Metal cutting removes excess material and shapes it according to specific requirements. Metal is a fundamental raw material in various industries and must be shaped and cut before it can be effectively utilized. Although many different types of metals have widely varying properties, they are generally very durable and strong. Cutting through metal is challenging, so shaping it requires specialized tools and technologies. One of the most common methods for cutting metal uses lasers to achieve a clean and precise result. Let’s explore how lasers cut metal and the strengths and weaknesses of this method.

Metal Cutting Methods

There are various methods for cutting metal, with laser cutting being just one of them. Metal cutting methods fall into two main categories, which include the following:

Mechanical

The removal, cutting or shaping of metal using sharp tools and force constitutes mechanical metal cutting processes. This method involves using blades, saws, shears, and milling equipment to carve out the desired shape. Water jet cutting is also a mechanical method of cutting metal as it makes use of the force of water and abrasive substances to apply force to the metal and cut it.

Thermal

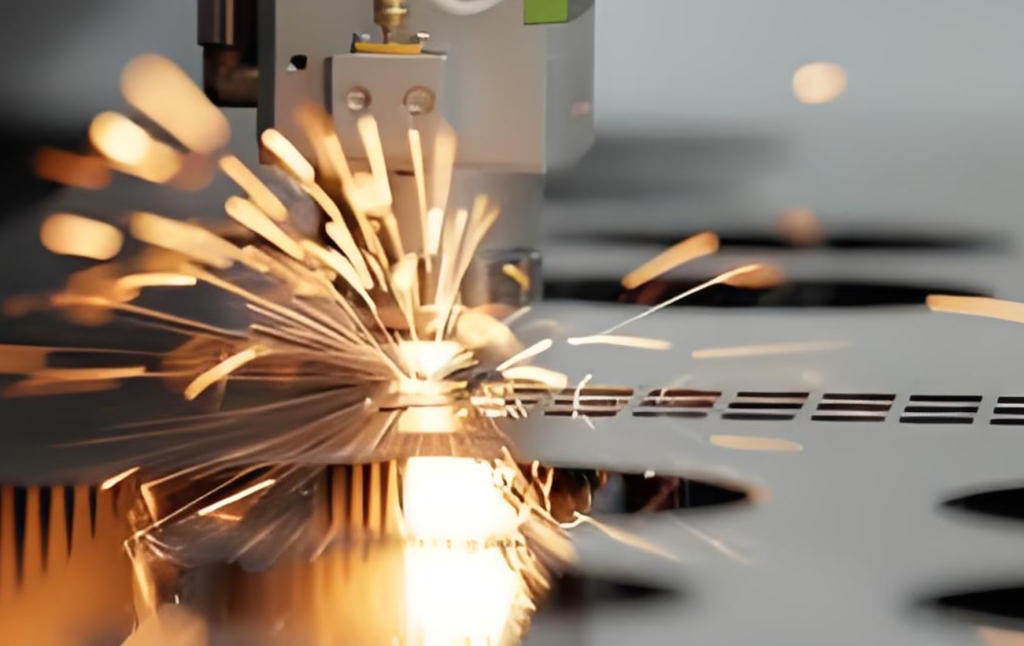

As their name suggests, thermal methods of cutting metal make use of heat to cut metal. Heat is used to make the metal melt so it can be shaped accordingly. Lasers are the most commonly used form of thermal metal cutting methods. Laser employs a powerful beam of light that directs heat to a targeted area for an accurate outcome.

How Do Lasers Cut Through Metal?

Laser is an acronym for ‘light amplification by stimulated emission of radiation’. In other words, lasers use energy, usually electricity, and convert it into light and heat energy that is emitted in a targeted manner for maximum impact. Lasers cut through metal using intense heat to heat the metal so it can be removed easily. Most laser cutters used for cutting metal use gas jets to get rid of the removed material to get a clean finish.

CNC (computer numerical control) laser cutting machines are utilized in most industries. CNC machining combines the automation and precision of computers with the power and efficiency of lasers for quality results.

Metals Suitable for Laser Cutting

Laser cutting sounds like the best way to cut metal due to its accuracy and swiftness. However, the suitability of laser cutting metal depends heavily on the type of metal that needs to be cut. Lasers are perfect for cutting metal with low reflectivity such as stainless steel, titanium, and carbon steel.

Metals with high reflectivity, on the other hand, are not suited for laser cutting. Metals like aluminum, brass, and copper are not suitable for laser cutting. The high reflectivity of polished metals causes the light of the laser to be reflected back to the machine emitting the laser. This may lead to the machine being overheated and damaged. CNC laser cutting machines may overheat and fail to work properly when cutting high reflectivity metals.

Types of Laser Cutting

Different types of lasers can be used for cutting. Some are more appropriate than others for cutting metals. These include the following:

Fiber Laser

Fiber lasers make use of fiber optic cables to generate power. Developed in 2008, the fiber laser makes use of the latest technology to achieve a cost-effective and efficient outcome. Fiber lasers are suitable for cutting through a wide variety of materials, even highly reflective metals.

CO2 Laser

True to its name, CO2 lasers use carbon dioxide to produce a laser beam. This type of laser is inefficient as most of its energy gets turned into waste. This is why CO2 laser is primarily used for non-metallic materials, though it can also cut through metal.

YAG Laser

Also known as crystal cutting, makes use of a crystal, yttrium aluminum garnet (YAG), to cut any material with great precision. YAG lasers are solid-state lasers. CNC cutting mostly involves either fiber lasers or YAG lasers.

Advantages of Using Lasers to Cut Metals

Here are some reasons why lasers are most appropriate for cutting through metals:

Accuracy

Lasers are very precise. The beam of light emitted is very fine and precise, making lasers perfect for cutting intricate patterns or making minute holes. CNC machining increases this accuracy by automating the controls.

Flexibility

Lasers can cut any kind of shape and perform well on a large number of materials. From straight lines or curves to more elaborate designs, lasers can cut any kind of shape.

Reduced Waste

Precision in cutting means there is very little waste. Lasers heat a very targeted area, preserving the integrity of the rest of the material that is being cut.

Easy Upkeep

CNC laser cutting machines require minimal maintenance. Regular maintenance and timely repairs keep the machine in good working condition for an extended period.

Operational Safety

Operating lasers is safe and practically hazard-free. CNC cutting, specifically, prevents any kind of human contact with the laser or the material being cut. Laser machines are safe to operate.

Limitations of Using Lasers to Cut Metals

Despite their advantages, laser cutting machines are not entirely flawless. Here are some limitations of CNC laser cutting machines:

Performance variations depending on the material

Results of laser cutting depend heavily on the type and thickness of the material being cut. Lasers, for example, are not the best choice for cutting metals that reflect light.

High equipment and operational cost

Lasers are constantly improving, incorporating recent advancements in technologies. This, however, means that existing lasers become obsolete quite quickly and newly developed ones are too expensive. Getting the most up-to-date version is costly and training individuals to operate the new machine also requires additional investment.

High energy consumption

Lasers use a lot of energy. They convert electrical energy into light and heat energy. The stronger the lasers, the more energy it will require to operate, driving up the energy costs.

Cutting Metal Using Lasers

Lasers are among the top ways to cut metal. Lasers are easy to operate, efficient, versatile, and accurate. Yes, lasers have their limitations, however, even with all the limitations, lasers provide the best solution to cutting metal. Lasers have become indispensable in industrial settings where cutting metal is common.