Injection molding is one of the most widely used manufacturing processes for producing a vast array of components, from small household products to complex industrial parts. However, precision injection molding, a specialized form of this process, has become crucial in industries requiring high-quality, intricate, and highly detailed parts. This article explores the concept of precision injection molding, its key features, applications, advantages, disadvantages, and how it compares with conventional injection molding.

1. Basics of Precision Injection Molding

Precision injection molding is a specialized technique of injection molding that focuses on producing parts with extremely tight tolerances, high precision and superior surface finishes. This process is an enhancement of traditional injection molding, ensuring that each part produced meets the most demanding specifications, which are essential in industries like aerospace, medical, and electronics. In this process, the molten material is injected into a mold under high pressure. The mold is designed and fabricated with greater accuracy, ensuring that the resulting parts have minimal variation and can be produced consistently at high volumes.

Key Features of Precision Injection Molding

- Tight Tolerances: Precision injection molding is known for its ability to maintain tight tolerances, often in the range of ±0.001 inches (±0.025 mm), which is far tighter than what is achievable with standard injection molding processes.

- High-Quality Surface Finish: The process can produce parts with smooth surfaces, eliminating the need for post-processing steps like polishing or grinding.

- Consistency and Repeatability: Precision injection molding ensures that each part produced meets the same specifications and quality, making it ideal for high-volume production.

- Complex Geometries: The technique allows the creation of parts with intricate designs and fine details that would be difficult or impossible to achieve with traditional manufacturing methods.

Advantages and Disadvantages of Precision Injection Molding

- Tight Tolerances and High-Quality Surface Finish: One of the key benefits of precision injection molding is its ability to produce parts with highly accurate dimensions and smooth, aesthetically pleasing surfaces. This is crucial for industries where even slight variations could lead to failure.

- Cost-Effectiveness in the Long Run: Although precision injection molding may have higher initial setup costs due to specialized molds and equipment, its high-speed, repeatable production ensures low cost per unit in the long term, making it ideal for large-scale manufacturing runs.

- Complex and Intricate Parts: The technology allows the production of intricate geometries, micro-features, and complex internal structures, which are often necessary for high-tech industries such as medical and aerospace.

- Minimal Waste: Since precision injection molding uses materials more efficiently, it helps reduce waste, which is beneficial both environmentally and economically.

Disadvantages

- Higher Initial Tooling Costs: The most significant disadvantage of precision injection molding is its high initial cost for designing and creating custom molds. These molds are typically made from high-grade materials, which increase the upfront costs. However, these costs can be offset by the long-term benefits of the process.

- Longer Lead Times: Due to the complexity of designing and fabricating the molds, the lead times for setting up precision injection molding processes can be longer than traditional injection molding.

- Limited Material Selection: Although a wide range of materials can be used in precision injection molding, certain complex or advanced materials may not be suitable for this type of process.

2. Applications of Precision Injection Molding

Aerospace and Automotive Parts

Precision injection molding is extensively used in the aerospace and automotive industries for producing components that need to meet exacting standards for safety, performance, and durability. Parts such as fuel system components, connectors, housings, and structural components are typically manufactured using precision injection molding due to the need for high precision and consistency.

Medical and Pharmaceutical Components

In the medical field, components such as surgical tools, drug delivery systems, and diagnostic devices often require precision injection molding. These parts are typically made from biocompatible materials and must adhere to stringent regulatory standards. The high precision of the process ensures that these parts fit seamlessly and function properly in critical medical applications.

Electronics and Optical Devices

Electronics and optical devices, including connectors, enclosures, lenses, and circuit boards, often demand precision injection molding. With the rise of miniaturized and high-performance electronics, the ability to produce extremely small and intricate parts has become a crucial requirement in this sector.

3. Precision Injection Molding Process and Techniques

The precision injection molding process involves several key steps, from mold design to post-production quality control. Each step is executed with the highest level of care to ensure that the final product meets all required specifications.

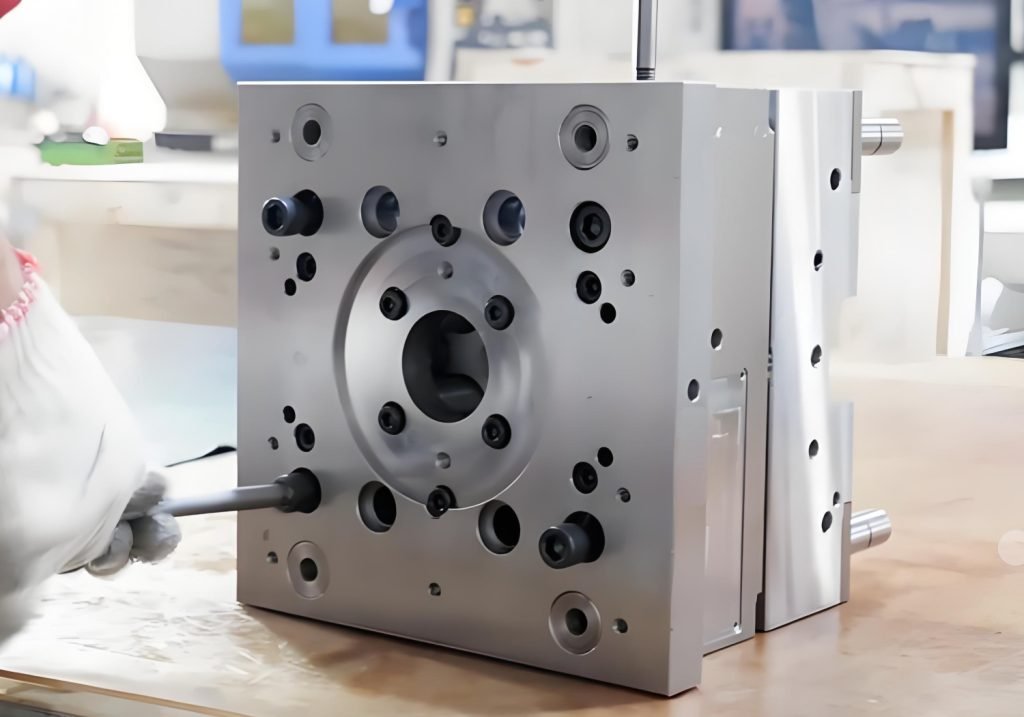

Mold Design and Tooling Precision

The first step in the precision injection molding process is mold design. Unlike standard molds, which may be designed for general use, precision molds require detailed planning and high levels of accuracy. This stage involves the use of advanced CAD software to design the mold, followed by the creation of high-precision tooling. The tooling must be fabricated to tight tolerances to ensure the desired part quality.

Role of Process Control and Automation

In precision injection molding, maintaining consistent temperature, pressure, and injection speed is crucial to achieving the desired quality. Automation systems are often employed to monitor and control these variables, ensuring that each part is produced with the same level of precision. Advanced sensors and real-time data collection enable operators to make adjustments to the process as needed.

Equipment Used in Precision Injection Molding

High-Precision Injection Molding Machines

Precision injection molding requires specialized machinery capable of delivering consistent pressure and temperature control. These machines are equipped with advanced features such as closed-loop feedback systems, which ensure that all variables—such as injection speed, pressure, and temperature—are tightly controlled during production.

Advanced Cooling and Monitoring Systems

Cooling plays a significant role in the quality of the molded part. Precision injection molding machines are often equipped with advanced cooling systems that help to control the cooling rate of the material as it solidifies. This ensures that the material is molded to the required dimensions and prevents issues such as warping or dimensional inconsistencies.

Materials Used in Precision Injection Molding

Engineering Plastics (PEEK, POM, PC)

In precision injection molding, high-performance engineering plastics such as Polyetheretherketone (PEEK), Polyoxymethylene (POM), and Polycarbonate (PC) are commonly used. These materials are chosen for their superior mechanical properties, heat resistance, and chemical stability, making them ideal for demanding applications.

Composite and Reinforced Materials

Precision injection molding can also accommodate composite and reinforced materials, which combine plastics with fibers, metals, or other materials to enhance their strength, stiffness, and durability. Carbon fiber-reinforced plastics, for instance, are often used in aerospace and automotive applications due to their lightweight and high-strength properties.

4. Cost Considerations in Precision Injection Molding

Several factors influence the cost of precision injection molding, including the complexity of the mold, the choice of material, the size of the production run, and the required tolerance levels. Custom tooling and mold design can increase initial costs, while high-quality materials may also contribute to higher expenses.

Tooling, Machine Calibration, Material

Tooling costs are often the most significant contributor to the high upfront costs of precision injection molding. Machine calibration is another important cost factor, as the precision equipment used requires frequent adjustments to maintain optimal performance. The choice of material also plays a role in cost, as high-performance materials such as PEEK and reinforced composites tend to be more expensive than standard thermoplastics.

Cost Comparison with Standard Injection Molding

While precision injection molding typically incurs higher initial costs due to tooling and material choices, its ability to produce high-quality parts with minimal waste and high repeatability often results in lower per-unit costs over the long run, especially for large-scale production. Standard injection molding may be cheaper upfront, but its lack of precision can result in higher rates of defects, rework, and waste, ultimately making precision injection molding a more cost-effective solution for high-quality parts.

5. Precision Injection Molding vs. Conventional Injection Molding

The primary difference between precision injection molding and conventional injection molding lies in the tolerances and quality of the finished products. Precision injection molding is designed to produce parts with tighter tolerances and superior surface finishes, which are necessary for industries that demand the highest standards of quality and performance. Conventional injection molding, on the other hand, may not be able to meet these stringent requirements.

Cost and Production Efficiency Comparisons

While precision injection molding typically incurs higher initial costs, it offers benefits in terms of reduced waste and increased efficiency in high-volume production. Conventional injection molding, while less expensive initially, may lead to greater material waste and quality issues, ultimately resulting in higher costs over time. Thus, precision injection molding is the preferred choice for high-performance applications where quality and reliability are paramount.

6. FAQs about Precision Injection Molding

What is the primary difference between precision injection molding and conventional injection molding?

The main difference between precision injection molding and conventional injection molding lies in the level of accuracy and quality achieved during production. Conventional injection molding, on the other hand, typically does not meet the same stringent requirements for high-performance applications, resulting in parts with less precision and potentially higher variations.

What industries benefit most from precision injection molding?

Industries that require high-precision components, such as aerospace, automotive, medical, pharmaceutical, electronics, and optical devices, are the primary beneficiaries of precision injection molding. These sectors demand parts that meet strict standards for safety, durability, and performance, making precision molding the ideal choice to ensure high-quality, reliable parts in critical applications.

Why are the initial costs of precision injection molding higher?

The initial costs of precision injection molding tend to be higher due to the custom design and fabrication of high-precision molds and tooling, as well as the use of specialized, high-performance materials. Creating molds that can maintain tight tolerances requires advanced technology and detailed craftsmanship, which can drive up costs.

What materials are typically used in precision injection molding?

In precision injection molding, engineering plastics such as PEEK (Polyetheretherketone), POM (Polyoxymethylene), and PC (Polycarbonate) are commonly used due to their excellent mechanical properties, heat resistance, and chemical stability. Additionally, composite and reinforced materials, such as carbon fiber-reinforced plastics, are often chosen for applications requiring enhanced strength, stiffness, and durability, particularly in industries like aerospace and automotive.

How does precision injection molding ensure consistent quality in production?

Precision injection molding ensures consistent quality by using advanced machinery and precise process control techniques. High-precision injection molding machines are equipped with systems to control temperature, pressure, and injection speed, ensuring uniformity throughout the production process.

7. Conclusion

Precision injection molding is a high-tech manufacturing process that enables the production of parts with exceptional accuracy, fine details, and superior surface finishes. Its advantages include tight tolerances, high-quality surface finishes, and the ability to handle complex geometries, making it ideal for industries like aerospace, medical, and electronics. When deciding whether to use precision injection molding, manufacturers must consider factors such as the complexity of the part design, the required tolerances, material choices, and cost constraints. While it may involve higher upfront costs, the long-term benefits in terms of part quality, production efficiency, and reduced waste make precision injection molding a valuable choice for high-performance components.