In industries where failure is not an option, such as automotive and aerospace, the reliability of every component is paramount. Connectors, often small but vital links in complex electrical systems, are no exception. These components must withstand extreme conditions, from intense vibrations and temperature fluctuations to harsh chemical exposures, all while maintaining flawless electrical conductivity.

The foundation of such high-performance connectors lies not just in their design and materials, but critically, in the precision molds used to manufacture them. This blog post will explore the stringent demands placed on connectors in these critical sectors.

The Stringent Demands of Automotive Connectors

The automotive industry is a crucible for component reliability. Modern vehicles are increasingly reliant on sophisticated electronic systems, from advanced driver-assistance systems (ADAS) to infotainment and powertrain control. Each of these systems depends on a vast network of connectors that must perform flawlessly under a variety of challenging conditions. Key requirements for automotive connectors include:

- Extreme Temperature Fluctuations: Connectors in engine compartments or near braking systems must endure wide temperature swings, from sub-zero cold starts to scorching operating temperatures, without degradation in performance.

- Vibration and Shock Resistance: Constant vibrations from the engine and road, along with potential impacts, necessitate connectors that can maintain secure electrical connections and structural integrity over the vehicle’s lifespan.

- Environmental Sealing: Exposure to moisture, dust, road salt, and various automotive fluids demands robust sealing mechanisms to prevent corrosion and electrical shorts.

- Miniaturization and High Density: As vehicles become more compact and feature-rich, there’s a continuous push for smaller, higher-density connectors that can fit into confined spaces without compromising performance.

- Compliance with Industry Standards: Automotive connectors must adhere to rigorous standards such as USCAR-20 (Performance Standard for Automotive Electrical Connector Systems) and LV214 (German automotive industry standard for electrical connectors), which define critical performance and testing criteria. IATF16949 certification ensures quality management systems are in place for automotive connectors.

Meeting these demands requires not only advanced material science but also exceptionally precise manufacturing processes for the molds that produce these connectors. Any imperfection in the mold can lead to defects in the connector, potentially causing critical system failures in a vehicle.

Aerospace Connectors: Precision in the Skies

The aerospace industry operates under even more extreme conditions, where the consequences of component failure can be catastrophic. Aircraft, spacecraft, and satellites rely on connectors that must function flawlessly in environments ranging from the vacuum of space to high-altitude atmospheric pressures, and through rapid changes in temperature and pressure. The demands on aerospace connectors are incredibly high:

- Extreme Environmental Resilience: Connectors must withstand severe temperatures, radiation, vacuum, and corrosive fluids without compromising signal integrity or power delivery.

- Lightweight and Compact Design: Every gram and cubic centimeter matters in aerospace applications. Connectors must be as light and small as possible while maintaining robust performance.

- High Vibration and G-Force Tolerance: During launch, flight, and landing, connectors are subjected to intense vibrations and G-forces, requiring designs that prevent disconnections or damage.

- EMI/RFI Shielding: To ensure reliable communication and control, connectors must provide effective shielding against electromagnetic and radio frequency interference.

- Long-Term Reliability and Durability: Aerospace components are expected to have exceptionally long service lives, often decades, with minimal maintenance. This necessitates materials and manufacturing processes that guarantee long-term stability.

- Adherence to Aerospace Standards: Compliance with standards like AS9100 (Quality Management System for Aviation, Space, and Defense Organizations) is mandatory, ensuring the highest levels of quality and safety.

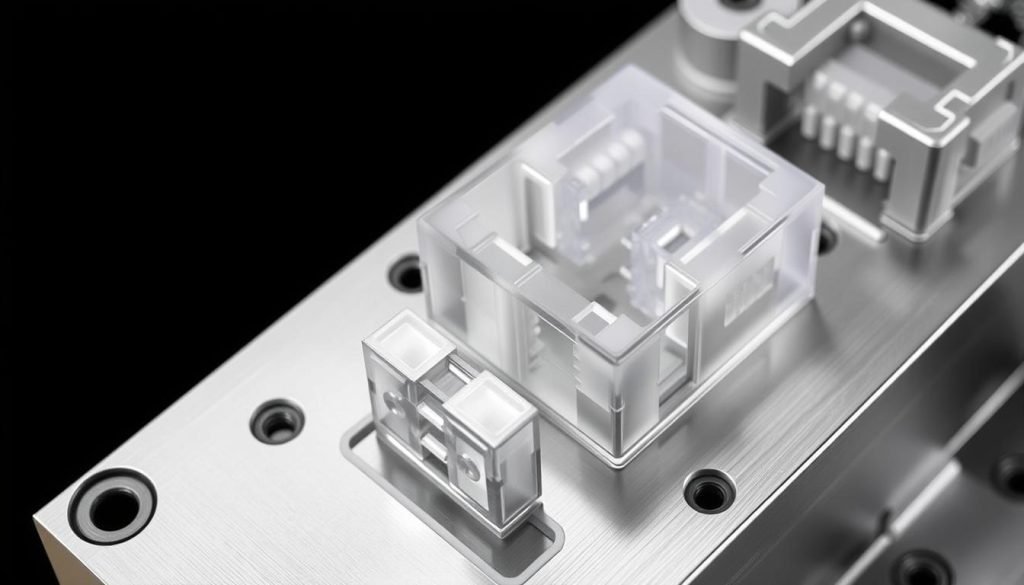

For both automotive and aerospace applications, the manufacturing process of these connectors is paramount. The molds used to create the intricate plastic housings and precisely position metal contacts must be engineered and produced with unparalleled accuracy.

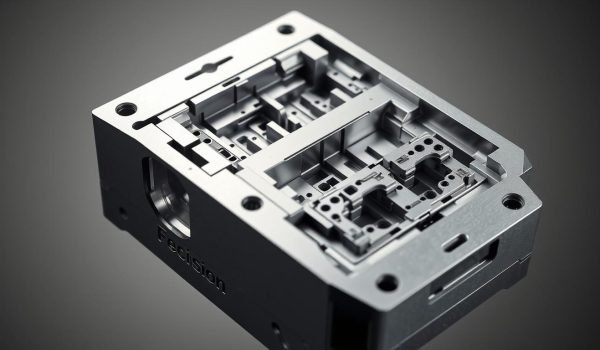

Precision Connector Molds: The Foundation of High-Reliability Connectors

Precision connector molds are the backbone of high-reliability connectors used in automotive and aerospace applications. The quality of these molds directly impacts the performance and reliability of the connectors. These molds are critical for producing connectors with precise dimensions and consistent material properties.

Manufacturing Process for High-Precision Connector Molds

Manufacturing connectors for these demanding industries requires molds capable of producing parts with extremely tight tolerances, often down to ±0.005mm. This level of accuracy is crucial for ensuring perfect mating, secure electrical contact, and consistent performance. Fecision achieves this through:

- Advanced CNC Machining: Utilizing state-of-the-art CNC equipment to mill mold components with exceptional accuracy.

- Electrical Discharge Machining (EDM): Employing EDM for intricate geometries and fine details that conventional machining cannot achieve, ensuring precise features in the connector design.

- In-Process Inspection with CMM: Our Coordinate Measuring Machines (CMM) provide real-time, highly accurate measurements during the manufacturing process, allowing for immediate adjustments and verification of critical dimensions.

Material Selection for Durability and Performance

The choice of mold material and the materials used for the connector itself are vital. Fecision works with a wide range of high-performance materials, including:

- High-Grade Tool Steels: Selecting specialized tool steels for molds that offer superior hardness, wear resistance, and thermal stability to withstand the rigors of continuous production.

- Engineering Plastics: Expertise in molding advanced engineering plastics (e.g., PEEK, Nylon, Polycarbonate) that offer excellent dielectric properties, high temperature resistance, and mechanical strength for connector housings.

- Exotic Alloys: Capability to work with exotic alloys for specialized connector contacts or inserts that require exceptional conductivity, corrosion resistance, or strength.

Design for Manufacturability (DFM) and Simulation

Our engineers collaborate closely with clients from the initial design phase, applying Design for Manufacturability (DFM) principles to optimize connector designs for molding. This proactive approach helps to:

- Prevent Defects: Identifying and mitigating potential molding issues like sink marks, warpage, or flash before mold construction begins.

- Optimize Performance: Ensuring that critical features like draft angles, gate locations, and parting lines are designed to enhance part quality and mold longevity.

- FEA Simulation: Utilizing Finite Element Analysis (FEA) to simulate material flow and stress distribution within the mold, predicting and correcting potential issues to achieve optimal part integrity.

Adherence to Industry-Specific Quality Standards

Fecision’s commitment to quality is underscored by our comprehensive certification portfolio, which is particularly relevant for automotive and aerospace applications:

- IATF 16949:2016 (Automotive): This certification demonstrates our adherence to the highest quality management standards specific to the automotive industry, ensuring reliability and consistency for automotive connector molds.

- AS 9100 (Aerospace): Our AS 9100 certification signifies compliance with the stringent quality management system requirements for the aviation, space, and defense industries, guaranteeing the utmost precision and safety for aerospace connector molds.

- ISO 9001:2015: The foundational quality management system that underpins all our manufacturing processes.These certifications are not just badges; they represent a deeply ingrained culture of quality, precision, and continuous improvement that is essential for producing molds for high-reliability connectors.

Conclusion

In the demanding worlds of automotive and aerospace, the performance of connectors is non-negotiable. These small components are critical to the safety, functionality, and reliability of complex systems. The ability to produce connectors that consistently meet stringent requirements for temperature, vibration, environmental protection, and precision is directly tied to the quality of the molds used in their manufacture.

Fecision stands as a trusted partner in this critical endeavor. Our unwavering commitment to precision, advanced manufacturing technologies, deep material expertise, and adherence to the highest industry standards (IATF 16949, AS 9100) ensure that the molds we produce are the bedrock of high-reliability connectors. By choosing Fecision, you can be confident that your connectors will perform flawlessly, even in the most challenging environments, driving innovation and ensuring safety for the future.