In injection molding, over molding is a high-level molding process that allows two or more materials to be moulded together in a single part. This would allow producers to make multi-material parts with additional functionality, like better grip, sealing, or cosmetic requirements. Overmolding involves the molding of one material over or around a previously moulded item or substrate to mould the two together into a single item. It is commonly applied in such industries as automotive and electronics production, medical devices and consumer goods. It is critical that for the best product performance and low production costs, this over-molding technique is understood.

This article describes how to over mold, design considerations, applications, and the challenges involved in the production of multi-material, injection-moulded products.

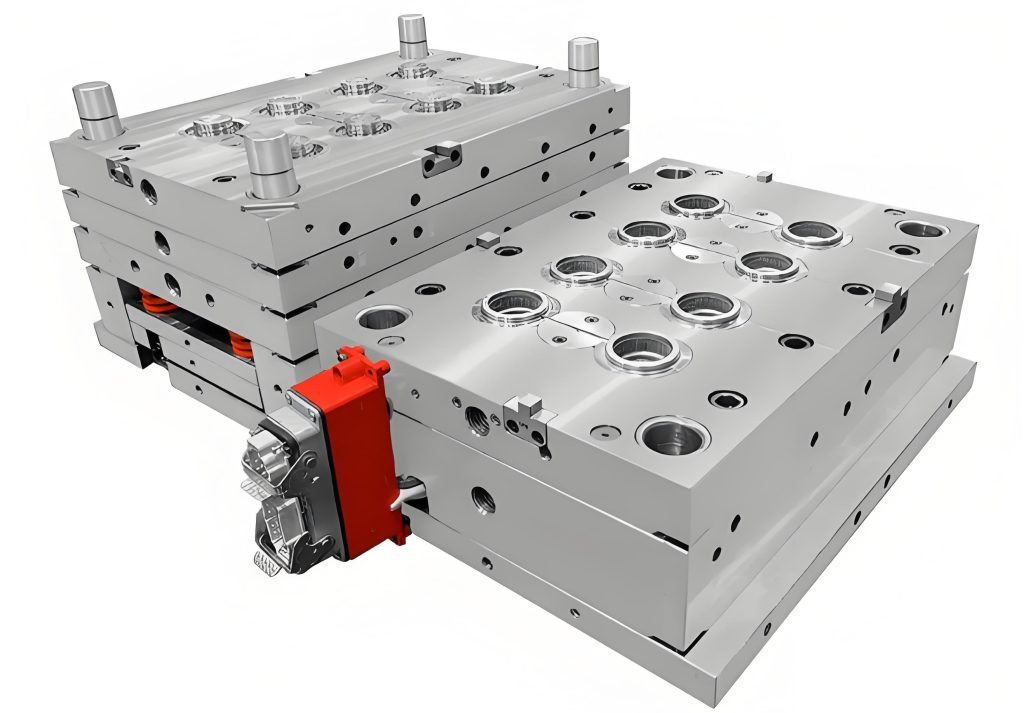

The Overmolding Process

Overmolding is a unique injection molding process in which a first material is injected over or around a pre-molded piece, the substrate. With this synergy, manufacturers can combine a variety of materials or colours into a single finished product, adding value to both form and function.

The overmolding procedure begins with the manufacture of the base, or substrate, which is generally formed from a rigid plastic material. When the mold cools, the substrate is inserted into a submold cavity that is configured to receive the second material. The second material, which is typically less rigid or more flexible, is subsequently injected over or around the first material and is bonded to the first material as the combined first and second materials cool. The result? One-piece part with multi-material performance.

Material Types is so important in overmolding. The two materials must bond well both chemically and mechanically to prevent delamination. Typically, the two-part combinations are two such resins in combination with envisaged uses, including the use of flexible materials on rigid materials for grips, seals or impact resistance, for example, thermoplastic elastomer (TPE) over polypropylene (PP) or rubber-like materials over rigid plastics.

There are different methods of overmolding:

- Two-shot molding: This process utilizes a machined injection molding machine that can inject two different materials into a mold without removing the part, which reduces setup time and cycle time.

- Insert molding: The first piece is molded separately and then manually or robotically placed into a second mold, and the second material is injected. The process is a flexible solution for smaller batches of parts or parts which are tough to handle.

- Secondary overmolding: if the base part cannot be made by injection molding, then it is placed into the mold and molded with plastic over it for other molding materials and technologies, such as adding coatings or different materials.

Precision control of the processing variables, including ones such as melt temperature, injection speed and pressure, is necessary to ensure acceptable bonding and lack of defects, such as warpage or incomplete fill. Tooling must also be designed to handle varied material flow and cooling rates.

Overmolding has countless advantages, such as better part ergonomics, improved sealing, more attractive finishes, and the ability to eliminate a number of assembly steps by housing a variety of parts within a single part. Knowing the nuances of overmolding enables manufacturers to maximize design, minimize cost, and maintain the overall quality of the multi-material part.

Design Considerations for Overmolding

Overmolding design necessitates careful preparation for robust bonding, functional integrity, and efficient production. The quality of double injection course refers to the compatibility of the materials, design of the molds, and the settings of the parameters.

An important consideration is the choice of materials that adhere to each other. The compatibility of the substrate and the overmold material to each other by chemical affinity provides a strong bond. In case of material incompatibility, separation can happen, or a weak bond may form, leading to mechanical failure of the part. Designers typically evaluate material pairings or leverage adhesive primers to improve adhesion.

An Overmold Tale of Two Parts Mold design is critical to the success of overmolding. The mold is contemplated, under the requirement of forming by two-step injection, to have an accurate register between substrate and overmold cavities. Good gating and venting are necessary to avoid short-filling and possible air traps or voids.

In addition, the substrate geometry has to be taken into account by the designer. Things such as undercuts, grooves or textured surfaces can help materials interlock mechanically. These design features are permanently bonded together, making the connection more than a purely chemical bond.

It is also crucial to control processing conditions. Melt temperatures, injection pressures and cooling times should be modified for both materials in order to prevent damage due to warpage, shrinkage and such stress creation. Cycle times must trade off productivity with part quality.

Overmolding also often increases complexity and cost, so designers will need to weigh those against improved features along with this increased range of options. When this collaboration between design and manufacturing teams begins early enough, the result is overmolded parts that achieve performance targets and cost.

By thinking about these factors, manufacturers can maximize the potential benefits of overmolding for creating strong, good-quality, multi-component parts.

Applications of Overmolding

The Overmolding process encompasses many different applications, from functionality and ergonomics and also changing the cosmetic appearance along with the incorporation of dissimilar material types. Its multi-material capabilities make it useful for developing items with increased performance properties and design freedom.

In the automotive world, overmolding is also widely used to produce elements such as grips, seals and buttons. Soft touch surfaces that are molded over rigid plastic bases make ends soft and comfortable to grip. Overmolding also facilitates the production of intricate assemblies that minimize the number of extra parts and assembly steps.

Overmolding’s Impact on Electronics

The use of overmolding in the electronics industry is widespread and can extend product housings and connectors and provide enhanced durability and environmental protection. Seal overmolded containing prevents ingress of dust, dirt and moisture, soft grip handles improve comfort and ergonomics.

In consumer products such as power tools, kitchen tools and medical devices, overmolding is widely used to unite hard plastics with soft elastomers. This provides more grip, less vibration and looks sleek. It also permits colours and textures to be customized with no additional assembly.

The key advantages of overmolding in such applications are:

- Added longevity to the product and added comfort

- The number of parts was decreased, and the assembly was simplified

- Enhanced sealing and environmental shielding

As an all-in-one process that combines several materials, overmolding provides manufacturers the flexibility to accommodate multiple functional and aesthetic requirements in a range of markets.

Benefits of Overmolding

There are many reasons why OverMolding is a value-added practice and why manufacturers so often use this process. Overmolding brings together multiple materials in one part, adding function value, design freedom, and process optimization.

Enhanced Product Functionality

Soft-touch and hard materials can be combined in overmolding to enhance grip, feel, and durability. For instance, soft-touch grips in automotive and consumer electronics improve user experience and strength.

Cost and Time Efficiency

This type of process allows for several materials to be utilized in a single processing step therefore saving you assembly time. This reduces the cost of labor and simplifies the manufacturing process, making it suitable for mass production.

Design Flexibility

Designers can play with materials, color and textures to make visual interest and functional parts. Overmolding enable the production of complex moulded parts with fine details and multifunctional properties.

Durability

Overmolding delivers additional protection against abrasion, moisture and UV damage in tough working conditions to help lengthen product life.

Challenges in Overmolding

Although overmolding is an attractive feature, it also comes with some challenges which manufacturers want to solve to produce successful and better-quality parts. One of the serious problems is the lack of adhesion strength between the overmold material and the substrate. Mismatched materials can cause delamination that can have a detrimental impact on the part’s durability and performance.

Material contractions and distortions were also common phenomena. Cooling shrinks different materials at different times, which leads to stress inside the part or a twist at the end. Designers need to choose compatible materials and further their process parameters in order to reduce such influences.

Another struggle is to deal with the complexity of mold design. Overmolding tools demand perfect placement and the right tool technology for the use of more than one injection phase. This can be a more complex arrangement and may result in higher tooling expenses and/or tool maintenance.

Air inclusion and incomplete sample filling are likewise problematic. The use of suitable gating and venting is a necessity to prevent defective air pockets.

Through careful design and material selection and by using informed process control, these problems can be identified and mitigated, which will enable manufacturers to fully realize the potential of overmolding while still benefiting from producing reliable, quality multi-material parts.

Final Thoughts

It is a strong method of injection molding which allows the creation of multi-material parts with improved design flexibility and functionality. Although it is still challenged by material adaption and mold complexity, these issues can usually be addressed with some well-designed and controlled process. The technique is widely used in such industries as automotive, electronics and consumer goods to enhance product durability, ergonomics and aesthetics.

Through familiarity with the overmolding process and the factors that need to be considered, manufacturers can produce quality, affordably priced elements that meet a range of customer needs and make strides to improve production practices.