Manufacturing has improved a lot especially in making things faster and more accurate. One big improvement is called mill turn machining. Mill turn machining does both in one step instead of moving a part between different machines for milling and turning. This means less efforts, fewer mistakes, and faster results.

You will find mill turn machining used in making different things including car parts, medical tools, electronics, and more. CNC mill-turn machining works great for parts that have tricky shapes or need both round and flat areas.

Here we will explain everything about mill turn machining all in a simple and easy-to-understand words.

What Is Mill Turn Machining?

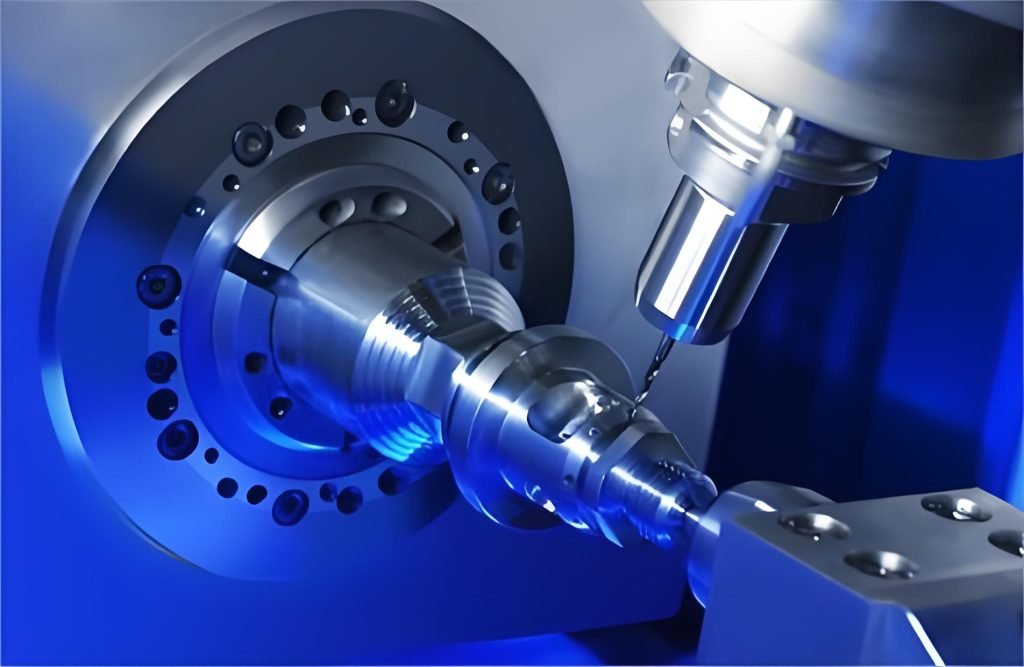

CNC Milling Turning is a smart way to cut and shape parts. It uses both the spinning motion of the milling cutter and the workpiece at the same time. This turning milling helps to create parts that are very accurate and have smooth surfaces.

This process is more than just putting milling turning together on one machine. It means the machine can do both cutting actions at once or one after the other to work on many different surfaces.

You can get precise and complex parts much faster and cheaper than usual with mill-turn machining services. This method works well for making a few prototypes or large amounts of parts.

Overall, it is a faster, cost-effective way to make detailed and accurate pieces.

CNC Mill Turn Machine Working Principle

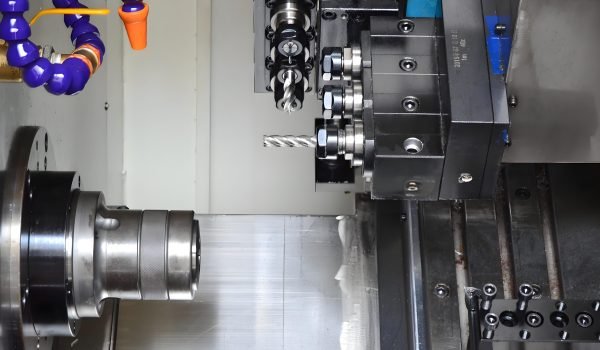

CNC mill-turn machines can do both milling and turning together. This means they work like both a mill and mill turn lathe in one machine.

Here is how they work.

- First, you start with a big block of material called the workpiece on which the CNC mill-turn center works. The machine begins with the turning process. In this process it uses cutting tools to shape the spinning workpiece into round and cylindrical parts. These cutting tools also takes the material away from the workpiece.

- Next, the workpiece moves to the milling part of the machine. Here, a rotating cutting tool again removes material to create flat or uneven surfaces. This stage is called milling.

Mill-turn CNC machines make parts with great precision, accuracy, and speed. They are also flexible and can work on many different shapes and materials.

In short, these machines help make complex parts quickly and perfectly.

What Makes Mill Turn Machining Beneficial?

Mill turn machining offers various real-world advantages. This is true especially for industries that rely on complex parts and tight deadlines.

Here is a closer look at the key benefits.

- Shortened Production Cycle

Turn-mill machines help manufacturers to speed up their research and development work. Using mill-turn CNC machines, making products or prototypes becomes faster and more efficient.

- These machines can use many special tools and smart setups. These can help them to cut down the time spent changing tools. As a result, this makes the process quicker.

- Turn-mill processing can do most or all of the work in one go without moving the part around. This saves a lot of time and shortens the whole production process.

Customers get a big advantage during R&D and production because the products and prototypes are ready faster. In simple terms, mill turn machining services make it quicker and easier to go from idea to finished product.

- Improved Precision

CNC machines are usually very accurate for both milling and turning. However, the turn mill center has improved the degree of precision. That is because the machinist only needs to set up the material once for the whole process.

The high accuracy of mill-turn machines is especially helpful when making parts that need very tight measurements. Otherwise, even small errors from moving the part can cause the whole process to fail.

So overall, mill-turn machines keep things precise by doing everything in one setup which helps in reducing mistakes and making better parts.

- Save Money on Production Processes

Mill-turn services help lower production costs by working faster and more efficiently. Manufacturers and customers can save a lot of money on both regular production and quick prototypes. This is true because mill turn machining cuts down the time needed to make parts.

- Mill-turn machining reduces extra time spent changing setups and waiting for special tools or fixtures. This speeds up the whole process and helps companies make more in less time.

- These machines are built strong to handle tough materials and often have automatic feeding systems. So, they can work continuously without stopping.

- Labor costs also go down as less time is needed to make each part. This means customers get high-quality, precise products at a lower price.

In short, mill-turn machines make production faster and cheaper without losing quality.

- Complex Parts Machining

Traditional machining tools can only handle geometrical shapes up to a certain level of complexity. Machinists often have to move them from one machine to another when parts are very detailed or tricky. The process as a result takes extra time and can cause mistakes.

CNC mill-turn machines fix this problem. This is because they can make complex shapes all in one machine without moving the part around. This not only improves the quality of the final product but also speeds up the whole manufacturing process.

In simple terms, mill-turn machines make it easier and faster to create complicated parts with better results.

- Automated Menial Tasks

Most mill-turn machines are newer and come with more built-in automation than older machines. They can load materials, check parts, and remove finished pieces automatically. This lets machinists spend their time on more important and interesting work.

Key Applications of Mill Turn Machining

Here are top applications to know about.

- Medical

Turn-mill technology is used to make implants, surgical tools, and prosthetics. These machines create smooth surfaces and very accurate parts.

- Aerospace

Aerospace companies use turn-mill machines to make parts like engine covers, turbine blades, and strong structural pieces. These machines can work with tough materials like Inconel and titanium.

- Energy

The oil and gas industry uses mill-turn machines to make parts that control the flow of fuel. Nuclear power plants also need very precise and detailed parts. Fortunately, mill-turn machines are helpful to make those.

- Electronics

Electronic parts like circuit boards, motherboards, and amplifier cases need precision. So, mill-turn machines can create these with high accuracy.

- Machine Engineering

Mill-turn machines are also used to make many machine parts like gears and housings. Because they can do both turning and milling in one machine, they save time and make parts more accurate.

- Automotive Industry

Car makers use turn-mill machines to make different parts. These include gear housings, pistons and shafts. These machines can create both round and flat shapes which helps speed up making lots of car parts quickly.

Get High-Quality Mil Turn Machining Services from Fecision!

You get the most benefits from mill-turn machining when it is done the right way by skilled experts. At Fecision, we have the right team to make sure you get high-quality mill-turn parts. We offer a full range of mill-turn services that are affordable and fast. Just upload your CAD files, and we will give you helpful feedback to get started today.

In simple words, Fecision makes it easy and affordable to get great mill-turn parts quickly.