Have you ever picked up a plastic bottle and thought about how that perfect hollow cavity in the middle was created? Or, have you thought about the cool patterns of a phone case design with all the nooks and crannies? Almost everything we use in modern life is made or shaped from some form of plastic, but what you likely never realized is that there could be amazing heroes behind the magical process, especially in injection molding.

Today, we are going to dive in and learn about core pins in injection molding – what is a core pin, how mold core pins work in injection molding, what they are made of, and why they are important mold components of injection molding. We guarantee that by the end of the article, you will have a better appreciation of these little shapers!

What Are Core Pins in Injection Molding?

What are core pins injection molding? Let’s break down core pin definition. Imagine you are working with LEGOs. The big blocks are going to form the whole structure. But smaller, defined mold parts are going to make the hollows, the openings, and all the cool designs inside of the item in injection molding.

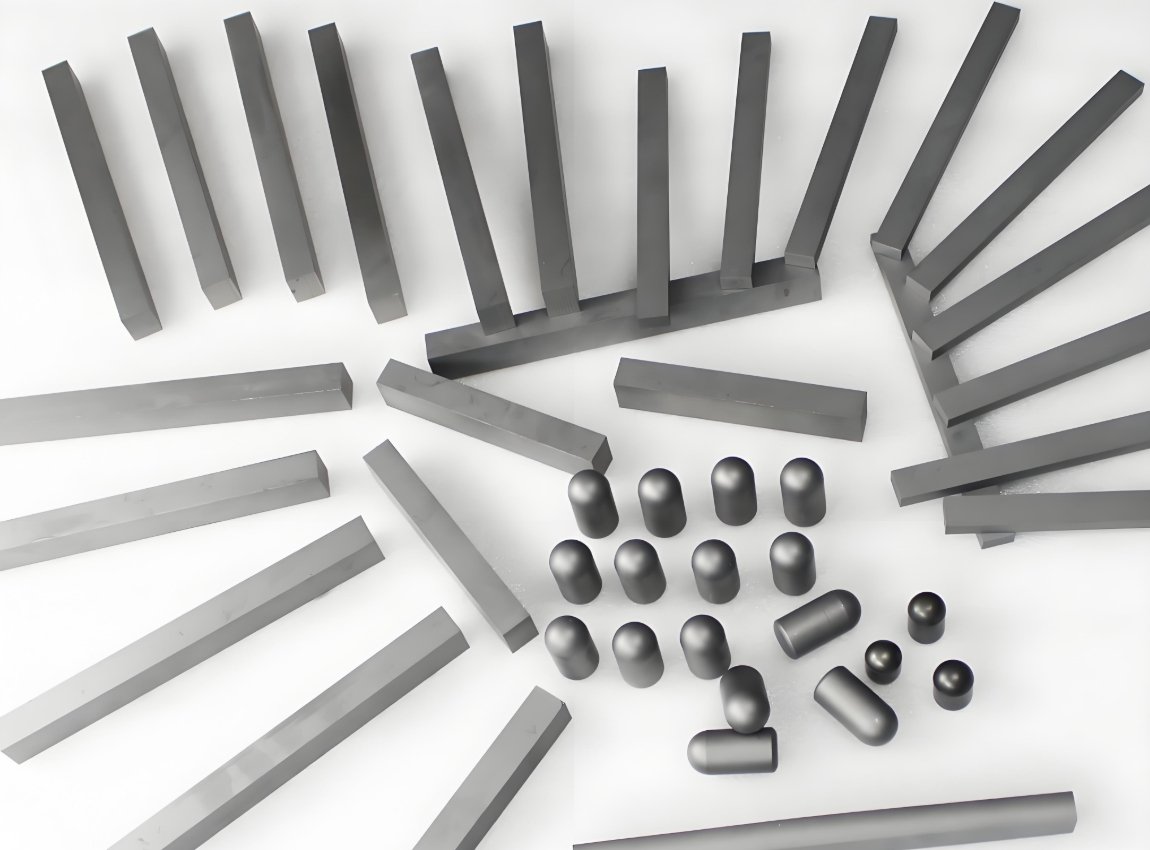

To put it simply, core pins are small, cylindrical mold components used in injection molding. Their job is to create internal features like holes, slots, and other detailed shapes. Think of them as tiny sculptors. They carve out the space inside a mold, allowing molten plastic to flow around them and form the desired shape.

Now, why are these little guys so important? Well, without core pin injection molding, a huge chunk of the products we rely on wouldn’t be possible. Think about it:

- How would you have a hollow plastic bottle to drink from?

- How would the screw holes in your furniture line up perfectly?

- How would medical devices have those precise internal channels for fluids?

Core pins are the key to achieving this precision and functionality. They allow manufacturers to create mold components that aren’t just solid chunks of plastic but have the necessary internal architecture to perform their intended tasks. They’re the silent enablers of so much of modern manufacturing!

How Does a Core Pin Work Within a Mold?

Let’s take a look at the injection molding machine to see how core pins work. Think about it: You have a mold, which is a large metal cookie cutter with precise tolerances. Molds usually consist of two halves that are clamped together. The core pin is installed and secured in one (or both) of the mold halves before injections begin. Once the mold is closed, the hot molten plastic is injected into the cavity at high pressure.

The core pin is now acting as a solid body in the path of the moving plastic. While the plastic is injected, it must flow around the core pin and fill all the other areas of the mold cavity. However, it is not as simple as just putting a pin into the mold and proceeding with the injection. Core pins are required to meet some strict requirements to perform correctly. Here are a few technical requirements:

- Material Matters: Core pins are usually made from high-strength steels or tungsten carbide. These materials are chosen because they can meet the challenges of the injection process and not bend under pressure and heat.

- Tolerance Talk: Core pins have tolerances around ±0.02mm (smaller than the width of a human hair). You should make sure that they fit perfectly into the mold and create features with minimum defects.

- Smooth Operator: The surface finish of a core pin can be one of the smoothest surfaces you’ll come across, polished to a nice smoothness (Ra 0.2-0.8 micrometers). This helps the plastic flow smoothly around the pin as well as generate a mold part that releases well from the mold without sticking to it.

- Heat It Up (Sometimes): To add even more toughness and wear resistance, core pins can also be heat treated to harden the steel. You can effectively harden the overall core pin so that it lasts longer and maintains its shape better under whatever harsh conditions it faces.

So what is the big deal with all this precision? Well, precision with core pins is critical for:

- Fewer Defects: When core pins are exact, you can expect lower quantities of warped or distorted mold parts.

- Longer Mold Life: Properly designed and positioned core pins will reduce the stress on the mold itself, leading to a longer life.

- Higher Quality Product: At the end of the day, if the core pins are made accurately, you will receive products that meet the specifications and are going to perform correctly.

Materials Used for Core Pins

As we mentioned before, core pins must be tough enough to withstand the operating conditions inside an injection mold. Let’s break down some of the most commonly found core pin material:

Steel: The Strong and Reliable Choice

Steel is the most commonly used material for core pins. It is a very strong, durable material and can be hardened to an even greater degree when heat-treated. The most commonly used type of steel is H13 tool steel. H13 is very popular for its toughness and its ability to resist thermal fatigue. Toughness is an important consideration when dealing with plastic that is constantly being melted at high temperatures.

Stainless Steel: The Corrosion Crusader

If your core pins are operating in environments and processes that operate at high humidity, or if your core pins are in contact with certain plastisols that can corrode and deteriorate the core pins, make sure they are stainless steel. Stainless steel is more resistant to corrosion, especially in high-humidity processes, and does not deteriorate as fast; therefore, the amount of time your core pins are in use will be reduced. This provides you with longer life and more consistent quality for mold parts.

Copper: The Cool Performer

Copper (or copper alloys) can be effectively used in core pins if there is a strong need for thermal conductivity. Copper is the best thermal conductor of all metals, which can assist with quicker cooling of the plastic in the mold. A quicker cooling time can be a time efficiency in cycles, thus potentially increasing production rates.

So how do you determine what the right core pin material is? It comes down to a few factors:

- Hardness: Hardness refers to how long the pin will last until it gets worn out. You would like to have something that can be used repeatedly before having to replace it.

- Thermal Conductivity: Thermal conductivity is needed to dissipate heat in the molding process. Air and some materials will cool the plastic faster. This can help more quickly with cycle times.

- Surface Finish: Surface finish impacts how well the plastic flows and how well the mold parts can be ejected. The smoother the surface finish, the better the release and the fewer defects.

Main Applications of Core Pins

Now, let’s look at some of the industries with core pins. Core pins are used in so many different industries. Here are some examples:

- Automotive: Whether it is the holes for buttons and switches on the dashboard of your car, internal channels in fluid containers, or unique shapes of modish interior trim components, core pins do it all.

- Aerospace: Strong, lightweight plastic mold components with complex internal structures for fuel efficiency and safety purposes are commonly molded with core pins.

- Medical Devices: The internal lumens in a syringe, complex housings for diagnostic equipment, or components of drug delivery systems could not exist without the precision of core pins.

- Consumer Electronics: The cutouts for memory cards and SIM trays in your phone, or the openings for buttons and speakers, or the supports for brackets in electronic housings—core pins do that.

- Packaging: Think of the hollow necks of bottles, spouts on containers, and internal features that ensure that the caps get screwed on securely; core pins do that.

So, whether it is the device in your hands, the car you drive, or medical devices that save lives, core pins have more than likely played an important role in providing you those molds. Core pins are the unsung heroes of many industries!

Custom Core Pins vs. Standard Options in Injection Molding

When it comes to core pins, you generally have two options: standard core pins or custom core pin design. Let’s dive into some detail.

| Feature | Standard Core Pins | Custom Core Pins |

| Pros | • Cost-effective for simpler applications and initial setups. | • Customized to your specifications, it gives a perfect fit and higher performance for your specific mold part design. |

| • Available in standard shapes and a range of standard sizes, it allows you to source more quickly for conventional requirements. | • You can use precision and advanced materials and optimize the materials for application needs like wear resistance, thermal conductivity, or chemical and corrosion resistance for a specific plastic type. | |

| • Quick to obtain, which can be advantageous for rapid prototyping or when facing tight project timelines with standard part features. | • Can effectively handle more complex part geometries, intricate internal features, and challenging unique designs that standard options cannot accommodate. | |

| Cons | • Limited customization could mean you have to compromise your original design or lower efficiency for a unique mold need. | • There is an increased up-front cost, as there are costs associated with the customized design, engineering, and manufacturing process to develop a pin for your exact requirement. |

| • Core pins may not perfectly fit every unique or complicated mold and may lead to dimensional variation or secondary adjustments required. | • Longer lead times are typically required for the design, material sourcing (if specialized), and manufacturing of custom core pins |

So, when should you choose custom core pins? The decision boils down to the specific requirements of your project. Consider going with custom core pins if:

- Your part design involves high precision and tight tolerances.

- You need to create unique or complex internal geometries that standard pins can’t handle.

- Your application demands specific material properties for durability or performance.

- In the long run, the value of better quality, reduced downtime, and less rejected work outweighs the initial cost.

Standard core pins can be an acceptable option for standard applications as long as applications are not too demanding; however, custom core pins offer an added level of precision and design flexibility that can benefit the success of demanding applications. The comparison is similar to off-the-shelf suits versus custom suits. Both will do the job, but the custom suit will fit better and perform better over time.

Best Custom Core Pin Manufacturer

Now comes the important part of choosing the right core pin manufacturer. You need someone who has a broad understanding of precision engineering and provides excellent quality and support. That is where Fecision comes in.

Fecision: Your Precision Partner in Custom Core Pins

At Fecision, we understand that the heart of exceptional injection molding lies in the precise execution of every mold component– and core pins are no exception. We’re not just a supplier; we’re your dedicated partner in crafting top-tier custom core pins that elevate your molding process. Here are the reasons Fecision should be your preferred vendor:

- Precision: Fecision employs a broad range of advanced manufacturing techniques, including CNC machining and EDM.

- Quality Materials: From high-strength steel to specialized alloys, Fecision chooses the best materials for your needs. No compromises here!

- Customization: Need something unique? Fecision can create custom core pins tailored to your mold design. They’ll work with you to make sure everything is just right.

- Support: Fecision doesn’t just sell you a product and disappear. We provide design feedback and support throughout the process. We are here to help you attain the best results.

Thus, if your injection molding applications require precision-engineered custom core pins that can handle complex geometries and provide consistent and high-quality results, consider Fecision’s line of molding components. By visiting our website or speaking to our informative staff, you could unlock the full potential of your manufacturing process. We can be your trusted partner for molding success!