Die casting is a process through which different metals are heated and molded into strong metal parts for multiple manufacturing needs. However, not all metals used in this process are equal in performance, cost, and durability.

According to reports, non-ferrous metals such as zinc, copper, aluminum, and tin-based alloys are mostly used for die casting. Each of these metals offers unique benefits depending on the intended use.

In this article, we’ll break down the most common materials used in die-cast metal. Let’s get into it.

What is Die Casting?

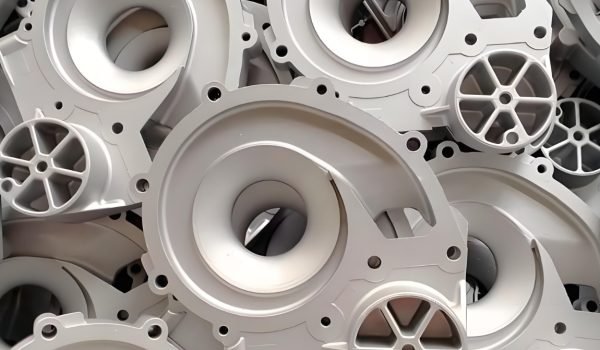

Metal Die casting is a manufacturing process used to make metal parts by forcing molten metal into a mold under high pressure. The mold, also called a die, is made from hardened steel and designed to create thousands of identical parts with high precision.

This process is best for making parts that need to be strong, lightweight, and detailed, like engine components, power tool housings, or smartphone frames.

There are two main types of metal die casting:

- Hot chamber die casting: Best for metals with low melting points, like zinc and magnesium.

- Cold chamber die casting: Used for metals like aluminum that melt at higher temperatures.

Metal die casting is fast, cost-effective for mass production, and creates parts that usually need little to no machining afterward. That’s why it’s commonly used in the automotive, aerospace, electronics, and industrial sectors.

Most Common Die-Cast Metals That Are Used

Let’s discuss the most common metals used in die casting in detail:

| Material | When should you use it? | Industries used in |

| Aluminum | Ideal for lightweight parts with high strength and heat resistance. | Automotive, Aerospace, Consumer Electronics |

| Zinc | Best for complex, thin-walled parts with high precision and smooth finishes. | Electronics, Automotive, Medical Devices |

| Magnesium | Choose this option when you need lightweight, strong components with great electrical performance. | Aerospace, Consumer Electronics, Automotive |

| Copper Alloys | Great for high-strength parts that need good conductivity and wear resistance. | Plumbing, Electrical, Industrial Machinery |

| Lead and Tins | Typically used for decorative or low-friction parts, but is less common due to toxicity concerns. | Niche Industrial, Vintage Hardware |

1. Aluminum

Aluminum is a widely used metal in die casting. It’s known for being lightweight yet extremely strong, corrosion-resistant, and excellent at handling high temperatures. That makes it perfect for parts requiring strength and performance, like engine components or structural supports.

Why Choose Aluminum?

- High strength-to-weight ratio

- Excellent thermal and electrical conductivity

- Corrosion resistance

- Cost-effective for mass production

Common Applications

Engine blocks, housings, brackets, LED light housings, and automotive frames.

2. Zinc

Zinc is perfect when your part needs fine details, complex shapes, or tight tolerances. It melts easily into molds, making it ideal for thin-walled castings. Zinc parts also have a smooth surface finish, which reduces post-processing time.

Why Choose Zinc?

- Excellent for small and intricate designs

- Great dimensional stability

- Long life expectancy due to low melting point.

- High impact strength

Common Applications

Locks, gears, connectors, toys, and medical devices.

3. Magnesium

Magnesium is the lightest structural metal used in this procedure. It’s about 33% lighter than aluminum but still offers impressive strength. Moreover, magnesium has great vibration-damping and electromagnetic shielding properties.

Why Choose Magnesium?

- Very lightweight

- Strong and stiff

- Good for electromagnetic shielding

- Excellent machinability

Common Applications

Laptop and smartphone casings, automotive steering wheels, and power tools.

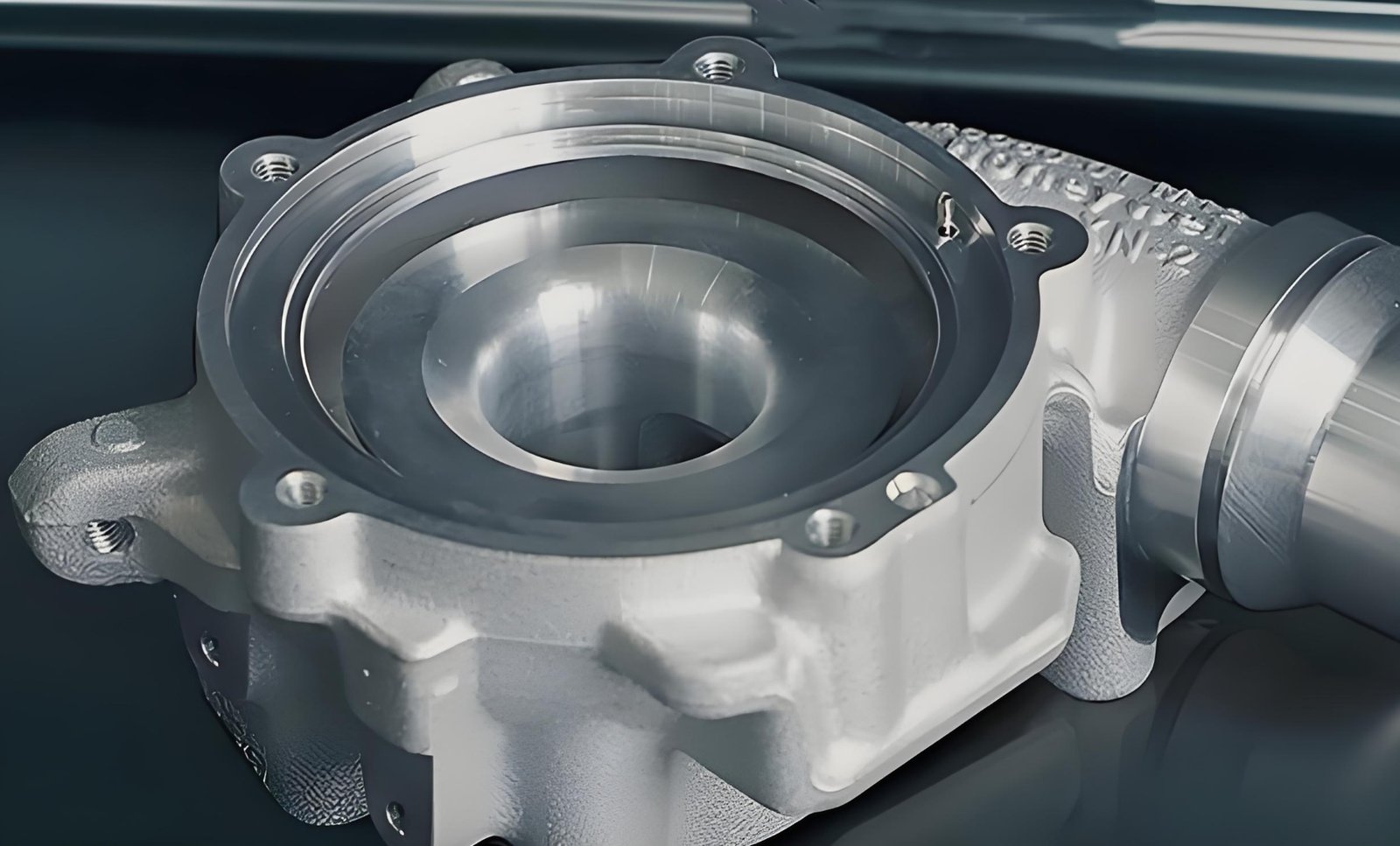

4. Copper Alloys (Including Brass and Bronze)

Copper-based alloys like brass and bronze are not as common in die casting as aluminum or zinc, but they’re used when durability and conductivity are top priorities. These metals resist corrosion and have excellent wear resistance.

Why Choose Copper Alloys?

- High mechanical strength

- Great corrosion resistance

- Excellent electrical conductivity

- Long service life

Common Applications

Electrical components, plumbing fixtures, bushings, and industrial equipment.

5. Lead and Tin

Lead and tin were historically used in metal die casting for low-friction and decorative applications, such as antique parts and badges. However, due to health and environmental concerns, their use is now limited to specialized or regulated applications.

Why Choose Lead and Tin?

- Easy to cast

- Low melting points

- Smooth surface finish

- Good for artistic or historical replicas

Common Applications

Decorative trims, bearings, soldering parts, and antique reproductions.

Choosing the Right Metal for Die Casting

Selecting the right metal for your die-casting project depends on the needs of your product. Different metals offer different advantages. Here’s a breakdown of the most crucial factors to help you make an informed choice.

1. Strength

If your part needs heavy loads or high stress, go for metals with excellent mechanical strength. For instance:

- Aluminum offers a great balance between strength and weight, making it ideal for automotive and aerospace components.

- Copper alloys are the strongest among common die-casting metals and are best for wear-heavy parts like gears or valves.

Best choice for strength: Copper Alloys > Aluminum > Zinc

2. Weight

Weight matters in industries where lightweight design is key, like aerospace, electronics, or EVs. A couple of metals that fit well in this category include:

- Magnesium is the lightest die-cast metal, 33% lighter than aluminum, and great for handheld or portable devices.

- Aluminum is also lightweight and more commonly used due to its balance of cost and strength.

Best choice for weight-saving: Magnesium > Aluminum > Zinc

3. Corrosion Resistance

Exposure to water, humidity, or chemicals can damage some metals over time. That’s why it’s important to choose a metal with natural corrosion resistance that will extend the life of components.

- Copper alloys are highly resistant to corrosion and suitable for plumbing and marine applications.

- Zinc has decent corrosion resistance and is often plated or coated for more protection.

Best for corrosion resistance: Copper Alloys > Aluminum > Zinc

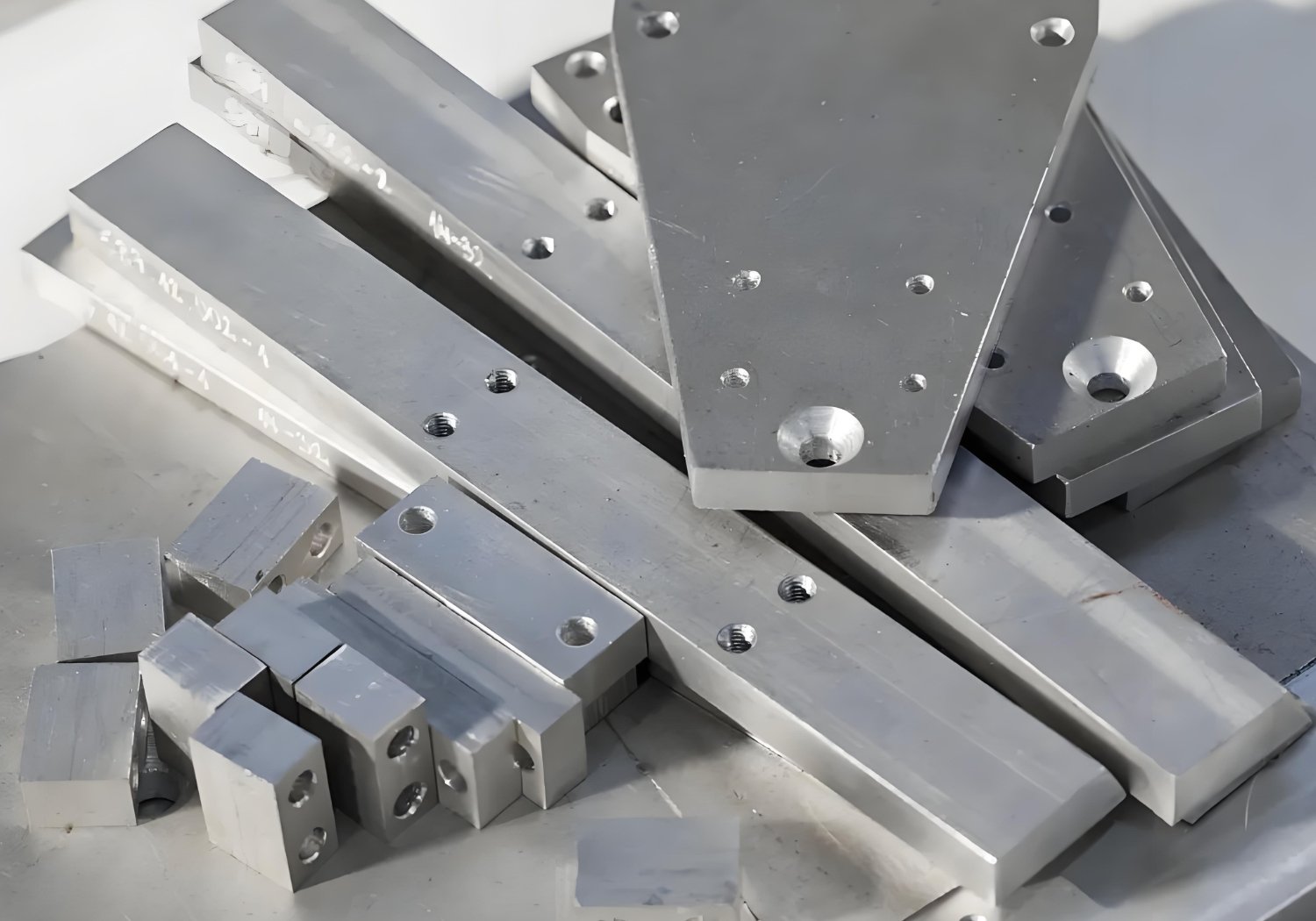

4. Machinability

A metal’s machinability affects how easily and cleanly it can be cut, drilled, or shaped. It’s crucial because some die-cast parts may need additional machining after casting. A couple of the best options if you’re going for something like this:

- Magnesium has excellent machinability and is often chosen when secondary operations are required.

- Zinc is also easy to work with and great for high-precision jobs.

Easiest to machine: Magnesium > Zinc > Aluminum

5. Cost and Quantity

The last factors that will play a role in your choice of a die-casting metal are your budget and production volume. The best ones include:

- Zinc is the most cost-effective for high-volume production due to fast cycle times and long die life.

- Aluminum is moderately priced but can cost more due to tooling and slower cold chamber casting.

Best for budget and bulk orders: Zinc > Aluminum > Magnesium

Partner with Fecision for Precision Die Casting Solutions

Choosing the right metal for die casting isn’t just about the material—it’s about what your part needs to do, how it will be used, and how efficiently it can be produced.

At Fecision, we help you make the best choice based on your design, performance, and cost goals. With a team of experts, we deliver high-quality components across industries—from automotive to electronics and beyond.

Contact us today for a consultation or custom quote!