Custom Aluminum Metal Stamping Services

Aluminum metal stamping transforms sheet metal into precise components through specialized forming techniques. This versatile fabrication process creates durable, lightweight parts essential across multiple industries.

At Fecision, we combine advanced technology with metallurgical expertise to deliver custom aluminum stamped parts that meet exacting specifications while maintaining cost efficiency.

Durable

Impact-resistant

Machinable

Aluminum Stamping at Fecision

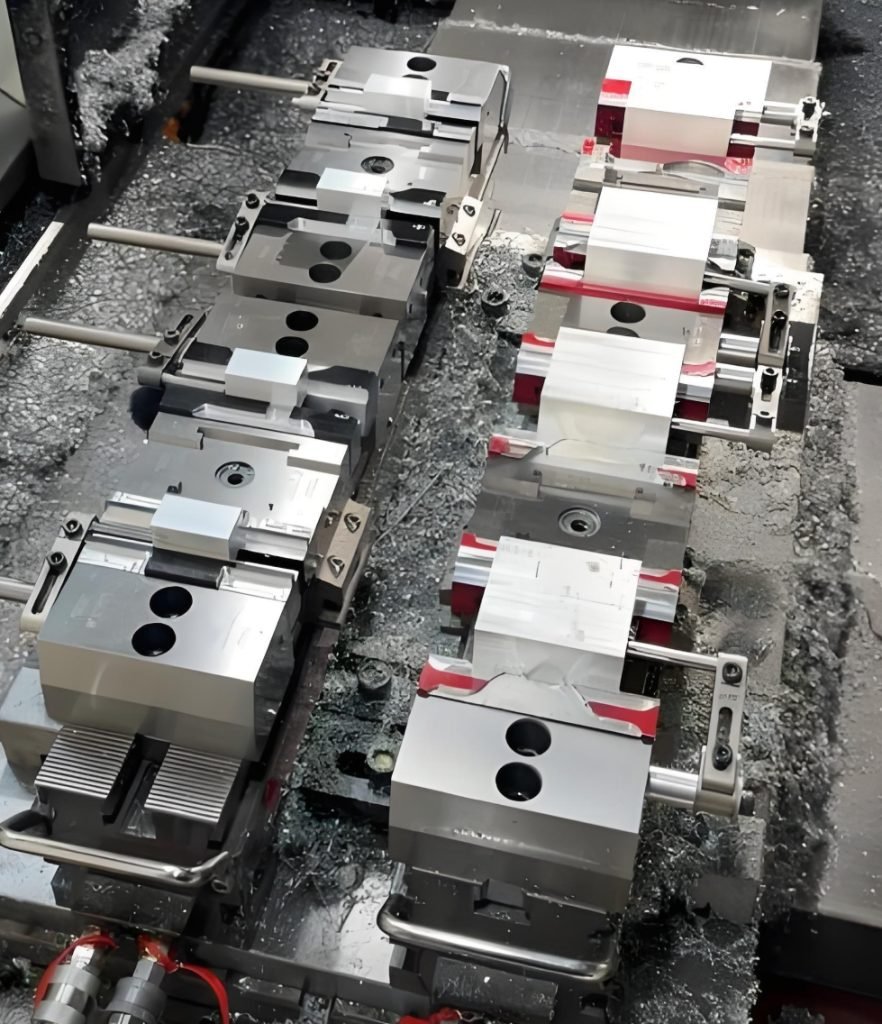

Fecision specializes in precision aluminum metal stamping services tailored to diverse manufacturing needs. Our state-of-the-art facility houses advanced stamping equipment capable of handling projects from prototype development to high-volume production runs.

Our engineering team works closely with clients to develop custom aluminum stamping solutions that optimize both performance and production efficiency.

Using advanced progressive die technology and precision tooling, we maintain tight tolerances across production runs.

Whether you need small batch prototypes or high-volume production, our aluminum metal stamping capabilities scale to meet your requirements.

Advantages of Aluminum

Why Use Aluminum for Progressive Stamping

Aluminum offers unique advantages that make it ideal for progressive stamping applications across numerous industries.

- Exceptional strength-to-weight ratio (up to 3x lighter than steel)

- Natural corrosion resistance through oxide layer formation

- Excellent thermal and electrical conductivity

- Superior formability and workability

- 100% recyclable with minimal quality degradation

- Non-magnetic and non-sparking properties

- Maintains strength in low-temperature environments

For applications requiring lightweight, corrosion-resistant components with good conductivity, aluminum metal stamping provides an optimal balance of performance and cost-efficiency.

Limitations to Consider

Lower tensile strength compared to steel

Higher material cost than some alternatives

More challenging welding requirements

Potential for springback during forming

Some alloys are not heat-treatable

Commonly Used Aluminum Alloys for Metal Stamping

Each alloy offers specific properties that make it suitable for different applications and forming requirements.

| Alloy | Key Properties | Formability | Common Applications |

| 1100 | 99% pure aluminum, excellent corrosion resistance, high thermal conductivity | Excellent – highly ductile | Decorative parts, cookware, chemical equipment, heat exchangers |

| 3003 | Manganese-alloyed, moderate strength, good workability | Very good | Kitchen equipment, storage tanks, general sheet metal work |

| 5052 | Magnesium-alloyed, high fatigue strength, excellent corrosion resistance | Good | Marine components, appliance parts, electronic chassis |

| 6061 | Heat-treatable, good weldability, moderate strength | Moderate | Structural components, automotive parts, aerospace applications |

Aluminum Metal Stamping Process

The aluminum metal stamping process involves several precise steps to transform raw sheet metal into finished components.

Design & Engineering

Our team creates detailed CAD models and simulations to optimize part design for manufacturability and performance.

Forming Operations

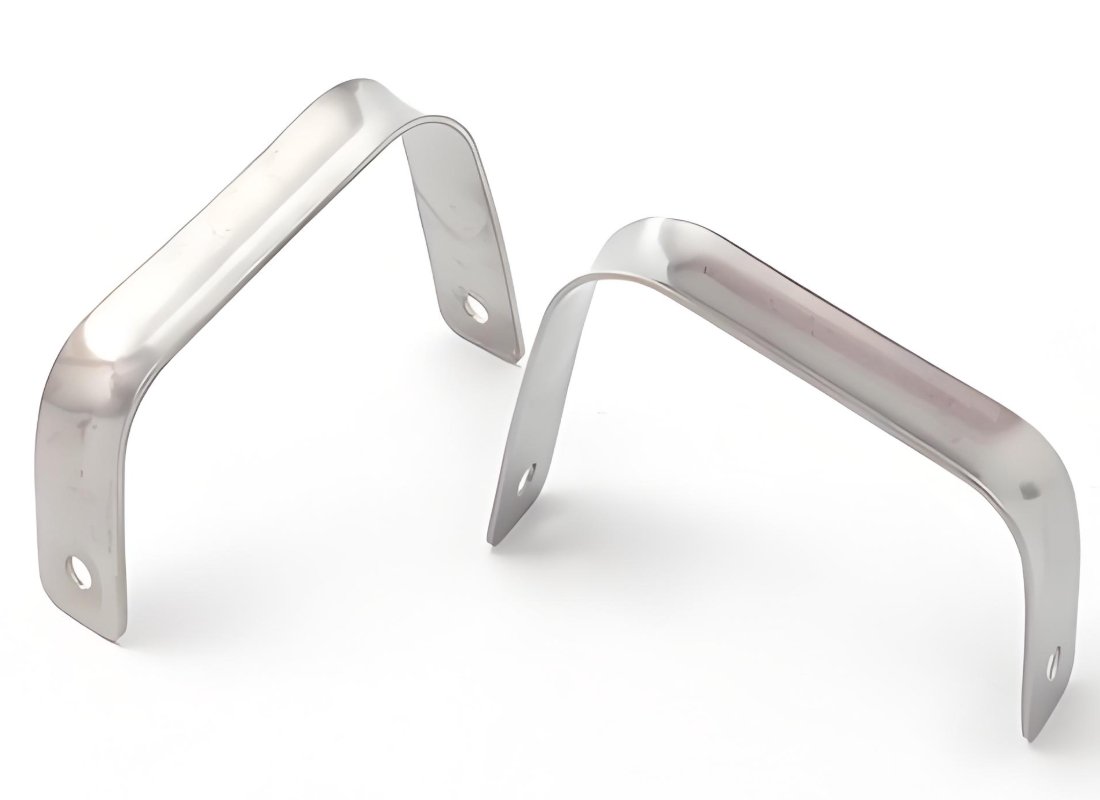

The blank undergoes various operations including bending, drawing, embossing, or coining to create the desired shape.

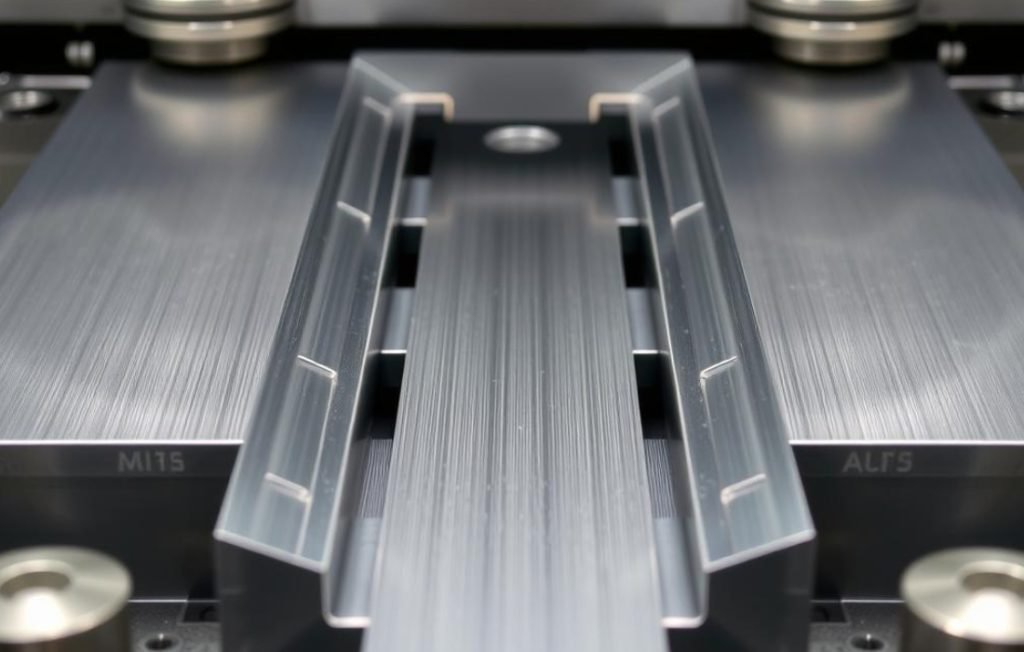

Tooling Development

Custom dies and tooling are precision-machined to exact specifications, ensuring consistent part quality.

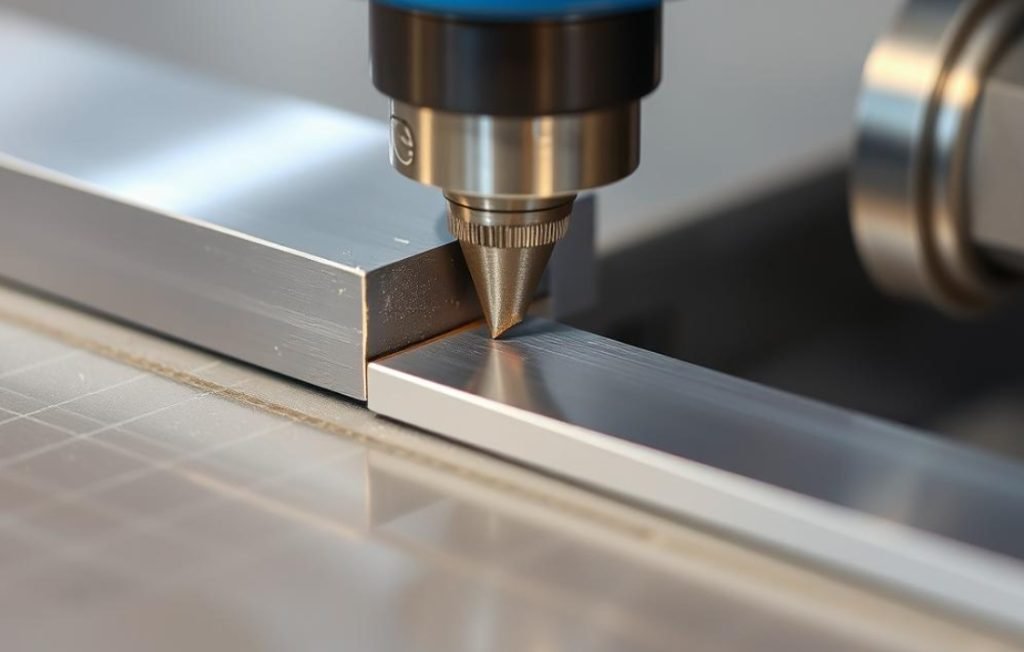

Piercing & Cutting

Holes, slots, and other features are added through precision cutting operations.

Material Selection

The appropriate aluminum alloy is selected based on application requirements and forming characteristics.

Quality Inspection

Parts undergo dimensional verification and quality checks to ensure they meet specifications.

Blanking

Sheet aluminum is cut to create the initial form (blank) that will be further processed.

Finishing

Optional surface treatments like anodizing, painting, or powder coating may be applied.

Stamping Operation Types

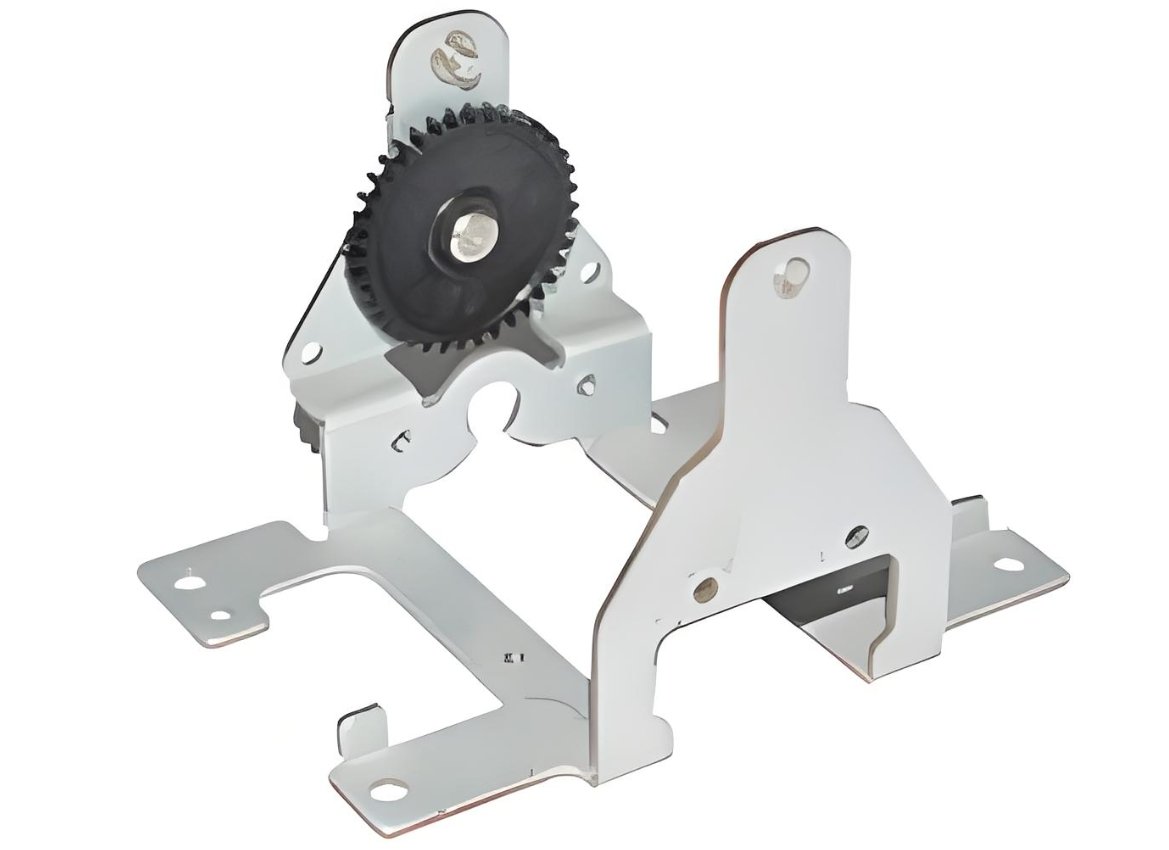

Progressive Die Stamping

Ideal for high-volume production, it performs multiple operations as the aluminum sheet advances through a series of stations within a single die set. It’s perfect for complex parts requiring multiple forming steps.

Transfer Die Stamping

For larger aluminum components, it uses automated systems to move parts between separate dies. This provides flexibility for complex geometries while maintaining production efficiency.

Fine Blanking

When exceptional edge quality and tight tolerances are required, fine blanking produces aluminum parts with smooth, perpendicular edges. This eliminates secondary operations for critical components.

Advantages of Metal Stamping Aluminum

Aluminum metal stamping offers significant advantages over other manufacturing methods and materials.

Cost Efficiency

- High-speed production reduces labor costs

- Minimal material waste compared to machining

- Lower energy consumption than casting or forging

- Reduced need for secondary operations

- Economical for both low and high-volume production

Technical Advantages

- Exceptional dimensional accuracy and repeatability

- Complex geometries achievable in single operations

- Superior surface finish requiring minimal post-processing

- Consistent mechanical properties throughout parts

- Ability to incorporate multiple features in one component

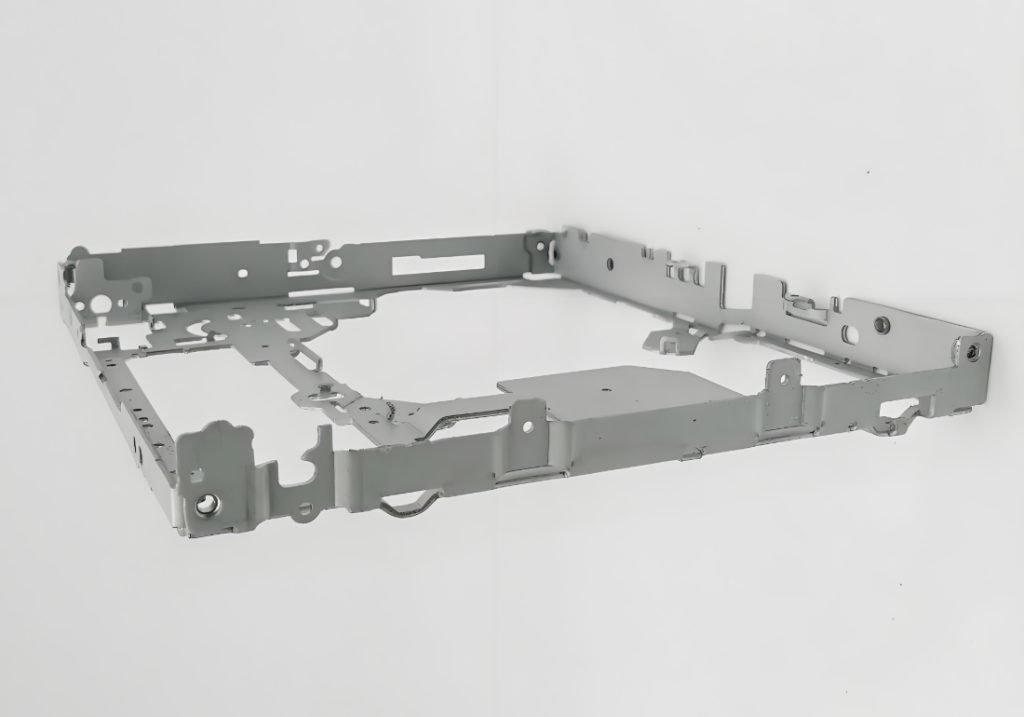

Industrial Applications for Stamped Aluminum Parts

Aluminum stamped parts serve critical functions across numerous industries. Their combination of lightweight properties, corrosion resistance, and formability makes them ideal for applications where weight reduction and durability are essential.

Automotive

Aluminum stamped components help reduce vehicle weight, improving fuel efficiency and performance.

- Body panels and structural components

- Heat shields and thermal management parts

- Brackets, clips, and mounting hardware

- Interior trim components

- Electrical housings and connectors

Aerospace

The aerospace industry relies on lightweight, high-strength aluminum components for:

- Aircraft interior components

- Avionics housings and enclosures

- Structural support brackets

- Fuel system components

- Ventilation and cooling system part

Electronics

Aluminum’s excellent conductivity and EMI shielding properties make it ideal for:

- Heat sinks and thermal management

- Electronic enclosures and chassis

- EMI/RFI shielding components

- Computer and mobile device housings

- Connector brackets and mounting hardwar

Aluminum Metal Stamping FAQs

Need to discuss aluminum metal stamping project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Quality You Can Trust

At Fecision, quality control is integrated throughout our aluminum metal stamping process.

Our commitment to excellence ensures that every component meets or exceeds industry standards and customer specifications.

Certifications

- ISO 9001:2015 Certified

- IATF 16949 Automotive Compliance

- AS9100D Aerospace Standards

Testing Capabilities

- 3D Coordinate Measuring Machines

- Mechanical Property Testing

- Surface Finish Verification

Quality Guarantees

- 100% Inspection Options

- Statistical Process Control

- Documented Quality Procedures

Ready to Discuss Your Aluminum Metal Stamping Project?

Our engineering team is available to review your specifications and provide expert recommendations for your custom aluminum stamping needs.