types. Quality gears are cost-effective in the long run due to their long lifespan.

Disadvantages: Gear manufacturing can be expensive at the start, especially for small production runs. It also requires skilled workers and time. Some materials limit manufacturing options. Certain gears require special bearings, and regular maintenance, such as lubrication, is necessary.

Despite some challenges, the benefits of gear manufacturing make it an important component in many industries.

What Are the Tolerances for Gear Manufacturing?

Gear manufacturing tolerances are the acceptable ranges of minor inaccuracies in the shape and size of a gear. Such tolerances are based on the nature of the gear, its size, degree of precision demanded and the process of manufacture.

The three common types of gear tolerances are as follows:

- Form tolerance: This is a check of the accuracy of the shape of the gear teeth. It is quantified in millimetres or micrometers.

- Pitch tolerance: This is used to determine the consistency of the gear teeth spacing. It is also indicated in millimetres or microns.

- Runout tolerance: This is a measure of the variation in shape between a perfect round shape and the form that results when the gear is being rotated. It is typically calculated in degrees.

The tolerating needs of a gear are mostly dependent on the purpose it is meant to serve. For example, gears in high-precision instruments would have tight form and pitch tolerance limits compared with gears in heavy-duty industrial machines.

Most commercial gears are usually made to form pitch tolerances of +-0.1 mm or smaller, and runout tolerances of +-0.5 degrees or smaller.

How Is Quality Controlled in Gear Manufacturing?

Quality control is very important in gear manufacturing because gears must be accurate and strong. The process includes several carefully checked steps.

First, the appropriate raw material is selected. The steel type is important as it determines the strength and durability of the gear. The steel is then trimmed to the right size and shape, which also has to be done very carefully to prevent bending and damage.

Then, the gear teeth are cut. This process is very precise, as any slight errors may lead to poor performance or breakdown of the gear.

Heat treatment is performed on the gears after machining. This increases the hardness and strength of the metal, thus enabling the gear to support heavy loads and extended usage.

Lastly, all gears are tested prior to shipment. This is the last test that the gear is defect-free and of good quality and performance.

Why Choose Fecision as Your China Gear Manufacturer

Fecision is a trusted China gear manufacturer with extensive experience in custom gear machining for global clients. The company combines advanced CNC technology with rigorous quality control to deliver reliable, high-performance gears.

Key advantages of Fecision:

- Knowledge of various types of gears and materials.

- Contemporary machining and inspection tools.

- Effective communication and project management.

- Price competition without quality sacrifice.

- Punctuality and quality control.

- Compliance with ISO, DIN, AGMA, and other standards

Fecision combines technical excellence with manufacturing efficiency, making it an ideal long-term partner for global customers.

Conclusion

Gear machining is a vital part of modern manufacturing, combining precise engineering, advanced machinery, and the right material choices to ensure reliable performance. Every step plays a role in producing durable and efficient gears from different gear types to precision standards and quality control. Working with experienced custom gear manufacturers helps businesses achieve the right balance between accuracy, cost, and long-term reliability. Professional gear machining delivers even higher efficiency and consistency as technology continues to advance.

If you are looking for high-quality, custom gear solutions with global standards and dependable delivery, Fecision is ready to support your needs. Visit Fecision to contact and start your custom gear manufacturing project today.