When developing a project that will include the making of plastic parts, it’s very important to understand injection molding costs. You will have the ability to budget, plan the project and avoid unpleasant surprises associated with costs. If you do not understand the costs associated with injection molding, it is very likely you will encounter unexpected costs that negatively affect your project planning, calendar timelines, and budget.

In this guide, you will have an overview of the exact numbers, along with hidden costs and tactics to keep your custom injection molding cost low. Factors such as the complexity of your part design, the materials you use, and the quantity of parts you need are all important. This is not a flat fee, and every project has its own unique structure of costs.

Introduction: How Much Does Injection Molding Cost?

You may be asking yourself what the average plastic injection molding cost is. You may see prices as low as USD 100 for a basic 3D printed prototype mold or as high as USD 100,000 for a strong steel mold with multi-cavities. There’s a wide range of price variability based on the nature of the part and the volume of production.

For example, if you are looking for low-volume prototyping, the prices will be much lower in general than mass production. Prototyping is typically simpler molds and not high quantities, thus the upfront investment is smaller. Mass production includes more robust and typically multi-cavity molds with more setup involved, which will be much higher in cost.

The main point to consider is: the more parts you make, the lower the per-unit cost. That is because the more parts you have, the more you get to spread out your upfront costs. The total cost of a large production run will be higher, but your individual part cost will decrease.

Types of Costs in Injection Molding

When trying to figure out the complete cost of injection molding, it can be helpful to categorize the many types of charges or costs that you could experience. We will take a look at the major types of expenses.

Equipment Costs

Injection molding machines are amazing pieces of equipment, but typically, you won’t need to purchase them yourself if you are outsourcing your production. However, a desktop machine for a production run of less than 1,000 parts could range from USD 1,000 to USD 10,000, while the industrial presses that most suppliers use for larger production runs can cost between USD 50,000 and USD 200,000.

Since you will work with a supplier, the costs of the equipment have already been rolled into the service fee. This means that you will not have to worry about making the large, upfront investment to purchase your own machines. Instead, what you are paying for is access to that company’s amazing machines, tooling, and expertise.

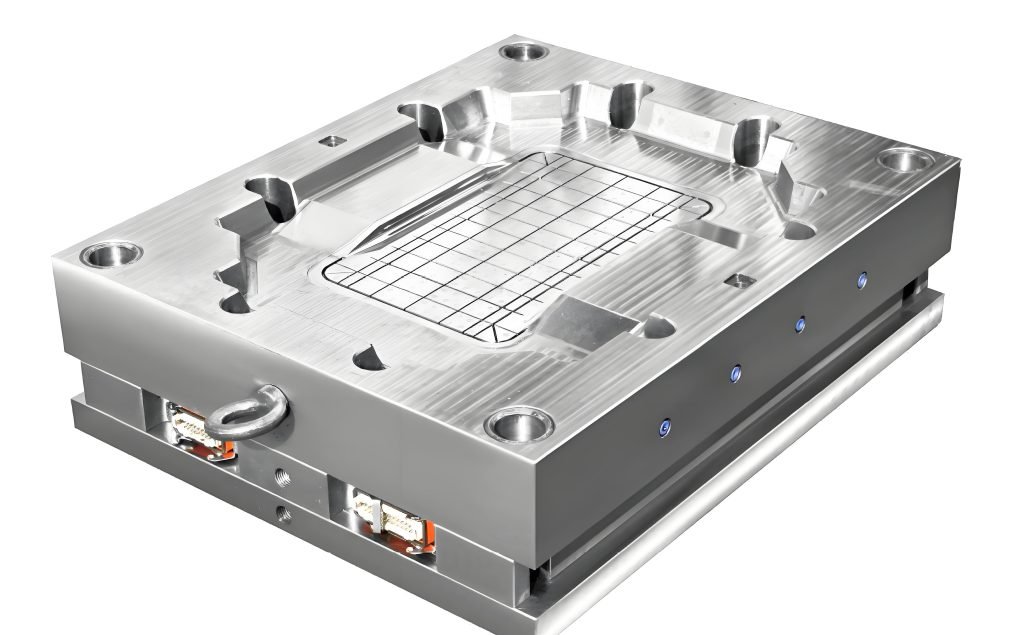

Mold Costs (Tooling Costs)

The mold (or “tool”) is typically the biggest upfront expense in injection molding. The price of the mold will be based on the material and complexity of the tool. For extremely low volume or prototypes, a 3D printed mold (most commonly from SLA resin) can cost anywhere from USD 100 to 1,000. These are ideal for testing designs using rapid prototyping without investing too much time or money.

For medium runs (1,000-5,000) parts, a CNC aluminum mold is a good option that will cost about $2,000-$5,000. The aluminum mold is easier to process and is cheaper. For 100,000 or more parts, you will need a robust hardened steel mold that could range anywhere from $10,000 to $100,000 and can be rated for high volume durability. Complex shapes, undercuts, or high-polish will all increase the overall injection mold cost.

Injected Material Cost

The plastic material is a key part of your total cost, usually measured per pound. Common plastics like Polypropylene (PP) might be around $0.90 per lb, while ABS could be $1.30 per lb. For specialized uses, Polycarbonate (PC) might cost $2.30 per lb.

Remember to include the cost of any additives, which can raise the material price by 5–50% for things like UV protection or added strength. You’ll pay for the weight of your finished part plus a small amount of waste, typically 3–5%, from the molding process. This waste is often reused, but it’s still part of your material expense.

Labor or Service Costs

You’ll also pay for services that the molding process requires, on top of the mold and material. Typically, there is a setup charge for each run of production, somewhere in the range of USD 200 to 500. The setup charge includes labor to set up the machine, load the dry resin, mount the mold, and tune the process.

In addition, the mold will require that the machine run; you will be charged an hourly rate, which is determined by the size of the press and how the process is designed. For estimation purposes, it is assumed the hourly rate will range from $30 to $120 an hour. If your part needs secondary operations, whether trimming, pad printing, assembly, or any special packaging requirements, secondary operations will usually increase the cost between $0.05 and $1.00 per part. Recognize that they can build up at any volume and account for your final costs.

Injection Molding Cost Overview

This summary outlines the injection molding tooling cost for different production volumes to allow you to budget for prototype or mass production.

| Cost Factor | Low-Volume (100-1,000 parts) | Medium-Volume (1,000-50,000 parts) | High-Volume (50,000+ parts) |

| Mold Type | 3D-printed polymer / Soft aluminum | Machined aluminum | Hardened steel |

| Equipment | Desktop machines / Outsourced | Industrial presses | High-tonnage machines |

| Mold Cost | $100–$2,000 | $2,000–$10,000 | $10,000–$100,000+ |

| Material Cost | $0.5–$5/part varies by resin | $0.3–$3/partbulk discounts | $0.1–$2/part economies of scale |

| Labor/Service Cost | $2–$10/part manual setup | $1–$5/partsemi-automated | $0.5–$2/part fully automated |

| Total Cost | $500–$20,000 | $10,000–$200,000 | $100,000–$1M+ |

| Cost Per Part | $4–$20 | $1–$10 | $0.5–$5 |

Variables That Impact the Injection Molding Cost

There are many factors that can impact the final price of your injection molded parts, and being aware of them will help you make good choices in the design and production stages.

Part Size

The size of your part directly affects the cost. Larger parts naturally require more raw material, which increases material expenses. Also, larger parts will require larger injection molding machines and more complex molds.

Bigger molds use more material to make the tool itself. Bigger molds take longer and might require special equipment, so now you are adding compounding factors that increase the overall cost of creating bigger parts. Always consider if you can reduce the size of your part and retain its functionality.

Part Design

The complexity of your part’s design is a huge cost driver. Parts requiring complex geometry, such as undercuts, thin walls, or very tight tolerances, will also cause a significant increase in the injection molding mold cost. These features on molded parts will require complex mold designs, often including movable parts such as slides and lifters, increasing tooling costs.

Additionally, highly complex designs will often include longer cycle times during production and may require more careful monitoring for consistent quality control. Creating a simpler design can save you significant costs in tooling and production.

Production Volume

Your production volume is essential for determining mold type and cost. For lower volumes (for prototypes or limited runs), using 3D-printed or aluminum molds justifies the cost, since there is no upfront investment, although the total per-part cost is higher.

For high volumes (like over 10,000 parts), hardened steel molds give you the cheapest cost over time and are the best option. Although the cost of a hardened steel mold is high, the per-part cost, over the steel mold’s estimated million-part life, is practically zero. This is where your initial investment truly pays off.

Part Volume and Cavities

The number of mold cavities directly impacts how many parts you get per cycle. A single-cavity mold is simpler and cheaper, producing one part per cycle, good for very low volumes or large parts.

However, a multi-cavity mold, though more expensive upfront, can cut per-part cycle costs by 50–80%. You produce more parts in the same time. If you need more than 10,000 parts, generally, multiple cavity molds as an initial investment are usually worth it because you are going to save a lot of money on a per-part basis.

Saving Money on Injection Molding

Saving on injection molding parts is not about the least expensive supplier; it can be as much about planning and design. Here are some great ways.

Design for Manufacturing (DFM)

First, focus on Design for Manufacturing (DFM). This means considering how your part will be molded during the design phase. For example, uniform wall thickness helps plastic cool evenly, reducing defects and cooling time. Eliminate unnecessary undercuts to avoid complex, costly mold slides. Simple design often leads to simpler, cheaper molding.

Pick the Right Material

Second, be smart about picking the right material. A less expensive plastic may work just as well. For example, iff clarity is not as critical, there is the option of using polypropylene (PP), which saves you almost 60% of resin costs over polycarbonate (PC). Use materials that satisfy functional requirements and meet your budget.

Combine Parts & Reuse Runners

Third, explore combining parts. Designing snap-fits or living hinges into your plastic part can eliminate separate metal hardware like screws, saving significant assembly costs. Fourth, ask your supplier about reusing runners. Many facilities re-grind plastic from the runner system, feeding it back into the machine. This can cut material waste by 5–10%, saving you money.

Plan Ahead & Bundle Services

Finally, think ahead. Buying spare mold components upfront is wise; if a critical part breaks, a spare prevents costly downtime. Also, try to order both molding and secondary operations from one supplier. Companies like Fecision often provide bundled quotes that save you shipping and setup fees because everything is done under one roof.

Injection Molding Lifter vs Slider

When your part design includes undercuts, special mold mechanisms are needed to release the part. The two main types are sliders and lifters. Understanding their differences helps you predict mold costs accurately.

A slider moves sideways within the mold to create and release external undercuts, like side holes or threaded features. These mechanisms are more complicated, usually adding roughly USD 500 – 2,000 to the mold price. They will require close tolerances and robust configuration to provide reliable operation for many cycles.

In contrast, a lifter moves upward at an angle when the mold opens. Lifters commonly release internal undercuts, such as snap hooks inside a part. Usually simpler than slides, they add around USD 300–1,500 to the mold cost. Both increase tooling expense. A crucial tip: discuss your design with an engineer early; a simple tweak might eliminate the need for either, saving you money.

| Feature | Lifters | Sliders |

| Mechanism | Internal (moves with mold core) | External (side-action movement) |

| Best For | Small/internal undercuts (e.g., clips, hooks) | Large/side undercuts (e.g., threads, complex side features) |

| Complexity | Simpler design | More complex mechanism |

| Tooling Cost | Lower (integrated into mold) | Higher (additional components) |

| Maintenance | Easier/cheaper | More frequent/labor-intensive |

| Part Suitability | Small-to-medium parts | Complex/large parts |

| Lead Time | Shorter (fewer components) | Longer (requires precise alignment) |

Get Started With Rapid Injection Molding at Fecision

Are you ready to have your plastic part made in a short amount of time, and at a low price point? At Fecision, we provide primarily low-cost, high-quality injection molding solutions, so your product launch can proceed in a timely manner to market. Our injection molding knowledge and experience will provide value every step of the way.

Our Services Include:

- Prototyping to Mass Production: From a few test parts to hundreds of thousands, we scale to your exact production needs.

- Competitive Injection Molding Costs: We optimize for efficiency and smart tooling, offering excellent value and keeping your costs low without sacrificing quality.

- Fast Turnaround with Durable Molds: Our rapid tooling ensures quick part delivery with molds built to last for your production volumes.

Ready to see how Fecision can help you? Contact Fecision for a personalized quote today, and let’s get your project started.