An injection mold is made of several key components, each of which plays a vital role in shaping, cooling, and releasing the final part. Understanding the basic injection mold components can help you design better products, perform troubleshooting, and improve product quality.

In this guide, we’ll break down the main parts of an injection mold, how they work, and why each one matters in the process.

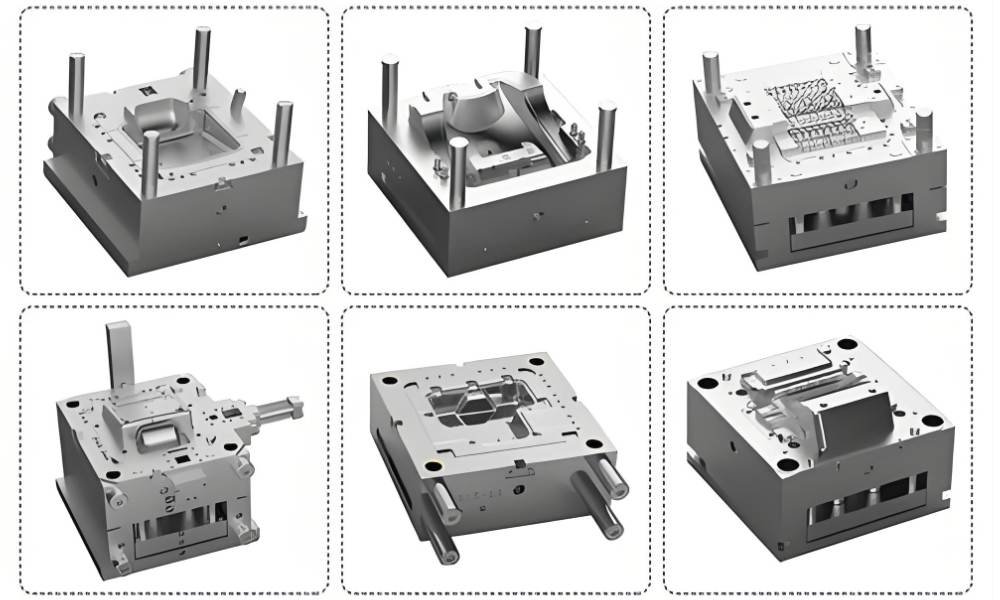

Types of Injection Molds

Before understanding injection molds and their basic types, what is injection molding?

Injection molding is a manufacturing process used to produce large quantities of plastic parts. It works by melting plastic pellets, injecting the liquid plastic into a mold, and cooling it to form a solid shape. This method is fast, efficient, and great for making strong, lightweight, and detailed parts.

Because the mold can be used repeatedly, injection molding is ideal for production where consistency and quality are important. Injection molds come in various types, each with its unique structure and production capabilities to suit different needs. Let’s look at some common types of injection molds:

Single-Cavity Mold

Single-cavity injection molds are the simplest type, suitable for design verification or low-to-medium volume production. Because there is only one cavity, a single-cavity mold can only produce one part per injection. These molds are quick to manufacture, low in cost, and easy to adjust. Therefore, they are ideal for prototyping and small-volume parts production. Their quality and control are excellent. However, production efficiency may not keep up with increased production volume, and a multi-cavity mold may be needed.

Multi-Cavity Mold

Multi-cavity molds can produce multiple identical parts in a single injection, significantly increasing production volume. Depending on the part size and machine tonnage, the number of cavities in an injection mold can reach 4, 8, 16, or even more than 64. The resulting advantage is a lower cost per part. This mold structure is naturally more complex and more expensive to manufacture. All aspects, such as runners, cooling, and venting, must be carefully balanced during design to ensure that each cavity is filled and cooled in the same way. Unlike single-cavity molds, multi-cavity molds are ideal for high-volume production.

Family Mold

Family molds are a compromise between single-cavity and multi-cavity molds. They can simultaneously produce multiple different but related parts, such as the left and right rearview mirror housings of a car, or a set of snap fasteners. Compared to manufacturing a separate mold for each part, family molds can save costs, especially for medium-volume production. The design and manufacturing challenges of this type of mold lie in balancing the runner system and cooling system to ensure that each part is filled and shrinks consistently, even if their geometries are different. If designed properly, family molds are a cost-effective option.

Two-Plate Mold

Two-plate molds are the most common and simplest design in injection molding. It consists of a fixed plate (A-side) and a moving plate (B-side), with the cavity and core located on these two plates respectively. The gate and runner system are located on the parting line, so the part and the runners are ejected together. Two-plate molds have a simple structure, are cost-effective, and easy to maintain, making them suitable for most standard parts.

Three-Plate molds

Compared to two-plate molds, three-plate molds add an extra plate between the fixed and moving sides, creating a separate runner plate. In this case, the runner system is ejected separately from the part. During the injection molding process, the gates and runners detach, while the part remains on the core side. Its advantages lie in clean gate marks or automatic runner separation. Three-plate molds have a more complex structure and are more expensive, ideal for parts with high aesthetic requirements or applications where manual trimming of runners needs to be avoided.

Two-Shot/Multi-Shot Molds

Two-shot/multi-shot molds allow for the sequential injection of two different materials within the same mold, creating parts with both hard and soft sections, such as a rigid base material with a flexible grip, or parts with different colors. These molds require precise design and specialized equipment for production, typically using rotating cores or transfer methods. Two-shot/multi-shot injection molding eliminates secondary assembly, improves bonding strength, and provides products with a high-quality appearance and feel – making it very popular in consumer goods and automotive interiors.

Insert Molds

Insert injection molding involves placing pre-formed parts, usually metal parts such as terminals, pins, bushings, or threaded inserts, into the mold, and then injecting plastic around them to create a securely bonded hybrid component without separate assembly operations. These molds must accurately position and secure the inserts, control heat transfer, and prevent flashing around the metal. It is widely used in electronic connectors, automotive sensors, and medical instrument handles.

Stack Molds

Stack molds double or multiply the number of cavities by using multiple parting lines stacked on top of each other, with all cavities fed from a single injection point. These molds are expensive and mechanically complex, requiring very precise synchronization and balancing. They are ideal for high-volume production of flat parts such as lids, trays, or thin-walled containers, significantly increasing output without a larger tonnage.

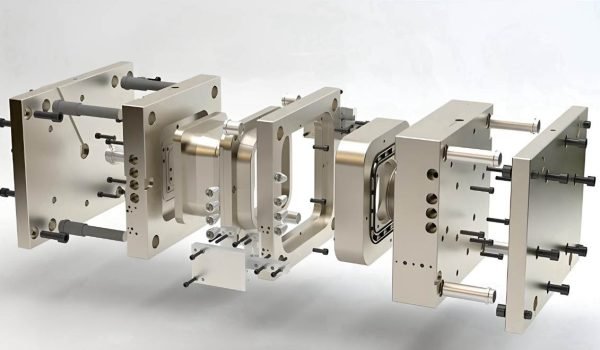

Key Parts of an Injection Mold

An injection mold consists of several key components that work together to shape, cool, and eject plastic parts. Let’s look at the most important plastic injection mold parts:

1. Clamping Plate / Mold Base

The clamping plate, often part of the mold base, is the foundation of an injection mold. It holds the mold securely in the injection molding machine and provides structural support during operation.

It has two sides: a stationary plate (attached to the machine) and a moving plate, which opens and closes during injection. These sides ensure proper mold alignment and withstand the high pressures of the injection molding process.

If the mold base isn’t strong enough, the mold could shift or break during production.

2. Cavity and Core

The cavity and core are the heart of an injection mold, determining the actual shape of the plastic part. Together, they define the part’s dimensions, design, and surface finish.

- A cavity is the hollow part where plastic is injected, forming the outer shape of the product.

- The core is the raised section that fits inside the cavity to create the inner surfaces.

Example: In a plastic cup mold, the cavity shapes the outer walls, while the core creates the hollow inside.

3. Runner System

The runner system is a set of channels that guides the molten plastic from the injection nozzle into the mold cavity. This system includes three components:

- Sprue: Main vertical passage from the nozzle.

- Runners: Horizontal channels that distribute plastic to each cavity.

- Gates: Small openings that control the flow into the cavity.

The runner system is important because it reduces waste, ensures an even flow, and improves part quality.

4. Cooling System

The cooling system helps solidify the molten plastic after it enters the mold. It uses channels inside the mold that circulate water or oil to absorb heat. Proper cooling is crucial to avoid warping, sink marks, or long cycle times.

Moreover, it directly affects the speed and consistency of the product. With efficient cooling, your parts will be of better quality, and the production time will be greatly reduced.

5. Ejection System

Once the plastic part has cooled and solidified, the ejection system separates it from the mold quickly and cleanly without damaging the product. Key components of this part include:

- Ejector pins: Push the part out of the core.

- Ejector plate: Moves all ejector pins at once.

- Return pins/springs: Reset the system for the next cycle.

6. Venting System

The venting system allows trapped air and gases to escape from the mold during the injection procedure. It has tiny gaps or grooves near the cavity edges to allow air to escape without letting plastic leak out.

Without proper venting, air pockets or burn marks can appear on the final part. This also ensures smooth surfaces for the plastic parts and prevents any defects.

Optional or Advanced Parts of an Injection Mold

While basic injection molds work well for simple parts, complex designs often require extra components. Some of these injection mold parts include:

1. Slides Cores / Side Actions

Slide cores or side actions are moving injection mold parts that are used to create features like holes, undercuts, or side slots—things that can’t be manufactured with just the cavity and core moving up and down.

They slide in from the side when the mold closes and move out when it opens. This part is used for molded-in hooks, holes through the side of a part, or snap-fits.

2. Lifters

Lifters are injection mold components that move at an angle when the mold opens to release parts with angled or curved undercuts. They rise and pull away from the part before ejection.

This part is used when features are not reachable by a slide or would complicate the mold design. It’s commonly applied to angled locks, tabs, or clips on a product’s interior.

3. Hot Runner System

A hot runner system keeps the plastic inside the runner channel hot and molten throughout molding. Unlike a cold runner, it reduces material waste because there are no leftover runners after each cycle.

It includes heated nozzles and manifolds to keep plastic flowing until it reaches the gate. Additionally, the benefit of using this part includes faster cycle times, better temperature control, and higher part quality.

4. Insulator Plates

Insulator plates are placed between the mold and the injection molding machine’s platens. They help reduce heat transfer from the mold to the machine. This helps maintain stable mold temperature, especially during long production runs.

This part matters because it improves energy efficiency and reduces wear on machine components.

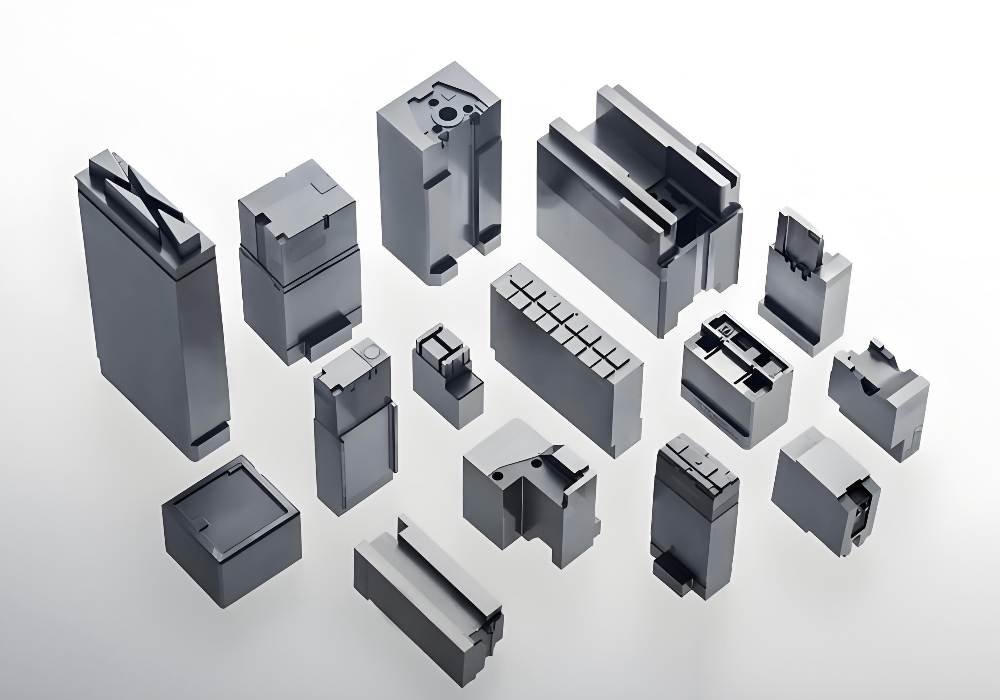

Materials for Injection Mold Components

The selection of materials for injection mold parts is crucial for ensuring the durability, precision, and wear resistance of the overall mold. Different mold parts require different materials depending on their function and the stresses, heat, and pressure they are subjected to.

Materials for Mold Base

Mold bases are typically made of P20 steel, low-carbon steel, or stainless steel. These materials possess high strength and resistance to deformation, ensuring the mold structure remains stable under high pressure and temperature conditions.

Materials for Core and Cavity

Cores and cavities are usually made of H13, S136, or 420 stainless steel. These materials offer excellent wear resistance and heat resistance. They are also easily precision machined, resulting in high-quality injection molded products.

Materials for Runner and Gate

To withstand the continuous flow of molten plastic, runners and gates require high-wear-resistant hardened tool steel. This prevents wear while maintaining stable material distribution.

Materials for Ejector Pins and Sleeves

Ejector pins and sleeves are made of high-hardness steel or nitrided steel to resist wear and corrosion from long-term use. Their high strength facilitates smooth part ejection, ensuring the integrity of the molded parts.

Materials for Cooling System Component

Cooling system parts are made of beryllium copper or copper alloys to achieve optimal thermal conductivity. These materials improve the cooling performance of the parts, shorten cycle times, and increase production efficiency.

Material selection directly impacts the lifespan and efficiency of the mold. Appropriate material selection effectively reduces wear, minimizes maintenance downtime, and extends the overall lifespan of the mold.

Manufacturing Processes for Mold Components

High-quality mold parts require advanced manufacturing techniques that guarantee accuracy and durability. The most commonly used processes for manufacturing mold parts include:

CNC machining: Using computer-controlled milling and lathe processing, precise mold cavities, mesons, and bases are manufactured with severe tolerances.

EDM: Used to process complex shapes and details that are difficult for conventional machining.

Grinding and polishing: Realizes smooth surface finish of mold parts, reduces friction, and improves protrusion of parts.

Heat treatment: Increase the hardness and wear resistance of the mold steel and extend the life of the mold. Surface coating Hard chrome plating, nitriding treatment, PVD coating, improve wear resistance, reduce friction.

These manufacturing processes ensure that mold parts meet the requirements for accuracy and durability and achieve stable performance.

How Do Mold Components Affect Mold Durability and Lifespan?

The durability of injection molds depends on several factors, such as part quality, material selection, and maintenance practices. Key aspects influencing mold lifespan include:

Material Hardness: High-hardness materials ensure wear resistance and deformation resistance, extending service life. Durable materials maintain mold accuracy, reducing defects and maintenance needs.

Lubrication and Coatings: Proper lubrication and wear-resistant coatings minimize friction between moving parts. This reduces part wear and prevents overheating, thus extending mold life.

Cooling System Efficiency: A well-designed cooling system prevents thermal stress and reduces material fatigue over time. Efficient cooling maintains stable temperatures during production, extending mold lifespan.

Regular Maintenance: Regular inspections and timely replacement of worn parts prevent unexpected failures. Routine maintenance ensures consistent performance and prevents costly production delays.

Maintenance and Troubleshooting of Mold Components

Regular maintenance of injection mold components helps prevent failures and ensures long-term performance. Common maintenance practices include:

Cleaning

Regular removal of plastic residue, dust, and contaminants prevents defects and extends mold life. Proper cleaning ensures a smooth molding process and maintains part quality. Clean molds minimize cycle time fluctuations and improve efficiency. Specialized cleaning agents protect delicate surfaces from damage.

Clearing debris from cooling channels allows for efficient heat dissipation and prevents overheating. Blockages can lead to uneven cooling and defects such as warping and deformation. Regular cleaning with flushing solutions maintains optimal cooling efficiency.

Lubrication

Applying grease and lubricants to moving parts such as ejector pins and sliders reduces friction and wear. Proper lubrication prevents sticking, ensures smooth demolding of molded products, and maintains consistent performance. However, excessive lubrication should be avoided to prevent contamination of molded parts.

Regular Inspections

Regular inspections for wear, cracks, and misalignment allow for early detection of potential failures. Identifying worn and damaged parts prevents costly repairs and production delays.

Detailed inspections maintain mold accuracy and product consistency. Addressing common mold problems such as flashing, short shots, and warping requires identifying defective parts and making necessary adjustments.

Final Thoughts

From basic parts like the cavity and runner system to advanced features like the lifter and hot runners, each part of injection molds plays an important role in ensuring smooth operation, high-quality production, and long-term durability.

Material selection, precision processing, and regular maintenance greatly affect mold lifespan and the stability of production. By applying high-quality parts and adopting advanced manufacturing processes, reliability and cost-effectiveness can be ensured.

Fecision specializes in injection mold parts manufacturing. Contact us to support your mold projects.

Frequently Asked Questions

How do different types of gate systems affect mold performance?

Gate systems such as edge gates, hot runners, and submarine gates affect the flow of molten plastic, cycle time, and the quality of molded products. Selecting the right gate type improves efficiency, reduces waste, and improves surface finish.

How does a mold vent prevent injection molding defects?

Proper vents allow air and gas trapped during the injection to be discharged to prevent problems such as burning traces, air pockets and incomplete filling. Strategic placement of vents improves molded products uniformity and overall production quality.

How does the temperature and cooling speed of the mold affect production efficiency?

Temperature control is very important to prevent warping, shrinkage, and variations in component dimensions. Efficient cooling channels reduce cycle times, improve parts quality, and increase overall manufacturing efficiency.

What are the advantages of modular mold design?

Modular mold can replace specific inserts and components without redesigning the entire mold. This approach reduces downtime, reduces costs, and increases flexibility for product variations.