Did you know that over 80% of the world’s aluminum production is used in applications where corrosion resistance and durability are crucial? One of the most effective ways to enhance these properties is through anodizing, a versatile finishing process that creates a protective layer on the surface of aluminum parts. This comprehensive guide will introduce you to the world of anodizing and its benefits for your projects.

Understanding Aluminum Anodizing

Anodizing aluminum is an electrochemical process that not only protects the metal from corrosion but also enhances its appearance.

What Is Aluminum Anodizing?

Aluminum anodizing is a technique that enhances the natural oxide layer on aluminum, making it thicker and more protective. When aluminum is exposed to air, it naturally forms a thin oxide layer. However, this natural layer is not very durable. Anodizing is an electrolytic process that thickens this layer, making it more robust and durable. The result is a surface that is not only more resistant to corrosion but also more aesthetically pleasing.

The Science Behind the Oxide Layer

The anodizing process involves submerging the aluminum in an electrolytic bath and passing an electric current through it. This causes the aluminum surface to be converted into aluminum oxide (Al₂O₃), creating a layer that is both porous and tightly bonded to the base metal. The porous nature of the anodized layer allows for additional treatments, such as sealing or dyeing, enhancing both the protection and appearance of the aluminum.

The resulting oxide layer is integral to the aluminum, providing a strong bond that doesn’t flake or peel. This characteristic makes anodized aluminum particularly useful in applications where durability is crucial.

The Aluminum Anodizing Process

Anodizing aluminum involves a multi-step process that includes preparation, electrolytic processing, and post-treatment. This comprehensive process transforms aluminum parts into durable, corrosion-resistant products with enhanced aesthetic appeal.

Pre-Anodizing Preparation

Before aluminum can be anodized, it must be thoroughly cleaned and etched to remove dirt, cutting fluid, or grease. General cleaning is usually performed using a strong degreaser followed by thorough rinsing with water. This step is crucial for ensuring a uniform, high-quality finish.

The surface preparation step is critical because any contaminants left on the aluminum surface can affect the anodizing process, leading to uneven or poor-quality results.

The Electrolytic Process Explained

The electrolytic process requires an anodizing tank, a positive electrode (anode), and a negative electrode (cathode). The aluminum part to be anodized functions as the anode in an acid bath, typically sulfuric acid, while an electrical current is passed through the solution, creating the oxide layer on the aluminum surface.

The equipment setup, including tanks, power supplies, and cathode materials, is essential for successful anodizing. The acid bath and electrical current work together to create a durable oxide layer.

Post-Anodizing Treatments

After anodizing, parts are rinsed with water to remove any residual acid. They can then be colored using dyes, followed by sealing to lock in the colors and enhance the protective properties of the anodized layer. Sealing is typically done using hot water or a chemical sealing solution.

Types of Aluminum Anodizing Processes

Anodizing aluminum involves various techniques, including Type I, Type II, and Type III processes. Each type has its unique characteristics, applications, and benefits. Understanding these differences is crucial for selecting the most appropriate anodizing method for your specific needs.

Type I – Chromic Acid Anodizing

Type I anodizing, also known as chromic acid anodizing, produces the thinnest coating among the three types, typically around 2.5μ. Despite its thin layer, it offers excellent corrosion resistance, making it ideal for aerospace applications where dimensional tolerance is critical. The chromic acid process is less damaging to the fatigue properties of aluminum compared to other anodizing methods.

Type II – Sulfuric Acid Anodizing

Type II, or sulfuric acid anodizing, is the most commonly used anodizing technique. It produces a coating thickness ranging from 5.1 to 30.5μ, offering a good balance between corrosion resistance and wear resistance. This process is highly versatile and can be easily dyed to various colors, making it suitable for a wide range of industries, from consumer goods to architectural applications.

Type III – Hard Coat Anodizing

Type III, also known as hard coat anodizing, uses sulfuric acid but under more intense conditions, resulting in a much thicker coating (12.7μ to 50.8μ). This process provides superior wear resistance and is used in high-stress applications, such as in the manufacture of hydraulic cylinders and other heavy-duty equipment. The thicker layer also offers enhanced corrosion protection.

Benefits of Aluminum Anodizing

The process of anodizing aluminum provides a multitude of advantages, enhancing both the durability and aesthetic appeal of the metal.

Enhanced Durability and Corrosion Resistance

Anodizing aluminum significantly enhances its durability and corrosion resistance. The anodized layer is exceptionally hard and fully integrated with the base metal, providing superior abrasion and corrosion protection. This makes anodized aluminum parts ideal for high-wear applications and harsh environments, including exposure to saltwater and industrial chemicals.

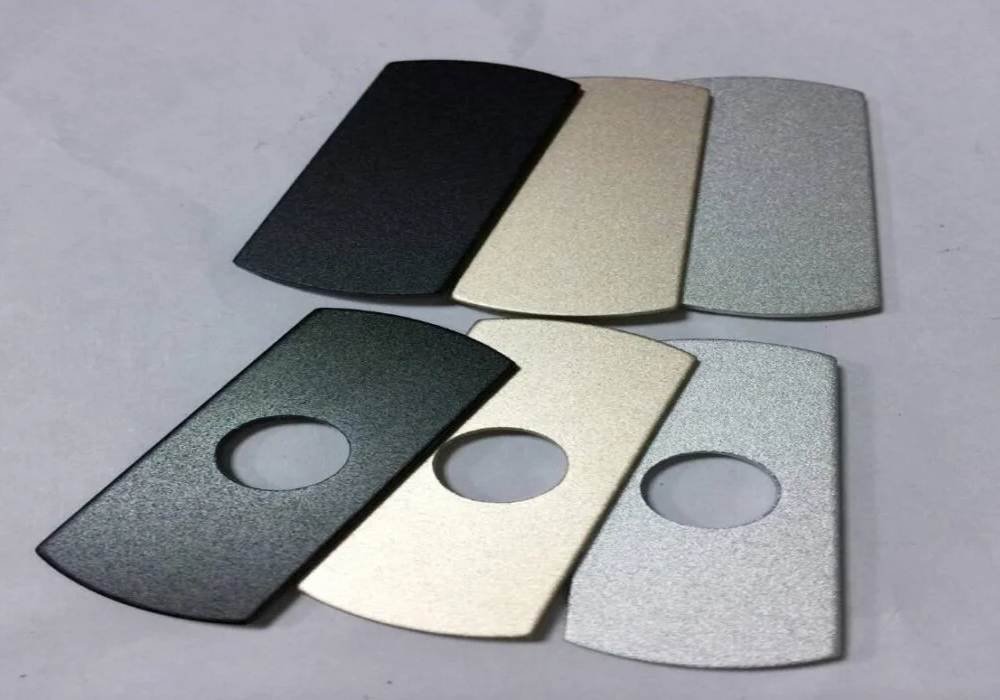

Aesthetic Versatility

Anodized aluminum offers a range of aesthetic options, from matte to high gloss finishes, and the ability to achieve vibrant, long-lasting colors. This versatility allows designers and manufacturers to create visually appealing products that meet specific design requirements. The smooth surface of anodized aluminum also resists dirt and grime, making it easy to clean and maintain.

Environmental Advantages

Compared to other metal finishing methods, anodizing is environmentally friendly. It is a non-toxic process that generates minimal waste and is recyclable. The durability of anodized aluminum also reduces the need for frequent replacements, further minimizing environmental impact.

Limitations of Aluminum Anodizing

While aluminum anodizing offers numerous benefits, it’s not without its limitations. As you consider using anodized aluminum for your projects, it’s essential to understand these constraints to make informed decisions.

Color Range Constraints

The process of achieving certain colors on anodized aluminum can be challenging. Some colors are difficult to achieve consistently, and exact color matching between batches can be problematic due to variations in the anodizing process.

Thermal Stress Considerations

Extreme temperature fluctuations can cause the anodized layer to develop microcracks. This thermal stress can impact the appearance and performance of the aluminum surface, potentially leading to durability issues.

Electrical Conductivity Issues

The anodized layer on aluminum is an insulating oxide, which significantly affects the electrical conductivity of the surface. This characteristic can be a limitation in applications where electrical contact is necessary.

Innovative Techniques in Anodizing

As technology advances, new methods are being developed to improve the anodizing process.

Plasma Electrolytic Oxidation

Plasma electrolytic oxidation (PEO) is a cutting-edge technique that produces ceramic-like coatings on aluminum surfaces. This high-voltage process results in coatings with exceptional wear resistance and thermal stability, making it ideal for applications in extreme environments.

Laser-Assisted Anodizing

Laser-assisted anodizing is another innovative technique that uses precision laser technology to etch designs and patterns onto anodized aluminum surfaces. This method allows for selective anodizing and the creation of intricate patterns, enhancing the aesthetic and functional properties of aluminum components.

Nanotechnology Applications

Nanotechnology is being applied in anodizing to change the structure of metals at a microscopic level. This electrochemical process improves the uniformity, strength, and functionality of anodized coatings. Surfaces created using nanotechnology can exhibit self-cleaning, antimicrobial, and super-hydrophobic characteristics, opening new possibilities for aluminum components in specialized applications.

These innovative techniques are expanding the capabilities of aluminum anodizing, enabling its use in a wider range of industries and applications. By enhancing the properties of anodized aluminum, these advancements are contributing to the development of more durable, functional, and aesthetically pleasing products.

Industry Applications of Anodized Aluminum

The versatility of anodized aluminum makes it a valuable material in multiple sectors. Its unique combination of durability, corrosion resistance, and aesthetic appeal has led to its widespread adoption across various industries.

Electronics and Consumer Goods

Anodized aluminum is widely used in the electronics industry for manufacturing smartphones, laptops, cameras, and other consumer goods. The anodizing process enhances the appearance and durability of these products, providing a premium finish that is resistant to wear and corrosion.

Architectural Applications

In architectural applications, anodized aluminum is used for curtain walls, window frames, roofing, and trim. Its weather resistance and low maintenance requirements make it an ideal choice for building facades and interior design elements.

Medical Equipment

Anodized aluminum is often used in the manufacture of medical equipment due to its biocompatibility and ease of sterilization. The corrosion-resistant properties of anodized aluminum ensure that medical devices remain in good condition even after repeated cleaning and sterilization.

Sporting and Outdoor Equipment

Sporting and outdoor equipment, such as bicycle components, marine hardware, and camping gear, benefit from the lightweight strength and corrosion resistance of anodized aluminum. The durability of anodized aluminum parts ensures that they withstand the rigors of outdoor use.

Comparing Anodizing to Other Aluminum Finishes

Anodizing vs. Powder Coating

Anodizing and powder coating are both popular for their durability, but they work in different ways. Anodizing creates a seamless, oxide layer that’s highly corrosion-resistant. Powder coating, on the other hand, applies a dry powder that’s then baked onto the surface. While both methods offer excellent protection, anodizing tends to be more durable and less prone to chipping.

Anodizing vs. Painting

Painting aluminum is a cost-effective method that offers a wide range of colors, but it doesn’t match anodizing in terms of durability and scratch resistance. Anodizing provides a uniform, integral layer that’s less likely to chip or fade over time. Painting, however, can be more versatile in terms of color options and is generally easier to repair.

Anodizing vs. Electroplating

Electroplating deposits a layer of material onto the aluminum surface, often for conductivity or aesthetic purposes. While electroplating can provide a highly conductive surface, it lacks the wear resistance of anodizing. Anodizing, by integrating with the aluminum, offers superior durability and corrosion protection.

Conclusion

With a deeper understanding of aluminum anodizing, you can now make informed decisions about enhancing your projects with this versatile finish. Aluminum anodizing is a great way to increase durability while also adding some custom flair to your parts.

As you consider aluminum anodizing for your next project, keep in mind the various applications and industries that benefit from this process, from precision components to decorative elements.