Reaction Injection Molding (RIM) is one of the best processes to produce lightweight, durable, complex parts. This process is versatile as it permits the fast and high-performance parts with high strength-to-weight ratio advantages that allow you to create designs with unmatched restrictions, giving you many freedoms. It’s an efficient solution for creating intricate parts.

Understanding the reaction injection molding process is an important step to making use of it. This guide will provide a review of the RIM process, allow you to see the reaction injection molding advantages and disadvantages, and lay out the various applications, demonstrating that RIM is an extraordinarily useful manufacturing process.

What Is Reaction Injection Molding?

Definition

Reaction injection molding (RIM) is a low-pressure manufacturing process. It involves precisely mixing two raw materials in a liquid state, then injecting that mixture into a mold. The mixture then cures and becomes a solid reaction injection molding part with a chemical reaction within the mold.

The process of reaction injection molding is inherently different from standard injection molding because RIM utilizes thermoset plastics. These plastics will harden permanently once made inside the mold. Thus, it allows for very large and tough parts. You will find that with these parts, there are virtually no sink marks, meaning that they will look great right out of the box.

Benefits

With the reaction injection molding process, you can design freely. This process enables you to add ribbing, bosses, undercuts, and different thicknesses, with all of these features being added in one shot. You can concentrate on your designs without being limited by manufacturing constraints.

RIM can also build large, lightweight, strong parts, like car dashboards, medical device housings, or aircraft interior panels. Apart from being large, these parts also have an excellent strength-to-weight ratio. They are very durable, and even larger parts are not heavy. And you’ll love the cosmetic finish right from the mold.

Finally, low-cost tooling is a tremendous advantage; aluminum or epoxy molds are far cheaper than steel. As a result, you will get a fast turnaround which is terrific for prototypes or small production runs. The easy ability to use inserts and foam cores by incorporating metal or foam during the RIM reaction injection molding will appeal to all designers.

Limitations

Even though reaction injection molding has a lot of positives, it is important to understand the limits. One of the limitations is fine detail; very small text or extremely thin ribs can be hard to get to fill reliably in RIM. If you are designing a product that includes small or intricate features, you will either need to modify your design intent or consider options outside of custom reaction injection molding.

Also consider tool life. Molds in the reaction injection molding process often utilize softer materials such as aluminum or epoxy. This softer tooling can yield wear after thousands of cycles. This is worth mentioning if you intend to produce in very high volume over a long period of time, and RIM can affect your overall tooling cost.

Additionally, your material choice is limited. Only thermoset polyurethanes and other similar resins can be processed through RIM; common plastics like ABS or PP are limited. For very large parts, you may have fill and cure limits, which may require a longer cycle time, or you may have to use some specialized gates to allow for proper fill and cure for the entire mold.

Applications

Reaction injection molding services are utilized to bring high-performance, lightweight, durable parts to many industries. From automotive and medical devices, reaction injection molding services can deliver complex geometries and good strength-to-weight ratios. Below are more detailed examples of parts using the RIM process categorized by industry.

| Industry | RIM-Produced Parts |

| Automotive | Bumper coversFender flaresSpoilers & aerodynamic panelsInterior trim & dash componentsHVAC housings |

| Electronics & Consumer Goods | Kiosk housingsDrone fuselagesTool handles & protective casesWearable device enclosuresElectronic instrument casings |

| Medical & Healthcare | Medical device enclosuresProsthetic componentsSurgical tool housingsDiagnostic equipment panels |

| Aerospace & Defense | Aircraft interior trimUAV (drone) componentsRadar housingsSeating & cabin panels |

| Marine & Recreational | ATV/UTV body panelsBoat hatches & trimRV roofs & compartmentsWatercraft housings |

| Industrial & Machinery | Machine guards & coversPump housingsConveyor componentsExercise equipment shells |

Suitable Materials

Reaction injection molding materials usually take the form of two-part systems that will create a chemical reaction with each other to form a solid part. The most common materials are polyurethane (PU) systems; there are also other thermoset materials of polyamide, silicone, polyesters, and fiber composites, that retain special properties. Tier the material closest for strength, flexibility, heat resistance, etc., for your use case.

Here are the suitable materials you can use with RIM:

| Material | Typical Properties | Best For |

| Polyurethanes (PU) | High impact, flexible, wide hardness, paintable. | Automotive, medical, large enclosures, ergonomic grips. |

| Polyamides (PA-RIM) | Chemical-resistant, high-heat, stiff, and strong. | Under-hood auto, fluid reservoirs, and industrial parts. |

| Fiber Composites | Very high strength-to-weight, stiff, impact-resistant. | Structural, aerospace, high-performance sports, and auto panels. |

| Silicone (LIM) | Flexible, extreme temp resistant, biocompatible, electrical insulator. | Medical, seals, gaskets, wearables, electrical, food-contact. |

| Polyester (DCPD-RIM) | Rigid, good impact, excellent heat resistance. | Agricultural, heavy truck, construction, and large industrial enclosures. |

How RIM Works?

Types of Reaction Injection Molding

Reaction Injection Molding (RIM) can provide specialized forms that all offer unique solutions for varying manufacturing needs. We will discuss the differences between Standard RIM, Structural RIM (SRIM), and Reinforced RIM (RRIM).

Standard RIM

Standard RIM consists of two low-viscosity liquid components being mixed together and cured in the mold. The result is lightweight but solid reaction injection molding parts suitable for a range of uses. When needing to create complex shapes with medium strength potential for general use products, RIM is a proven method.

You should pick Standard RIM for items like car interiors, various medical device housings, and many consumer goods. Its ability to produce well-finished, solid components efficiently makes it a go-to method for parts that don’t require extreme structural reinforcement.

SRIM – Structural RIM

SRIM or Structural RIM, is a process where long glass or carbon fibers are laid into the mold before the liquid resins are injected. The added step of strategic fiber placement produces stiff and strong large panels.

SRIM is best for large parts that will be used to carry heavy loads or endure extreme forces. It is typical for applications like automotive body panels, aerospace structural walls, and heavy-duty industrial covers that require high strength and rigidity.

RRIM – Reinforced RIM

Reinforced RIM is RIM with short chopped fibers added to the liquid resin blend prior to injection. The addition of fibers gives the parts internal reinforcement, resulting in reaction injection molding parts with impact resistance, increased strength, and improved dimensional stability, meaning they can retain their shape better for a longer time under stress.

You should pick RRIM for parts that require extra durability and impact strength without the need for separate, pre-laid reinforcement. This is a great choice for manufactured parts that require high degrees of use, durability and additional resistance to impact and deformation.

Quick Summary

| Type | Key Feature | Strength Level | When to Use |

| Standard RIM | Liquid mix cures in mold | Medium | Complex shapes, general parts (car interiors, medical housings) |

| SRIM | Long fibers laid in mold first | Very high | Large load-bearing panels (auto body, aerospace walls) |

| RRIM | Short fibers mixed into resin | High impact | Tough, impact-resistant parts without extra lay-up |

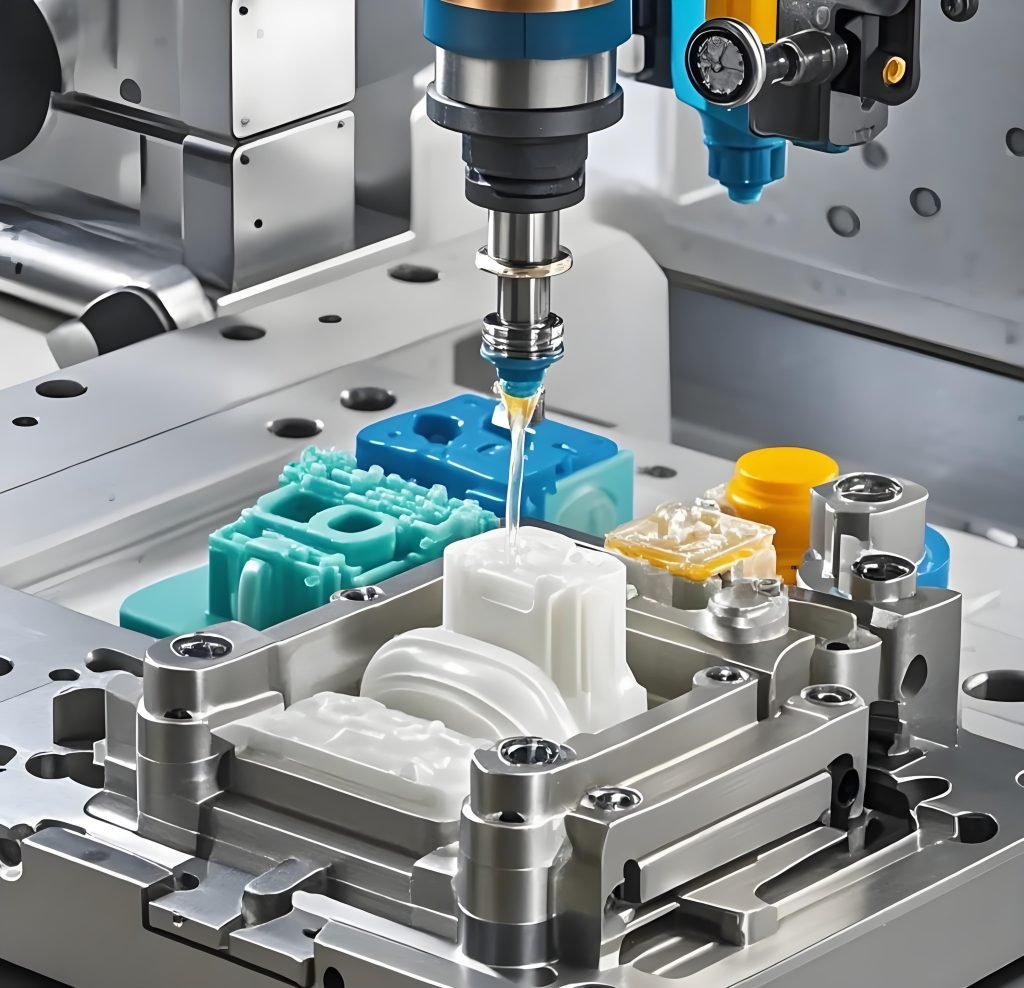

Key RIM Equipment & Process

The reaction injection molding process is executed precisely by following the steps, using the appropriate equipment, and turning your design into a physical form.

The storage hopper keeps the two liquid chemicals clean and dry in sealed bins. An integrated heating system uses inline heaters and jacketed hoses to maintain each resin at a precise temperature, ensuring fast and even curing once mixed. This preparation phase is crucial for material stability and optimal reaction.

Next, the metering & mixing unit employs high-precision pumps and static mixers to deliver the perfect A: B chemical ratio with every shot. The injection pump, hydraulic or electric piston-driven, will smoothly supply the perfectly blended resin into the mold at a controlled low pressure and begin the chemical process.

Ultimately, the mold clamping unit uses hydraulic, pneumatic, or servo screw type clamps to accurately align the mold halves and withstand injection pressures. RIM also hires a PLC/CNC control system with a touchscreen to oversee the entire cycle, including monitoring mold temperature, pressure, process time, and component ratio for repeatability and production consistency.

Reaction Injection Molding Design Guidelines

When designing parts for RIM, keeping a few reaction injection molding design guidelines in mind can help ensure the best results:

Wall thickness

RIM is quite forgiving with wall thickness. Ideal thicknesses range from 3 mm to 10 mm. However, you can make much thicker sections with less worry of sink marks – often associated with traditional injection molding when you have thick walls.

Draft angles

Due to the relatively low injection pressure (10 MPa) and the qualities of the materials, there are no large draft angles required for RIM parts. An angle of 0.5° to 1° is typically adequate for removing the part from the mold when finished.

Radii

Always use generous radii – especially on inside corners. It is good practice to include a minimum of 1mm inside radius so stress concentrations are not present in the part to prevent a potential for cracking.

Undercuts

Undercuts are absolutely possible with RIM. Molds for RIM are most often made of softer materials, often aluminum or epoxy, and some materials may even flex slightly during demolding, which makes removing pieces with undercuts that much easier.

Inserts

Metal or plastic inserts can be located directly in the mold in advance of the liquids being injected. When the liquid polymers are injected, they will flow around the inserts and will encapsulate them – creating a strong bond. This is a great means of providing threaded holes, mounting points or other features in a piece.

Why Choose Fecision for Custom Reaction Injection Molding Services?

RIM, or Reaction Injection Molding, blends liquid polymers to create strong yet lightweight parts of virtually any complexity. It is used for automotive, medical, and industrial applications, and has significant advantages in design freedom and cost efficiency using polyurethane or composite materials.

If you are looking for a good custom reaction injection molding manufacturer, Fecision provides precision RIM services for high-performance lightweight components. Our custom RIM services leverage advanced technology to produce durable components with complex geometries for automotive, medical, electronics, and industrial applications.

Why Choose Fecision?

- Advanced RIM Expertise – Cutting-edge equipment and engineering support

- Custom Solutions – From prototypes to mass production

- Wide Material Selection – Polyurethane, polyurea, and reinforced composites

- Cost-Effective Production – Lower tooling costs vs. traditional methods

Ideal for bumpers, medical housings, drone components, and more, our RIM process ensures strength, precision, and design flexibility.

Get a Quote Today! Contact Fecision for reliable reaction injection molding services.