A lot depends on the pogo pins. These spring-loaded connectors are made to make sure that electrical ties are stable and reliable in a variety of situations.

From technology to cars, many different fields depend on these small connectors to work smoothly. Their ability to keep the pressure steady is important for high-tech devices to work properly.

Let’s explore how they work and their significance in CNC machining, shedding light on their manufacturing process and diverse uses.

What are Pogo Pins?

Let’s define pogo pins in relevance to CNC machining.

Pogo pins are spring-loaded connectors that are commonly used to make secure electrical connections in a wide range of conditions. Most importantly, these plugs are necessary for checking and connecting batteries, which require reliability and precision. Pogo pins’ complex design and usefulness depend on careful production processes that make sure they always work.

This is where CNC machining is very important.

CNC machining can make pogo pins that are exactly what you need and up to high quality standards thanks to its computer-controlled accuracy.

When it comes to mission-critical applications, nothing beats the consistent and precise results that CNC machining can provide. It is necessary to use CNC machining when making pogo pins for better electrical connection, whether they are for mobile devices, car parts, or aircraft technology.

Structure of Pogo Pins

Pogo pins are fascinating in their simplicity yet vital in their role. Understanding how they are put together helps us understand why these tiny parts are so important in electronics.

The Basic Parts

- Plunger

The part of the pogo pin that can move and make touch with the matching surface is called the plunger. The shape makes it easy for it to slide inside the barrel while still connecting securely.

- Barrel

The plunger and spring are housed inside the barrel. It makes sure the plunger goes in a straight line and stays in place while it’s working. The barrel needs to be strong enough to hold the internal parts firmly while still letting them move easily.

- Spring

The spring gives the plunger the force it needs to stay in touch with its partner. The pin’s performance depends on how strong and flexible the spring is, especially in situations where the pin needs to be engaged and disengaged many times.

Materials Used

We will look at the materials that are used in all of the parts now:

For the plunger and barrel, brass or phosphor bronze is usually used, and gold is often added on top. Gold finishing is especially popular because it is very good at conducting electricity and resisting rust, so it will last for a long time.

When making a spring, most people choose to use stainless steel or beryllium copper because they are durable and have excellent spring properties.

Hint: Why is choosing appropriate materials important for performance?

For pogo pins to work well and last a long time, it’s important to choose the right materials for each part. The electrical conductivity, mechanical strength, and general dependability of the connection are all directly affected by the materials used.

For example, plating the plunger and barrel with gold improves their conductivity and resistance to rust, which is important for keeping the electrical link stable over time. Similarly, making the spring out of a strong material like stainless steel makes sure that it can handle being compressed and then released many times without losing its shape.

So, carefully choosing the right materials is a key part of making pogo pins work best in a wide range of situations.

Now that we’ve seen how pogo pins are structured, let’s explore how they work.

Working Principle of Pogo Pins

Pogo pins, which are also called spring-loaded pins, are very important in electronics for making sure that electrical links are stable. Many different types of businesses use these small but very effective connectors because they can provide regular contact points even in tough situations.

Let us learn more about how they do their job.

Mechanism with a Spring

The smart spring-loaded system inside a pogo pin is what makes it work. The structure is mostly made up of a barrel, a plunger, and a spring. When you put pressure on it, the plunger squeezes into the barrel, which then squeezes the spring. When you let go of the pressure, the spring pushes the plunger back to where it was.

This simple but effective method is very important for keeping a steady and continuous connection.

You can’t say enough about how important touch pressure and steadiness are. The pressure from the spring makes sure that there is enough force to keep the plunger firmly against the joint surface. This is especially important in places with a lot of shaking or when the link needs to stay stable for a long time.

Electrical Connectivity

Pogo pins are recognized for making electrical links with very little resistance. When the pin with the spring loaded contacts a contact point, it makes sure that the electrical line is stable and consistent. These features make them necessary in many different kinds of electronic gadgets and circuits, from simple electronics like smartphones to complex medical and vehicle systems.

Pogo pins are used to make short-term links in many electronic gadgets so that they can be tested and programmed.

Also, they are particularly significant in battery and charge interfaces, where electrical links need to be made often but last a long time. Pogo pins are perfect for these tough yet substantial jobs because they provide steady pressure and low resistance contact.

Types of Pogo Pins

Pogo pins, also known as spring-loaded pins, come in various shapes and sizes to fit diverse electrical needs. We understand how important it is to know the different types, which is why we’ve laid out most types for you.

Let’s look at the different kinds of pogo pins, what makes each one special, and where they are commonly used.

1. Standard Pogo Pins

These are the basic type often used for general-purpose connections. They guarantee stable electrical contact and are durable enough to be engaged and disengaged multiple times, making them suitable for everyday electronic devices like smartphones, tablets, and gaming consoles.

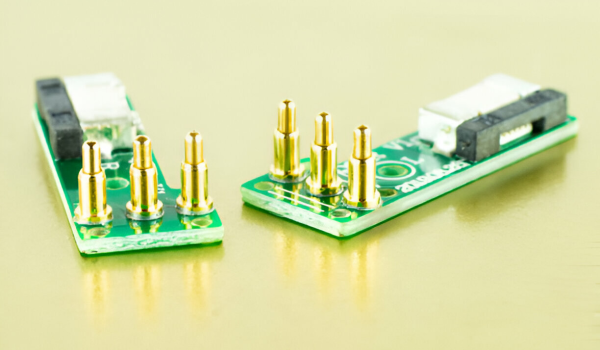

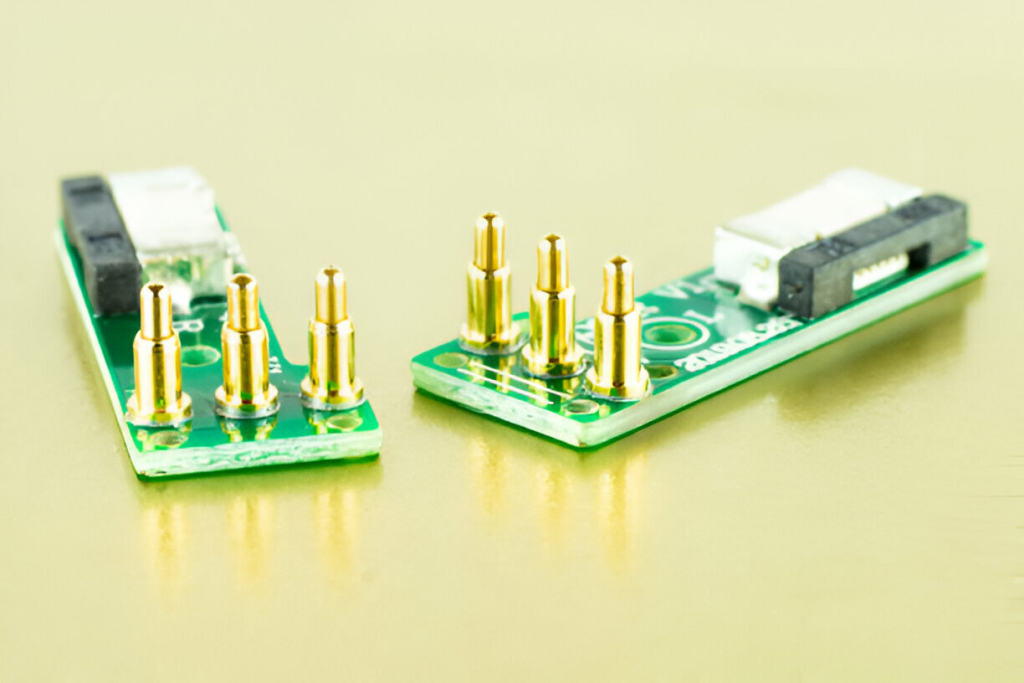

2. SMT/SMD Pogo Pins

Surface Mount Technology (SMT) or Surface Mount Device (SMD) pogo pins are designed to be mounted directly on printed circuit boards (PCBs). Their design is compatible with automated assembly processes, which simplifies manufacturing and enhances production efficiency. They are widely used in consumer electronics, automotive control systems, and wearable devices.

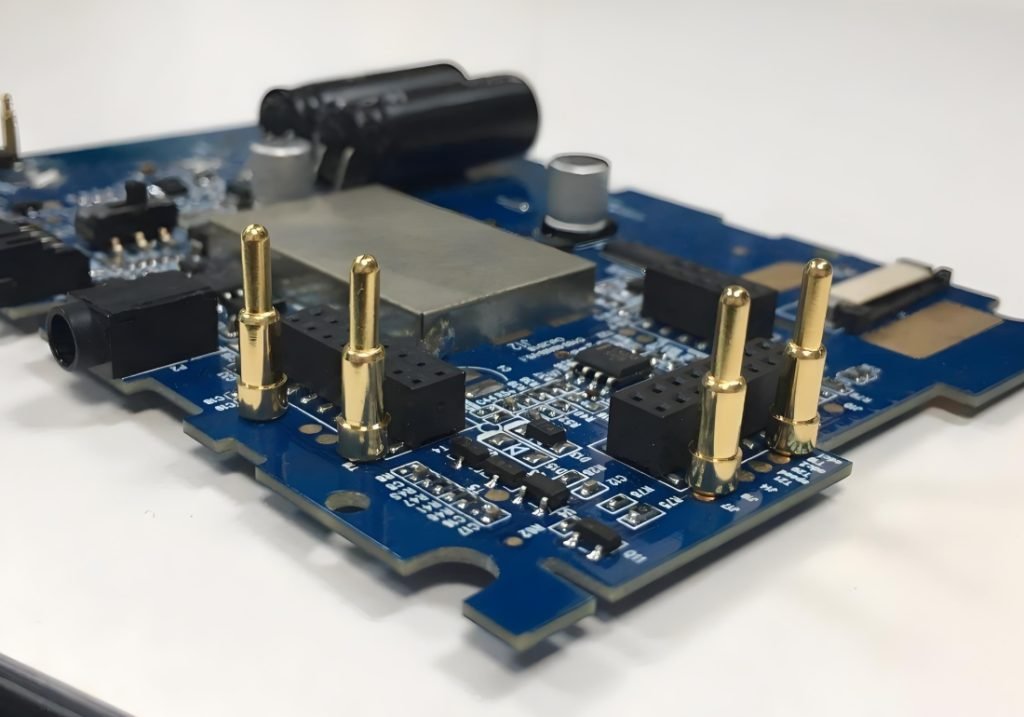

3. Through Hole Pogo Pins

Unlike SMT pins, through hole pogo pins are inserted through holes in the PCB and soldered in place. This type offers a more secure mechanical connection, which can be significant in applications where the board may be subjected to mechanical stress or vibration. Industries like aerospace, industrial machinery, and robust medical equipment commonly utilize hole pogo pins.

4. Double-Ended Pogo Pins

These pins have spring-loaded plungers on both ends, making them ideal for board-to-board connections. Double-ended pogo pins are especially useful when space is limited and connections on both sides of the pin are required. They are often used in multilayer PCBs and medical devices where compact and reliable connections are needed.

5. High Current Pogo Pins

When it comes to transmitting higher electrical currents efficiently, high current pogo pins are the solution. Built with robust materials and designs, these pins can handle larger currents without overheating or losing efficiency, making them perfect for applications like electric vehicle battery connections, power systems, and heavy-duty charging stations.

6. High-Frequency Pogo Pins

For applications that necessitate the transmission of high-frequency signals, high-frequency pogo pins are essential. They are designed to minimize signal loss and interference, ensuring clear and reliable data transmission, which is critical in RF communication systems, satellite communications, and high-speed data transfer equipment.

7. Right Angle Pogo Pins

These pins are oriented at a right angle to the mounting surface, providing flexibility in space-constrained designs. Right angle pogo pins are excellent for tight spaces where vertical height is a concern, offering alternate routing options without compromising connectivity. They are used in compact sensors, wearable technology, and limited-space PCB assemblies.

8. Thread Screw Pogo Pins

Pogo pins with a threaded screw design provide a secure and adjustable connection. These are particularly useful in applications requiring fine-tuning or adjustable connection points, ensuring a reliable hold that can be easily modified if needed. They are often found in testing equipment, calibration devices, and custom jigs.

How Pogo Pins Are Used in Different Industries?

Even though they look small, pogo pins play an important role in ensuring reliable electrical connections across many industrial settings.

Their usefulness and adaptability contribute significantly to advancements in various fields, reflecting the market’s substantial growth trajectory, which saw a valuation of USD 335 million in 2023 and is projected to reach USD 576.1 million by 2031.

Here is a full look at what they do in different industries:

● Medical Companies

Pogo pins are very important in the medical field, where steadiness and accuracy are very important. They are used in testing tools and systems that keep an eye on patients to make sure that links are accurate and reliable, which can mean the difference between life and death.

● Electronics Business

Smartphones, wearable tech, and Internet of Things (IoT) gadgets all need pogo pins to work. Their small, sturdy design lets you put them together and take them apart easily, saving room and making sure they work well for a long time.

● The Auto Industry

Pogo pins are an important part of systems like battery control in the auto industry, especially with the rise of electric cars. Their ability to handle steady moving and changes in temperature makes sure that electrical systems work well, which is important for the safety and efficiency of vehicles.

● Industrial Applications

Pogo pins keep sensor lines connected even in rough conditions in fields that use heavy machinery, robots, solar panels, and automation systems. They are made to keep the quality of the link even in harsh conditions, which makes them essential for efficient industrial operations.

● Telecommunications Business

Pogo pins make sure that world communication networks work smoothly. In high-frequency radio, they make sure that links are clear and stable with little signal interference. This is very important because the need for steady communications is growing.

Conclusion

Pogo pins might be small, but they have a big impact on modern technology. Understanding their function and manufacturing offers insight into quality control’s importance.

If you seek reliable components for your projects, consider partnering with experts in pogo pin production. Their contribution to connectivity is undeniable and invaluable.

Get in touch with us to discover how incorporating pogo pins in CNC machining can revolutionize your production line and drive your business growth!