A properly chosen rake angle can significantly enhance the efficiency of your CNC machining operations. The rake angle, which is the angle between the cutting tool bit and the cutting chips, plays a crucial role in determining the cutting resistance, chip emission, cutting heat, and service life of the tool.

Definition of Machining Rake Angle

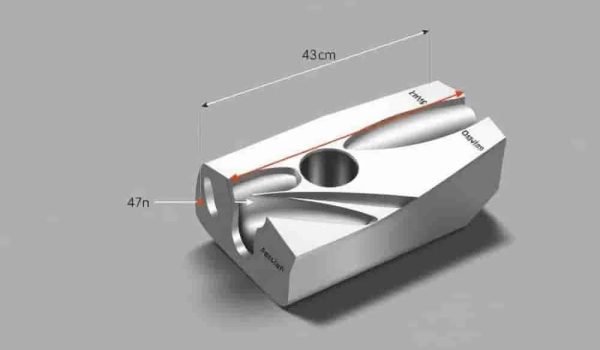

The rake angle, a fundamental aspect of cutting tool geometry, directly impacts the machining process. It’s a critical geometric parameter that influences how a cutting tool interacts with the workpiece during machining. Rake angle is measured as the angle between the tool’s rake face, where chips flow, and a perpendicular line to the workpiece surface. It is closely related to other tool geometry elements, such as the relief angle and cutting edge preparation.

The Importance of Rake Angle in CNC Machining

The importance of rake angle in CNC machining cannot be overstated, as it directly impacts cutting forces, tool life, and surface finish. By optimizing the rake angle, you can significantly improve overall machining efficiency by optimizing cutting parameters and reducing cycle times.

Impact on Cutting Forces and Tool Life

The rake angle significantly affects the cutting forces experienced during machining operations. A properly selected rake angle reduces resistance and power requirements, making the cutting process more efficient. Additionally, the rake angle influences tool life by controlling stress distribution, heat generation, and wear patterns on the cutting edge. A suitable rake angle minimizes tool wear, thereby extending tool life.

Effects on Surface Finish and Part Quality

The rake angle also has a direct relationship with surface finish quality. The right rake angle promotes clean cutting rather than material tearing or deformation, resulting in a better surface finish. Furthermore, a well-chosen rake angle influences chip control and evacuation, which are critical factors in preventing chip recutting and maintaining consistent machining performance. This, in turn, affects the overall quality of the finished part.

Types of Rake Angles for Different Applications

Rake angle types play a significant role in the success of your machining projects, affecting both tool life and surface finish. The choice of rake angle depends on the material being machined, the desired surface finish, and the specific machining operation. Understanding the different types of rake angles and their characteristics is crucial for optimizing your CNC machining processes.

Positive Rake Angle: Characteristics and Uses

A positive rake angle is characterized by the tool face leaning forward toward the cut. This geometry results in lower cutting forces, a smoother surface finish, and reduced heat generation. However, it also leads to a weaker cutting edge that is more prone to chipping. Positive rake angles are ideal for machining soft, ductile materials such as aluminum, brass, plastics, and soft steels.

Negative Rake Angle: Characteristics and Uses

In contrast, a negative rake angle features the tool face leaning away from the cut, creating a stronger cutting edge. This design can handle hard materials and interrupted cuts, making it durable at high speeds and temperatures. However, it generates higher cutting forces and more heat. Negative rake angles are best suited for machining titanium, hardened steels, nickel alloys, and other hard materials where tool strength is a priority.

Zero Rake Angle: Characteristics and Uses

A zero rake angle represents a neutral cutting edge, with neither a forward nor backward lean. This geometry offers a balance between the advantages of positive and negative rake angles, providing moderate toughness and balanced performance. Zero rake angles are suitable for general turning operations where a compromise between tool strength and surface finish is required.

Compound Rake Angles

Compound rake angles combine different angular orientations to optimize performance for specific cutting directions and operations. This complex geometry allows for tailored tool designs that can improve machining efficiency and tool life in certain applications. By understanding and utilizing compound rake angles, machinists can further refine their processes to achieve better outcomes.

Material-Specific Rake Angle Recommendations

To maximize efficiency and precision in CNC machining, it’s essential to understand material-specific rake angle recommendations. The optimal rake angle varies significantly depending on the material being machined, as different materials have unique properties that affect the cutting process.

Soft Materials: Aluminum, Brass, and Plastics

For soft, ductile materials like aluminum, brass, and plastics, a positive rake angle is typically recommended. Angles between 5-15 degrees work well, as they reduce cutting forces and promote smooth chip evacuation. This helps prevent work hardening and ensures a better surface finish. A gentle cutting-edge radius and a slightly larger clearance angle also contribute to improved machining performance.

Medium-Hardness Materials: Mild Steel and Stainless Steel

When machining medium-hardness materials such as mild steel and stainless steel, the optimal rake angle often falls between slightly positive and neutral. The exact angle depends on the specific alloy properties and the desired balance between cutting forces and tool life. For instance, a slightly positive rake angle can help reduce cutting forces, while a neutral angle may provide a better balance between tool life and surface finish.

Hard Materials: Hardened Steel and Cast Iron

For hard, brittle materials like hardened steel and cast iron, a negative rake angle is generally preferred. Angles ranging from -5 to -15 degrees increase edge strength and wear resistance, which are critical for successful machining of these challenging materials. A more substantial cutting-edge radius and a smaller clearance angle also enhance cutting stability and tool longevity.

Exotic Materials: Titanium and Nickel Alloys

Exotic materials such as titanium and nickel-based superalloys require specialized rake angle considerations. These materials are known for their high strength, low thermal conductivity, and tendency to work harden. Unique combinations of rake angles and cutting edge preparations are often necessary to achieve optimal results. For example, a specific positive rake angle combined with a customized cutting edge radius can help manage the challenges associated with machining these materials.

Advanced Machining Techniques and Rake Angle Considerations

As you explore advanced machining techniques, understanding how rake angle considerations impact your CNC operations becomes crucial. The rake angle significantly influences the cutting process, affecting tool life, surface finish, and overall machining efficiency.

High-Speed Machining and Rake Angle

In high-speed machining, the optimal rake angle can shift due to increased cutting speeds. A positive rake angle is often preferred for high-speed operations as it reduces cutting forces and temperatures, thereby enhancing tool life. However, the exact rake angle depends on the material being machined and the specific cutting conditions.

Interrupted Cutting Operations

For interrupted cutting operations like milling keyways or turning parts with holes, edge strength is critical. A negative rake angle may be used in these situations to provide a stronger cutting edge, capable of withstanding the intermittent cutting forces without chipping or breaking.

Chip Control and Evacuation

The rake angle plays a crucial role in chip formation and evacuation. A positive rake angle tends to produce thinner, more curled chips, which are easier to evacuate, improving safety and reducing the risk of chip re-cutting. In contrast, a negative rake angle results in thicker, more segmented chips. Understanding how different rake angles affect chip control is essential for optimizing machining operations.

By adjusting the rake angle, you can significantly influence the cutting process, from reducing cutting forces and temperatures to improving chip evacuation and surface finish. The interaction between rake angle and other cutting parameters like feed rate, depth of cut, and cutting speed must be carefully considered to achieve optimal machining performance.

Practical Guide to Selecting the Right Rake Angle

Optimizing your CNC machining process begins with selecting the right rake angle for your specific application. The rake angle significantly influences the cutting process, affecting factors such as tool life, surface finish, and material removal rates.

Assessing Your Machining Requirements

To choose the optimal rake angle, you must first assess your specific machining requirements. Consider factors such as material properties, desired surface finish, production volume, and machine capabilities. Understanding these elements will help you narrow down your rake angle options.

Tool Selection Criteria

When selecting a tool, consider the criteria that will impact your rake angle choice. This includes the type of material being machined, the desired surface finish, and the tool’s edge strength. For instance, a positive rake angle is often used for soft materials, while a negative rake angle is preferred for harder materials.

Testing and Optimization Strategies

To optimize your rake angle, you should conduct controlled tests and measure the results effectively. Start by selecting a range of rake angles suitable for your material and application. Then, monitor factors such as tool wear, surface finish, and cutting forces. Analyze the data to determine the optimal rake angle that balances your machining objectives.

Conclusion: Optimizing Your CNC Performance Through Proper Rake Angle Selection

Rake angle selection is a fundamental factor in determining the efficiency and quality of your CNC machining operations. Proper rake angle selection directly impacts key performance metrics, including tool life, surface finish quality, and machining efficiency.

By understanding the material-specific rake angle recommendations and applying them to your workpiece properties, you can significantly enhance your CNC machining performance.