Have you ever wondered what happens to silicone materials when they’re exposed to high temperatures? As a manufacturer, understanding the thermal properties of silicone rubber is crucial for producing high-quality products.

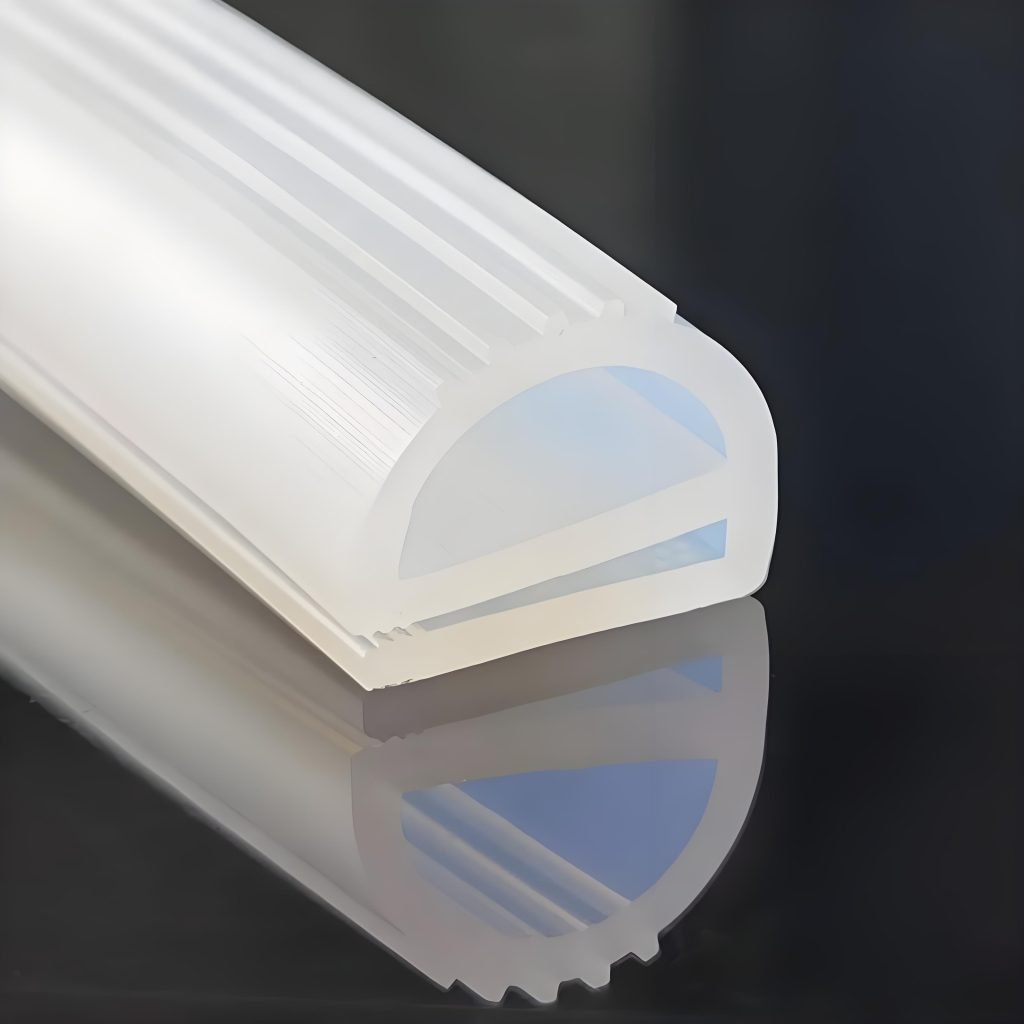

Silicone materials are known for their versatility and resilience, making them a staple in various industries, from automotive to medical devices. Their unique composition provides flexibility, thermal stability, and resistance to chemicals and weathering.

But what happens when silicone rubber is subjected to extreme heat? Unlike conventional materials, silicone rubber exhibits unique behavior, making it essential to understand its melting characteristics for proper application in industrial processes.

The Unique Thermal Properties of Silicone Rubber

Silicone rubber is renowned for its exceptional thermal properties, making it a crucial material in various high-temperature applications. You might be wondering what makes silicone rubber so special. The answer lies in its unique composition and structure.

What Makes Silicone Different from Other Materials

Silicone rubber stands apart from conventional polymers due to its silicon-oxygen backbone (Si-O-Si), which creates stronger bonds than the carbon-carbon chains found in organic rubbers. This results in exceptional thermal stability, allowing silicone rubber to maintain its mechanical properties across a wide temperature range. Unlike most polymers that soften and melt at relatively low temperatures, silicone rubber is flexible yet heat-resistant.

Chemical Composition and Structure

The chemical composition of silicone rubber includes silicon, oxygen, carbon, and hydrogen. The silicon-oxygen bonds provide remarkable resistance to oxidation and thermal degradation. The molecular structure features alternating silicon and oxygen atoms with organic groups attached to the silicon atoms, creating a flexible yet heat-resistant material. Various additives and fillers can be incorporated into silicone formulations to enhance specific properties, such as improved thermal conductivity or flame resistance.

By understanding the unique thermal properties of silicone rubber, you can appreciate its value in high-temperature applications and make informed decisions about its use in various industries.

Does Silicone Rubber Actually Melt?

Unlike other materials, silicone rubber doesn’t melt in the traditional sense when exposed to high temperatures. Instead, it undergoes a process known as thermal degradation.

The Thermal Degradation Process

When silicone rubber is exposed to extremely high temperatures, typically above 200°C (392°F), it begins to break down rather than melt. The exact threshold varies based on the specific formulation and additives present in the silicone rubber.

During thermal degradation, silicone rubber first softens and loses its elasticity. As the temperature continues to rise, it becomes increasingly brittle before ultimately breaking down into silicon dioxide (silica) and various gaseous byproducts.

Difference Between Melting and Degradation

The distinction between melting and degradation is crucial for manufacturing applications. Unlike thermoplastic materials that melt and resolidify, silicone rubber maintains its structural integrity until it reaches the point of chemical breakdown.

Understanding that silicone rubber degrades rather than melts helps engineers design parts and select appropriate processing methods for high-temperature applications. The degradation process is irreversible, meaning once silicone rubber has thermally degraded, it cannot be reformed or reprocessed.

Silicone Rubber Melting Point: Understanding the Range

When it comes to silicone rubber, the concept of a melting point can be misleading, as it doesn’t behave like traditional materials. Unlike many other polymers, silicone rubber doesn’t have a sharp melting point; instead, it exhibits a range of temperatures where it softens and eventually degrades.

Standard Temperature Ranges for Different Silicone Types

Different types of silicone rubber have varying temperature ranges. General-purpose silicones typically operate between -50°C to 200°C (-58°F to 392°F), while specialized high-temperature formulations can function at temperatures up to 300°C (572°F) for intermittent periods. Standard silicone rubber usually softens around 150°C (302°F) and can degrade around 200°C (392°F). In contrast, high-temperature silicone can withstand up to 250°C (482°F) or higher.

Understanding these temperature ranges is crucial for selecting the right silicone rubber for your specific application. Whether you’re working in the automotive, aerospace, or medical device industry, choosing a silicone rubber that can withstand the required temperatures is essential for ensuring the longevity and performance of your product.

How to Interpret Manufacturer Temperature Specifications

When manufacturers specify temperature ratings for silicone rubber, they’re typically referring to the maximum continuous operating temperature—the highest temperature at which the material can function for extended periods without significant degradation. It’s essential to distinguish between short-term temperature resistance and long-term temperature stability when interpreting these specifications. Silicone rubber can often withstand brief exposures to temperatures higher than its rated continuous operating temperature, but prolonged exposure can lead to degradation.

By understanding the temperature range of silicone rubber and how to interpret manufacturer specifications, you can make informed decisions about material selection and ensure optimal performance in your applications.

Working Temperature Ranges for Different Grades of Silicone

Understanding the working temperature ranges of different silicone grades is crucial for selecting the right material for your application. Silicone rubber is available in various formulations, each designed to perform optimally within specific temperature ranges.

General Purpose Silicone

General-purpose silicone grades typically offer a working temperature range from -50°C to 200°C (-58°F to 392°F), making them versatile for a wide variety of standard applications where moderate heat resistance is required. These standard silicone formulations provide excellent flexibility, electrical insulation, and weather resistance across their operating temperature range.

High-Temperature Silicone

High-temperature silicone grades are specially formulated with heat-stabilizing additives that extend their upper temperature limit to 260°C-300°C (500°F-572°F) for continuous use and even higher for intermittent exposure. These premium high-temperature silicones maintain their mechanical properties and elasticity at temperatures where standard grades would degrade.

Flame-Retardant Silicone

Flame-retardant silicone grades combine temperature resistance with self-extinguishing properties, typically withstanding temperatures up to 220°C (428°F) while meeting stringent fire safety standards. These specialized formulations contain additives that suppress combustion and minimize smoke generation, making them crucial for applications where fire safety is paramount.

By understanding the specific working temperature ranges for different silicone grades, you can select the optimal material for your application requirements, balancing performance needs with cost considerations.

Thermal Conductivity of Silicone Materials

Understanding the thermal conductivity of silicone is essential for selecting the right material for your specific needs. Silicone materials have unique thermal properties that make them suitable for various applications, from thermal insulation to heat dissipation.

How Thermal Conductivity Affects Performance

The thermal conductivity of silicone significantly impacts its performance in applications like LED lighting, power electronics, and battery systems. Standard silicone rubber has low thermal conductivity (0.15-0.3 W/mK), making it an excellent thermal insulator. For applications requiring heat dissipation, thermally conductive silicones are available, with conductivity values ranging from 1.0 to 5.0 W/mK.

Comparing Silicone to Other Manufacturing Materials

Compared to metals, silicone remains a relatively poor heat conductor, but it offers advantages in flexibility, electrical insulation, and corrosion resistance. When compared to other elastomers and polymers, silicone offers a unique combination of temperature stability and customizable thermal conductivity, making it valuable for specialized thermal management applications.

Factors Influencing the Melting Point of Silicone Rubber

Understanding the factors that affect the melting point of silicone rubber is essential for its application. The melting point is not just a simple value; it’s influenced by various elements that can be adjusted to suit specific needs.

Chemical Additives and Fillers

The type and concentration of chemical additives and fillers play a significant role in determining the thermal stability of silicone rubber. Reinforcing fillers like fumed silica can increase mechanical strength and raise the temperature at which degradation occurs. Metal oxide additives can also enhance or modify thermal properties for specific applications.

Cross-Linking Density

The cross-linking density is crucial in determining silicone rubber’s heat resistance. A higher cross-linking density generally results in better thermal stability and a higher degradation temperature. This is because cross-linking creates a three-dimensional network structure that restricts molecular movement, requiring more thermal energy to break down the material.

Curing Process and Methods

The curing process and methods used to manufacture silicone rubber significantly impact its final thermal properties. Different curing systems produce varying degrees of cross-linking and thermal stability. High-temperature vulcanization typically produces silicone with better heat resistance than room-temperature vulcanization.

By understanding these influencing factors, manufacturers can engineer silicone rubber formulations with precisely tailored thermal properties for specific application requirements.

Controlling and Optimizing Silicone Temperature Resistance

To achieve the desired temperature resistance in silicone rubber, you need to consider several factors, including material selection, manufacturing processes, and testing methods.

Material Selection Strategies

You can start by selecting specialized high-temperature formulations. For applications requiring enhanced heat resistance, choosing silicones with phenyl groups substituted for some methyl groups can significantly improve high-temperature stability. Incorporating specific heat-stabilizing additives like iron oxide or cerium oxide can also extend the upper temperature limit of silicone formulations.

Manufacturing Process Considerations

Manufacturing process considerations play a crucial role in optimizing temperature resistance. Factors like cure temperature, cure time, and post-curing treatments significantly affect the final thermal properties of silicone parts. Post-curing silicone components at temperatures above their intended operating range can complete cross-linking reactions and stabilize the material.

Testing and Validation Methods

Implementing rigorous testing and validation methods is essential for confirming that silicone components will perform as expected under actual operating conditions. Standard testing protocols like TGA and DSC provide valuable data on thermal degradation temperatures and heat capacity changes, helping to predict real-world performance.

By combining strategic material selection, optimized manufacturing processes, and comprehensive testing, you can develop silicone rubber components with precisely tailored temperature resistance for demanding applications.

Manufacturing Applications and Implications

Silicone rubber’s exceptional heat resistance opens up a wide range of applications across different sectors. Its unique properties make it an invaluable material in various industries.

Industries Benefiting from Silicone’s Thermal Properties

Silicone rubber is widely used in the aerospace, automotive, electronics, medical devices, and consumer products industries. In the automotive sector, silicone components withstand extreme temperatures in engine compartments.

Design Considerations for High-Temperature Applications

When designing components for high-temperature applications, engineers must consider factors like thermal expansion and potential chemical interactions at elevated temperatures. Proper design includes appropriate dimensioning and strategic reinforcement in high-stress areas.

Conclusion

Now that we’ve delved into the thermal characteristics of silicone rubber, the importance of precise manufacturing processes becomes apparent. Understanding the melting point and thermal stability of silicone is crucial for successful manufacturing applications. By considering factors that influence silicone’s thermal properties, you can select the optimal material for your needs.

For top-notch silicone molding, trust Fecision to deliver high-quality, precise parts. Our silicone molding services handle big projects and custom pieces with expert care. With deep material knowledge and processing expertise, BOYI ensures your components perform reliably in demanding thermal environments.

FAQ

What is the typical temperature range for silicone materials?

Silicone materials generally have a temperature range between -60°C to 250°C, although some high-temperature grades can withstand temperatures up to 300°C.

How does the chemical composition of silicone affect its thermal properties?

The chemical composition and structure of silicone, including the type and amount of fillers and additives, can significantly impact its thermal properties, such as heat resistance and thermal conductivity.

Can silicone actually melt like other materials?

Silicone does not melt in the same way as other materials; instead, it undergoes thermal degradation, breaking down into smaller components when exposed to high temperatures.

What is the difference between thermal degradation and melting?

Thermal degradation is a process where the material breaks down into smaller components, whereas melting is a phase transition from solid to liquid; silicone undergoes degradation rather than melting.

How do different grades of silicone affect their working temperature ranges?

Different grades of silicone, such as general-purpose, high-temperature, and flame-retardant, have distinct working temperature ranges, with some able to withstand extremely high temperatures.

What role do additives and fillers play in silicone’s thermal properties?

Additives and fillers can enhance or detract from silicone’s thermal properties, such as heat resistance and thermal conductivity, depending on their type and amount.

How can you optimize silicone temperature resistance in manufacturing?

Optimizing silicone temperature resistance involves selecting the right material, controlling the manufacturing process, and testing and validating the final product to ensure it meets the required specifications.

What industries benefit from silicone’s thermal properties?

Industries such as aerospace, automotive, and industrial manufacturing benefit from silicone’s thermal properties, using it in applications where high-temperature resistance is critical.