Unlike traditional manufacturing methods that rely on mass production, low volume manufacturing allows for the creation of parts in smaller batches, typically ranging from a few dozen to several thousand units.

This method offers numerous benefits, including flexibility in production planning, reduced need for expensive tooling, and faster time-to-market for new products. As a result, companies can respond more quickly to changing market demands and customer needs, making it an attractive option for businesses looking to stay competitive in today’s fast-paced market landscape.

Understanding Low Volume Manufacturing

As you explore manufacturing options, understanding low volume production is crucial for determining the best strategy for your product’s initial production phases. Low volume manufacturing refers to the production of parts in quantities that typically range from ten to tens of thousands.

What is Low Volume Manufacturing?

Low volume manufacturing is a production approach that caters to the needs of businesses requiring smaller batches of products. Unlike high-volume production, which focuses on mass-producing identical goods, low volume manufacturing offers greater flexibility and customization options.

This approach is particularly beneficial for companies that need to test the market with a new product or require specialized parts. Modern manufacturing processes have evolved to make low volume production more accessible and cost-effective.

Production Scale: From Prototypes to Small Batches

The production scale in low volume manufacturing can vary significantly, from one-off prototypes to small batch production. This flexibility allows businesses to refine their products and adjust production according to market demands.

Low volume manufacturing serves as a critical phase in the product development lifecycle, enabling companies to bridge the gap between prototyping and full-scale production. By understanding the production scale spectrum, you can better determine where your specific manufacturing needs fall within this range.

When to Choose Low Volume Manufacturing

In certain business contexts, opting for low volume manufacturing can be more beneficial than other production methods. This approach is particularly valuable during the early stages of product development or when dealing with specialized products.

Market Testing and Validation

Low volume manufacturing allows businesses to test the market’s response to a new product without significant financial risk. By producing small batches, companies can gauge consumer interest and gather feedback before deciding to scale up production. This approach helps in validating the product in the market, reducing the risk of launching a product that may not be well received.

Bridging Prototyping and Mass Production

Low volume manufacturing serves as an effective bridge between prototyping and mass production. It enables businesses to refine their manufacturing processes, identify potential issues, and make necessary adjustments before committing to large-scale production. This step is crucial in ensuring that the final product meets quality standards and is free from defects.

Custom and Specialized Products

For businesses dealing with custom or specialized products, low volume manufacturing is often the most feasible option. These products typically have unique specifications or require specific materials, making mass production economically unviable. Low volume manufacturing provides the flexibility to produce such products in small quantities, catering to niche markets or specific customer requirements.

Supply Chain Flexibility

Low volume manufacturing also offers supply chain flexibility, allowing businesses to adapt quickly to changes in market demand. By maintaining a low production volume, companies can reduce their dependency on external suppliers and adjust their production schedules as needed. This flexibility is particularly valuable in today’s fast-paced business environment, where market conditions can change rapidly.

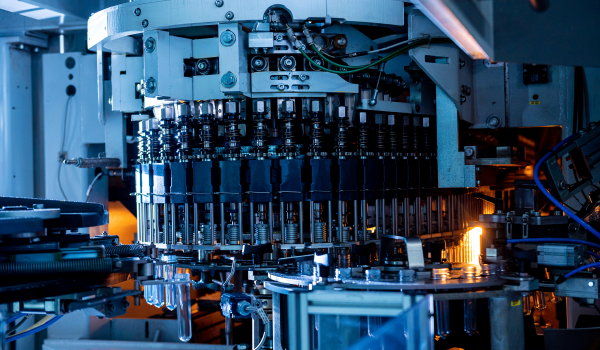

Technologies and Methods for Low Volume Manufacturing

To meet the demands of low volume production, manufacturers employ various advanced technologies. These technologies enable the efficient production of smaller batches without compromising on quality or significantly increasing costs.

3D Printing and Additive Manufacturing

3D printing and additive manufacturing have revolutionized low volume production by eliminating the need for tooling. This technology allows for the rapid production of complex parts and products, making it ideal for prototyping and small batch production.

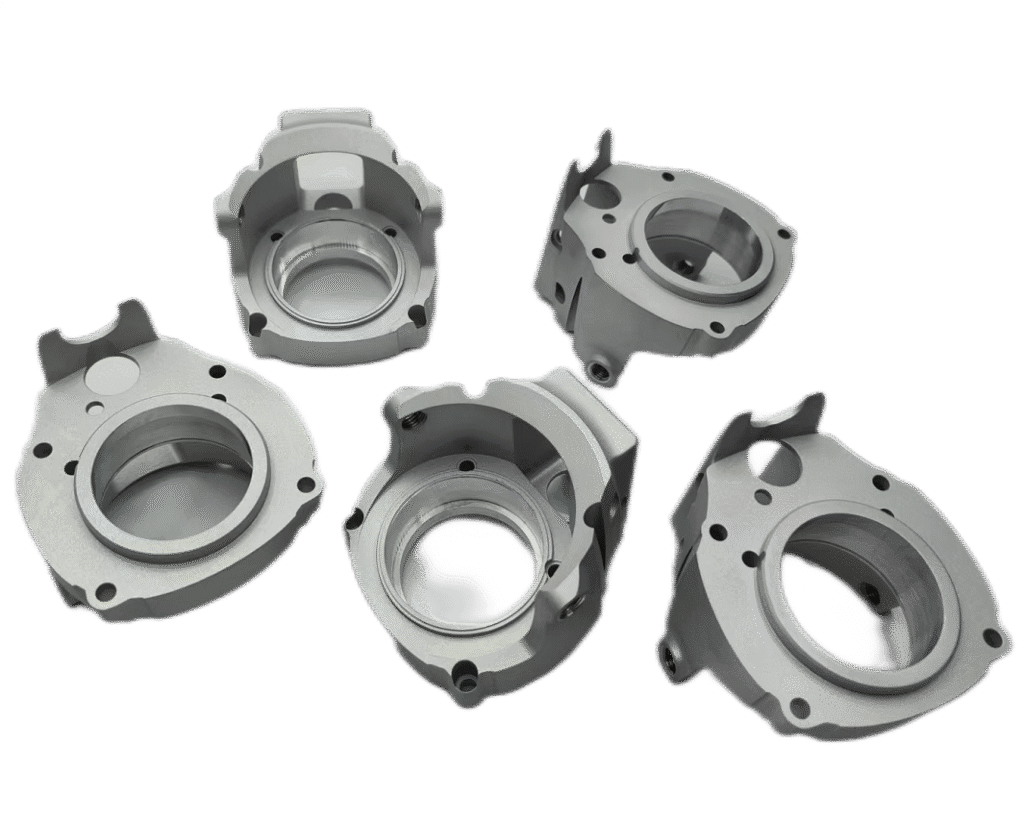

CNC Machining

CNC machining is another critical technology for low volume manufacturing, offering precision and versatility. It involves the use of computer-controlled machines to remove material from a workpiece, allowing for the production of complex components with high accuracy.

Rapid Tooling and Injection Molding

Rapid tooling has transformed injection molding for low volume production, making it more cost-effective. This approach enables the quick fabrication of tooling, reducing the time and cost associated with traditional injection molding processes.

Sheet Metal Fabrication

Sheet metal fabrication techniques have been adapted for low volume production, providing efficient solutions for structural components and enclosures. These techniques include cutting, bending, and assembling sheet metal to create the desired parts.

Each of these technologies has its advantages and is suited to different types of production needs. By understanding the capabilities and limitations of 3D printing, CNC machining, rapid tooling, and sheet metal fabrication, you can choose the most appropriate method for your low volume manufacturing requirements.

Key Benefits of Low Volume Manufacturing

Low volume manufacturing offers numerous benefits that can transform your production process. By leveraging this approach, you can significantly enhance your production efficiency, reduce costs, and improve product quality.

Cost Efficiency and Reduced Initial Investment

One of the primary advantages of low volume manufacturing is its cost efficiency. By eliminating or minimizing expensive tooling costs associated with mass production, you can reduce your initial investment requirements. This makes it more feasible to launch new products or test markets without incurring substantial upfront costs.

You can allocate resources more effectively, focusing on product development and market validation rather than expensive tooling. This flexibility enables businesses to be more agile and responsive to market demands.

Design Flexibility and Customization

Low volume manufacturing provides substantial design flexibility advantages. With the ability to implement design changes quickly and respond to customer feedback without prohibitive costs, you can iterate products rapidly. This flexibility is particularly valuable in today’s fast-paced markets, where adaptability is key to staying competitive.

Moreover, low volume manufacturing enables cost-effective customization options that would be financially unfeasible in mass production scenarios. This allows businesses to offer tailored products to their customers, enhancing customer satisfaction and loyalty.

Faster Time-to-Market

Low volume manufacturing dramatically accelerates time-to-market compared to traditional production methods. By compressing development timelines and reducing lead times for production, you can beat your competitors to the market. This speed is crucial in rapidly evolving markets, where being first to market can provide a significant competitive edge.

Quality Control and Consistency

With smaller production runs, quality control becomes more manageable. You can conduct more thorough inspections and testing of each unit, ensuring higher quality and consistency. This attention to detail is particularly important for products that require high precision or have critical applications.

By maintaining stringent quality control measures, you can enhance your brand reputation and build trust with your customers.

Challenges and Considerations in Low Volume Production

The path to efficient low volume manufacturing is fraught with challenges that need to be addressed proactively. As you navigate this production landscape, you’ll encounter several key considerations that can impact your success.

Balancing Cost Per Unit

One of the primary challenges in low volume manufacturing is balancing the cost per unit. With smaller production runs, the economies of scale that typically reduce costs in high volume manufacturing are not available. To mitigate this, you can optimize your production process and consider selective automation to manage labor costs effectively.

Material Selection and Availability

Finding the right materials in the required quantities can be a significant challenge, especially for custom or unique projects. You’ll need to develop strategies for sourcing specialized materials, understanding minimum order quantities, and managing lead times to ensure your production stays on schedule.

Quality Assurance Processes

Maintaining consistent quality is crucial, even in low volume production. Implementing quality assurance processes that are tailored to smaller production runs is essential. This might involve more rigorous inspection protocols and process controls to ensure that every unit meets your quality standards.

Scaling Production When Needed

As demand for your product grows, you’ll need to scale your production accordingly. Planning for this eventuality from the outset is vital. This includes developing flexible manufacturing processes and establishing relationships with suppliers who can adapt to changing demand.

High Volume vs. Low Volume Manufacturing

As you navigate the complexities of production, distinguishing between high volume and low volume manufacturing becomes essential. The contrast between these two approaches is stark, primarily revolving around the scale of production and the flexibility each offers.

Production Scale Differences

High volume manufacturing is characterized by large production runs, often resulting in thousands or millions of units. In contrast, low volume manufacturing involves producing tens or thousands of units. This difference in scale significantly impacts the manufacturing process, with high volume production benefiting from economies of scale but lacking flexibility.

Cost Structure Comparison

The cost structures of high volume and low volume manufacturing differ substantially. High volume manufacturing typically requires high initial tooling investments but results in lower per-unit costs. Conversely, low volume manufacturing has lower upfront costs but higher per-unit expenses. Understanding these cost dynamics is crucial for businesses to choose the most cost-effective approach.

When to Transition from Low to High Volume

Transitioning from low to high volume manufacturing depends on several factors, including demand patterns, market stability, and financial considerations. Businesses should consider scaling up production when they experience consistent high demand and have the financial resources to invest in necessary tooling and infrastructure.

Rapid Prototyping vs. Low Volume Manufacturing

The distinction between rapid prototyping and low volume manufacturing is often misunderstood, yet it’s vital for successful product development. While both are crucial in the product development cycle, they serve different purposes and involve different processes.

Purpose and Intent

Rapid prototyping focuses on quickly creating a scale model or prototype of a part or assembly to validate design and facilitate iteration. This approach allows for swift testing and refinement before moving to full-scale production. On the other hand, low volume manufacturing is aimed at producing a small batch of functional end-use parts. It’s about creating a limited quantity of products that meet specific requirements and are often used for market testing or as a bridge between prototyping and mass production.

Process and Material Differences

The processes involved in rapid prototyping prioritize speed and flexibility, often utilizing technologies like 3D printing and CNC machining. Materials used in prototyping may simulate the properties of the final product but are not necessarily the same. In contrast, low volume manufacturing emphasizes consistency and durability, typically using the actual materials intended for the final product. Understanding these differences is key to leveraging both approaches effectively in your product development strategy.

By recognizing the unique roles of rapid prototyping and low volume manufacturing, you can streamline your production process, ensuring that you’re using the right approach at the right time.

Industries Leveraging Low Volume Manufacturing

Diverse sectors are leveraging low volume manufacturing to meet their unique production needs. This approach allows companies to produce high-quality products in smaller quantities, making it an ideal solution for industries with specialized requirements.

Aerospace and Defense

The aerospace and defense industry relies on low volume manufacturing for producing specialized parts, such as airframe components and intricate engine parts. The focus is on using high-quality materials and precision manufacturing techniques to meet exacting specifications. Advanced materials that would be costly in mass production are used here, making low volume manufacturing a cost-effective solution.

Medical Devices and Healthcare

In the medical device industry, low volume manufacturing is critical for creating customized equipment, specialized surgical instruments, and limited-run medical devices. Precision and regulatory compliance are paramount in this sector. Low volume manufacturing enables the production of highly specialized products that meet stringent medical standards.

Automotive and Transportation

The automotive industry utilizes low volume manufacturing for producing custom parts, prototypes, and components for luxury or specialized vehicles. It’s also used for limited edition models that wouldn’t justify the cost of mass production tooling. This approach allows automotive manufacturers to offer unique products and test new designs without significant upfront costs.

Consumer Electronics

Consumer electronics companies employ low volume manufacturing for product testing, market validation, and producing high-end or niche electronic devices with specialized features. This approach enables them to gauge market response and refine their products before scaling up production, reducing the risk of large-scale manufacturing investments.

Industrial Equipment and Machinery

Industrial equipment and machinery manufacturers benefit from low volume production for specialized machinery, replacement parts for legacy equipment, and custom industrial solutions. This flexibility is crucial for maintaining and upgrading existing equipment without requiring large production runs.

Partner with Fecision for Your Low Volume Production Needs

With a comprehensive range of services, Fecision supports your product development cycle from initial design consultation through production and quality assurance.

Fecision‘s state-of-the-art manufacturing facilities are equipped with the latest technologies in CNC machining, and rapid tooling. This enables us to handle diverse production requirements efficiently. Our experienced team of manufacturing specialists works closely with clients to optimize designs for low volume production, ensuring cost-effectiveness.

By partnering with Fecision, you can streamline your product development cycle, reduce time-to-market, and gain the flexibility needed to respond quickly to changing market demands. Our commitment to quality and customer satisfaction is evident throughout their simple and efficient process, from initial consultation to final product delivery.

Whether you’re producing a few parts occasionally or require large parts made from non-standard materials, Fecision’s low volume manufacturing services are designed to meet your needs. Our expertise allows companies to bring production in-house or outsource to service bureaus or labs as needed.