Thermoplastic Elastomer (TPE) is transforming product manufacturing. TPE injection molding converts rubber-like flexibility into high-volume, production-grade parts in seconds. This eliminates slow vulcanization steps—just melt, inject, and eject, and the whole cycle takes seconds.

This guide will offer you the essentials: the definition of TPE, how its efficient injection molding process works, important design guides, and the important differences between TPU vs TPE for your next flexible product.

What Is TPE Material?

The distinct capabilities of TPE contribute greatly to its versatility as a material. Let’s review the fundamental structure and benefits.

Definition

Thermoplastic elastomer (TPE) is a rubber you can melt and treat just like plastic. It can flow easily when heated, and the practical heat resistance of TPE is usually between 100 and 150 °C. When the TPE cools to room temperature, it behaves just like traditional cured rubber. It is this nature to have a dual function that makes the material valuable in production.

The Science Behind TPE’s Flexibility

The unique structure of TPE provides this dual-type processing behavior. It contains two general types of segments: hard segments and soft segments. The hard segments, like polypropylene (PP) or polyurethane (PU), give it its plastic thermoplastic side.

The soft segments, like polyolefin (PO), provide the necessary rubber-like elastomeric behavior. Upon heating TPE, the physical bonds break, allowing the material to flow. The bonds re-form after cooling. This lets you re-melt the material multiple times without degradation.

Key Properties of TPE

Choosing TPE offers your products a wide range of benefits. It successfully merges the best qualities of both plastic and rubber in one material.

- Elasticity and Flexibility: TPE flexes easily and returns to shape quickly. It won’t tear when pulled or stay deformed when crushed. This rubber-like behavior works for seals, grips, and dampers.

- High Processability: TPE melts smoothly in injection molding machines. It fills complex molds and cycles fast—no special equipment needed.

- Broad Hardness Range: Available from extremely soft, rubber-like grades up to firm, highly durable grades.

- Durability and Wear: TPE surfaces resist scuffing and grinding. They maintain shape in repeated compression—think shoe soles that don’t pack down, or gaskets that keep sealing

- Weather Resistance: Most grades withstand UV exposure and temperature swings. They won’t crack in sunlight or become brittle in cold weather—suitable for automotive trim and outdoor tool housings.

- Environmental Edge: TPE contains no heavy metals or phthalates. Regrind scrap directly back into production—it processes cleanly with minimal property loss.

Major TPE Material Families

The TPE family is rather large, and each group has its own unique benefits depending on the environment. If you are familiar with the main types, it will help in selecting the perfect material for your part.

| Type | Key Properties | Typical Applications |

| 1. TPE-S (Styrenic Block Copolymers) | Large hardness range; Good abrasion; UV & ozone resistant. | Adhesives; Asphalt modification; Footwear; Low-grade seals. |

| 2. TPE-O (Thermoplastic Polyolefins) | Excellent weather resistance; Tougher than PP; Good chemical resistance. | Automotive bumpers; Dashboards; Airbag covers; Mudguards. |

| 3. TPE-V (Thermoplastic Vulcanisates) | High-temp resistance up to 120°C; Low compression set; Chemical resistant. | Automotive seals; Hoses; Pipe seals; Engine compartments. |

| 4. TPE-U (Thermoplastic Polyurethanes) | Excellent abrasion resistance; High tensile strength; Resistant to oils and fuels. | Caster wheels; Power tool grips; Hoses/tubes; Drive belts. |

| 5. TPE-E (Thermoplastic Copolyesters) | Long-term resistance up to 165°C; Resistant to creep; Dimensionally stable. | Vehicle air ducts; Ventilator bags; Dust boots; Conveyor belts. |

| 6. MPR (Melt Processable Rubber) | UV resistant; High friction coefficient; Resistant to gasoline and oil. | Automotive weather strips; Inflatable boats; Seals; Hand grips. |

| 7. TPE-A (Polyether Block Amides) | High-temp resistance up to 170°C; Good solvent and impact resistance; Flexible at low temps. | Aerospace components; Cable jacketing. |

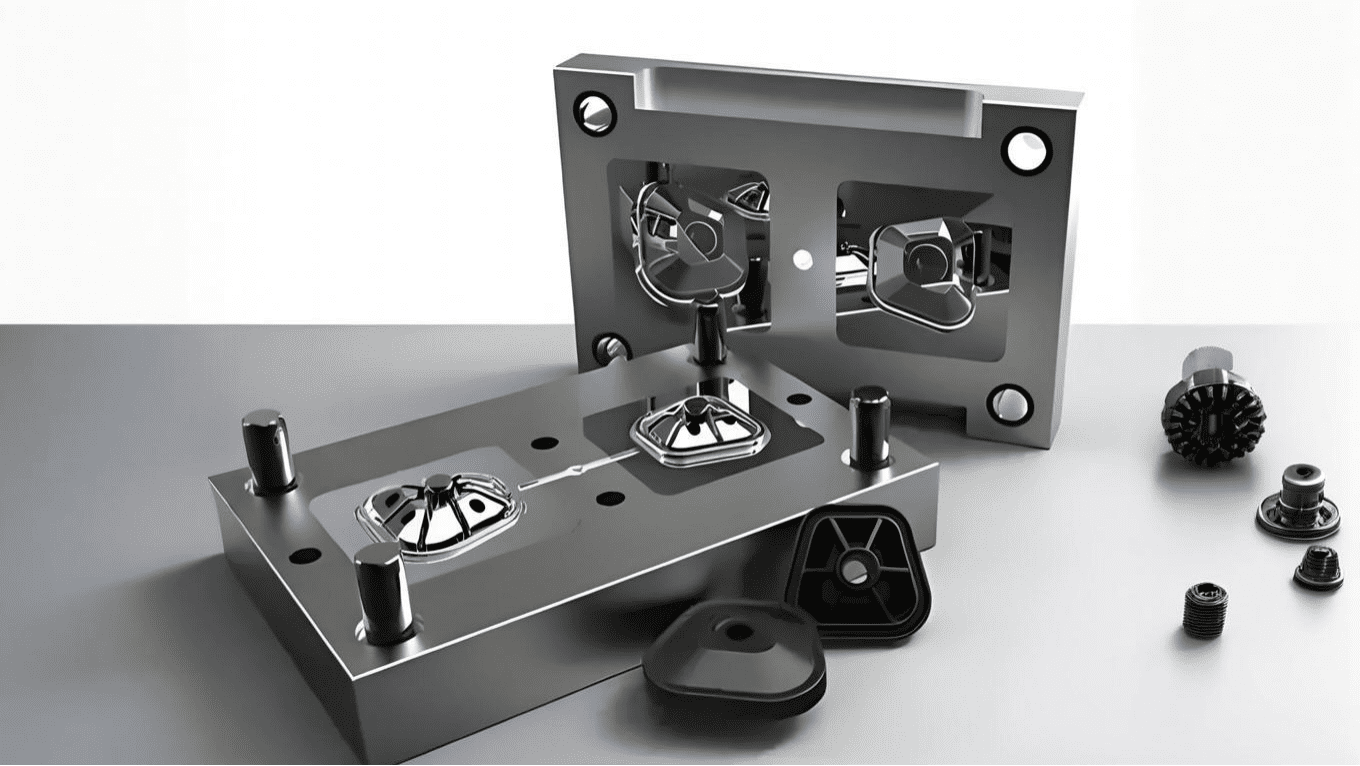

What Is TPE Injection Molding?

TPE has been developed for injection molding, and it changes how flexible parts are manufactured. Let us consider how this process works at such high speeds and why it is important.

Definition

TPE injection molding is a very fast cyclical process. It involves forcing molten TPE into a cooled mold cavity under high pressure. The material solidifies quickly into a finished, elastic part in a very short amount of time. This method is the most efficient way to mass-produce complex, consistent, soft components.

The Importance of TPE Injection Molding

The process delivers significant advantages over older methods, especially rubber molding. TPE provides the feel of rubber with the processability of plastics. This characteristic allows the designer to better develop complex designs for modern products.

TPE molding is faster than rubber vulcanization — it skips the long cure times and uses less energy. This allows you to greatly shorten your cycle time. High-speed molding makes TPE a very cost-effective process for mass production, generating far less material scrap than traditional rubber.

The TPE Injection Molding Process

Achieving perfect TPE parts requires careful control over every step. We will walk you through the entire TPE injection molding process, from preparing the raw pellets to final quality checks.

Preparing the Material

Some TPE families, such as TPU and TPE-E, readily absorb moisture from the air. You must dry these materials for two to four hours at 80 °C until moisture is below 0.05%. A hopper dryer with a desiccant wheel is mandatory. Drying prevents bubbles, streaks, and cosmetic flaws in your final molded parts.

Melting the TPE

The plastication step involves a careful temperature increase across the screw zones. The TPE is heated from about 160 °C at the feed zone near the hopper up to 230 °C at the nozzle. This ensures a perfect, uniform melt. If using a hot runner, the material drops are also kept at a high, consistent temperature to maintain flow.

Injection and Packing

Injection uses a multi-stage speed profile. You should use a slow initial fill to allow air inside the mold to fully vent out. Then, you quickly increase the speed to fill the remaining cavity volume. Finally, a controlled packing pressure is applied to compress the material, which ensures your finished part achieves perfect dimensional stability.

Cooling and Part Ejection

An ideal and uniform wall thickness of 1 to 3 mm is required for rapid cooling. And the mold temperature should be kept in the range of 30 to 70 °C for even solidifying and minimizing warpage. Ejection must be handled carefully. For soft parts, ejector pins are often coated with PTFE to reduce friction and prevent damage to the delicate surface of the finished part.

Post-Processing and QC

After ejection, some parts may need finishing. Tough TPE-V flash is often removed using a cryogenic trimming process. Quality control includes a 100% vision check for short-shots or incomplete filling. A batch is also tested for properties like tensile strength, following industrial standards such as ISO 37.

Key Considerations in TPE Injection Molding

Molding TPE parts successfully requires mastering a few specialized TPE injection mold design rules and process controls. Let’s look at the areas that require the most attention.

Shrinkage and Warpage Control

All TPE will shrink as it cools, typically up to 2.0%. Your mold must be made with a cavity tolerance of ±0.05 mm to achieve the final dimension. Applying a 1 degree draft angle to all vertical walls is essential. This small taper helps the soft TPE part release easily without sticking to the mold.

Critical Temperature and Heat Management

Barrel temperature needs precise control. This gives you optimal viscosity without degrading the TPE material. Keep mold temperatures steady between 30 and 70 °C—it cools the part faster and gives a cleaner surface finish. Watch the screw speed too; high speeds create excess shear heat, and that will damage the TPE’s structure.

Managing Vents and Flow Issues

Adequate mold venting is absolutely essential. This allows trapped air and gases to escape, preventing serious defects like short shots, voids, or burn marks (dieseling). Strategic gate location is crucial to ensure quick, balanced filling of the cavity, minimizing the visible appearance of weld lines, and allowing for clean, easy post-processing.

Overmolding and Adhesion Technology

For overmolding onto rigid substrates (like PP or ABS), the TPE must be chemically compatible with the substrate to achieve a strong bond. If chemical adhesion falls short, add mechanical locks like undercuts or dovetail grooves to the mold. Always start with a clean, dry substrate surface—any oil or dust will wreck the bond.

Regulatory Compliance and Traceability

For medical or automotive products, regulatory compliance is essential. Medical TPE-E grades must meet standards like USP Class VI. For full lot traceability, you must record the resin lot number, dryer chart, and process parameters. These records must be kept for up to 10 years for audit purposes.

TPU vs TPE Injection Molding – Selection Guide

In the case of needing a flexible component, you can usually choose between two material categories: TPU vs TPE injection molding. The differences in their performance are why you would choose one for your product over the other.

What Is TPU?

TPU is a subtype of TPE (specifically a TPE-U) that has excellent abrasion resistance, high tensile strength, and oil/fuel resistance. TPU is considered the “high-performance” category of thermoplastic elastomers.

What Is TPE?

TPE is a more generalized type of soft, flexible, recyclable thermoplastics that has good elasticity and can be processed easily. TPE typically will have a wider range of softness (Shore hardness) available when compared to pure TPU.

Key Differences Between TPU vs TPE Injection Molding

The following table will outline the unique performance features for each family regarding injection molding:

| Performance Characteristic | TPU (Thermoplastic Polyurethane) | TPE (Thermoplastic Elastomer) |

| Flexibility & Feel | Moderate flexibility; more rigid and load-bearing. | Higher flexibility; very soft to semi-rigid; rubber-like touch. |

| Hardness Range | Higher Shore hardness (60A to 85D); suitable for toughness. | Broader Shore hardness (20A to 90A); ideal for soft-touch. |

| Abrasion Resistance | Outstanding resistance; superior for high-friction parts. | Moderate resistance; adequate for general use. |

| Chemical & Oil Resistance | Superior resistance to oils, greases, and solvents. | Good general resistance; performance varies widely by type. |

| Dimensional Stability | High dimensional accuracy; better creep resistance. | Moderate dimensional accuracy; some warpage risk. |

| Processing & Cost | Higher material cost; requires precise drying and control. | Lower cost; wider processing window, easier molding. |

| UV and Heat Resistance | Excellent UV stability and high heat resistance. | Good UV and heat resistance; suitable for general products. |

Applications of TPE Injection Molding Process

TPE’s flexibility and efficiency mean it is utilized across almost every major industry. Its uses span from highly technical medical parts to everyday consumer products.

Automotive Components

TPEs are critical to automotive sealing applications. Producing exact seals, gaskets, and boots for doors and other engine parts that require good UV and temperature resistance. Inside the cabin, TPEs produce comfortable, non-slip, soft-touch grips for steering wheels and dashboard inserts to enhance driver comfort.

Consumer Goods and Electronics

You see TPE everywhere in consumer items. It creates soft, ergonomic, and anti-slip handles for power tools and kitchen utensils, improving user comfort and product life. For electronics, TPE is injected to form flexible, shock-absorbing protective casings for devices like smartphones, offering excellent drop protection.

Consumer Goods and Electronics

You see TPE in many consumer goods. It forms soft, ergonomic handles on power tools and kitchen utensils. The surface resists slipping—a big deal for safety and control. In electronics, TPE is injected to make shock-absorbing cases. These flexible bumpers protect devices like smartphones from accidental drops.

Medical Devices and Healthcare

TPE is essential in the healthcare field for its resiliency and safety. It’s used for flexible tubing and connectors in IV sets and catheters, often requiring biocompatible grades. It also molds precise seals and plungers for syringes, where flexibility and resistance to various sterilization processes are critical requirements.

Footwear and Apparel

TPE is a common choice for shoe soles, particularly in athletic and outdoor styles. This material stands up to wear, springs back after compression, and provides solid ground grip; that combination is key for runners and hikers. TPE is also molded into comfortable, waterproof, and easily cleanable straps and sandals for sports and casual wear.

Industrial Components

In industrial settings, TPE is used to fabricate durable, flexible components like custom hoses and belts for fluid and air transfer systems. These parts require good resistance to abrasion and chemicals. TPE also molds vibration-dampening pads and bumpers to reduce noise, absorb shock, and isolate machinery vibration.

Conclusion – A Flexible Future Awaits

TPE injection molding is an extremely powerful molding process that achieves the durability and flexibility of rubber, and combines that with the efficiency and cost-effectiveness of plastic. Based on the discussion of the primary material families, TPE injection mold design principles, and process requirements, you are all set to find the best TPE for your products.

If you are looking for top TPE injection molding manufacturers, consider Fecision. We offer you specialized expertise for flexible TPE materials, including high-performance TPU with its excellent abrasion and impact resistance. Our advanced machines ensure low material waste (under 5%) and tight tolerances (as low as ±0.025 mm), even for soft parts, delivering reliable, custom TPE components.

Choose Fecision for TPE injection molding that accelerates your launch. We offer high annual capacity with 24/7 automated production and strict quality control (CMM, SPC). Our comprehensive services, including JIT delivery and assembly, compress lead times and guarantee your flexible TPE parts meet the highest standards.