Injection molding is an accessible and effective way to make accurate plastic parts, from automobile parts to toys. It is a great process for producing complex shapes that require high accuracy in the realm of manufacturing.

During injection molding, demolding is a critical process where the finished plastic part comes out of its mold. It can degrade part quality and slow production if poorly done. Understanding the concept of demolding meaning is very important for assuring smooth production and achieving the best outcome in the production of plastic parts.

What is Demolding?

Definition and Importance

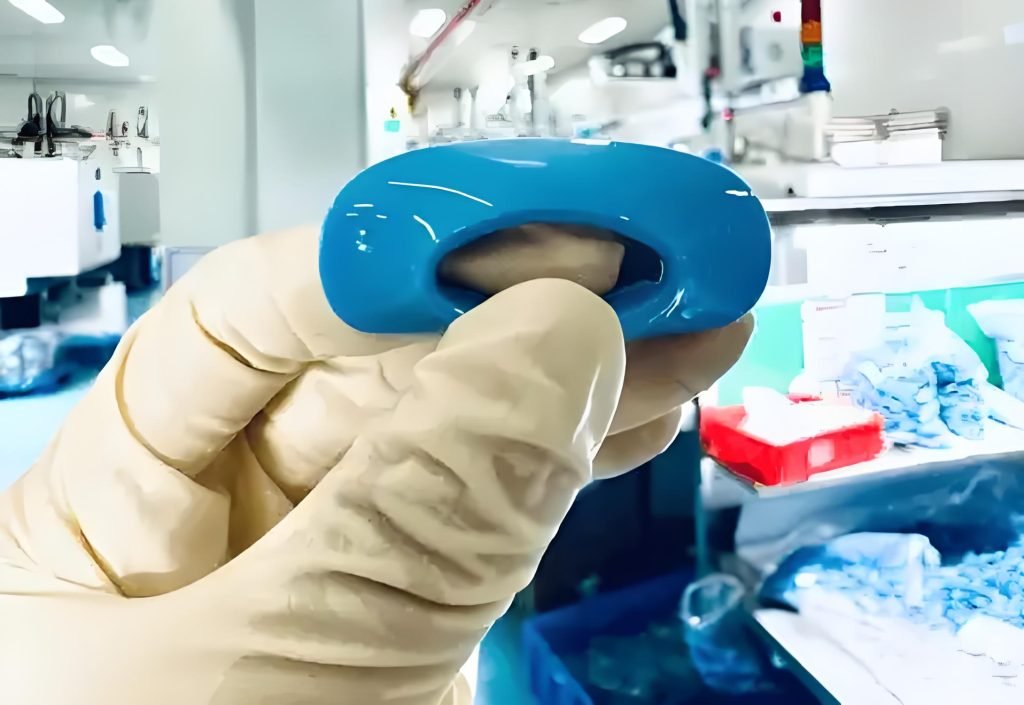

Demolding (or demold) is simply defined as the stage when a cooled plastic part has solidified and is removed from the mold cavity. Think of it like a perfectly baked cookie removed from its mold — you want it to come out whole and perfectly formed. This demolding definition highlights the goal of a flawless release.

This step is critical as the complete part will successfully be shaped, have a good surface finish, and be sized correctly. If the demolding process fails, defects result, and consequently, waste is produced and costs are incurred. This can lead to a failure to make properly formed parts every time.

Key Steps in the Demolding Process

The demolding process generally involves a number of steps that are sequenced clearly. These steps are intended to ensure the part can come out of the mold correctly without events leading to defects.

Step 1: Cooling and Solidification

Once the hot melted plastic has been injected into the mold, it must then cool down to achieve a solid state. This occurs inside the mold and is an important phase of the injection molding. Cooling your part requires the right time; too short leads to warped or stuck parts, and too long leads to delaying production. Properly cooling the part is the first step to a successful demold.

Step 2: Ejection

Once the plastic is solid, ejector pins or plates gently push the part out of the mold; it is almost like pressing a button to release something. The force applied in this step must be just balanced. Too much force could leave marks or crack the part; too little won’t push the part out at all. Precision is key, so your parts don’t get damaged.

Step 3: Part Removal

The part is finally either removed manually or removed by a machine entirely. This step must be done perfectly to check for surface defects such as scratches, or imperfections. Clean demolding indicates the part does not have any surface defects and it looks exactly as it should, before proceeding to the next step, or use.

Common Demolding Challenges

Warping and Deformation

One of the most frustrating things that can occur during demolding is warpage or deformation. This happens when your molded part comes out not as intended, but instead is twisted, bent, or some other form of misshapen. It will likely happen if the plastic has not cooled uniformly, or if the internal stresses are at a level that you cannot manage.

To minimize warpage, it is essential to be very precise in controlling not only the temperature of the mold, but also the time the part is in the mold. If you can manage to get these controls right, the plastic will cool, and solidify uniformly, which permits minimum warpage as it departs from the mold.

Part Sticking to the Mold

It’s always frustrating to find your plastic part stuck in the mold after injection. Sometimes it is simply insufficient mold release agent (the special spray that allows the parts to easily slide out), a rough surface of the mold causing sticky contact, or the part would be too warm and soft to the touch because the cooling process was insufficient.

To prevent sticking, and for a smooth clean finish, use high-quality mold releases to create very thin slippery surfaces. Your mold surfaces should always be polished and smooth to reduce friction. You could also add special surface treatments to some molds that relieve the natural stickiness of the mold and allow for a smoother release every time.

Discharge Marks and Surface Imperfections

At times, you might see discharge marks or imperfections on the surface of the finished plastic part. They are caused by the ejector pins, generally due to their improper placement or incorrect pressure on the part. In any case, these marks can really diminish the appearance and feel of the product.

To remedy this, you have the option to change the placement of the ejector pins to make them more spread out across the part. Another great option is to use air ejection. This releases the part with a blast of air rather than just relying on the physical pins to help release the part. Using air as ejection can help cut down or even eliminate marks, and give a much cleaner finish.

Quick Summary

| Challenge | Causes | Solutions |

| Warping/Deformation | Uneven cooling, internal stress | Optimize cooling time & mold temp |

| Part Sticking to Mold | Rough surfaces, inadequate release agents | Polish mold, use Teflon coatings |

| Ejector Marks | Misaligned pins, excessive force | Adjust pin placement, use air ejection |

Benefits of Improved Demolding Techniques

Faster Cycle Times

When you improve demolding, you’ll see faster cycle times, meaning you can produce more parts quicker. A smooth and rapid part removal allows your machine to immediately begin the next production cycle without delay.

Imagine how much faster things can run with specialized mold coatings or automated ejection systems. These advancements lead to shorter production cycles, getting more products out the door efficiently and boosting your overall output.

Reduced Part Defects

Better demolding techniques significantly reduce part defects. When parts come out smoothly, you typically do not get issues like cracks or warps due to the rough action of removing the part.

Parts that are not stressed or scratched during the demolding process will hold their part quality and integrity. High part quality like this leads to happy customers and saves you money by not wasting materials on scrapping products or reworking defective products.

Lower Production Costs

All of these improvements have a direct effect on production costs. Increased cycle times mean more parts in a given cycle of production, which improves efficiency. Likewise, fewer defects mean not wasting costly materials on bad products.

This increased efficiency can also reduce labor needs, as machines run smoothly with less manual intervention for inspection or repair. Less material waste and higher output combine for significant cost savings for your business.

Sustainability

Efficient demolding also has a great impact on sustainability. Optimizing the process naturally reduces energy consumption, as parts cool efficiently and machines don’t need to run as long per part.

You will also see much less material waste overall. There are fewer parts scrapped due to demolding defects. The positive trend of using more eco-friendly mold release agents and greater cooling systems also supports a greener manufacturing process.

Best Tips on Effective Demolding

1. Improving the Mold Design to Extract the Part

The best place to start improving demolding is right at the mold design stage. A good mold can make all the difference in how easily a part comes out of the mold. Think of designing a cake pan that will practically pop the cake out effortlessly!

Draft Angles

An important design feature is draft angles. These are slight tapers on the wall of the parts to make them wider at the mold opening. Even a small angle (1 to 3 degrees) will provide the part with assistance to slide out without sticking or scraping. This simple clearance ensures a smooth release.

Smooth Surface Finish

Ensuring a finished smooth surface internally within the mold cavity is also important. A very polished mold reduces friction, which allows the plastic to slide along the walls, and allows you a better chance to release the part. And it helps to avoid ugly marks from being on the surface.

Adequate Venting

Adequate venting in the mold is important as well. If air ends up trapped during the injection of the plastic, it can cause issues such as incomplete filling or unintended vacuum effects, which can impact release. A proper vent allows the air to escape for part forming and will help demold your parts much more easily.

2. Storage Requirements and Temperature Duration

In addition to the mold design, handling the cooling and the temperature of the part is very important for the part to come out of the mold successfully. It’s not just about the part getting cool; it’s about it getting cold properly.

Controlled Cooling

Controlled cooling is important, and temperatures and rates depend on the plastic. Consider thermoplastics, for example, generally keeping the mold at temperatures from 50-90° C (122-194° F). Cooling too quickly can impart stress or warping to the part, whereas cooling too slowly prolongs the cycle. It is also important to avoid any non-uniform cooling so that the part, once solidified, maintains its shape and can easily be ejected from the mold.

Real-Time Monitoring

Real-time monitoring of the cooling is the best way to ensure controlled cooling. Advanced temperature controllers and sensors allow close monitoring of both the mold temperature and the cooling of the part. Real-time data allows you to fine-tune cooling times of the part and also mold temperatures to ensure the part is sufficiently solid for easy removal, reduce defects, and decrease cycle times.

3. Lubricants and Mold Release Agents

Sometimes, even with the best mold design and cooling, you need a little extra help to get the part out. This is where lubricants and mold release agents come in.

Choosing the Right Agents

It is important to pick the correct mold release agent according to your specific plastic material. Each plastic material has specific properties that may require a special release agent to effectively allow the part to be demolded. These agents create a thin layer that is non-stick, so that the part can separate easily, allowing the part to come out cleanly every time. Using the wrong agent or using too little agent, can lead to stuck parts and damaged parts.

Surface Treatments

You may want to consider pursuing surface treatments for your mold that are more permanent. You can apply Teflon or chrome plating directly to the mold to improve the natural release properties of the mold. This is because the treated surfaces are inherently more slippery, leading to fewer applications of release agents, resulting in much more consistent demolding and extending mold lifespan.

4. Future Trends in Demolding Technology

Injection molding continues to be an evolving world, and demolding technology is no exception. Here are several trends to watch for that are on the verge of changing the industry landscape.

Automation and Robotics

One of the critical trends is the increased use of automation and robotics. Robotic arms are increasingly common, precisely removing parts with speed. Automated ejection systems can even self-adjust for optimal release. This ensures more consistent demolding, fewer errors, and faster production with less manual effort.

Advanced Materials

The development of advanced materials is also improving demolding. More environmentally friendly, bio-based mold release agents are hitting the market, many of which are more health and environmentally safe. Innovations in the mold materials themselves are also creating surfaces with inherently better release properties so that it is no longer necessary to use an outside spray agent.

Conformal Cooling

Conformal cooling is another new application. Instead of straight lines, there are cooling channels that exactly follow the cavity shape. The cooling of the plastic part is much more uniform; it results in a higher quality piece with less stress or warping. Uniform cooling also makes demolding easier, improves efficiency, and makes defects less likely.

Partner with Fecision for Expert Demolding Solutions

As demolding technology advances, partnering with an expert ensures you stay ahead. At Fecision, we combine cutting-edge techniques with decades of injection molding services to solve your toughest demolding challenges.

We provide:

- Precision mold design for easy demolding: We build our molds with accurate angles and a smooth finish, so your parts demold easily every time.

- High-quality surface finishes: You will receive parts with perfect surfaces without any marks, as we focus on precision.

- Fast cycle times and cost savings: Our efficiencies lead to faster production times and high-quality parts that save you time and money.

- Sustainable production practices: We work with you to minimize waste and maximize efficiencies, and help you make strides to meet your sustainability targets.

Eliminate demolding defects and boost production efficiency – Contact Fecision today for a free consultation on optimizing your injection molding process!

Conclusion

As we have outlined, demolding is a vital aspect of injection molding. If you do this well, your plastic part quality improves, production cycle times come down, and the costs are lower. Understanding some of the common issues and the practices of demolding will return the process of injection molding to an efficient process free of defects.

If you wish to improve your injection molding and get to efficient, high-quality production, consider working with Fecision. The expertise, technology, and commitment to quality and sustainable practices provided by Fecision will help you accelerate your innovative solutions.