Did you know that over 50 million tons of synthetic fibers are produced worldwide each year, with polyester being one of the most dominant materials?

When it comes to choosing the right synthetic material for your needs, understanding the differences between polyamide and polyester is crucial. Both are widely used in clothing, sportswear, and industrial applications.

This comprehensive guide will explore the unique properties, benefits, and limitations of these versatile materials, helping you make an informed decision based on your specific requirements.

By comparing these two popular synthetic fibers, you’ll gain a clear understanding of which material is best suited for your particular needs, whether it’s for clothing, industrial use, or home furnishings.

Understanding Synthetic Fabrics

Understanding synthetic fabrics is crucial in today’s world where materials like polyester and polyamide are ubiquitous. Synthetic fabrics have transformed the textile industry, offering a range of benefits over natural fibers.

Why Material Selection Matters

Selecting the right synthetic material is crucial as it directly impacts the functionality, longevity, comfort, and overall performance of the final product. Understanding the differences between polyester and polyamide helps in making informed decisions that align with specific application needs and performance expectations.

As you consider the use of synthetic fabrics, it’s essential to evaluate their advantages and limitations. The growing focus on sustainability has also influenced how these materials are produced, used, and recycled in modern applications.

What is Polyamide?

Polyamide, also known as nylon, has been a staple in the textile industry since its invention. It’s a synthetic fiber that offers great elasticity and impressive mechanical resistance, making it a popular choice for sportswear and other applications.

Chemical Composition and Manufacturing Process

Polyamide is characterized by amide bonds that link its molecular chains, giving it distinctive properties. The manufacturing process involves a chemical reaction between diamine and adipic acids, creating a polymer that’s then melted, extruded, and stretched to form fibers. Nylon is a polyamide made from petroleum.

Common Types of Polyamides

Common types of polyamides include Nylon 6, Nylon 6,6, Nylon 11, and Nylon 12, each with slightly different properties suited for various applications. These variations make polyamide a versatile material used in numerous industries, from textiles and carpeting to automotive components and industrial applications.

Physical Properties of Polyamide

The physical properties of polyamide, such as strength and elasticity, set it apart from other synthetic materials. As a versatile and widely used material, polyamide’s characteristics make it suitable for various applications.

Strength and Durability Characteristics

Polyamide, commonly referred to as nylon, exhibits exceptional tensile strength, making it one of the strongest synthetic fibers available. Its molecular structure creates strong intermolecular bonds, contributing to its remarkable resistance to abrasion, wear, and tear. This durability is a key factor in its popularity for demanding applications.

Elasticity and Flexibility

Nylon fibers can stretch up to 20% of their original length and return to their initial state, providing excellent elasticity and recovery properties. This flexibility, combined with its strength, makes polyamide particularly valuable in applications where materials must withstand repeated bending or flexing. Its resistance to oils, many chemicals, and fungi further enhances its durability.

Benefits of Polyamide

Polyamide, commonly known as nylon, offers several advantages that make it a preferred choice in many industries. Its unique combination of properties makes it suitable for a wide range of applications.

Superior Strength and Flexibility

One of the key benefits of polyamide is its exceptional strength-to-weight ratio, making it ideal for applications where durability is crucial without adding significant weight. Additionally, its natural elasticity provides excellent flexibility and recovery, maintaining its shape even after repeated stretching or compression.

Mildew and Acid Resistance

Polyamide also offers superior resistance to mildew, mold, and fungal growth, which is beneficial in humid environments or applications exposed to moisture. Furthermore, its resistance to many acids and chemicals enhances its durability in harsh conditions, extending the life of polyamide products.

| Property | Benefit | Application |

| Strength-to-Weight Ratio | Durability without added weight | Outdoor gear, sportswear |

| Mildew Resistance | Longevity in humid environments | Activewear, outdoor fabrics |

| Acid Resistance | Durability in harsh chemical environments | Industrial textiles, protective gear |

What is Polyester?

As a synthetic fiber, polyester is made from a combination of coal, air, water, and petroleum products. You may have come across this versatile material in various applications, from clothing to industrial uses. Polyester is known for its wear resistance and high melting point, making it a popular choice for many industries.

Chemical Composition and Manufacturing Process

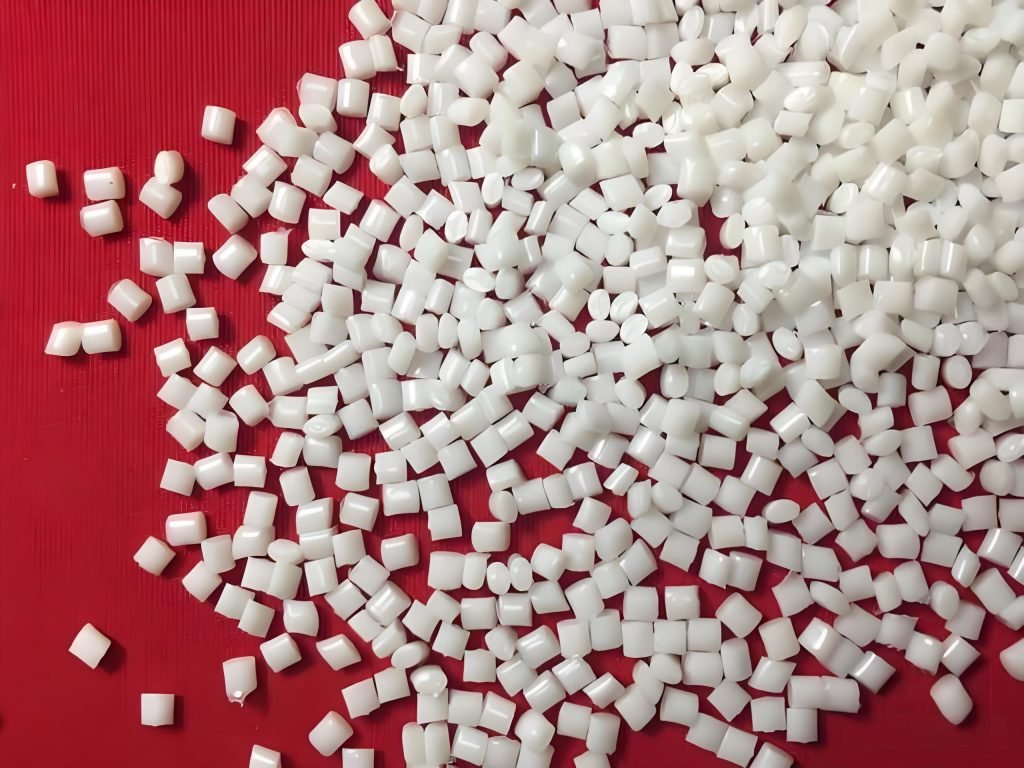

Polyester is a synthetic polymer made from purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol. The manufacturing process involves polymerization of these compounds to form polyethylene terephthalate (PET), which is then melted, extruded, and spun into fibers. This process allows for the creation of a wide range of polyester types.

Evolution and Varieties of Polyester

Over the decades, polyester has evolved from a basic synthetic fiber to include specialized varieties such as microfiber polyester, textured polyester, and high-performance polyester blends. Modern polyester production also includes recycled options made from post-consumer plastic bottles, offering more environmentally friendly alternatives to virgin polyester. As a result, polyester generally accounts for approximately 58% of worldwide synthetic fiber production.

Physical Properties of Polyester

When considering synthetic fabrics, understanding the physical properties of polyester is crucial for determining its suitability for various applications.

Durability and Resistance Features

Polyester is renowned for its exceptional durability and resistance to wear. It demonstrates excellent dimensional stability, maintaining its shape even after repeated washing and wear, making it highly resistant to stretching and shrinking. The material also exhibits strong resistance to most chemicals, including acids, bleaches, and solvents, contributing to its longevity in various applications.

Thermal and Optical Properties

Polyester has a high melting point of approximately 260°C/500°F, providing superior heat resistance compared to many other synthetic fibers. Its natural resistance to UV degradation makes it suitable for outdoor applications. Additionally, polyester has low moisture absorption, contributing to its quick-drying properties and resistance to mildew and bacterial growth. Its optical properties include good light reflection and the ability to accept bright, long-lasting dyes.

Benefits of Polyester

One of the most significant benefits of polyester is its ability to withstand various environmental factors, making it an ideal material for a wide range of applications. You can appreciate the durability and versatility that polyester brings to your daily life, from clothing to home furnishings.

UV Resistance and Hydrophobic Properties

Polyester is known for its excellent UV resistance, which prevents degradation and color fading when exposed to sunlight. This property makes it a popular choice for outdoor apparel and gear. Additionally, polyester’s inherent hydrophobic nature results in minimal water absorption, allowing for quick drying. This characteristic is particularly beneficial for activewear and outdoor clothing, as it keeps you dry and comfortable.

Wrinkle Resistance and Color Retention

Polyester also demonstrates superior wrinkle resistance, maintaining a crisp appearance even after extended wear or packing. This reduces the need for ironing, making it a low-maintenance fabric. Furthermore, polyester’s exceptional color retention properties ensure that colors remain vibrant and long-lasting, resisting fading through multiple washes and extended use.

| Property | Benefit | Application |

| UV Resistance | Prevents degradation and color fading | Outdoor apparel, gear |

| Hydrophobic Nature | Minimal water absorption, quick drying | Activewear, outdoor clothing |

| Wrinkle Resistance | Maintains crisp appearance, reduces ironing need | Travel clothing, business attire |

| Color Retention | Vibrant, long-lasting colors | Fashion apparel, home decor |

By understanding the benefits of polyester, you can make informed decisions about the materials you choose for your needs. Whether it’s for durability, low maintenance, or aesthetic appeal, polyester offers a range of advantages that make it a popular choice across various industries.

Polyamide vs Polyester: Key Differences

When deciding between polyamide and polyester, understanding their key differences is crucial. Both materials have unique properties that make them suitable for various applications.

Mechanical Strength Comparison

Polyamide, also known as nylon, generally offers superior tensile strength and better resistance to tearing than polyester. This makes polyamide preferable for high-stress applications, such as outdoor clothing and gear.

Water Absorption and Drying Time

Polyamide absorbs more water than polyester, which can make polyamide clothing heavier when wet. In contrast, polyester absorbs only 0.4% of its weight in water, resulting in faster drying times. This difference is crucial for outdoor and athletic applications.

Heat and UV Resistance

Polyester has better heat resistance than polyamide, with a melting point around 260°C compared to polyamide’s 220°C. Additionally, polyester is more UV resistant, maintaining its integrity and color longer when exposed to sunlight.

Limitations of Each Material

While both polyamide and polyester have their advantages, they also come with certain limitations that are essential to consider. Understanding these drawbacks can help you make informed decisions about their use in various applications.

Drawbacks of Polyamide

Polyamide, or nylon, has several limitations. It can absorb up to 8% of its weight in water, leading to heavier garments and longer drying times. Additionally, polyamide is sensitive to UV radiation, which can cause it to degrade and fade over time. Its lower heat resistance compared to polyester also limits its use in high-temperature applications.

Disadvantages of Polyester

Polyester, while having many benefits, also has its drawbacks. One of its main limitations is its lower breathability, which can lead to uncomfortable moisture buildup in clothing. The hydrophobic nature of polyester can make it more difficult to dye and may require special treatments to improve moisture-wicking capabilities.

Comfort and Wearability

When choosing between polyamide and polyester, comfort is a crucial factor to consider. You want clothing that not only looks good but also feels great against your skin.

Feel and Texture Against Skin

Polyamide, commonly known as nylon, typically offers a softer and silkier texture that many find more comfortable for direct skin contact. Its smooth feel makes it ideal for clothes that require skin contact. In contrast, polyester has improved significantly in terms of comfort, with modern manufacturing techniques creating softer variants, though it still tends to feel less luxurious than polyamide.

Breathability and Moisture Management

Breathability is crucial for comfort, with polyamide generally offering better air permeability than standard polyester. However, specialized polyester fabrics can be engineered for enhanced breathability. Moisture management differs between the materials; polyamide absorbs some moisture, making it feel more comfortable in moderate conditions, while polyester’s hydrophobic nature wicks moisture away from the skin.

Applications and Uses

You can find polyamide and polyester in numerous products, from apparel to home furnishings. Both materials are versatile and have a wide range of applications.

Clothing and Apparel Applications

Polyester is widely used in clothing due to its durability and easy care. Polyamide, or nylon, is particularly valued for specific applications like hosiery, activewear, and performance outerwear, where its strength and elasticity are crucial.

Industrial Uses

Polyamide’s exceptional strength makes it ideal for industrial applications such as tire cord, conveyor belts, ropes, and fishing nets. Polyester is used in areas requiring chemical resistance and dimensional stability, such as filter fabrics and reinforcement materials.

Home Furnishings and Everyday Items

Both polyamide and polyester are used in home furnishings like carpeting, upholstery, and decorative fabrics. They are also found in everyday items such as luggage, backpacks, and sports equipment, where their unique properties are utilized.

Care and Maintenance

To keep your polyamide and polyester items looking their best, proper care is essential. Both materials are relatively low-maintenance, but following some simple guidelines can significantly extend their lifespan.

Washing and Drying Recommendations

For washing, use mild detergents and cool to warm water temperatures (30-40°C/85-105°F). Both polyamide and polyester can be machine washed and dried on a low heat cycle. However, remove them from the dryer immediately to prevent wrinkles.

Long-term Care Tips

To maintain their quality, store both materials away from direct sunlight to prevent UV degradation. Avoid using fabric softeners, as they can reduce moisture-wicking properties. For polyester, dry-cleaning is sometimes an option, but never dry-clean polyamide, as the solvents can damage it.

Environmental Impact

As you consider the materials used in your clothing and products, it’s essential to understand their environmental footprint. The production and disposal of synthetic materials like polyamide and polyester have significant environmental implications.

Production Footprint

The production of both polyamide and polyester has a substantial environmental impact due to their petroleum-based composition and energy-intensive manufacturing processes. Polyamide production tends to have a higher environmental footprint compared to polyester, consuming more energy and water, and releasing more greenhouse gases.

| Material | Energy Consumption | Water Usage | Greenhouse Gas Emissions |

| Polyamide | High | High | Significant |

| Polyester | Moderate | Moderate | Lower than Polyamide |

Recycling and Sustainability Options

While neither polyamide nor polyester is biodegradable, recycling options are available, reducing their environmental impact. Recycled polyester, often made from PET bottles, is becoming increasingly common, and innovations in recycled polyamide are emerging, offering potential for closed-loop systems.

Cost Considerations

The price difference between polyamide and polyester is a key consideration for consumers and manufacturers alike. When evaluating these materials, understanding the cost implications is crucial.

Price Differences and Value Assessment

Polyamide, commonly known as nylon, typically commands a higher price point than polyester due to its more complex production process and higher energy requirements. The raw material costs for polyamide are often 20-30% higher. However, when assessing value, it’s essential to consider the entire lifecycle cost. While polyamide products may cost more initially, their superior durability and strength can provide better long-term value in high-wear applications.

Factors Affecting Cost

Several factors influence the cost of both polyamide and polyester. Market fluctuations in petroleum prices directly impact the cost of these materials, though polyester production is generally less sensitive to these changes. Production volume also significantly affects pricing, with polyester benefiting from economies of scale. Regional manufacturing differences, such as lower labor and operational costs in Asia, also contribute to cost variations.

Alternative Materials to Consider

Exploring alternative materials can help you find the perfect fabric for your specific needs, whether it’s for clothing, industrial uses, or home furnishings. As you consider your options, you may discover new materials that offer improved performance, sustainability, or comfort.

Natural Fiber Alternatives

Natural fibers like cotton, wool, silk, and linen offer excellent breathability and comfort. Emerging options such as bamboo and hemp provide sustainable alternatives with impressive properties. Bamboo offers natural antimicrobial qualities and moisture management, while hemp provides exceptional durability and improves with age.

Other Synthetic Options

For applications requiring stretch and recovery, elastane (spandex) is often blended with other fibers to create performance fabrics. Acrylic serves as a synthetic alternative to wool, providing warmth and softness at a lower cost. Specialty synthetic fibers like polypropylene and chlorofibers serve niche applications where specific properties are required.

Conclusion

To make an informed choice between polyamide and polyester, evaluate your needs. Consider strength, durability, and environmental impact. Choose based on your priorities, whether it’s polyamide’s strength or polyester’s quick-drying properties.