Steel is a great choice for many CNC machining jobs because it is easy to work with and has a consistent structure. It is strong, welds well. It can bend without breaking and can be shaped to meet the needs of your project. Steel is one of the most popular materials for CNC machining because of its strong and durable qualities. It has high strength and resists rust, which helps parts last longer.

This guide will explain everything you need to know about steel CNC machining here.

The Complete Process of CNC Machining

Here’s a simple explanation of the CNC machining process.

- Designing the Part

First, the part is designed using special computer software called CAD. This design shows all the sizes and details needed to make the part.

- Creating the CNC Program

Next, the CAD design is turned into a set of instructions for the machine using CAM software. These instructions tell the CNC machine exactly how to make the part.

- Setting Up the Machine

The operator prepares the CNC machine by putting in the right cutting tools and securing the material that will be shaped.

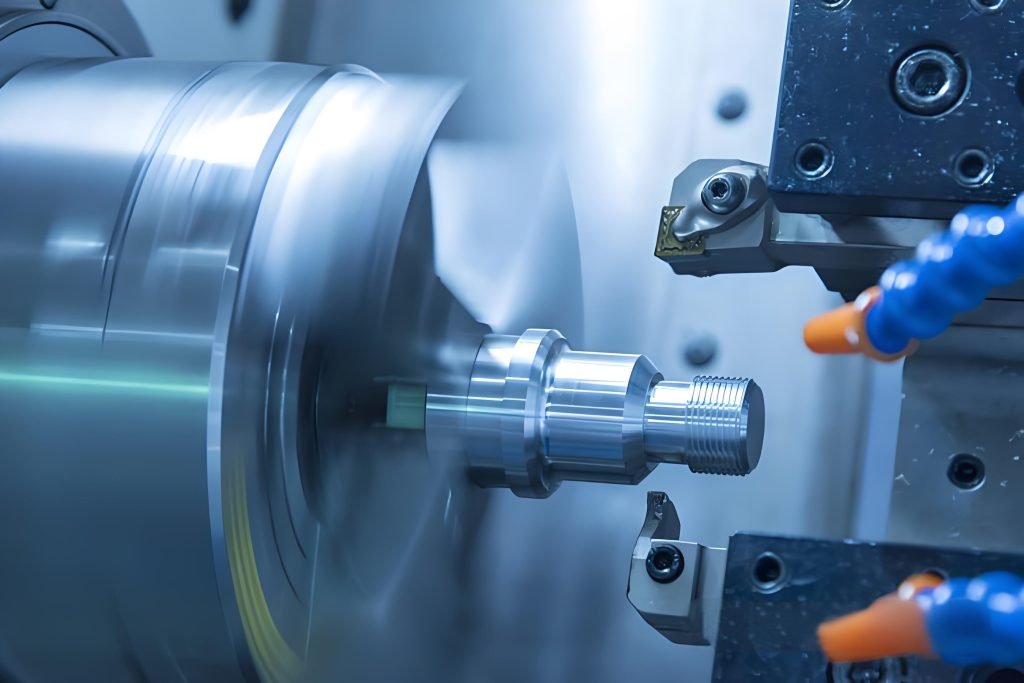

- Machining the Part

The machine follows the instructions to cut and shape the material precisely for creating the part.

- Checking and Finishing

Finally, the part is checked to make sure it matches the design. Sometimes, extra finishing work is done to make the surface smooth or improve accuracy.

In short, CNC machining starts with a detailed design, turns that into machine instructions, sets up the machine, cuts the part, and then checks it to make sure everything is just right.

Steel Grades for Steel CNC Machining

Here we will explain different steel CNC machining grades in detail.

- Low Carbon Steel

Low-carbon steel has less than 0.3% carbon in it. This makes it soft, easy to bend, and simple to weld or shape. While it is not very strong or hard but it is tough enough for everyday use.

- People often use low-carbon steel for things like bolts, pipes, gears, and car or building parts. Carbon steel CNC machining is great because it is easy to cut and shape. These characteristics make it perfect for making lots of parts quickly.

- However, if the cutting is not done right, the steel can get harder during machining. As a result, this can wear out tools faster. Sharp tools and good lubrication are important to keep things cool and smooth and avoid this problem.

In short, low-carbon steel is a smart choice if you don’t need super high strength or extreme wear resistance.

- Medium Carbon Steel

Medium carbon steel has about 0.3% to 0.6% carbon. This makes it stronger and harder than low-carbon steel. It offers a good mix of toughness and ease of machining. So, it is great for parts that go through friction, stress, and wear.

- You can make it even tougher and harder with heat treatment which is useful for parts that need to last under heavy use.

- This type of steel is often used for things like crankshafts, gears, connecting rods, railway components, and hydraulic parts. Basically, it is suitable for parts that need to handle repeated stress and stay strong over time.

- Medium carbon steel machining works well but needs sharp tools and good lubrication to protect the cutting tools. Sometimes, extra work is needed after cutting to smooth out rough edges.

In short, medium carbon steel is a reliable choice when you want a balance of strength, durability, and cost.

- High Carbon Steel

High-carbon steel has more than 0.6% carbon which makes it very hard and resistant to wear. It is much tougher than steels with less carbon. So, it is great for parts that need to handle constant pressure or rubbing.

- It is also more brittle and less flexible because of its hardness. It is harder to weld or shape, though heat treatment can make it even stronger and more durable.

- You will often see high-carbon steel in tools like saw blades, knives, drills, punches, springs, heavy machine parts, and dies. These need to stay sharp, strong, and reliable for a long time.

- High carbon steel machining can be tricky because of its hardness. It usually needs slower cutting speeds, coated tools or special carbide, and careful work to avoid cracks or overheating. Good cooling and the right tools are important to keep everything precise and protect the steel.

Overall, high-carbon steel is the right choice when you need parts that stay sharp, resist wear, and keep their shape even under tough conditions.

- Alloy Steel

Alloy steel has extra elements like chromium, nickel, and molybdenum that make it tougher, stronger, and more resistant to wear. Some types also resist rust better. This makes alloy steel great for parts that face heat, stress, or tough conditions.

You will often find CNC machined alloy steel parts in cars, airplanes, and heavy machines. It is used for gears, pressure tanks, shafts, and tool parts, especially the ones where strength and durability are important.

How easy alloy steel is to machine depends on the exact type. Some are harder to cut and need special carbide tools with coatings. Using good cooling and lubrication helps keep tools sharp and prevents overheating.

Overall, alloy steel is a solid choice when you need parts that last long, are strong, and perform well under pressure.

- Stainless Steel

Stainless steel is a strong metal that does not rust easily. This is because it has at least 10.5% chromium. This chromium creates a protective layer that stops rust and damage which is making stainless steel great for tough conditions. Different types of CNC machining stainless steel offer different levels of strength and resistance to chemicals and wear.

The common applications of stainless-steel CNC machining are medical tools, kitchen equipment, boat parts, and building materials. These are used in places where staying clean, resisting moisture, and longevity are important.

Stainless steel CNC machining can be a bit tricky because it can get harder while being cut. This creates heat and can wear down tools faster. Using the special coated tools, right cooling, and the right cutting speed helps get smooth and accurate parts. Stainless steel is the best choice when you need parts that resist rust and look nice.

Pros and Cons of Steel CNC Machining

Here are the Pros and Cons of Steel CNC Machining to know.

- Steel CNC machining can make steel parts that fit exact measurements really well.

- Steel CNC machining work great with different types of steel, shapes, and designs.

- This technology makes steel parts with the same high quality every time which is perfect for reliable results.

- It is easy to change designs to create custom steel parts made just for your needs.

- Steel is naturally strong and durable which is making it great for parts that need to last and perform well.

- Steel CNC machines cost a lot to buy at first.

- Hard steel can be tricky to work with using CNC machines.

- Steel can wear out the cutting tools fast which means more maintenance and costs.

Steel CNC Machining Applications

Here is a quick overview of steel CNC machining applications to know.

Automobiles: Used for making machine parts, gears, and brackets. Steel parts in cars need to handle high heat and stress, so CNC machining is the best way to make them strong and precise.

Aerospace: Used for landing gear and structural supports. In airplanes, parts must be very precise and reliable. So, CNC machining helps meet these high standards.

Medical: Used for surgical tools and prosthetics. Medical parts need to be very accurate and safe for the body, and CNC machining can create these perfect parts.

Industrial Equipment:Used for shafts, transmissions, and engine parts. Machines in factories face tough conditions. So, steel parts made by CNC machining last longer and work better.

Construction: Used for fasteners, connectors, and structural steel. Building projects need strong and exact steel parts, and CNC machining makes sure they fit and work well.

Experience Seamless Steel CNC Machining with Fecision!

No matter what material you need for your project, Fecision is ready to help. Our CNC machines are stronger and more precise than others. So, you can get top-quality stainless steel CNC machining services every time.

You can get quick quotes and expert support to make sure your parts are made exactly right with Fecision We are here to make your required metal machining services and production smooth and reliable!