Injection molding is one of the most important processes used in modern manufacturing, making it possible to create plastic parts on a massive, even molecular level used in everything from automobile components to consumer electronics. Problem Warpage of the molded part is one of the problems that has long been encountered in this respect, and warpage impairs function and appearance of the part. How and Why Warpage Happens – and How It Can Be Overcome The knowledge of warpage and its reasons is indispensable for manufacturing companies that want to ensure the production of products without a fault.

This article discusses warping for injection molding, including the definition, causes, factors, and effective solutions to liftable features to make usre that they do not warp or distort parts while maintaining their quality and use.

What is Warpage in Injection Molding?

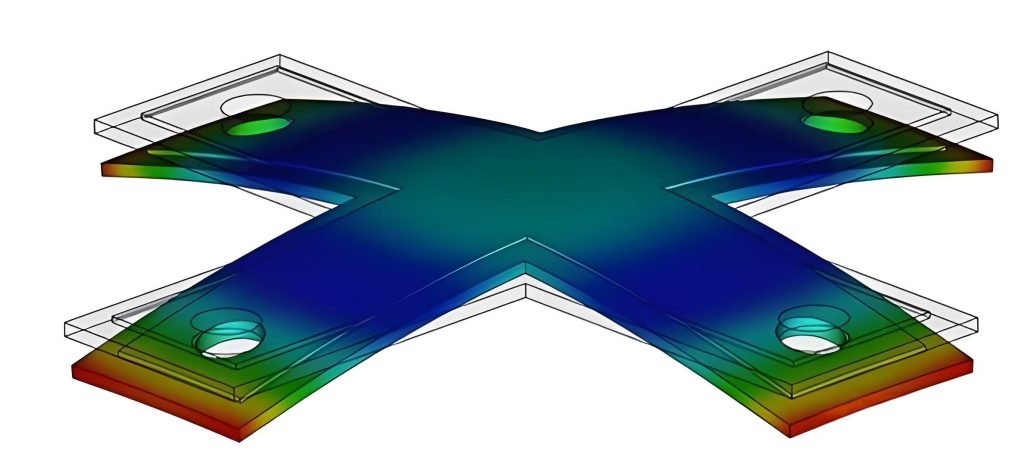

Injection molding warpage is the deviation from the intended shape that is caused by the process of ejection of the plastic part from the mold and cooling down afterwards. Rather than maintaining its designed form, the part may become too twisted, bent, curved, warped or otherwise not in accordance with the intended dimensions. This type of defect arises from non-uniform stresses present in the material as it solidifies. This warpage may have only minor dimensional errors, to the extent that the part is not functional, or extensive distortion so that the part is cosmetically unappealing.

Warpage is especially concerning due to its impact on the structural features of the article and its performance. A plastic housing for an electronic device, for instance, may be warped such that it does not mate properly during assembly; this results in expensive rework or scrap. Manufacturers must understand the causes of warpage so that they can produce repeatable, reliable parts that comply with exacting industry specifications.

Causes of Warpage Defects in Plastic Injection Molded Parts

Warpage is a multifaceted problem that is affected by many factors, as described in terms of material properties, process parameters, and mold design. In the end, warping is due to differing cooling and shrinkage throughout the molded part. These internal stresses develop in response to different rates of cooling or nonuniform shrinkage in various parts of the part, resulting in that part deformation. Here, we will identify the most common cause of warpage failure in injection moldings.

Material-Related Factors Contributing to Warpage

The types of materials are an important warping factor. Each plastic has its own characteristics, including shrinkage, thermal expansion, and molecular structure; these properties affect the way they will react under the molding process. The following are the primary material-related causes of warpage:

- Crystalline versus amorphous polymers: Crystalline polymers such as polyethene and polypropylene have a more ordered molecular structure, which undergoes a greater shrinkage upon cooling than do amorphous polymers like polystyrene or polycarbonate. This increased shrinkage can result in more warpages if not controlled.

- Filler Content: A substance that is incorporated to help impart a desired physical property; in plastics, fillers such as glass fibres or talc are used to increase strength or lower cost. However, these fillers tend to induce anisotropic shrinkage, which is when the material shrinks at a different percentage rate in the direction of flow than in the transverse flow direction. This maldistribution of shrinkage raises the possibility of uneven bowing or warpage.

- Hygroscopicity: There are hygroscopic materials, such as nylon, that tend to absorb moisture. If allowed to off-gas during molding, moisture can cause inconsistent cooling and warpage.

- Material Inhomogeneities: Heterogeneities in resin, which can include different molecular weights or viscosities, can cause shrinkage and cooling to change in unpredictable ways, resulting in warpage.

Warpage risk factors Methods to minimize warpage Identifying the right material and ensuring material consistency are crucial in reducing warpage risk.

Process Parameters Affecting Warpage

- Cooling Time and Temperature: Uneven cooling is the number one culprit of warpage. Shrinkage becomes difficult to control when one area of the mold cools faster than another, causing the part to form internal stresses. The uniformity of the cooling process in the mold is also important.

- Injection Pressure and Speed: Too much injection pressure and injection speed will result in an uneven material flow that creates high stress on some part areas. On the other hand, since a mold does not fill enough due to low pressure, warp may be retarded.

- Melt Temperature: If your molten plastic is too hot, it can cool more slowly and lead to differential shrinkage. If it is too cold, it will not flow properly and create a stress concentration.

- Packing and Holding Pressure: An extra pressure is added to force the material into the die during the cooling process to prevent it from shrinking. Improper sizing pressure or duration may cause non-uniform shrinkage and warp.

- Cycle Time: Cycles that are too short for sufficient cooling or too long for too much pack and part degradation result in the wave.

Fine-tuning of these settings must be done carefully to maintain consistent part quality.

Mold Design Considerations Impacting Warpage

The form of the mould in itself is a predominant cause of warping. Improper mold design can make unequal cooling and stress, and the defect becomes more serious. The following mould design suggestions may be some typical factors to be considered:

- Cooling System Design: The mold cooling channels have to be designed in such a way that they provide uniform cooling of the part. Insufficient or improperly distributed cooling channels can create hot spots, resulting in non-uniform shrinkage and warpage.

- Gate Location and Size: This is where the plastic enters the mold in a molten state. Misaligned or improperly sized gates produce uneven material flow, which generates stress concentrations and warpage. More than one gate may be required for complicated parts to achieve a balanced fill.

- Wall Thickness: Different wall thicknesses will cool at different rates because a thicker area will take longer to cool down compared to a thinner counterpart. It reduces warpage hazards when you use parts with consistent wall thicknesses.

- Ejector Pin Placement: Ejector pins transmit the finished part out of the mold after cooling. Misapplied pins can exert uneven pressure, and the part can be deformed as it is ejected.

- Mold Material and Surface Finish: Mold material and its surface finish can influence heat transfer rates and the ease with which the part will be ejected from the mould, both of which can affect the warpage.

Well-designed mould accounts for these factors to minimize warpage and ensure consistent part quality.

Methods and Techniques to Prevent and Reduce Warpage

Warpage can only be eliminated by a combination of material selection, process control and mold design. Here are some proven ways and techniques to minimize warpage in an injection molding process:

- Material Selection and Preparation: Use material with a low shrinkage factor and see to it that it is properly dried to no moisture. It also doesn’t hurt that the quality of the resin remains consistent through strict supplier checks.

- Optimized Process Parameters: Employ methods like Design of Experiments (DOE) to optimize injection pressure, cooling time, melt temperature, and packing pressure. The software simulation can be used to predict the possibility of warp and to set parameters.

- Uniform Cooling Systems: Molds with well-distributed and efficient cooling circuits guarantee an even cooling process. The use of advanced cooling, for example, conformal cooling, may also assist in reducing warpage in complex parts.

- Balanced Mold Design: Balanced wall thickness, the location of the gate, and ejection pins. Mold flow analysis software at the design stage can help reduce warpage risks at the outset.

- Post-Molding Techniques: Annealing or stress relieving can decrease the molded-in stress of parts and reduce warp. Parts can also be retained in their desired shape when cooling by fixtures or jigs.

- Prototyping and Testing: Develop prototypes for material and mold testing under real-world conditions. The use of iterate testing enables us to find and fix the warpage early enough in the process to avoid warpage-related problems during production.

By combining these strategies, manufacturers can significantly reduce warpage and improve part quality.

Impact of Warpage on Part Quality and Usability

Warpage affects injection-molded parts’ quality and usability. Warped parts may miss dimensional tolerances, causing assembly issues like misaligned automotive dashboards, leading to gaps. Aesthetically, uneven surfaces harm consumer products’ appeal, risking brand reputation. Functionally, warpage can cause mechanical failures, especially in precision-critical industries like aerospace. Warpage also raises costs through rejections and extra quality controls. Proactive warpage management ensures efficiency and profitability.