According to estimates, the global CNC market will reach $23 billion by 2026, up from $14.6 billion in 2018.

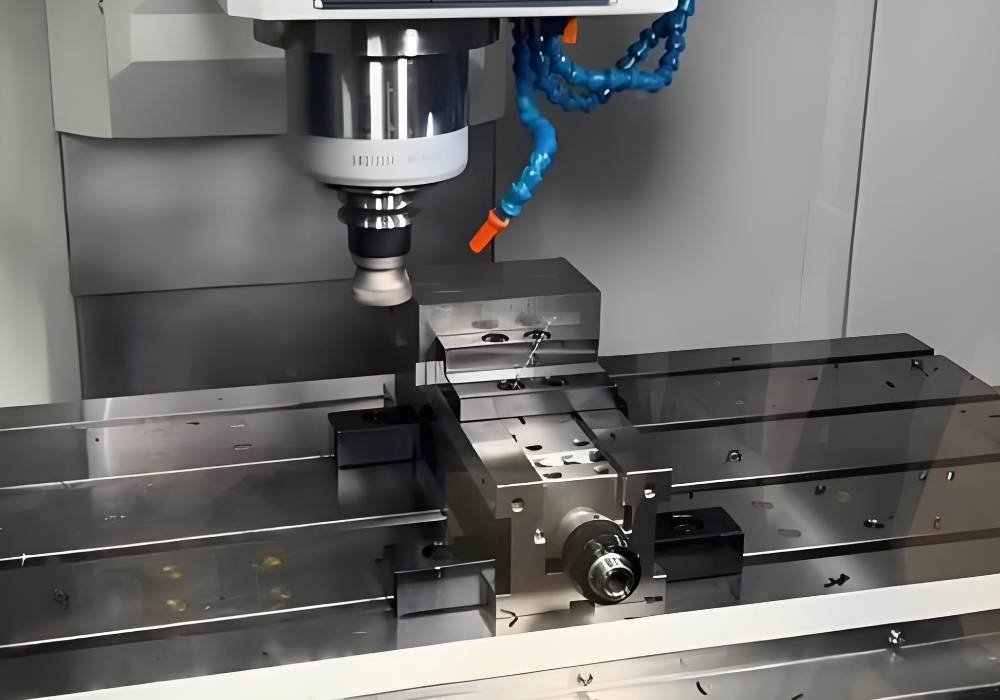

CNC machining involves using computers while controlling tools to transform raw materials into precisely crafted parts. This technology is very popular in the aerospace, automotive, and electronics industries, where precision is required. We have made a detailed guide on CNC machines to provide in-depth knowledge.

What is CNC Machining?

CNC machining is a technique used in the manufacturing industry that involves shaping materials with the aid of automated tools. CNC machines operate under instructions issued by a computer, performing functions like cutting, drilling, and shaping parts. Thus, every piece produced is as good as the last. Industries that require precise results without variation will benefit from this technology.

Computerized CNC machines stand out in contemporary factories. They complete tasks with narrow tolerances, which means the parts match together perfectly without leaving any gaps or flaws. Workers can always rely on the CNC machine to deliver duplicates of the same product.

What Does ‘CNC’ Stand For?

CNC stands for Computer Numerical Control. In CNC, a computer “talks” to the machine by moving it around using numbers and a combination of different codes. These codes help the tools know their specific points of action and objectives, like supplying the machine with a map.

The first thing operators do is come up with a design, which they then convert into commands known as G-code. The G-code describes every step, such as “move left 2 inches” or “cut 0.5 inches deep.” The machine reads this G-code and moves its tools as instructed. This is a more advanced way of maintaining control over a machine than previously used, where controls were manually operated.

Automation is the most significant selling point of CNC. Older machines would require an operator to turn wheels or move levers to make the machine function. Cutting that out is one of the great features of CNC technology.

Once the code is given to the device, it takes charge and executes all the commands. This reduces the chance of error by a human and increases the speed of execution. All that needs to be done by the operator is to load the device, after which the machine does everything on its own.

Modern CNC devices are capable of performing multi-step operations without breaking a sweat. They read complex designs to real objects using modern software. This is what distinguishes – smartness and speed as well as accuracy to performance.

Conventional Machining vs. CNC Machining

Here’s a table the key differences between conventional machining and CNC machining based on the provided text:

| Aspect | Conventional Machining | CNC Machining |

| Control Method | Operated manually by skilled workers | Controlled by computers |

| Operation Speed | Slower; involves manual adjustments and handling | Faster; machines operate automatically |

| Precision and Accuracy | Prone to human error; slight variations possible | High precision; consistent results every time |

| Setup Process | Requires manual setup and adjustments for each job | One-time setup; the machine runs the same process repeatedly |

| Ideal Use Cases | Best for one-off projects or small batches | Best for large-scale manufacturing and mass production |

| Flexibility | Flexible for custom jobs and unique pieces | Less flexible; focused on identical parts |

| Cost Efficiency | Maybe less cost-effective for large production runs | More cost-effective to produce hundreds of parts |

| Example | Hand-spinning material and moving tools | The machine spins material and adjusts tools automatically |

What Are the Benefits of CNC Machining?

Using CNC machines offers a multitude of benefits such as accuracy. These machines can pull tolerances to as tight as 0.001 inches, which means the part gets produced exactly how it was designed.This is helpful in areas such as engine gears or surgical equipment, where the tiniest of errors can discredit the entire work.

Ultimate Time Saver

CNC machines operate 24/7, irrespective of time. After initial setup, workers are not needed because CNC machines do not require breaks, unlike human workers.

This nonstop operation significantly decreases workload timelines, reducing them by as much as 50%. As a result, businesses are able to complete various tasks on time, and products are made available in the market as soon as possible.

Cost-effective for Companies

Cutting down time means cutting down costs as well. CNC machines work with a small margin of errors, and when they do occur, the rework costs are minimal.Another great advantage is that CNC machines make intelligent cut designs that require zero excess metal or plastic waste. This means companies use less of their resources, making them more money in the long run.

Complete Accuracy

It is easy to work on complex shapes with CNC accuracy. Manual tools face issues with curves, angles, or small details, while CNC machines don’t face such problems.

They can perform fantastic feats, such as following a complex G-code to carve out parts in ways that humans cannot. With this, the boundaries of engineering creativity can be expanded to even contours of car components and delicate jewelry pieces.

Main Steps for the CNC Machining Process

When using CNC Machines, it’s crucial to check if all components work together seamlessly.For the first step, the engineers will use the applicable software CNC design, which specifies the part’s specific shape, dimensions, and other details. The next step automatically flows from it: the design needs to be turned into G Code.

Translating the Design into G Code

G Code is used for the CNC Machine, as it has all the instructions for the CNC Machine to operate and function correctly. In other words, the machine must be told how to manage and what tools must be used to fully make the specified shape.

Furthermore, the G Code takes care of cutting instructions, how deep to cut, how deep to move the machine, and at what speed the cuts should be done. The raw measurements which make up the shape are then transferred into the software as a drawing.

Setting Up the CNC Machine

Once the draft is finalized, it is time to set up the CNC Machine and check the next steps of the process. Different tools, like drills and cutters, need to be selected and mounted on the machine. After that, the required materials—metal, wood, or cast—should be securely placed on the machine using statues to clamp them.

Executing the Machining Process

Once that is set, the machine can be started. When the machine turns on, it switches to the G Code, rotating its tools, which allows it to drill holes, shave edges, or carve a specific shape, all in one motion, while the computer controls the entire process.

Quality Inspection and Refinement

The operators review the component and examine the dimensions to confirm that it follows the design parameters.

They readjust the machine or correct the element if any discrepancies are found. They may also simply polish the component. This step maximizes the quality of the element before it undergoes shipping.

Every single step is dependent on the previous one. Everything from the design and the CNC machine’s final check, every aspect, is how a dream becomes a reality. It is efficient as well as reliable.

Different Types of CNC Machining Operations

CNC machines perform various tasks. Here are the most common operations:

- Milling: A rotating tool cuts material from a stationary workpiece, creating flat surfaces, slots, or grooves.

- Turning: The workpiece spins while a tool shapes it. This makes cylindrical parts like shafts or bolts.

- Mill-Turn: A hybrid machining process that combines turning and milling operations on a single machine to produce complex, high-precision parts in one setup.

- Drilling: The machine bores holes with a spinning drill bit into the material.

- Grinding: A wheel smooths surfaces or sharpens edges for a fine finish.

- EDM (Electrical Discharge Machining): Shape hard or complex materials by removing metal using controlled electrical sparks.

- Laser Cutting: Use a focused laser beam to cleanly cut or engrave materials with exceptional accuracy and speed.

- Plasma Cutting: Use an ionized gas jet to cleanly cut electrically conductive metals with speed and precision.

- Waterjet Cutting: Use a high-pressure stream of water, often mixed with abrasive particles, to precisely cut a wide range of materials without heat distortion.

- Routing: Similar to milling, this cuts softer materials like wood or composites.

- Boring: Enlarge or refine existing holes with exceptional accuracy, ensuring tight tolerances and superior surface finish.

- Shaping/Broaching: Form internal or external keyways, splines, and complex profiles with consistent accuracy and efficiency.

Each operation suits different shapes and materials, making CNC machining highly adaptable.

Parts and Equipment of A CNC Machine

Types of CNC Machines

There are several types of CNC machines, each designed for specific tasks.

- CNC Mills: Use rotary cutting tools to shape straight or contoured surfaces.

- CNC Lathes: Rotate the workpiece to perform precise turning operations.

- CNC Swiss-Type Machines: High-precision sliding-headstock lathes for small, complex parts.

- CNC Machining Centers (Vertical & Horizontal): Automated, high-precision milling systems with tool changers and enclosed work envelopes.

- CNC Multi-Tasking Machines (Mill-Turn): Combine milling, turning, drilling, and sometimes grinding in a single setup.

- CNC Drilling Machines: Specialized units designed for rapid, accurate hole-making.

- CNC Grinding Machines: Precision grinders that finish surfaces to extremely tight tolerances and smoothness.

- CNC EDM Machines (Wire & Sinker EDM): Electrical discharge machines that cut hard or complex materials with high accuracy.

- CNC Routers: Best for cutting softer materials like wood and foam.

- CNC Plasma Cutters: It is designed for cutting metal sheets using plasma torches.

- CNC Laser Cutters: Provide clean and precise cuts with laser technology.

Key Components of CNC Machines

CNC machines rely on various components to function effectively.

- Direct Motor Drives: Ensure accurate positioning and secure the workpiece.

- Spindle: Rotates the cutting tool for machining operations.

- Worktable: Holds the workpiece in place during processing.

- Code Reader: Translates instructions for the machine’s operation.

- Peripheral Devices: Includes motors, sensors, and other elements that control movement.

Common Support Software for CNC Machining

Software plays a big role in CNC machining. Designers use CAD (Computer-Aided Design) programs to draw parts. Popular options include AutoCAD and SolidWorks, which let users craft detailed 3D models.

Following that, specialized CAM Software converts the CAD model into G-code. Fusion 360 and Mastercam have a well-earned reputation as sophisticated G-code generators. They compute the tool path and speed parameters for the machine.

Some machines also incorporate the usage of a process simulation package to identify any omissions in the procedure that could lead to problems in pre-production.

Compatible Materials for CNC Machining

Metals

CNC machining works exceptionally well with a range of metals. Aluminum alloys such as 6061 and 7075 are lightweight, easy to machine, and ideal for prototypes and production parts. Steel and stainless steel offer strength and corrosion resistance for structural and wear-resistant components.

Brass and copper are highly machinable and perfect for precision fittings or conductive parts. High-performance metals like titanium, magnesium, and nickel alloys provide exceptional strength, lightweight properties, and resistance to extreme environments.

Plastics

Plastics are widely used in CNC machining for parts requiring low weight, chemical resistance, or electrical insulation. Common options include ABS for impact-resistant components, nylon (PA) and Delrin (POM) for low-friction mechanical parts, and polycarbonate (PC) for transparent, tough components.

Engineering plastics like PEEK and PTFE withstand high temperatures and harsh chemicals, while PVC, HDPE, and acrylic (PMMA) cover a range of general-purpose and aesthetic applications.

Composites

CNC machining can also handle composite materials. G10 or FR4, a glass-reinforced epoxy laminate, is strong, stable, and ideal for electrical and mechanical applications. Carbon fiber composites provide exceptional stiffness and lightweight properties, making them perfect for high-performance parts in aerospace, robotics, and sports equipment.

Special care with tooling and machining parameters ensures these composites can be cut precisely without delamination or fraying.

By understanding the strengths and characteristics of different material categories, engineers can select the best option for their CNC-machined parts, ensuring optimal performance, reliability, and cost-effectiveness.

Parts and Components Crafted Through the CNC Machining Process

CNC machining produces a vast number of products. In the automotive industry, it makes engine blocks, brackets, gear, turbine blades and structural panels.

CNC is used in electronics to house and connect the circuit board connectors. Even medical devices like surgical tools and implants are crafted through CNC machines.

CNC can produce both small pieces like screws or fittings and big pieces like airplane wings, which shows the reach of CNC Machines. It is capable of handling both simple and complex designs efficiently.

CNC machines are used for weapons and vehicles in the defense industry, fittings and fixtures in construction, and wooden or metallic designs in furniture design.

Conclusion

With its incredible precision and speed, CNC machining drastically changed the face of manufacturing. It can transform digital concepts into usable components, empowering various industries around the globe.

With the advancement of technology, CNC machining has evolved to meet new requirements. It’s capable of producing complex parts from a wide range of metals, plastics, and composites. Its flexibility, high accuracy, and repeatability make it ideal for industries from aerospace and automotive to medical devices and consumer products. Whether you need prototypes, small batches, or full-scale production, selecting the right material and machining strategy is key to achieving optimal performance and durability.

At Fecision, we combine advanced CNC technologies with expert engineering to deliver high-quality, custom-machined components tailored to your specifications. Contact us today to explore our CNC machining services and bring your designs to life with precision and reliability.