The right mold selection is critical in injection molding – it affects the quality of the part, costs, and production time, whereas a wrong choice can cause significant issues. You need a mold that is suitable for your part design and the budget you are maintaining.

The primary types of injection molds are the two plate mold and three plate mold. Each type has unique structures and operates differently. Understanding these differences will assist in selecting the best mold type for your needs. Let’s examine these two types to assist with your decision.

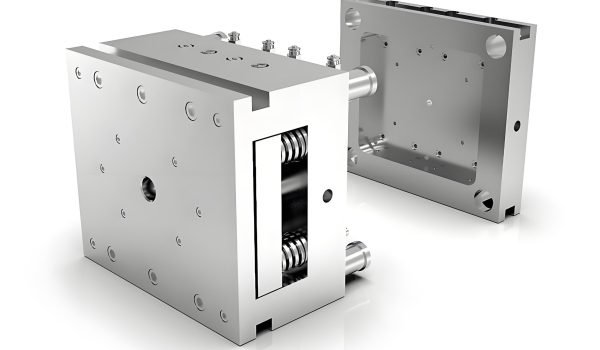

What Is Two Plate Mold?

A two plate mold is the most basic and common type of injection mold you will find. It’s a great choice for many projects because of its simple design and straightforward operation.

Definition

What is two plate mold? Generally, it is the most basic type of injection mold. It has a simple design with just two main plates. These are the cavity plate and the core plate. These two plates come together to form the part you want to create. It’s a very straightforward and popular mold design.

The basic structure of a two plate mold is what makes it so efficient. It is made up of two parts with one parting line for manufacturing simplicity. This setup is perfect for creating simple components without complex features. By eliminating part complexity, you will reduce unnecessary time wasted in production.

Working Principle

The way a two plate injection mold works is quite straightforward. First, the mold closes, with the cavity and the core plates meeting to form a single parting line. Molten plastic is then injected through a runner system, which is usually located right at that parting line. The plastic fills the mold and then cools and solidifies.

The mold opens once the plastic has cooled, and the finished part is then ejected from the mold. The runner system that delivered the plastic is also ejected at the same time. This simple, one-step ejection process is a key reason for the mold’s quick production cycles.

Advantages

In terms of two plate mold advantages, first, they are cost-effective to make. Their simpler design means less time and materials to build them. If you are working with a tight budget, this is a good option. You can get a mold made without a huge initial investment.

They are also perfect for flat or simple parts. Since they have a single gate, they work best for parts that don’t need complex filling. This simplicity also leads to quick cycle times. The mold opens and closes fast, which means you can produce parts more quickly. This speed can be a big plus.

The design simplicity also means a reduced lead time. Because they are so easy to build, you can get your mold in a much quicker time. This can help you keep your project on schedule by meeting tight deadlines. A quicker start means you can get your product to market sooner.

Disadvantages

The biggest disadvantage would be limited design flexibility. With a single parting line, you cannot design complex parts with undercuts – a two plate mold design will only allow for flat, simple designs. This will largely limit the products you can manufacture.

The single gating point can also cause uneven plastic flow, resulting in defects such as warpage or sink marks. This setup may also require a higher injection pressure, which will create excess stress on the part and can cause flash – the extra plastic seeping out – if there is not enough clamp to hold the molds.

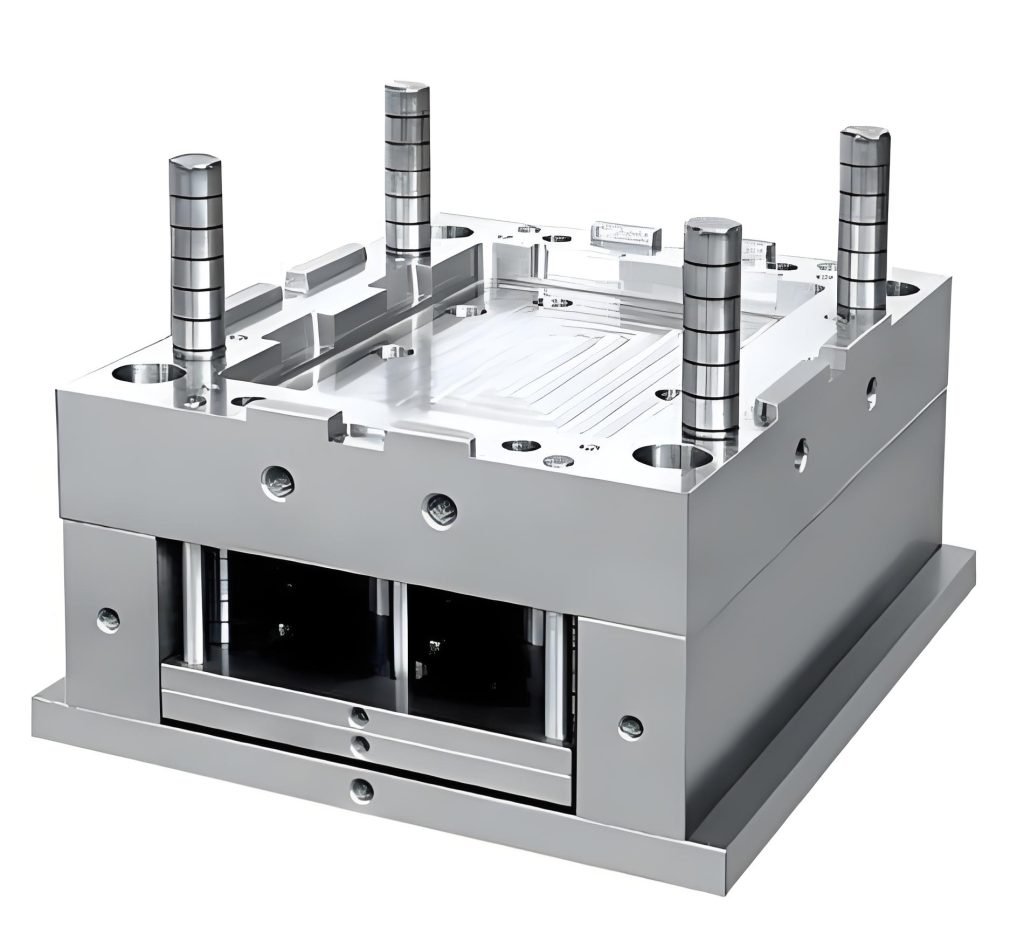

What Is Three Plate Mold?

A three plate mold is more advanced and complex than a two plate mold. It’s used when your part design requires more flexibility and a higher level of detail.

Definition

A three plate mold is a more complex design. It includes an extra component called a runner plate. This makes it much more versatile than a basic two plate injection mold. The three plate design handles parts that have complex shapes and details. It also allows for multiple gating points.

This kind of mold gives you a lot more control over your final product. You can create parts with complex geometries and tricky undercuts. It’s the go-to choice when a standard two plate mold just won’t work for your design.

Working Principle

The three plate mold works differently because it has two parting lines. One is located between the cavity and runner plates. The other is between the runner and core plates. Molten plastic is injected into the mold and flows through the runner system to fill the cavities.

After the plastic cools, the mold opens in two distinct stages. The runner plate separates first, which causes the runner system to drop away. Then, the core plate separates to eject the finished part. This two-step process ensures clean separation.

Advantages

Three plate molds offer huge versatility and design flexibility. Because they have multiple gating points, you can create complex parts with intricate details and shapes. This allows you to design products with undercuts and other features that a two plate mold can’t handle.

They also help reduce cosmetic defects. The multiple gating points will assist in plastic flowing more evenly throughout the mold. This will help mitigate any weld lines or sink marks, producing a better-looking finished part, and you will have a better quality product right off the mold.

The multiple gating points are a significant benefit. They provide assurance that the plastic will fill out the mold cavity evenly and consistently, especially beneficial on larger parts that require uniform filling. The result is a more robust and cosmetically appealing product.

Disadvantages

The complexity of a three plate mold design means it’s much more costly to design and build. The extra plate and intricate mechanism increase the initial investment. This complexity makes them less desirable if the budget is tight or your part is too simple.

The two-stage opening will take longer and result in slower cycle times. Additionally, the larger runner system leads to higher material wastage, increasing your long-term costs. The complex design also requires a higher ejection pressure to remove both the part and the runners.

Two Plate Mold vs Three Plate Mold: Key Differences

Now that you are familiar with two plate mold and three plate mold, this side-by-side comparison will allow you to see the evident differences in the construction and what each option can complete for your project.

Structure

The most obvious difference is the structure. A two plate mold has just a single parting line. This is where the cavity and core plates meet. In contrast, a three plate mold has two parting lines. It has an additional runner plate. This extra plate gives you a lot more design freedom.

Complexity

In terms of complexity, a two plate mold design is a much simpler design. It has fewer components and mechanisms. A three plate mold is far more complex. It has extra plates and moving parts, which makes it more intricate to design and build.

Application

When it comes to what they are used for, a two plate mold is best for simple, flat parts. Think of a simple lid or a panel with no tricky features. A three plate mold is perfect for complex parts. This includes things with intricate designs, undercuts, or multiple gates.

Production Efficiency

Two plate molds are faster. Their simpler design means you get quicker cycle times. The mold opens and closes very quickly. Three plate molds are slower. The additional steps in the mold opening process mean production takes more time. This is an important factor to consider for high-volume projects.

Cost

Cost is a major difference. A two plate mold has a lower initial investment and lower maintenance costs. Its simple structure is cheaper to build. A three plate mold has a higher initial investment and higher maintenance costs. The extra parts and added complexity make it more costly to build and maintain in the long run.

Maintenance

Maintenance is also different based on the different structures. A two plate mold is easier to maintain. Fewer components mean less can go wrong. A three plate mold is more challenging to maintain. The additional parts and mechanisms require more specialized knowledge and effort to keep running smoothly.

Injection Method

The way plastic is injected also differs. A two plate mold design typically has a single injection point located at the parting line. This can sometimes lead to uneven filling. A three plate mold design can have multiple injection points. These allow for a more even distribution of material throughout the mold. This helps to reduce cosmetic defects and improve part quality.

Comparison: Two-Plate Mold vs. Three-Plate Mold

| Feature | Two-Plate Mold | Three-Plate Mold |

| Structure | Two plates with a single parting line. | Three plates with two parting lines. |

| Complexity | Simple design, easy to operate. | More complex mechanism. |

| Application | Simple, flat parts without undercuts. | Complex parts requiring multiple gates. |

| Production Efficiency | Faster cycles, higher efficiency. | Slower cycles due to sequence. |

| Cost | Lower initial investment. | Higher initial cost. |

| Maintenance | Easier and less frequent. | More complex and frequent. |

| Injection Method | Single, often manually trimmed gate. | Multiple automatic gates. |

How to Choose the 2 or 3 Plate Injection Mold for Your Project?

Choosing the right mold for your project depends on several key factors.

Part Complexity

The first thing to consider is your part’s complexity. A two plate mold is perfect for simple parts with flat shapes and no undercuts. They are very efficient and cost-effective. For more complex designs with undercuts, or when parts have multiple features, you should use a three plate mold. The added flexibility for complex geometries is very beneficial.

Cost and Production Volume

Think of your budget and production needs. For simple parts, a two plate mold is a cost-effective approach to produce at high volumes because it has a lower upfront cost and generally shorter cycle times. A three plate mold costs more initially, but the added cost will be worthwhile because you will have more freedom with regard to design and improved part quality.

Quality Requirements

Your quality standards are key. Assuming that you are not very concerned about achieving a perfect surface finish, a two plate mold can be appropriate. However, to achieve high-quality finishes and prevent cosmetic defects like weld lines, a three plate mold is the way to go, since it has multiple gates, which creates a more consistent and aesthetically pleasing look.

Lead Time

The project timeline is another consideration. Two plate molds have shorter lead times because their simpler design means they can be manufactured in a shorter time frame. If timing is important, this is an advantage. Three plate molds will typically have longer lead times because they are more complex in design and require more time to build up and test.

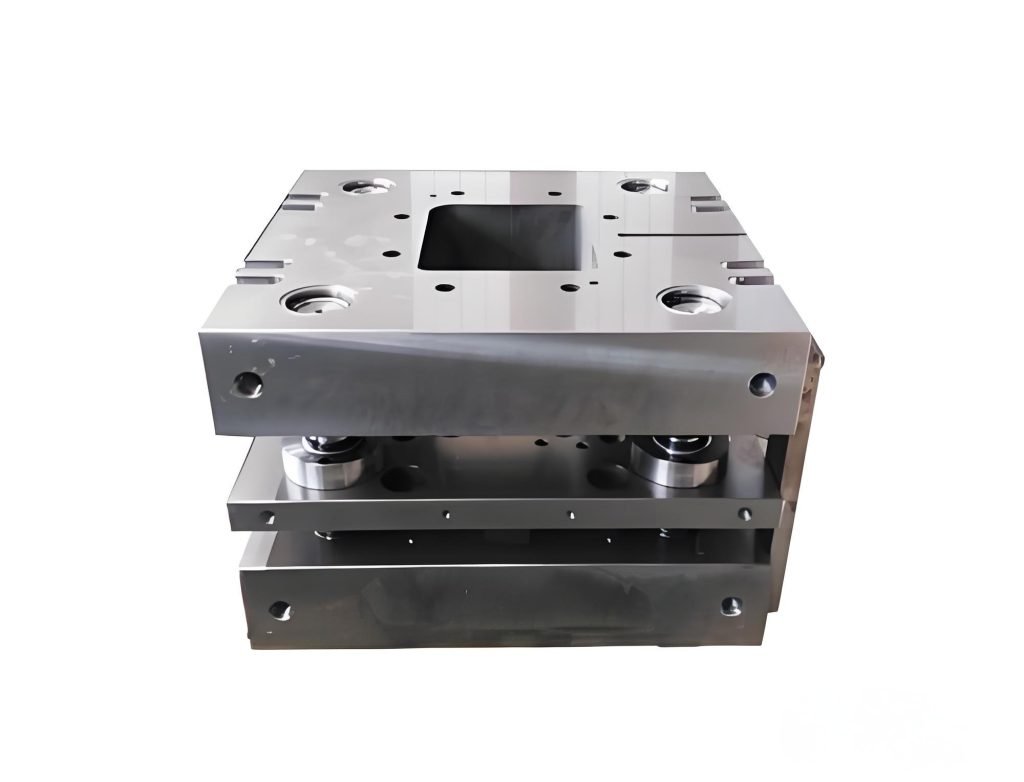

Conclusion

Whether to use a two plate injection mold or a three plate injection mold for your project is ultimately dependent on your part’s design, gating, and production goals. The two plate mold provides a reliable and cost-effective solution for simpler parts, while a three plate mold offers greater capabilities to facilitate and automate production runs for complex parts.

Selecting the option requires a partner with expertise in both design and manufacture. This is where Fecision excels. At Fecision, we specialize in high-precision mold tooling, with advanced technology and decades of experience to deliver the right solution for your project. Our comprehensive service manages your mold, from a simple two plate mold design to a complex three plate injection mold, and ensures that your mold is designed for performance, durability, and cost-efficiency.

Our core capabilities include:

- Expert Mold Design: Perfecting gate location, cooling, and overall performance through advanced analysis.

- Precision Machining: Creating long-lasting molds with advanced CNC and EDM processes.

- Rapid Prototyping: Supplying aluminum molds for fast concept validation and testing.

- Production Tooling: Building high-volume or multi-cavity molds for mass manufacturing.

Are you ready to build a high-performance mold that perfectly fits your needs? Contact Fecision Today for expert guidance on your project.