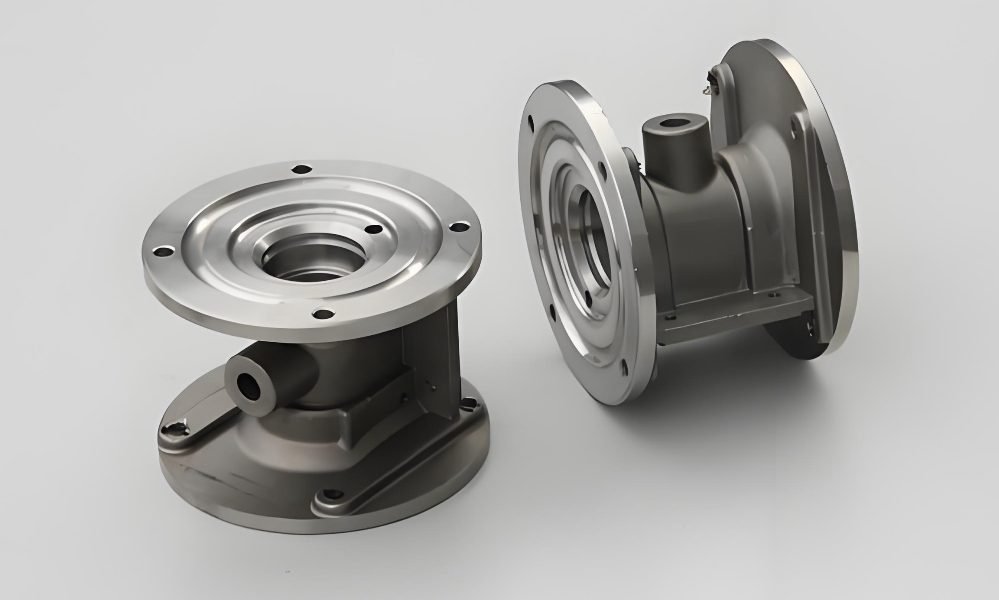

Professional Steel Casting for Industrial Applications

Steel casting represents a critical manufacturing process that transforms molten steel into complex, durable components with exceptional strength and versatility.

At Fecision, we deliver precision-engineered steel casting services tailored to your exact specifications.

Durable

Precise

Strong

Types of Steel Used in Our Casting Processes

Steel castings offer exceptional versatility through various alloy compositions, each providing specific performance characteristics. At Fecision, we work with multiple steel types to deliver the optimal solution for your application requirements.

Carbon Steel Castings

Excellent tensile strength

Good wear resistance

Cost-effective solution

Suitable for structural components

Alloy Steel Castings

Enhanced hardenability

Superior impact resistance

Improved fatigue strength

Better performance at extreme temperatures

Low Alloy Steel Castings

Good weldability

Balanced mechanical properties

Moderate heat resistance

Cost-effective for many applications

Stainless Steel Casting: Corrosion-Resistant Solutions

Stainless steel casting provides exceptional corrosion resistance combined with excellent mechanical properties.

Advantages of Stainless Steel Castings:

- Superior corrosion resistance in harsh environments

- Excellent high-temperature performance (up to 1700°F)

- Exceptional hygiene for food and medical applications

- Outstanding aesthetic appearance with minimal maintenance

- Good weldability and machinability

- Extended service life in corrosive environments

Why Choose Stainless Steel for Casting?

These specialized alloys contain a minimum of 10.5% chromium, creating a passive oxide layer that protects against environmental degradation. Our stainless steel casting service delivers components that maintain their integrity in the most challenging environments.

Stainless Steel Grades We Cast

Fecision offers casting services for a wide range of stainless steel grades, each with specific properties suited to different applications.

Our metallurgical expertise ensures we select the optimal grade for your project requirements.

| Grade | Type | Key Properties | Common Applications |

| 304/304L | Austenitic | Excellent corrosion resistance, good formability | Food processing equipment, chemical containers |

| 316/316L | Austenitic | Superior corrosion resistance, especially to chlorides | Marine equipment, pharmaceutical processing |

| 17-4 PH | Precipitation Hardening | High strength, moderate corrosion resistance | Aerospace components, high-stress parts |

| 410 | Martensitic | Good strength, moderate corrosion resistance | Turbine blades, pump components |

| CF8M | Cast Equivalent of 316 | Excellent corrosion resistance, good weldability | Valves, pumps, chemical processing equipment |

Need Help Selecting the Right Stainless Steel Grade?

Our metallurgists can recommend the optimal alloy for your specific application requirements.

Steel Casting Methods at Fecision

We employ various casting techniques to achieve the optimal balance of quality, precision, and cost-effectiveness for your steel casting projects.

Each method offers distinct advantages depending on your component's complexity, size, and production volume requirements.

Sand Casting

Our sand casting process uses expendable sand molds to create complex steel components. This versatile method is ideal for both small and large castings with moderate complexity.

- Suitable for components from a few ounces to several tons

- Cost-effective for low to medium production volumes

- Accommodates complex internal geometries

- Excellent for large components with intricate features

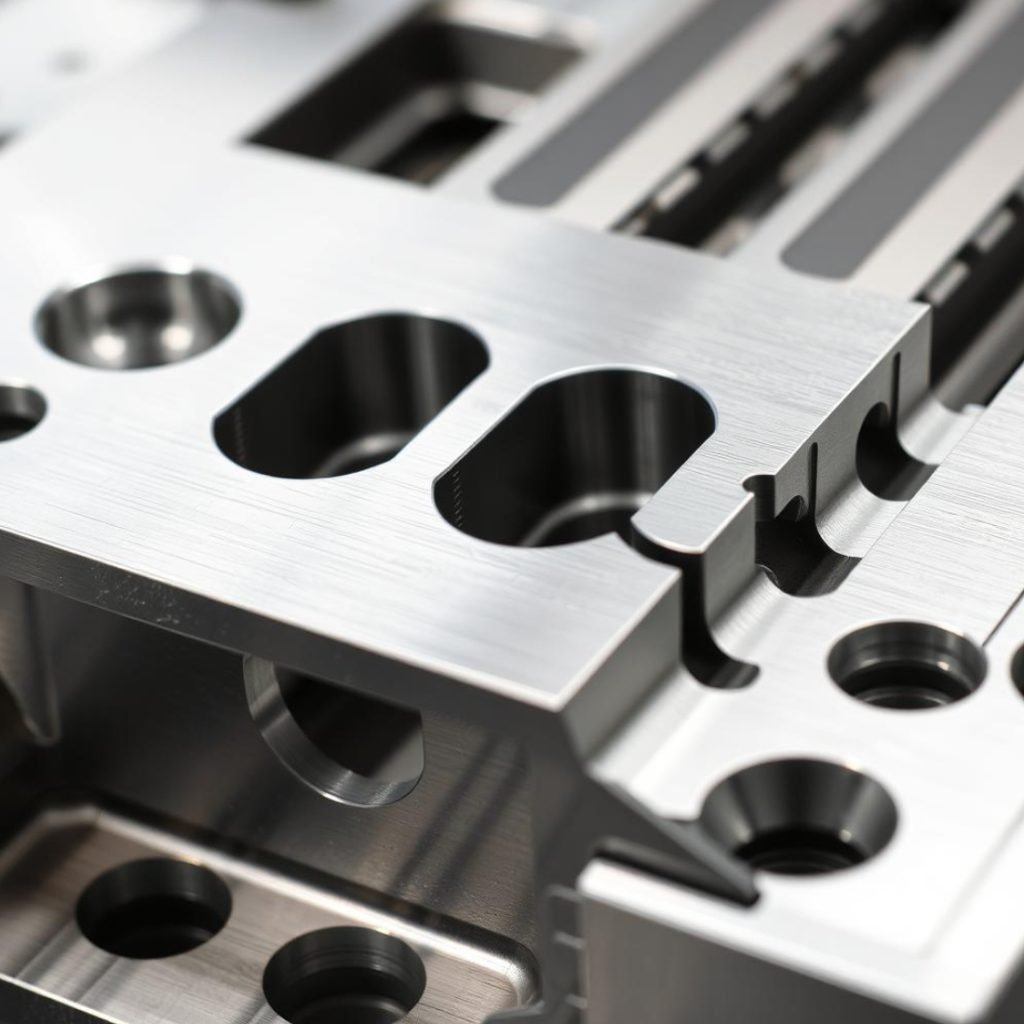

Investment Casting

Our investment casting (lost wax) process delivers exceptional surface finish and dimensional accuracy for complex steel components. This precision method is ideal for intricate parts requiring minimal machining.

- Superior surface finish and dimensional precision

- Excellent for complex geometries and thin walls

- Reduced need for secondary machining

- Ideal for components requiring tight tolerances

Shell Mold Casting

Combine elements of sand and investment casting to deliver good surface finish with moderate production costs. This method is ideal for medium-sized components with moderate complexity.

- Better dimensional accuracy than sand casting

- Good surface finish requiring minimal machining

- Cost-effective for medium production runs

- Suitable for components with moderate complexity

Technical Parameters of Our Steel Castings

Fecision maintains strict quality control standards throughout our steel casting processes. Our technical capabilities ensure we can meet demanding specifications across a wide range of parameters.

Dimensional Capabilities

| Parameter | Sand Casting | Investment Casting |

| Weight Range | 0.5 kg – 5000 kg | 0.05 kg – 250 kg |

| Dimensional Tolerance | ±0.5 mm + 0.005 mm/mm | ±0.1 mm + 0.003 mm/mm |

| Minimum Wall Thickness | 5 mm | 1.5 mm |

| Surface Finish (Ra) | 12.5-25 μm | 1.6-3.2 μm |

Heat Treatment Capabilities

We offer comprehensive heat treatment services to optimize the mechanical properties of your steel castings:

- Annealing: Stress relief and improved machinability

- Normalizing: Enhanced grain structure and uniform properties

- Quenching & Tempering: Optimized hardness and strength

- Solution Treatment: For stainless steel grades

- Stress Relief: Dimensional stability improvement

Applications of Steel Castings

Precision-engineered Liquid Silicone Rubber (LSR) injection molds are pivotal in manufacturing critical components across a diverse range of demanding industries.

Automotive & Transportation

★ Chassis components

★ Suspension parts

★ Brake system components

★ Transmission housings

★ Railway equipment

Energy & Power Generation

★ Valve bodies and components

★ Pump housings and impellers

★ Turbine components

★ Pressure-containing parts

★ Pipeline fittings

Mining & Construction

★ Excavator components

★ Crusher parts

★ Bucket teeth and adapters

★ Structural components

★ Heavy equipment parts

Industrial Machinery

★ Gearbox housings

★ Machine bases and frames

★ Hydraulic components

★ Bearing housings

★ Tool holders and fixtures

Marine & Offshore

★ Propellers and shafts

★ Rudder components

★ Offshore platform parts

★ Shipbuilding components

★ Underwater equipment

Defense & Aerospace

★ Structural components

★ Landing gear parts

★ Armored vehicle components

★ Weapons systems parts

★ Ground support equipment

FAQs About Steel Casting

Need to discuss steel casting project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your Steel Casting Project?

Contact our team today to discuss your requirements and receive a customized quote.