Precision Aluminum Casting Services

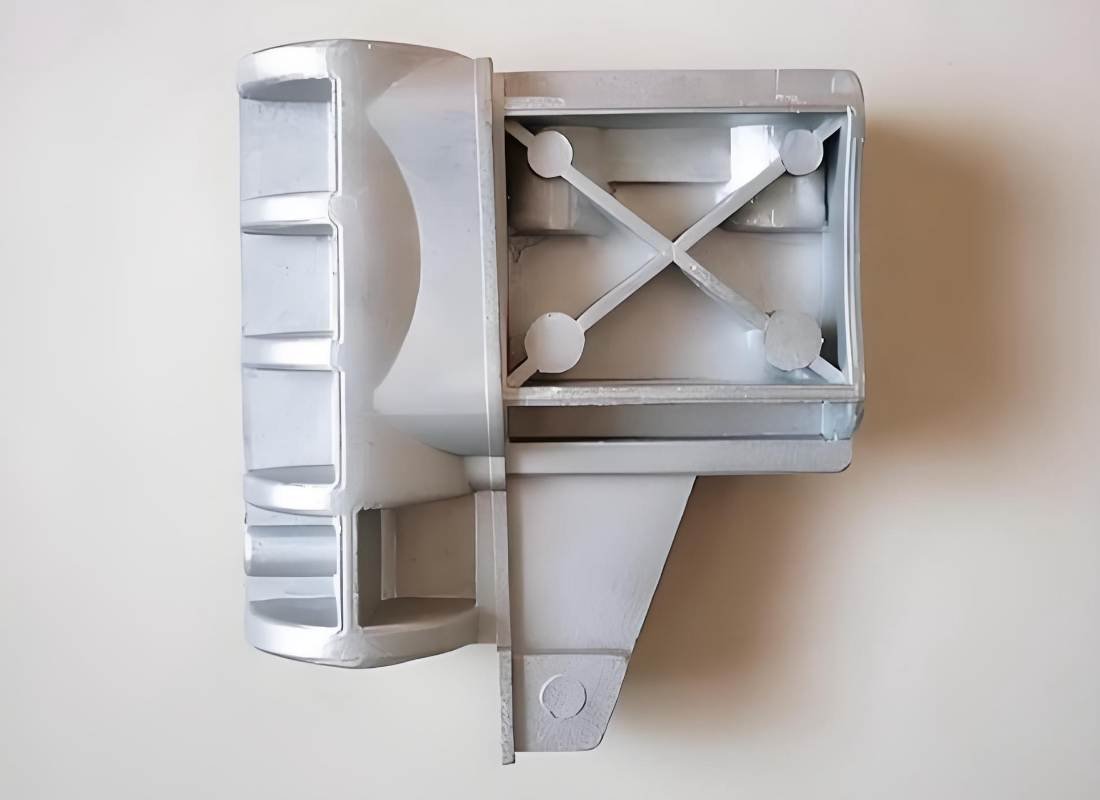

Fecision’s comprehensive aluminum casting services deliver precision-engineered parts that combine lightweight durability with exceptional performance across diverse applications.

Whether you need high-volume production runs or custom prototype development, our expert team provides tailored services to meet your exact specifications.

Durable

Precise

Lightweight

What is Aluminum Casting?

Aluminum casting leverages the unique properties of aluminum—lightweight, corrosion resistance, good thermal and electrical conductivity, and strength-to-weight ratio—to produce components for a wide range of applications.

It is a manufacturing process where molten aluminum is poured into a cavity or mold to create a desired shape. The process transforms liquid aluminum directly into finished or semi-finished products with complex geometries that would be difficult or impossible to achieve through other manufacturing methods.

The aluminum used in casting typically refers to various alloys rather than pure aluminum. These alloys contain elements like silicon, magnesium, and copper that enhance specific properties such as strength, corrosion resistance, and castability. With a relatively low melting point of 1215°F (657°C), aluminum alloys flow easily when molten and solidify to form strong, lightweight components with excellent dimensional accuracy.

Depending on the process, the casting may undergo various finishing operations to achieve the final dimensions, surface quality, and mechanical properties required.

Different Types of Aluminum Casting Processes

Various aluminum casting processes offer different advantages depending on part complexity, production volume, and quality requirements.

Die Casting

Molten aluminum is forced into steel molds under high pressure, producing parts with excellent dimensional accuracy and surface finish.

- High production rates

- Excellent dimensional accuracy

- Smooth surface finish

- Complex shapes with thin walls

Sand Casting

Molten aluminum is poured into sand molds, offering a cost-effective solution for large components and low to medium production volumes.

- Low tooling costs

- Suitable for large parts

- Versatile for complex shapes

- Ideal for prototypes and small runs

Investment Casting

A precision process where molten aluminum is poured into ceramic molds created from wax patterns, producing complex parts with fine details.

- Exceptional dimensional accuracy

- Fine surface finish

- Complex geometries possible

- Minimal post-processing required

Dimensions and Tolerances for Aluminum Casting Services

Our aluminum casting capabilities accommodate a wide range of part sizes and precision requirements.

The following specifications outline our standard capabilities, though custom solutions are available for specialized needs.

| Process | Part Size Range | Typical Tolerances | Minimum Wall Thickness | Surface Finish |

| Die Casting | 0.5 oz-75 lbs | ±0.002″ per inch | 0.020″ (0.5mm) | 63-125 RMS |

| Investment Casting | 0.1 oz-50 lbs | ±0.005″ per inch | 0.030″ (0.8mm) | 125-250 RMS |

| Sand Casting | 1 lb-500+ lbs | ±0.030″ per inch | 0.187″ (4.8mm) | 250-500 RMS |

Note

Tolerances for aluminum casting may vary based on specific part geometry, alloy selection, and process parameters. Our engineering team will work with you to determine the optimal specifications for your application.

Need Aluminum Casting Services?

Not sure which aluminum casting process is right for your project?

Benefits of Aluminum Die Casting

Aluminum Die Casting for Precision Applications

Among the various aluminum casting processes, die casting stands out for its ability to produce high-precision, complex components with exceptional consistency and efficiency. This process is particularly valuable for applications requiring tight tolerances, thin walls, and superior surface finishes.

Dimensional Accuracy

Tolerances as tight as ±0.002 inches (0.05mm) for precise fit and function

Complex Geometries

Ability to produce intricate shapes with undercuts, thin walls, and detailed features

Superior Surface Finish

Tolerances as tight as ±0.002 inches (0.05mm) for precise fit and function

High Production Rates

Fast cycle times for cost-effective high-volume manufacturing

Corrosion Resistance

Natural resistance to environmental degradation

Cost-Effectiveness

Reduced material waste and minimal finishing requirements

Thermal and Electrical Conductivity

Excellent heat dissipation and electrical properties

Excellent Strength-to-Weight Ratio

Ability to produce lightweight yet durable components

Our Precision Die Casting Capabilities

50-1200

Tons of clamping force

Range of our die casting machines

±0.001"

Tightest tolerance achievable

For critical dimensional features

0.8mm

Minimum wall thickness

Depending on part geometry

50-1200

Surface finish capability

As-cast Ra value achievable

The Die Casting Process

Die casting involves injecting molten aluminum under high pressure into a steel mold cavity. The process follows several key steps.

This highly automated process enables rapid production cycles, typically ranging from a few seconds to a few minutes per part, making it ideal for high-volume manufacturing requirements.

The die casting mold is prepared and treated with lubricant

Molten aluminum is maintained at optimal temperature (typically 1300-1400°F)

The aluminum is injected into the die at pressures between 1,000 and 25,000 psi

The metal solidifies rapidly under pressure, ensuring excellent density

The die opens and the finished part is ejected

Any excess material (flash) is trimmed and the part undergoes finishing operations

Post-Processing Services in Aluminum Casting

Our comprehensive post-processing capabilities transform raw aluminum castings into finished components ready for your application. These secondary operations enhance performance, appearance, and functionality.

CNC milling and turning

Drilling and tapping

Reaming and boring

Precision grinding

Anodizing (Type I, II, and III)

Powder coating

Painting and e-coating

Chromate conversion

Deburring and deflashing

Polishing and buffing

Shot blasting and peening

Tumbling and vibratory finishing

Solution heat treatment

Artificial aging

Stress relief

Annealing

Insert installation

Component assembly

Welding and joining

Hardware installation

Dimensional verification

Non-destructive testing

Material certification

Functional testing

Industries We Serve

Customized Aluminum Castings for Unique Applications

Our expertise extends beyond standard aluminum casting services to include specialized solutions for unique and challenging applications. We work closely with clients across diverse industries to develop custom casting solutions that meet specific performance requirements.

Automotive & Transportation

Aerospace & Defense

Medical Equipment

Industrial Machinery

Consumer Products

Energy & Utilities

FAQs About Aluminum Casting

Aluminum casting offers several advantages over other manufacturing methods, including the ability to create complex geometries that would be difficult or impossible to machine, cost-effective production for medium to high volumes, excellent dimensional accuracy, and the ability to incorporate internal features without additional assembly. Additionally, casting allows for the optimization of material properties through alloy selection and heat treatment.

The optimal casting process depends on several factors including production volume, part complexity, dimensional requirements, surface finish needs, and budget constraints. Die casting is typically best for high-volume production of complex parts with tight tolerances. Investment casting excels at producing intricate components with excellent surface finishes. Sand casting is ideal for larger components and lower production volumes. Our engineering team can help determine the most appropriate process for your specific application.

Common aluminum casting alloys include:

- A356/A357 (AlSi7Mg): Excellent castability and good mechanical properties, widely used in aerospace and automotive applications

- A380 (AlSi8Cu3): Good castability and machinability, commonly used for die casting

- 319 (AlSi5Cu3): Good castability and moderate strength, used for automotive components

- 535 (AlMg7): Excellent corrosion resistance, used for marine applications

- 713 (AlZn8Cu): High strength and hardness, used for high-stress applications

The selection depends on your specific requirements for strength, corrosion resistance, thermal properties, and other performance characteristics.

Lead times vary based on the casting process, part complexity, and production volume:

- Tooling development: 2-8 weeks depending on complexity

- First article samples: 1-3 weeks after tooling completion

- Production runs: 2-6 weeks after sample approval

Expedited services are available for time-sensitive projects. Please contact us to discuss your specific timeline requirements.

Aluminum castings offer excellent durability for their weight. When properly designed and manufactured, cast aluminum components can provide decades of reliable service. The specific durability depends on the alloy selection, casting process, heat treatment, and application environment. Aluminum castings naturally resist corrosion through the formation of a protective oxide layer, and certain alloys can be heat-treated to significantly enhance strength and wear resistance.

Yes, aluminum castings are 100% recyclable without any loss of properties. Recycling aluminum requires only about 5% of the energy needed to produce primary aluminum from bauxite ore. Our manufacturing processes incorporate sustainable practices, including the use of recycled aluminum when appropriate for the application, and the recycling of all scrap material generated during production.

Get Started with Our Aluminum Casting Services

Ready to bring your aluminum casting project to life?

Our team of experts is prepared to help you develop the optimal casting solution for your specific requirements.

Ready to Discuss Your Custom Aluminum Casting Project?

Our engineering team is prepared to help you develop the perfect aluminum casting solution for your unique application.