Custom Stainless Steel Stamping Services

Fecision delivers precision stainless steel stamping solutions that meet the most demanding specifications across industries. Our advanced manufacturing capabilities, combined with decades of expertise, ensure superior quality components that perform reliably in critical applications.

Durable

Precise

Corrosion-resistant

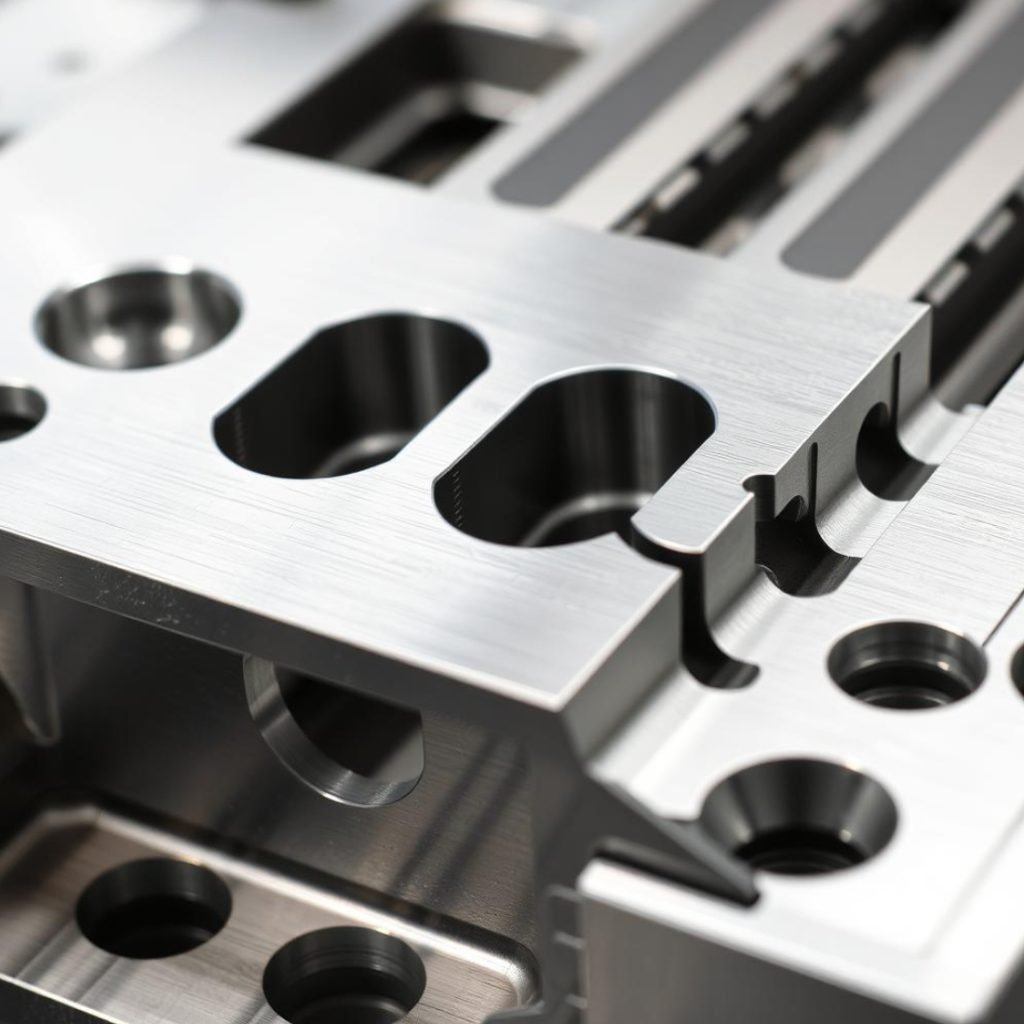

Custom Stainless Steel Stamping Services at Fecision

Fecision specializes in delivering tailored stainless steel stamping solutions that precisely match your engineering specifications. Our state-of-the-art equipment and experienced team ensure consistent quality across high-volume production runs while maintaining tight tolerances.

Our stamping capabilities includes:

- Progressive die stamping for complex components

- Transfer press technology for multi-stage operations

- Blanking and piercing with precision tolerances

- Deep drawing for three-dimensional forms

- Forming, bending, and coining operations

- Prototype to high-volume production capacity

Our engineering team works closely with clients from concept to completion, optimizing designs for manufacturability while maintaining critical specifications. This collaborative approach ensures cost-effective production without compromising quality.

Common Types of Stainless Steel Used in Metal Stamping

Selecting the right stainless steel grade is crucial for ensuring your components perform optimally in their intended environment.

At Fecision, we work with a wide range of stainless steel alloys to match your specific application requirements.

| Stainless Steel Grade | Properties | Common Applications |

| 304 Stainless Steel | Excellent corrosion resistance, good formability, non-magnetic when annealed | Food processing equipment, kitchen components, medical devices |

| 316/316L Stainless Steel | Superior corrosion resistance, especially to chlorides, added molybdenum | Marine environments, pharmaceutical equipment, chemical processing |

| 430 Stainless Steel | Good formability, magnetic, moderate corrosion resistance | Automotive trim, appliance parts, decorative components |

| 301 Stainless Steel | High strength when cold worked, good ductility | Springs, clips, transport equipment, structural components |

| 17-4 PH Stainless Steel | Precipitation hardening, high strength, moderate corrosion resistance | Aerospace components, high-stress applications, valve parts |

Benefits of Stainless Steel for Stamping

Stainless steel offers exceptional performance characteristics that make it ideal for a wide range of stamped components.

Understanding these benefits helps in making informed material selection decisions for your manufacturing projects.

Key Advantages of Stainless Steel

Exceptional Corrosion Resistance

Withstands harsh environments, chemicals, and moisture

Excellent Strength-to-Weight Ratio

Provides durability without excessive weight

Superior Hygiene

Non-porous surface prevents bacterial growth, ideal for medical and food applications

Temperature Resistance

Maintains structural integrity across extreme temperature ranges

Aesthetic Appeal

Attractive finish that can be further enhanced through various treatments

Long-Term Value

Higher initial cost offset by extended service life and reduced maintenance

Advantages of Stainless Steel Stamping

- Cost-effective for high-volume production

- Excellent dimensional consistency across parts

- Minimal material waste compared to other manufacturing methods

- Versatile forming capabilities for complex geometries

- Excellent surface finish quality

Challenges to Consider

- Higher tooling costs for initial setup

- Material hardness can increase tool wear

- Complex designs may require specialized equipment

- Premium grades have higher material costs

- May require secondary operations for certain features

Stamped Stainless Steel Parts for Various Industries

Fecision produces precision stainless steel stampings for diverse industries, each with unique requirements and specifications.

Our versatile manufacturing capabilities allow us to serve multiple sectors with consistent quality and reliability.

Automotive

- Fuel system components

- Sensor housings

- Exhaust system parts

- Structural brackets

- Decorative trim elements

Medical

- Surgical instrument components

- Implantable device parts

- Medical equipment housings

- Laboratory equipment components

- Diagnostic device elements

Aerospace

- Structural components

- Engine part housings

- Brackets and mounting systems

- Interior cabin components

- Fluid system elements

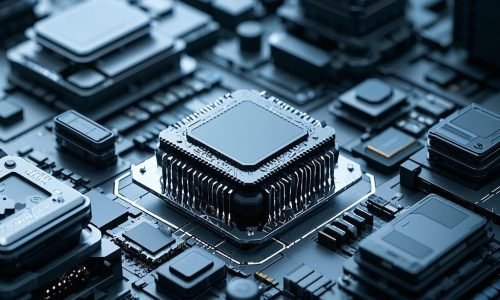

Electronics

- EMI/RFI shielding

- Heat sinks

- Connector components

- Terminal contacts

- Housing elements

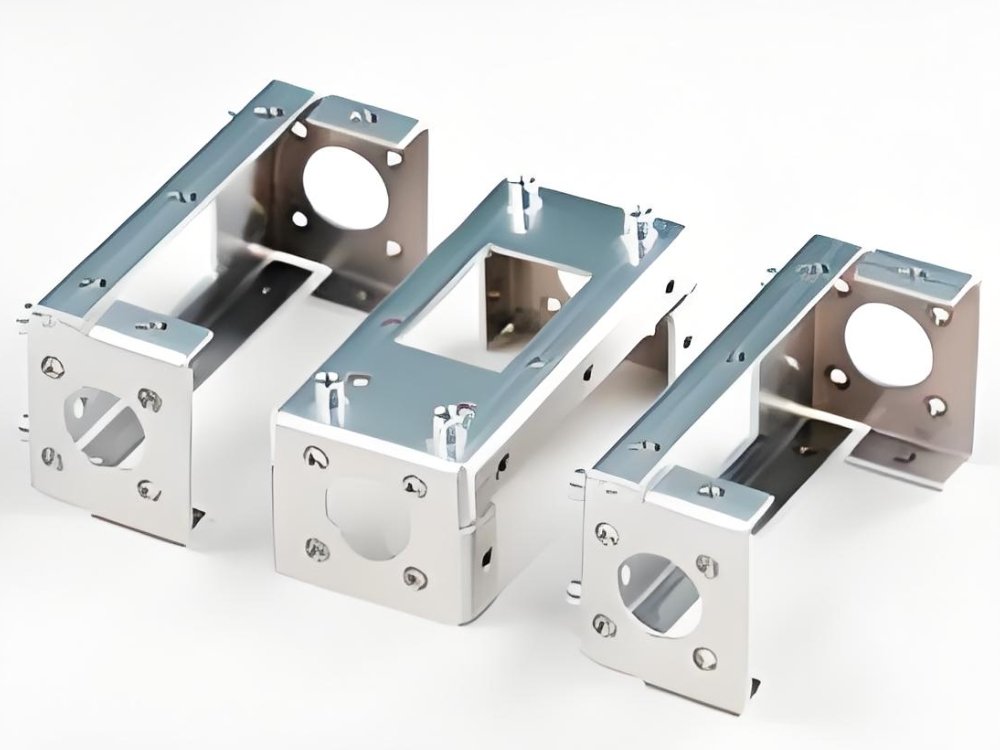

Robotics

- Robot Brackets

- Sensor Mounting Plates

- Motor Housings

- Robot Arm Covers

- Connector Shields

Industrial Equipment

- Pump and valve components

- Filtration system parts

- Heavy equipment elements

- Fastening and mounting systems

- Specialized industrial hardware

Stainless Steel Stamping FAQs

Need to discuss stainless steel stamping project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Quality You Can Trust

At Fecision, quality control is integrated throughout our stainless steel stamping process.

Our commitment to excellence ensures that every component meets or exceeds industry standards and customer specifications.

Certifications

- ISO 9001:2015 Certified

- IATF 16949 Automotive Compliance

- AS9100D Aerospace Standards

Testing Capabilities

- 3D Coordinate Measuring Machines

- Mechanical Property Testing

- Surface Finish Verification

Quality Guarantees

- 100% Inspection Options

- Statistical Process Control

- Documented Quality Procedures

Ready to Discuss Your Stainless Steel Stamping Project?

Our engineering team is available to review your specifications and provide expert recommendations for your custom aluminum stamping needs.