The material you pick shapes durability, cost, and customer satisfaction across a product’s life. Your choice affects how parts resist impact, chemicals, and wear, and it changes perceived quality and long‑term value.

One option offers high impact resistance, heat tolerance, and excellent clarity for optics and safety parts. The other delivers strong chemical and oil resistance, good abrasion behavior, and self‑lubrication that helps moving components in harsh environments.

Surface strategy matters: clear parts often need hard coats to prevent scratches and UV yellowing, while textured finishes can hide scuffs and extend a like‑new appearance. Cost also guides decisions—resin prices differ (roughly $1.30/kg vs. $2.80/kg), and recycled grades can narrow that gap.

Match the environment and loads to your design. For luggage and travel gear, balance structure, impact protection, and scratch behavior to keep contents safe and products looking new over many trips.

Understanding polycarbonate and polypropylene

Start by knowing how each resin’s internal structure shapes real-world performance. You’ll get simple definitions that link molecular form to the durability and flexibility you need for parts and luggage.

What is polypropylene

Polypropylene is a thermoplastic polymer known for a semi-crystalline structure. Isotactic, syndiotactic, and atactic arrangements change crystallinity and create a wide range of properties.

That structure gives chemical and oil resistance, abrasion resistance, and self-lubrication. Biaxially oriented PP (BOPP) boosts film clarity and toughness, so packaging and air‑handling parts perform well.

What is polycarbonate

Polycarbonate is an amorphous, glass-clear polymer with light transmission close to glass and standout impact resistance. It handles heat well and is widely used for lenses, shields, and lighting covers.

Scratch resistance is often improved with hard coats like melamine or silicates. Lower molecular weight grades mold more easily, while higher molecular weight grades give greater toughness for demanding parts.

Polypropylene vs. Polycarbonate: property and performance comparison

To pick the right resin, you need clear, side-by-side property figures and what they mean for parts you build. Below are the key mechanical, thermal, cost, and recycling markers that guide design and material selection.

Mechanical properties

Tensile strength ranges widely: about 9–80 MPa for polypropylene and roughly 28–75 MPa for polycarbonate. Elongation and modulus vary more in the first, so PP lets you design living hinges and flexible ribs.

Rockwell hardness is higher for PC (114–126) so it keeps shape under load. PC delivers high impact resistance and consistent stiffness for thin-wall lenses and covers.

Thermal properties

PP shows a true melting point (often >160 °C for isotactic grades) and service limits around 65–125 °C. PC softens rather than melts and holds service at about 115–135 °C.

CTE differences matter: PP can expand 18–185 µm/m‑°C, while PC sits near 50–70 µm/m‑°C. Account for these gaps when mating to metal or glass.

Cost, recyclability and sustainability

Raw resin cost favors PP (~$1.30/kg); PC runs about $2.80/kg but recycled grades narrow that gap. Value money often flips to polycarbonate when fewer failures and optics matter.

Both are recyclable with careful sorting. In practice, PP recycling rates stay low; PC finds success in closed automotive loops. Use this when choosing materials for luggage or widely used consumer parts.

Processing techniques for polypropylene and polycarbonate

How a polymer is molded or extruded changes its strength, clarity, and final cost. Your choices in processing influence part quality, cycle time, and warranty risk.

PP manufacturing: injection molding, extrusion, and films

Injection molding suits fast cycles and high volumes. Good flow and crystallization let you make living hinges, clips, and thin walls quickly.

Extrusion produces pipes, profiles, and sheets with strong abrasion and chemical resistance for sliding parts and cabinets.

Biaxial orientation (BOPP) turns film into clear, tougher sheets that work well in packaging and some luggage trims.

PC manufacturing: molding, extruded sheet, and grades

Molding and extrusion of polycarbonate need tight thermal control and careful gate design to keep optics and reduce stress.

Lower molecular weight grades flow better and cut cycle time for thin parts. Higher molecular weight grades increase toughness for impact covers and safety glazing, but raise cost and processing complexity.

Finishing and coatings

Hard coats such as melamine or silicates protect polycarbonate surfaces from scratches and UV. Antioxidants further extend outdoor life for lens and light covers.

Texturing, painting, and plating affect perceived quality and total cost. For luggage and housings, tool design, venting, and rib layout help minimize sink and hold dimensions across both materials.

Polypropylene vs polycarbonate: key applications

Picking the right resin depends on the job—what it must protect, how it looks, and how often it will be handled.

Automotive and industrial

For air handling, liners, and interior trims you’ll find polypropylene commonly used because of chemical resistance and abrasion performance.

For clear light covers and protective panels, polycarbonate wins thanks to impact strength and clarity.

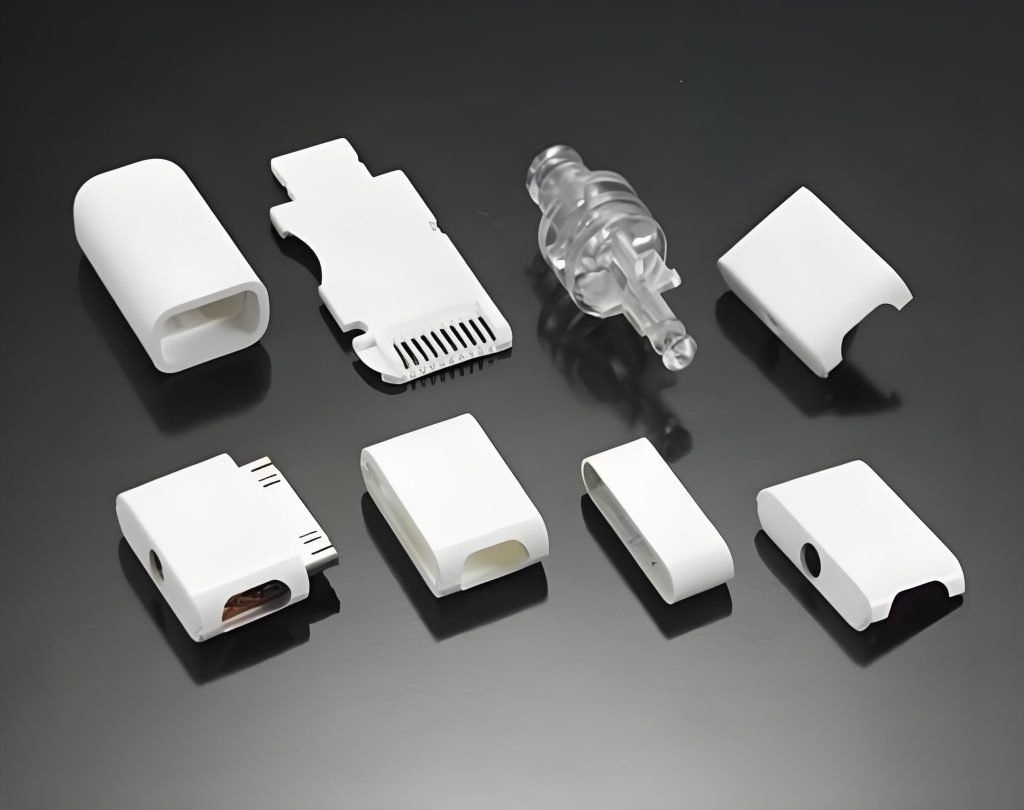

Medical and optics

In medical gear, you’ll see polycarbonate widely used for eyewear, lenses, and light guides where toughness and transparency matter.

Syringe barrels and sterile containers favor polypropylene for low reactivity and ease of sterilization.

Packaging and consumer goods

BOPP films and molded containers use polypropylene for low cost, scuff-hiding texture, and flexibility in household items and furniture.

Luggage and travel

For bags and suitcases aimed at rough handling, polypropylene luggage offers light weight and scuff masking. Rigid shells in polycarbonate give better structural protection for fragile contents.

Choose based on expected strength, finish, and how visible scratches will be in service.

Design trade-offs: weight, durability, and scratch behavior in real-world use

Balancing weight, scratch resistance, and impact protection is a daily challenge in luggage design. You must translate material traits into clear design choices that match how people use your product.

High impact resistance vs. scratch visibility: glossy PC vs. textured PP

You’ll weigh glossy, clear polycarbonate that absorbs high impact against its tendency to show scratches. For high-touch panels and display faces, specify a hard coat or a matte finish to protect appearance.

You’ll also consider textured polypropylene as a cost-effective option. Its softer surface and grain hide scuffs from frequent handling and rough surfaces, keeping bags and luggage looking newer longer.

Weight and flexibility: staying light without sacrificing protection

Use polycarbonate where rigidity reduces deformation under load, but watch weight budgets for airline limits. Choose polypropylene when lightness and flexibility help absorb shocks and allow living hinges or clips to survive repeated use.

Chemical resistance and environmental conditions

Start from the toughest exposure your part will see and work backward to material choice. If your design will face fuels, oils, or cleaning solvents, pick a resin with proven chemical resistance and test it early.

You’ll choose polypropylene when regular contact with aggressive chemistries or oils is likely. It holds up in automotive and industrial conditions and survives common cleaners without rapid breakdown.

By contrast, polycarbonate is vulnerable to many solvents and organic acids unless you add barriers. Use seals, compatible coatings, or design gaps to keep fluids away from exposed edges and fasteners.

Account for UV and heat: coatings and stabilizers reduce yellowing and embrittlement for clear parts. Also plan for thermal swings—thicker walls and appropriate ribbing limit stress cracking and dimensional drift in hot enclosures or cold storage.

Finally, validate with real tests: chemical soak, thermal cycling, and UV exposure. For travel gear and luggage, consider de-icers, fuels, and sun when you pick finish and cleaning protocols to keep parts functional and attractive over time.

Cost and value: balancing budget, performance, and lifespan

A smarter buy balances what you pay today with how long the part stays useful under real-world use. Upfront resin price tells only part of the story; service life, returns, and repair rates complete it.

Typical resin price sits near $1.30/kg for polypropylene and about $2.80/kg for polycarbonate. Recycled PP can cut price by 20–40%, while high‑grade recycled PC can approach ~$1.60/kg when sorting and cleanliness are controlled.

Where to invest for best value

Hard coats and higher molecular weight grades raise process cost, but they reduce returns from scratched or yellowed parts. For clear, impact‑critical pieces choose the premium option; for textured panels and luggage shells, recycled content often makes sense.

Think beyond material cost. Part consolidation, lower scrap, and better handling for rough handling environments can offset higher resin price in premium suitcases and protective gear.

Finally, factor weight and shipping into the business case. A lighter design may raise resin cost per kg but save on freight and use, delivering better value money over the product life. Match your tolerance for cosmetic variation, regulatory needs, and warranty risk to supplier quality to lock in consistent cost and performance.

Choose the right material for your project

Decide with a simple test: will your part need to flex, resist chemicals, or show crystal‑clear optics? Use that result to narrow options and avoid costly redesigns later.

Decision criteria: impact loads, stiffness, clarity, and aesthetics

Start by listing peak impact loads and stiffness targets. Pick polycarbonate for clear, impact‑critical parts and high heat resistance.

Choose polypropylene when flexibility, living hinges, and abrasion or oil resistance matter. Match finish to handling: glossy for display faces, textured for travel bags that hide scuffs.

Environment: exposure to solvents, oils, UV, and heat

Map chemical exposure and UV levels. Use the option that tolerates common cleaners and fuels, or add hard coats and stabilizers for outdoor clarity and UV protection.

Prototyping and testing: validating parts before scaling manufacturing

Run a focused prototype plan: material samples, wall thickness trials, texture and coating checks, and environmental tests (UV, thermal cycling, chemical soak).

Validate DFM points—gates, cooling, ejection, and shrink—then use a simple risk matrix for supply, recycled content, and regulatory limits. This checklist de‑risks production and locks in the best option for travel products and everyday protection.

Conclusion

Make the final pick by matching performance needs to real use conditions.

Polycarbonate delivers high impact resistance, clarity, and good heat performance but benefits from hard coats to fight scratches and UV. Polypropylene gives chemical and oil resistance, abrasion toughness, and flexibility; BOPP films add clarity where needed.

For luggage, suitcases, and bags choose rigid PC shells when structure and protection matter. Pick lighter PP shells when scuff concealment, weight, and cost drive value money in travel gear.

Use a short checklist—peak loads, environment, finish, budget, and testing—to specify materials and finishes with confidence.