Have you ever wondered why some silicone materials are marked as “platinum grade” while others are labeled “medical grade”? Both types are used in high-precision applications, but the differences between them can impact their performance and suitability for specific uses.

With the global silicone market expected to reach over $23 billion by 2026, understanding these distinctions is more important than ever.

So, let’s dive right in and learn about platinum grade silicone and medical grade silicone.

What is Platinum Grade Silicone?

Platinum grade silicone is a high-quality form of silicone that is made using platinum as the catalyst during its curing process. This method ensures that the silicone is extremely pure and highly stable, making it ideal for demanding applications.

The platinum curing process eliminates impurities and provides a material that is non-toxic, durable, and resistant to heat, cold, and environmental factors.

Common Uses of Platinum Grade Silicone

Platinum grade silicone is commonly used in medical devices, food-grade products, baby products, and high-performance seals because of its superior safety and reliability. It is known for being hypoallergenic, which makes it a preferred choice in sensitive applications such as implants, prosthetics, and kitchenware.

What is Medical Grade Silicone?

Medical-grade silicone is a specially formulated type of silicone designed for use in healthcare and medical applications. It is known for being biocompatible, which means it can safely interact with the human body without causing irritation or harmful reactions.

There are different classifications of medical-grade silicone for molding:

- Medical grade (non-implantable): For external medical devices like masks and tubing.

- Implantable grade: Approved for long-term use inside the body, such as breast implants or heart valves.

Before it is used, medical grade silicone must meet strict GMP (Good Manufacturing Practice) standards and regulatory approvals, such as those from the FDA or ISO 10993.

Common Applications of Medical Grade Silicone

This type of silicone is often used in products like implants, catheters, tubing, baby care items, and wound dressings. It is non-toxic, hypoallergenic, and resistant to bacteria, making it ideal for sensitive or internal use.

Medical-grade silicone is also highly durable. It can withstand sterilization methods like autoclaving or radiation, which is essential in hospitals and medical manufacturing.

Comparison of Properties: Platinum vs. Medical-Grade Silicone

When selecting the right silicone for medical or high-performance applications, understanding the nuances between them is important. Below are the key properties to help you choose the right one:

1. Purity and Contamination Resistance

Platinum grade silicone is renowned for its ultra-high purity. Cured using a platinum catalyst, it eliminates residual byproducts, which ensures minimal extractables and leachables. This makes it ideal for applications requiring the highest level of cleanliness.

On the other hand, medical-grade silicone may also offer high purity but is cured using either platinum or peroxide systems. Peroxide-cured variants can leave behind residual compounds, necessitating additional post-curing processes to reduce potential contaminants.

However, even though medical grade silicone is suitable for many healthcare applications, it does not match the ultra-pure standards of platinum grade silicone.

2. Durability

When it comes to durability, platinum grade silicone once again takes the lead due to its long-term stability in the most rigorous applications.

Medical-grade silicone offers durability and can withstand repeated sterilization methods, including autoclaving and gamma irradiation. However, its long-term stability may vary depending on the curing process used.

The platinum grade silicone, on the contrary, also exhibits exceptional durability, maintaining its mechanical properties over extended periods. Its resistance to environmental factors like UV radiation, ozone, and extreme temperatures ensures better durability than medical-grade one.

3. Biocompatibility

Biocompatibility is essential for materials intended for medical use, and both platinum-grade and medical-grade silicones meet this criterion.

Platinum-grade silicone offers excellent biocompatibility, making it suitable for long-term implantation and direct contact with bodily tissues and fluids. Its inert nature helps minimize the risk of adverse reactions.

Similarly, medical-grade silicone is designed to be biocompatible and is widely used in medical devices such as catheters, tubing, and wound dressings. It undergoes rigorous testing to ensure it is safe for short- to medium-term contact with the human body.

4. Flexibility and Transparency

Flexibility and transparency are important for applications that require material adaptability and visual monitoring. On one end, the medical grade silicone provides good flexibility and can be formulated to achieve varying degrees of softness or firmness as needed.

However, on the other end, platinum grade silicone is highly flexible and maintains its elasticity over a wide temperature range. It also offers superior optical clarity, making it ideal for applications requiring visual monitoring where transparency is crucial.

While even if medical grade silicone is quite transparent, it does not match the level of clarity offered by platinum grade one. This is why the latter is mostly used in applications where visual inspection is essential.

Why Medical Grade and Platinum Grade Silicone Matter in Injection Molding

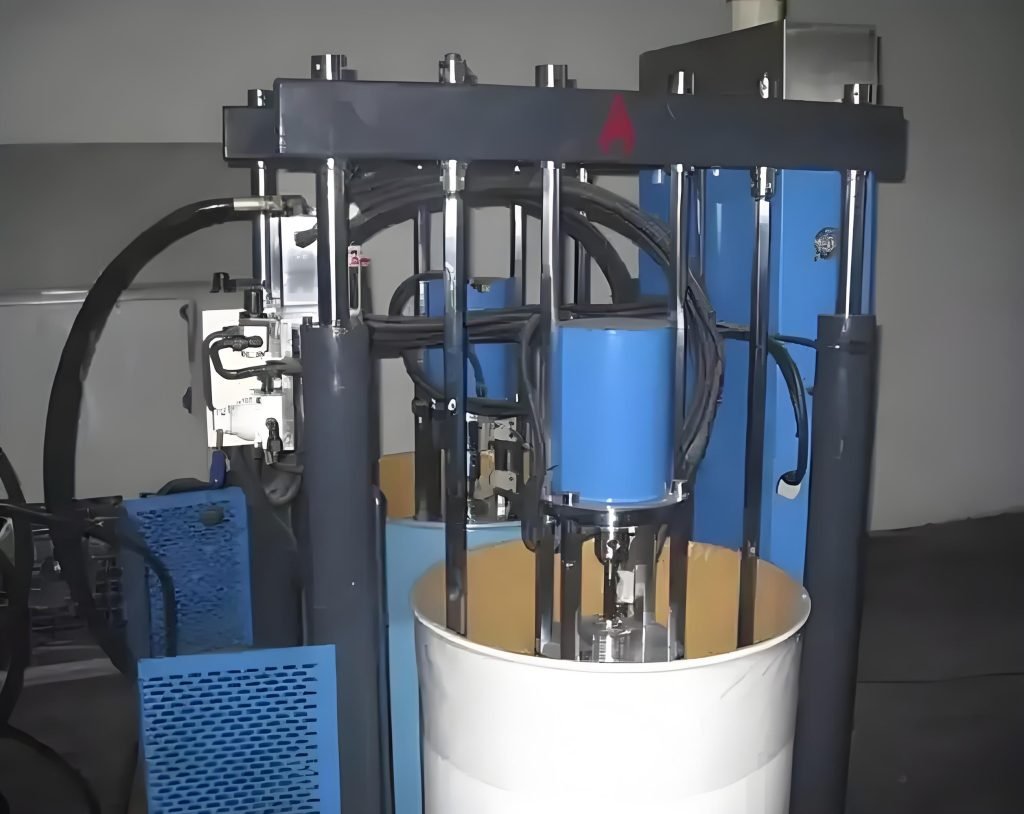

When it comes to medical silicone injection molding, the choice of material plays a huge role in ensuring product safety and durability. Both medical-grade and platinum-grade silicone are widely used in this industry, but they serve slightly different needs.

Medical grade silicone is specifically formulated and tested to meet strict biocompatibility standards such as USP Class VI and ISO 10993. It is ideal for medical products like tubing, catheters, and external-use devices.

Platinum grade silicone, on the other hand, represents the highest purity available. It is platinum-cured, meaning it has no byproducts, offers excellent stability, and resists yellowing or chemical leaching. This makes it perfect for highly sensitive applications, such as implants, surgical tools, and more.

In injection molding, using these grades ensures that molded parts meet the demanding requirements of the healthcare industry. Whether it’s producing tight-tolerance components or complex geometries, both types offer outstanding processing capacity, strength, and reliability during molding.

Why Choose One Over the Other in Injection Molding?

When it comes to injection molding, platinum grade silicone is often chosen for applications that require the highest purity, flexibility, and compatibility. For example, medical devices, baby products, and food contact parts. Its platinum curing process ensures minimal contamination.

Medical grade silicone, while also safe and effective, might be preferred for less demanding medical grade silicone injection molding projects where slight differences in purity or mechanical properties are acceptable. It offers a reliable and cost-effective option for many general healthcare and industrial uses.

Trust Fecision for Expert Solutions

Choosing between platinum grade silicone and medical grade silicone ultimately depends on your product’s specific needs. At the end of the day, the quality of parts also heavily relies on the expertise behind the mold tooling and production process.

That’s where Fecision steps in. With our advanced mold tooling, precision CNC machining, and expert molding services, we help you bring even the most demanding silicone projects to life.