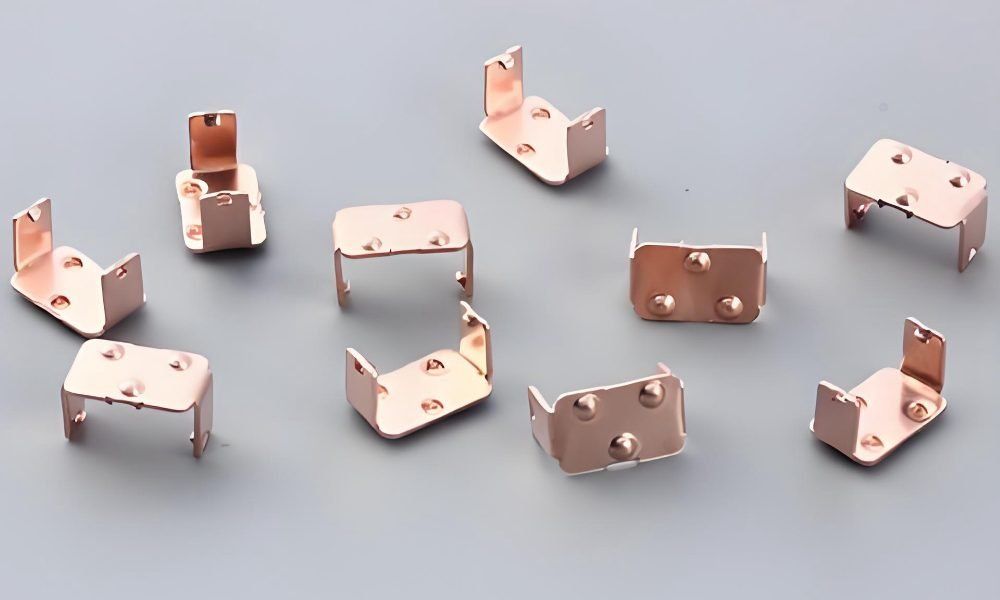

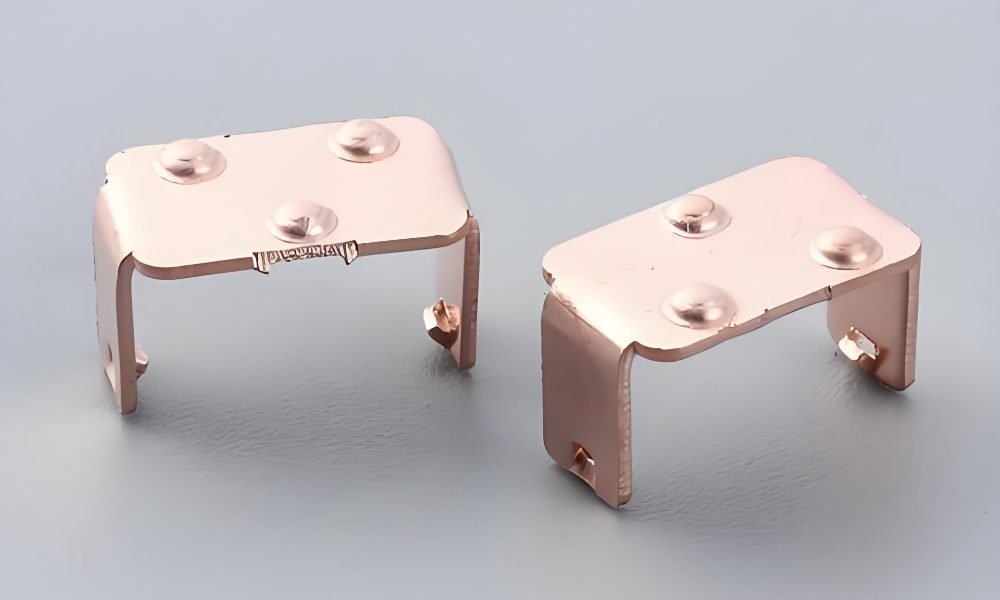

Custom Copper Stamping Services: Precision Parts for Every Industry

Copper stamping transforms raw copper sheets into precision components through specialized forming processes. At Fecision, we deliver high-quality custom copper stamped parts with exceptional conductivity, corrosion resistance, and durability for applications across electronics, automotive, aerospace, and more industries. Our advanced stamping capabilities ensure tight tolerances and consistent quality for your most demanding projects.

Durable

Impact-resistant

Machinable

----Our Copper Stamping Capabilities

Custom Copper Stamping Services at Fecision

Fecision specializes in delivering precision copper stamping solutions tailored to your exact specifications. Our state-of-the-art equipment and experienced engineering team work together to produce stamped copper parts with exceptional quality and consistency.

Precision Manufacturing

Precision stamping with tolerances as tight as ±0.001"

Superior Techniques

Progressive die stamping for complex designs

Production Capability

Prototype to High-volume production scaling

Custom Mold Tooling

Custom stamping tooling design and fabrication

Secondary operations

Secondary operations including plating and finishing

Types of Copper for Metal Stamping

Selecting the right copper alloy is crucial for your application's success. Each grade offers specific properties that make it suitable for different requirements and environments.

| Copper Grade | Properties | Common Applications | Conductivity | Corrosion Resistance |

| C11000 (ETP Copper) | High electrical conductivity, excellent formability | Electrical components, terminals, busbars | 100% IACS | Excellent |

| C17200 (Beryllium Copper) | High strength, excellent spring properties | Springs, connectors, switches | 22-28% IACS | Very Good |

| C26000 (Cartridge Brass) | Good formability, moderate strength | Electrical hardware, decorative components | 28% IACS | Good |

| C51000 (Phosphor Bronze) | Excellent spring qualities, fatigue resistance | Springs, contacts, fasteners | 15% IACS | Excellent |

| C70600 (Copper-Nickel) | Superior corrosion resistance in marine environments | Marine hardware, heat exchangers | 9% IACS | Superior |

Copper Metal Stamping Advantages

Copper's exceptional electrical conductivity (second only to silver) makes it ideal for electrical components. Stamped copper parts provide reliable current flow with minimal resistance, reducing energy loss and heat generation in electrical systems.

With thermal conductivity approximately 60% higher than aluminum, copper stamped components excel in heat transfer applications. This property makes copper ideal for heat sinks, cooling systems, and thermal management solutions in electronics and industrial equipment.

Copper naturally forms a protective patina that shields against corrosion, making stamped copper parts highly durable in various environments. This inherent corrosion resistance extends component lifespan and reduces maintenance requirements in challenging applications.

Copper's exceptional ductility and malleability allow for complex forming operations without cracking or tearing. This enables the creation of intricate designs and tight-tolerance components that would be challenging with other materials.

Copper surfaces naturally kill bacteria, viruses, and other pathogens, making copper stamped components ideal for healthcare and public space applications. This inherent antimicrobial action continues working 24/7 without additional treatments or chemicals.

Copper can be recycled indefinitely without loss of performance, making copper stamped parts environmentally sustainable. Using recycled copper in your components reduces environmental impact while maintaining the material's exceptional properties.

Key Beryllium Copper Properties

Beryllium Copper Stamping: High-Performance Applications

Beryllium copper (BeCu) combines copper's excellent conductivity with significantly enhanced mechanical properties, making it ideal for demanding applications requiring both strength and conductivity.

- Exceptional strength (up to 1400 MPa tensile strength)

- Superior spring properties with excellent fatigue resistance

- Good electrical and thermal conductivity

- Non-sparking characteristics for safety in explosive environments

- Excellent corrosion resistance, even in marine environments

- Maintains properties at extreme temperatures (-200°C to +315°C)

Beryllium Copper Safety

Fecision follows strict safety protocols when working with beryllium copper to protect both workers and customers. Our processes comply with all OSHA regulations for beryllium handling, and finished parts pose no health risks during normal use.

Stamped Copper Parts Across Industries

Copper's unique combination of properties makes it valuable across numerous industries.

At Fecision, we produce precision copper stamped components for diverse applications, each leveraging copper's specific advantages.

Electronics & Electrical

- Terminals and connectors

- EMI/RFI shielding components

- Busbars and current carriers

- Switch and relay components

- Battery contacts and cell connectors

Automotive

- Battery management system components

- Electric vehicle power distribution

- Thermal management components

- Sensor housings and brackets

- Brake system components

Aerospace & Defense

- Electrical distribution components

- EMI/RFI shielding for sensitive equipment

- Heat exchangers and thermal management

- Fuel system components

- Communication system parts

Medical & Healthcare

- Antimicrobial touch surfaces

- Electrical contacts for medical devices

- Thermal management in diagnostic equipment

- Surgical instrument components

- Implantable device housings

Renewable Energy

- Solar panel junction boxes and connectors

- Battery storage system components

- Power inverter busbars and contacts

- Thermal management in power electronics

- Wind turbine electrical components

Telecommunications

- RF connectors and shielding

- Base station components

- Signal transmission elements

- Heat sinks for network equipment

- 5G infrastructure components

Copper Metal Stamping FAQs

Need Copper Components for Your Industry?

Our industry specialists understand your unique requirements and can help design optimal copper stamped solutions.

Quality You Can Trust

At Fecision, quality control is integrated throughout our copper metal stamping process.

Our commitment to excellence ensures that every component meets or exceeds industry standards and customer specifications.

Certifications

- ISO 9001:2015 Certified

- IATF 16949 Automotive Compliance

- AS9100D Aerospace Standards

Testing Capabilities

- 3D Coordinate Measuring Machines

- Mechanical Property Testing

- Surface Finish Verification

Quality Guarantees

- 100% Inspection Options

- Statistical Process Control

- Documented Quality Procedures

Ready to Start Your Copper Stamping Project?

Contact us today to discuss your requirements and discover how our copper stamping expertise can benefit your application.