Pogo pin connectors are essential components in modern electronics, offering reliable, high-frequency electrical connections. These spring-loaded pins are widely used for charging, data transfer, and signal transmission in compact devices such as smartphones, wearables, and medical equipment.

Unlike traditional connectors, pogo pins do not require repeated plugging and unplugging, reducing wear and enhancing durability. Their design consists of a plunger, barrel, and spring, ensuring a stable and flexible connection. While they provide high reliability and low maintenance, they have limitations, such as sensitivity to misalignment and restricted current capacity. Understanding their advantages and applications helps in selecting the right connector.

What Are Pogo Pin Connectors?

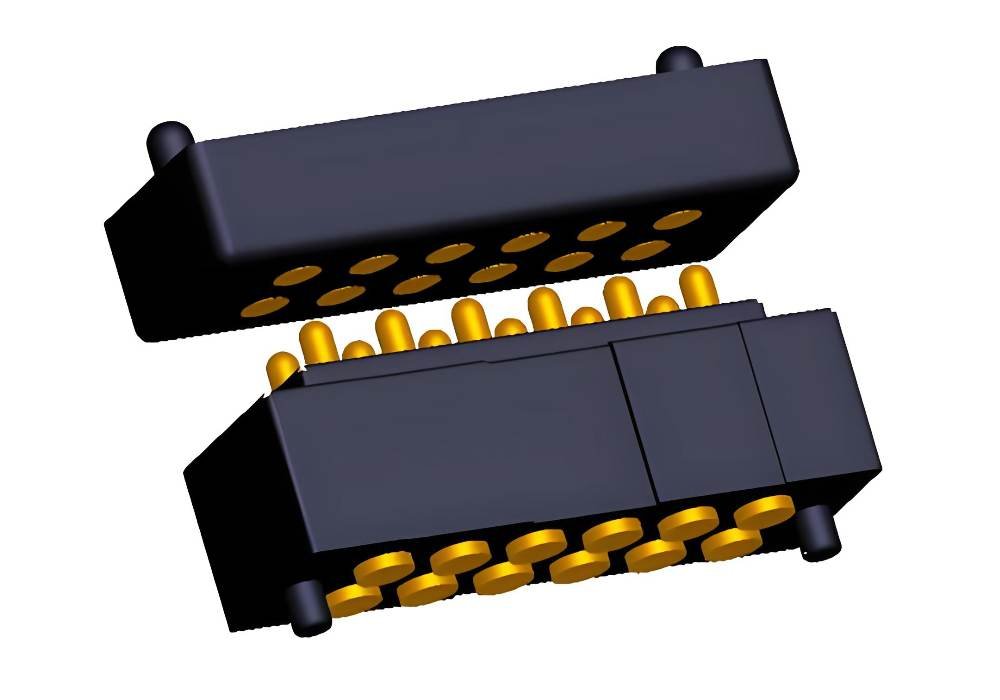

A pogo pin connector is a small, spring-loaded electrical connector used in many devices for charging, data transfer, and signal transmission. Unlike traditional connectors, pogo pins do not require plugging in and out, making them more durable and resistant to wear and tear. Pogo pins have three main parts:

Plunger: This is the tip of the pogo pin that touches the other device. It helps in transferring power or data by making a secure connection.

Barrel: This is the outer shell that holds the plunger and spring inside. It keeps everything aligned and protected.

Spring: A tiny coil inside the barrel that pushes the plunger up and down. It ensures a stable and flexible connection when the pogo pin is pressed.

These pins are compact, durable, and designed to last through thousands of connections, making them ideal for modern electronics and industrial tools.

How Pogo Pins Work

Pressing a pogo pin against a contact point makes the spring system compress under the force of the plunger to create an electrically secure connection. When the pressure is no longer applied the spring takes control and returns the plunger to its original position which interrupts the connection. The mechanical spring system gives pogo pins reliable performance while being ideal for tasks that need repeated connection and disconnection activities.

Advantages and Disadvantages of Pogo Pin Connectors

Pogo pin connectors are widely used in various industries due to their unique design and functionality. However, like any technology, they come with their own set of advantages and disadvantages. Understanding these pros and cons can help you determine whether pogo pin connectors are the right choice for your specific application.

Advantages of Pogo Pin Connectors

High Reliability and Durability: Pogo pin connectors are designed to handle thousands, and even millions, of connection cycles. They are thus extremely durable and reliable for use in applications where the connector needs to be frequently connected and disconnected. For instance, in consumer devices such as smartphones or wireless earbuds, pogo pins are utilized for charging, which requires daily plugging and unplugging. The spring retention makes them perform reliably over the long term, lowering the possibilities of failure.

Compact Design: One of the salient features of pogo pin connectors is compactness. They are made to occupy less space, making them a perfect fit for contemporary devices with a focus on compact and lightweight solutions. For example, in wearable devices such as smartwatches or fitness bands, pogo pins are a sound charging solution that doesn’t occupy too much space. Their compactness also enables greater design flexibility.

Low Maintenance: Spring mechanism in pogo pins provides not only a secure connection but also reduces wear and tear. In contrast to conventional connectors, which can necessitate frequent maintenance or replacement with respect to friction or corrosion, pogo pins are made for longer life with less maintenance. This renders them an economical solution in the long term, particularly for applications with limited accessibility for repair.

Ease of Use: Pogo pins are designed for quick and easy connections. Their spring-loaded mechanism allows for smooth engagement and disengagement, which is particularly useful in applications like testing equipment or modular devices. This ease of use saves time and effort, especially in industrial or manufacturing settings.

Versatility: Pogo pin connectors can be customized to meet specific requirements, such as different lengths, shapes, or plating materials. This versatility makes them suitable for a wide range of applications, from consumer electronics to medical devices and automotive systems.

Disadvantages of Pogo Pin Connectors

Limited Current-Carrying Capacity: Due to their small size, pogo pins are not ideal for high-current applications. They are typically designed for low to moderate current levels, which limits their use in power-hungry devices. For example, while they work well for charging small devices like earbuds, they may not be suitable for high-power applications like electric vehicle charging or industrial machinery.

Sensitivity to Misalignment: Pogo pins require precise alignment to function properly. If the pins are not aligned correctly with the contact points, it can lead to poor connections, intermittent signals, or even damage to the pins. This sensitivity to misalignment can be a challenge in applications where precise positioning is difficult to achieve or maintain.

Potential for Wear Over Time: While pogo pins are designed for durability, the spring mechanism can eventually wear out after extensive use. In high-cycle applications, the springs may lose their tension, leading to reduced performance or failure. Regular inspection and replacement may be necessary in such cases.

Higher Initial Cost: Compared to traditional connectors, pogo pin connectors can have a higher upfront cost, especially for custom designs or high-quality materials like gold plating. However, this cost is often offset by their long-term durability and low maintenance requirements.

Environmental Sensitivity: Pogo pins can be sensitive to environmental factors like dust, moisture, or extreme temperatures. Contaminants can interfere with the connection, while harsh conditions may affect the materials or spring mechanism. Proper sealing or protective measures may be required for use in challenging environments.

Applications of Pogo Pin Connectors

Pogo pin connectors are flexible and dependable, which is why many industries like to use them. Here are some common uses explained in easy words:

Consumer Electronics: Pogo pin connectors are also very common in wearables, tablets, and smartphones for data transfer and charging. Because they are very small and strong, they are specifically ideal for the daily device use such as wireless earbuds and smartwatches, allowing effective power transfer in small spaces.

Medical Devices: Medical devices like blood glucose monitors and diagnostic devices use pogo pins to connect reliably and accurately. The connectors ensure accurate measurement and have long lifespan, which is highly important in medical treatment.

Automotive and Industrial Applications: Pogo pins are used extensively in vehicle testing, enabling mechanics to test systems quickly and precisely. They provide simple part replacement in robots and machines and enable flexible design, simplifying maintenance and upgrade.

Key Features of Pogo Pin Connectors

Pogo pin connectors provide reliable, high-performance electrical connections with durability and flexibility.

- Spring-Loaded Design: Ensures consistent contact and conductivity.

- High Durability: Supports thousands of mating cycles.

- Low Contact Resistance: Enhances signal transmission efficiency.

- Compact & Flexible: Ideal for space-constrained applications.

- Corrosion & Wear Resistance: Ensures long-term reliability.

- Customizable Configurations: Available in various sizes, shapes, and plating options

Types of Pogo Pin Connectors

Spring-Loaded Pins: These are the most common type of pogo pins. They have a spring inside that pushes the plunger to make a secure connection. The spring ensures consistent pressure, making them reliable for frequent use, like in charging docks or testing equipment.

Solder Cup Pogo Pins: These pins have a cup-shaped end that can be easily soldered onto circuit boards. They are perfect for permanent installations where a strong, fixed connection is needed, such as in industrial control systems.

SMT Pogo Pins: SMT (Surface-Mount Technology) pogo pins are designed for automated assembly processes. They are mounted directly onto the surface of circuit boards, offering high precision and efficiency. These are commonly used in mass-produced electronics like smartphones.

Electrical and Mechanical Properties

Pogo pin connectors are designed with specific electrical and mechanical properties to ensure reliable performance. Here’s a simple explanation of two key aspects:

- Contact Resistance: Low contact resistance is crucial for efficient electrical connections. Pogo pins are designed to minimize resistance, ensuring optimal performance.

- Plating and Coating Materials: Pogo pins are often plated with materials like gold, nickel, or silver to enhance conductivity and prevent corrosion.

Design and Customization

Pogo pin connectors offer flexibility in design and mounting, making them adaptable to various applications. Here’s a closer look at their design and customization options:

Standard vs. Custom Pogo Pin Designs:

- Standard Pogo Pins: These are pre-designed for common uses, such as charging docks or testing equipment. They are cost-effective and easily available for general purposes.

- Custom Pogo Pins: These are tailored to meet specific needs, such as unique shapes, sizes, or performance requirements. Custom designs are ideal for specialized applications, like medical devices, aerospace systems, or industrial machinery, where standard pins may not suffice.

Housing and Mounting Options

- Plastic Housings: These are light and affordable, making them ideal for everyday gadgets like smartphones and smartwatches. They work well for devices that don’t need extra strength or heat resistance.

- Metal Housings: Strong and heat-resistant, metal housings are used in cars and heavy machines. They protect pogo pins from damage and ensure they last longer in tough conditions.

- Ceramic Housings: These can handle very high temperatures and are used in sensitive devices like medical tools and aerospace equipment. They provide excellent insulation and durability in extreme environments.

Manufacturing Costs of Pogo Pin Connectors

The cost of manufacturing pogo pin connectors depends on several factors, and understanding these can help in making informed decisions. Here’s a breakdown:

Factors Affecting Cost

- Materials: The type of materials used, such as gold plating for better conductivity or stainless steel for durability, can significantly impact the cost. High-quality materials increase the price but enhance performance and longevity.

- Design Complexity: Custom designs or complex features, like unique shapes or specialized coatings, add to the manufacturing cost. Simpler, standard designs are more cost-effective.

- Quantity: Bulk production reduces the per-unit cost due to economies of scale. Ordering in large quantities is often more affordable than small, custom batches.

Cost Comparison with Traditional Connectors

- Pogo Pin Connectors: While they may have a higher upfront cost due to their precision engineering and materials, their durability and low maintenance often result in long-term savings.

- Traditional Connectors: These are generally cheaper to produce initially but may require frequent replacements or repairs, increasing overall costs over time.

Pogo Pin Connector vs. Traditional Connectors

When choosing between pogo pin connectors and normal connectors, you need to know their differences when it comes to durability, cost, and optimum uses. This is a complete explanation to assist you in deciding which one you should use.

Differences in Durability and Lifespan

Pogo pins last longer than traditional connectors because they have fewer moving parts and don’t wear out easily.

- Pogo Pin Connectors: Connectors are made with a spring-loaded construction that renders them very durable. They withstand thousands of cycles of mating without a reduction in performance, making them ideal for applications where high usage is desired, like test equipment or charging docks.

- Traditional Connectors:Traditional connectors are not as long-lasting even though they function. They will degrade faster, especially with the application of high frequencies, and may require replacement or repair over time.

Cost and Manufacturing Considerations

Pogo pins are cost-effective to produce in large quantities, but material and design choices affect their overall price.

- Pogo Pin Connectors: They are pricier initially due to their precision engineering and quality materials like gold plating. Yet, their low maintenance and long lifespan make them cost-effective in the long run.

- Traditional Connectors: They are cheaper to produce initially, thus being attractive to low-budget projects. Their shorter lifespan and higher maintenance costs, however, can lead to higher total costs.

Best Use Cases for Each

- Pogo Pin Connectors: Ideal for applications requiring compact sizes, high-frequency connections, and high reliability. Examples include smartphones, wearables, medical devices, and test equipment.

- Traditional Connectors: They are better for applications where high current is needed or where one wants to save money initially. You typically find them in power systems, industrial equipment, and car wiring.

| Aspect | Pogo Pin Connectors | Traditional Connectors |

| Durability | High | Moderate |

| Lifespan | Long | Short |

| Cost | High (initial) | Low (initial) |

| Use Cases | Compact, reliable | High-current, cost-saving |

Pogo pins are ideal for compact, high-reliability applications, while traditional connectors are better for high-current or budget-focused projects. Choose based on your specific requirements

Conclusion

Pogo pin connectors play a vital role in modern electronics by providing reliable, durable, and compact spring-loaded connections for everything from consumer devices to medical, automotive, and industrial equipment. Their unique structure ensures consistent conductivity, long cycle life, and excellent resistance to shock and vibration, making them indispensable in applications that demand stable and repeatable performance.

At Fecision, we specialize in custom pogo pin and pogo pin connector manufacturing, offering precision engineering and high-quality materials to meet your custom electrical and mechanical requirements. Reach out to us today to develop custom pogo pin solutions that deliver exceptional reliability and performance for your next product.