Have you ever wondered how acrylic sheets perform under high temperatures, and what this means for their use in various projects?

Acrylic, known for its exceptional clarity and durability, is a versatile material used across numerous industries. As a thermoplastic, it’s derived from natural gas and composed of Methyl Methacrylate (MMA) and Poly Methyl Methacrylate (PMMA) resin, also known as polymethyl methacrylate.

When working with acrylic sheets, understanding their thermal properties, including their melting point and heat resistance, is crucial for selecting the right material for your applications. Whether you’re involved in construction, retail displays, lighting, or furniture design, knowing how acrylic behaves under different temperatures will help you make informed decisions.

What is Acrylic?

You’re probably familiar with acrylic, but have you ever wondered what it’s made of? Acrylic is a synthetic polymer made from polymethyl methacrylate (PMMA), a petroleum-based product. It’s known for its exceptional transparency and durability compared to other plastic materials.

Composition and Chemical Structure

Acrylic is composed of Methyl Methacrylate (MMA) and Poly Methyl Methacrylate (PMMA) resin. The chemical composition of acrylic gives it unique properties, including its remarkable clarity, with 92% light transmission, resistance to UV radiation, and ability to maintain its appearance over extended periods without yellowing. The molecular structure of acrylic contributes to its distinctive characteristics, including its thermal properties and melting point behavior.

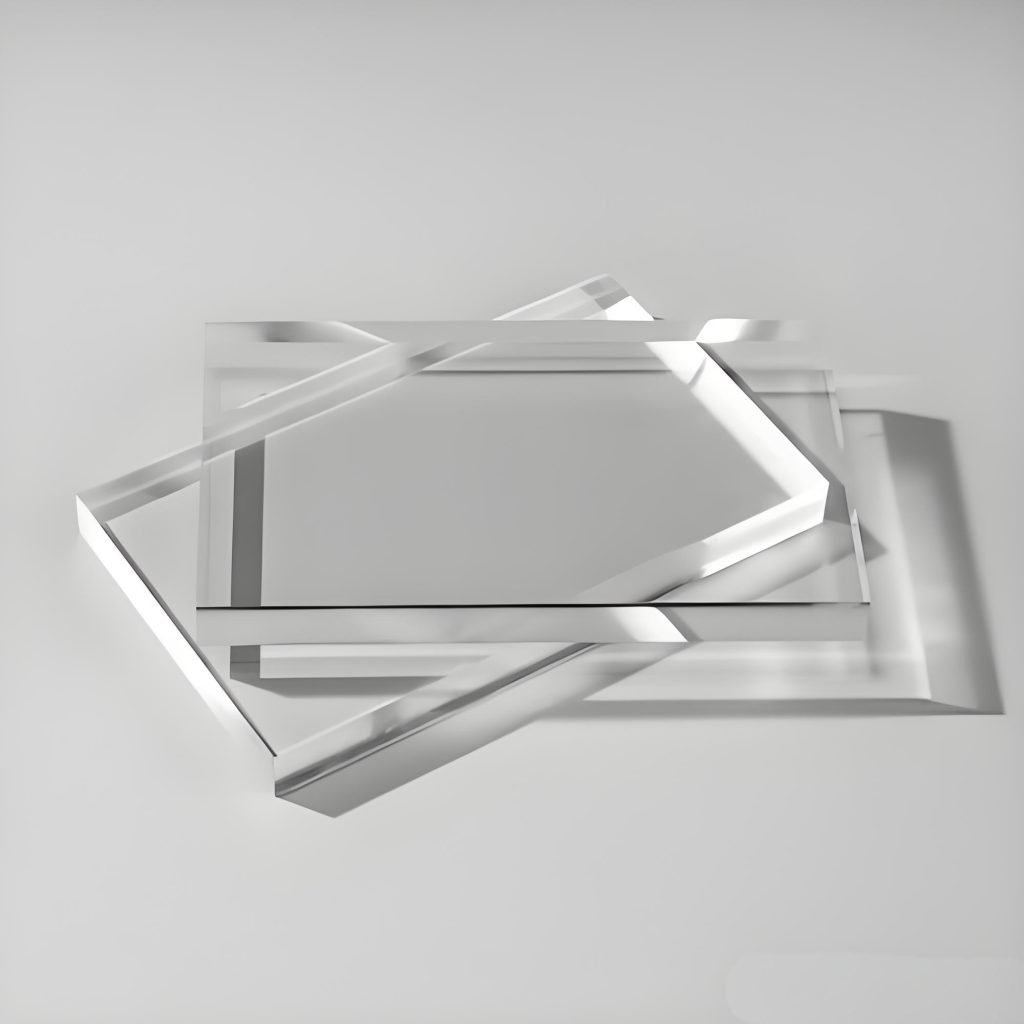

Types of Acrylic Sheets

Various types of acrylic sheets are available, catering to different applications and aesthetic preferences. These include Cast Clear Acrylic Sheets, known for their excellent optical clarity and superior surface finish, Opal Cast Acrylic Sheets, which are white and translucent with 30% light transmission, Extruded Acrylic Clear Sheets, an economical option with slightly less optical purity, and Neon Acrylic Sheets, available in vibrant colors. The manufacturing process, whether cast or extruded, also affects the properties of the acrylic sheets.

Understanding Acrylic Melting Point

To work effectively with acrylic sheets, it’s crucial to understand their melting point and how they react to heat. Acrylic materials are widely used in various applications, from architectural designs to retail displays, due to their versatility and aesthetic appeal. However, their thermal properties play a significant role in determining their suitability for different uses.

Softening Temperature vs. Melting Point

Acrylic sheets undergo distinct thermal transitions at different temperature thresholds. They begin to soften at approximately 160°F to 210°F (71°C to 99°C), becoming pliable and capable of being formed into various shapes. However, the actual melting point, where the material loses its structural integrity, occurs around 320°F (160°C). Understanding the difference between softening and melting is crucial for working with acrylic sheets.

Ignition Point and Flammability

While acrylic sheets can be molded and shaped when heated, they also have a risk of igniting at high temperatures. Acrylic can ignite at temperatures exceeding 860°F (460°C), making it unsuitable for extreme heat exposure. Although acrylic burns cleanly and does not emit harmful gases, it is still flammable and requires appropriate precautions around heat sources.

When working with acrylic sheets, it’s essential to consider their thermal properties to ensure safe handling and application. By understanding the softening temperature, melting point, and ignition point, you can make informed decisions about using acrylic in various projects.

Why Knowing Acrylic Melting Point Matters

Knowing the melting point of acrylic sheets is essential for making informed material choices. When designing products that may be exposed to varying temperature conditions or heat sources, understanding acrylic’s thermal limitations is crucial. This knowledge helps prevent design failures and ensures the longevity of your projects.

Material Selection Considerations

When selecting materials for your project, it’s essential to balance acrylic’s excellent optical and mechanical properties against its thermal limitations. For applications requiring exceptional heat resistance, materials like polycarbonate, tempered glass, or ceramic may be more suitable than acrylic. Understanding the heat resistance of acrylic is crucial, especially for applications involving high temperatures or outdoor exposure.

Design Limitations and Opportunities

Understanding acrylic’s melting point not only helps you avoid potential pitfalls but also opens up opportunities for creative design solutions. By intentionally thermoforming acrylic sheets, you can create custom shapes and designs for specialized applications. This process involves controlled heating of the sheets to achieve the desired form, allowing for innovative and complex designs.

Knowledge of acrylic’s melting point also influences installation methods, maintenance practices, and long-term performance expectations in various applications requiring thermal stability. By considering these factors, you can ensure that your projects meet the required standards and perform well over time.

Factors Influencing Acrylic Melting Point

Understanding the factors that influence the melting point of acrylic is crucial for its applications. The melting point is not solely determined by the material’s composition but is also affected by how it’s manufactured and any additives it may contain.

Manufacturing Process: Cast vs. Extruded Acrylic

The manufacturing process significantly impacts the thermal properties of acrylic sheets. Cast acrylic, produced by casting liquid polymer between two glass plates, offers a more uniform molecular structure and higher molecular weight compared to extruded acrylic. As a result, cast acrylic generally provides better heat resistance. For instance, cast acrylic typically begins softening at higher temperatures, closer to 210°F (99°C), whereas extruded acrylic may start softening at lower temperatures, around 160°F (71°C).

Additives and Their Effects on Heat Resistance

Various additives can be incorporated into acrylic during manufacturing to enhance its heat resistance. These include heat stabilizers, UV inhibitors, and impact modifiers. While these additives can improve the material’s thermal properties, they may also affect other characteristics, such as clarity or cost. The thickness of the acrylic sheets also plays a role in their thermal behavior, with thicker sheets generally offering better insulation.

Applications of Acrylic Across Industries

With its clarity, weather resistance, and light weight, acrylic has become a popular choice across different industries. Its versatility makes it suitable for a wide range of applications, from architectural projects to decorative elements.

Architectural and Construction Applications

In architectural and construction, acrylic sheets are widely used for skylights, windows, barriers, and decorative elements. Their clarity and weather resistance offer a durable alternative to glass, while their light weight simplifies installation.

Retail and Display Solutions

Retail environments benefit from acrylic’s versatility in creating display cases, signage, and protective barriers. These applications offer excellent visibility while maintaining durability in high-traffic areas, making acrylic a practical choice for businesses.

Lighting and Signage

The lighting industry leverages acrylic’s exceptional light transmission properties for diffusers, light guides, and fixtures. With up to 92% light transmission, acrylic distributes light evenly without hotspots or yellowing, making it ideal for lighting solutions.

Furniture and Interior Design

In furniture and interior design, acrylic brings a modern, sleek look to tables, chairs, shelving, and decorative elements. Its transparency creates a sense of spaciousness and elegance, making it a favorite among designers looking for innovative materials.

Across these industries, acrylic’s unique properties make it a valuable material, offering a blend of functionality, durability, and aesthetic appeal that is hard to match with other materials.

How Melting Point Affects Acrylic Applications

The melting point of acrylic plays a significant role in deciding where and how it can be used effectively. Acrylic’s moderate heat resistance means it softens at 160-210°F (71-99°C) and melts at 320°F (160°C), which directly influences its suitability for various applications.

Comparing Acrylic to Other Materials

When evaluating materials for a specific application, comparing their thermal properties is essential. Acrylic is often compared to glass and polycarbonate due to their similar uses.

Acrylic vs. Glass

Acrylic offers better insulation properties and impact resistance than glass, and it weighs significantly less, making it easier to handle and install. However, glass outperforms acrylic in heat resistance, maintaining its structural integrity at temperatures that would cause acrylic to soften or melt.

Acrylic vs. Polycarbonate

Polycarbonate has a higher heat resistance than acrylic, softening at 280-320°F (137-160°C) and melting at 450°F (232°C). It also offers greater impact strength. However, polycarbonate is more expensive, less clear, and more susceptible to scratching and yellowing from sunlight exposure.

Temperature Considerations for Different Environments

Environmental temperature fluctuations must be considered when installing acrylic outdoors. Expansion and contraction with temperature changes can affect mounting systems and potentially lead to warping if not properly accommodated. In applications like greenhouses, skylights, or automotive components, the interaction between direct sunlight, ambient temperature, and acrylic’s thermal properties requires careful engineering to ensure long-term performance while maintaining clarity and structural integrity.

You should carefully evaluate the operating temperatures and environmental conditions for your specific application to determine if acrylic is the most suitable material. Considering factors such as exposure to sunlight, heat sources, and required clarity will help you make an informed decision.

Safety Precautions When Working with Heated Acrylic

When working with heated acrylic, it’s crucial to follow safety guidelines to avoid potential hazards. Acrylic should never be used near open flames or direct high heat sources, as it can be flammable at certain temperatures.

To handle heated acrylic safely, you must use proper ventilation, as the material can release fumes at high temperatures that may cause respiratory irritation. Always wear heat-resistant gloves, eye protection, and appropriate clothing to prevent burns or injuries.

Never attempt to heat acrylic using open flames or uncontrolled heat sources, as this can lead to uneven heating, warping, or even ignition. Instead, use specialized equipment like strip heaters, ovens, or heat guns designed for thermoplastics.

When designing products with acrylic sheets, ensure adequate clearance from heat sources and consider using heat shields or insulation to prevent warping. For applications requiring higher heat resistance, consider alternative materials like polycarbonate.

FAQ

What is the heat resistance of acrylic sheets?

Acrylic sheets generally have a heat resistance up to 180°F to 190°F (82°C to 88°C), but this can vary depending on the type and manufacturing process. Extruded acrylic tends to have a lower heat resistance compared to cast acrylic.

Can acrylic be used for outdoor applications?

Yes, acrylic can be used for outdoor applications, especially when it’s UV-resistant. This type of acrylic is designed to withstand exposure to sunlight without degrading or losing its clarity.

What are the design limitations when working with acrylic?

When designing with acrylic, you need to consider its heat resistance and potential for warping or deformation under high temperatures. This material is also prone to scratches and cracks if not handled properly.

Is acrylic suitable for furniture and interior design?

Yes, acrylic is a popular choice for furniture and interior design due to its clarity, durability, and versatility. It can be used to create modern and sleek designs that are both functional and aesthetically pleasing.

Can acrylic sheets be laser cut?

Yes, acrylic sheets can be laser cut, making them a versatile material for various applications, including signage, display solutions, and custom designs.