Both Overmolding and Insert Molding are injection molding processes, but the approaches to solving problems are completely different. Don’t be fooled by the fact that both are pouring plastic into molds. One is playing the game of material stacking, while the other is engaged in part hide-and-seek. So insert mold vs overmold, which one to choose? It depends on whether what you want is superficial effort or inner strength.

What Is Overmolding?

Overmolding is a manufacturing trick where you layer materials to make a single finished product. Think of those toothbrushes with the hard plastic core and rubber grip—that’s overmolding in action. Here’s how it works: first, a base part (like rigid plastic or metal) gets made. Then, another material (like soft rubber or silicone) gets molded directly onto it, sticking them together without glue or screws.

There are two main ways to do this. Two-shot molding uses one machine and one mold to add both materials in a single cycle. It’s faster and gives a seamless look, but it needs expensive equipment. Insert molding, on the other hand, starts with a pre-made part (like a metal insert) placed into a mold before injecting plastic around it. This is cheaper for smaller batches but takes more manual work.

Overmolding solves problems regular molding can’t. For example, it adds grippy handles to tools, seals electronics against water, or combines rigid and flexible parts in medical devices. Materials matter here—thermoplastic elastomers (TPE) or silicone are popular for soft layers because they bond well with plastics like ABS or polypropylene.

But it’s not perfect. If the materials don’t “like” each other chemically, they might peel apart. Also, thick layers of soft material can be tricky to mold without air bubbles or uneven surfaces. Still, factories love it for cutting assembly steps and making products tougher. Next time you pick up a power tool or a razor, check the handle—chances are, overmolding made it comfy to hold.

What Is Insert Molding?

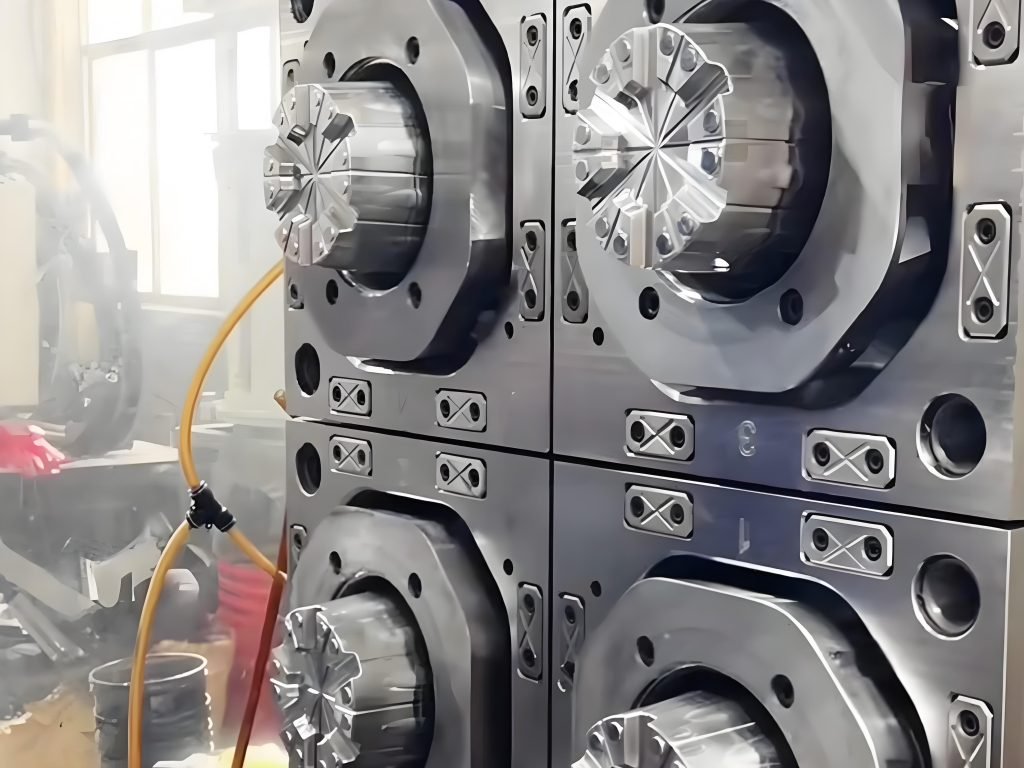

Insert molding is a special way to make plastic parts with other materials stuck inside them. Workers first put small metal pieces (like screws or wires) or other objects into a mold. Then they inject hot liquid plastic around these objects. When the plastic cools down, it hardens and holds everything together as one solid piece.

This method helps create parts that need both plastic and metal features. For example: phone chargers with metal connectors inside plastic bodies, or car parts combining rubber grips with metal frames. Factories like using it because it saves time – instead of putting pieces together later, everything gets made in one step.

It’s different from overmolding process(where workers add plastic layers to existing parts). Insert molding puts non-plastic materials inside first, while overmolding adds new plastic over old plastic. Both methods make strong products but work best for different needs.

Key advantages:

- Makes parts lighter than all-metal products

- Reduces loose connections between materials

- Allows complex shapes that regular assembly can’t make

Common uses include electrical connectors, medical tools, and vehicle components needing both insulation and metal strength. While setup costs might be high, it saves money in mass production by cutting assembly steps.

Overmolding vs Insert Molding: Differences Explained

1. How They Work

Overmolding Process

Think of making a toothbrush. First, a rigid plastic handle (substrate) is molded. Then, the machine swaps molds to inject rubber around it for a non-slip grip. Two separate steps, two materials. The first material must stay warm enough for the second layer to bond. If cooled too much, the rubber might peel off—like a cheap phone case.

Insert Molding Process

Picture assembling sunglasses. Workers place metal lenses into a mold, then inject plastic around them in one shot. No swapping molds are needed. Inserts must be perfectly positioned. A misaligned metal thread in a flashlight could ruin the entire batch.

2. Materials

Overmolding

Typical combinations pair rigid materials (ABS/PC plastics) with flexible options like TPE/TPU – think screwdriver handles needing grip and shock absorption. Metal-silicone blends (e.g., kitchen knives) combine strength with comfort. Avoid incompatible mixes: nylon paired with some rubbers risks layer separation, like peeling keyboard covers.

Insert Molding

Metal inserts (brass threads in plastic chairs, steel bolts in car parts) reinforce durability. Plastic-on-plastic designs, such as transparent polycarbonate over colored ABS in medical buttons, ensure both visibility and functionality.

3. Cost & Time

Overmolding costs more upfront (dual molds) but streamlines assembly—ideal for ergonomic grips or multi-material tools. Insert injection molding saves for mass production, though custom metal inserts (e.g., specialized bolts) hike expenses. Balance volume needs and part complexity.

4. Applications: From Daily Life to High-Tech

Overmolding Wins

Overmolding excels in user-centric designs where comfort and aesthetics take priority. Medical devices like blood pressure monitors use medical-grade TPE for soft, skin-friendly edges that reduce patient discomfort during prolonged use. For rugged applications, waterproof drone controllers pair rigid ABS bodies with silicone seals to block moisture without compromising grip. Aesthetic-driven products also benefit—toothbrushes with gradient-colored handles layer translucent TPU over PP cores, creating visual depth while maintaining hygiene standards.

Insert Molding Shines

When structural integrity is critical, insert molding steps up. Car brake pedals embed steel cores within reinforced plastics to handle repeated high-force impacts, while Wi-Fi routers integrate heat-resistant metal shields to dissipate heat from internal components. The technology also enables multi-material innovation: hearing aids combine ceramic sensors for precision with biocompatible plastics for long-term wearability, merging functionality and user safety in compact designs.

Quick Comparison Table

| Aspect | Overmolding | Insert Molding |

| Steps Needed | Two separate molds | Single mold with insert placement |

| Material Combo | Plastic + rubber/TPE | Metal/glass + plastic |

| Best for | Soft grips, seals | Structural reinforcement |

| Cost | Higher (two tools) | Lower (one tool) |

| Production Speed | Slower (two-stage) | Faster (one-shot) |

| Common Products | Tool handles, medical devices | Automotive parts, electronics |

Next time you use an electric shaver, check its grip: if it’s slightly textured rubber fused to plastic, that’s overmolding done right. The razor’s steel blade holder? Insert molding at work. These hidden techniques make products both functional and long-lasting.

How to Know If Overmolding or Insert Molding Is Better for Your Project?

Choosing between insert molding vs overmolding for your project can feel confusing. Both methods involve adding layers to a base part, but they work differently. To pick the right one, focus on your product’s purpose, materials, and production needs. Here’s a simple breakdown to help you decide.

1. Start With the Base Material

The first thing to check is what your base part is made of. Insert molding uses a non-plastic base—like metal, wires, or electronic parts. For example, screwdriver handles often use insert molding: a metal rod (the insert) gets covered with plastic in one step. If your project involves combining plastic with metal, circuits, or prefabricated parts, insert molding is likely better.

Overmolding requires a plastic base (called a substrate). The second layer is another plastic or rubber material molded onto it. Think of toothbrush handles: a hard plastic core gets coated with a soft rubber grip. If your design needs multiple plastic layers (like a rigid core + soft exterior), overmolding fits best.

2. Look at How Many Steps You Can Handle

Insert molding is a single-step process. The insert gets placed into the mold, plastic is injected around it, and the part is done. This saves time and cuts assembly costs since there’s no need to attach parts later. For instance, medical tools with embedded sensors use insert molding to seal electronics inside plastic in one go.

Overmolding requires two steps. First, the substrate is molded. Then, it’s moved to a second mold for the outer layer. This adds time and cost, especially for small batches. But it’s worth it for complex designs. A tool handle with a non-slip grip, for example, might need two materials that can’t be molded together in one shot.

3. Check Material Compatibility

Materials must stick together well. With insert molding, plastic bonds to metals or other inserts mechanically—the plastic flows around the insert’s shape, locking it in place. No chemical bond is needed. This works for parts like threaded metal inserts in plastic casings.

Overmolding needs materials that bond chemically or melt at similar temperatures. For example, ABS plastic pairs well with TPU rubber for grips. If materials don’t bond naturally, the layers might separate. A common fix is adding grooves or undercuts to the substrate so the overmold locks in physically.

4. Consider Costs and Volume

For high-volume production, insert molding often costs less. Once the mold is set, adding inserts (like metal fasteners) is fast. Automotive parts, such as dashboard components with built-in clips, use this method to save on assembly labor.

Overmolding is pricier upfront because it needs two molds. But it pays off for specialized products. A consumer device with a waterproof seal (like a rubber-coated USB port) might need overmolding to avoid leaks. For low-volume batches, though, the extra mold costs can be hard to justify.

5. Test for Functionality

Ask: What does the part need to do?

- Strength and durability: Insert molding strengthens parts by combining metal and plastic. Tools like pliers benefit from metal inserts that handle heavy force.

- Comfort or grip: Overmolding adds soft, ergonomic layers. Handheld devices (e.g., power drills) often use rubberized overmolds for better grip.

- Aesthetics: The overmolding process allows color contrasts or textures. A two-tone phone case can be made by molding a colored layer over a base.

6. Prototype and Consult Experts

Before finalizing, make prototypes. Try both methods if possible. For example, mold a metal insert into a plastic sample and check if it holds under stress. For overmolding, test if the layers bond without peeling.

Talk to manufacturers early. They can spot issues like incompatible materials or complex mold designs. For instance, a supplier might suggest using insert molding for a part with embedded wiring to avoid damaging delicate components during assembly.

Final Tips

Choose insert injection molding if:

- Your base part is metal, ceramic, or electronic.

- You need to embed pre-made parts (screws, sensors) in plastic.

- Reducing assembly steps is critical.

Choose overmolding if:

- You need multiple plastic/rubber layers.

- The product requires soft grips, seals, or decorative finishes.

- Chemical bonding between materials is possible.

Still unsure? Start with a small batch. Test both methods with simple parts to see which meets your quality and budget needs. For example, create a prototype handle using insert molding (metal core + plastic) and another using overmolding (hard plastic + rubber). Compare their feel, durability, and cost to decide.

By focusing on your project’s materials, steps, and end use, you’ll find the best method without guesswork.

Conclusion

Choosing between the overmolding and insert molding process depends on your project’s material needs, production scale, and design goals. For example, insert molding works best when embedding metal parts or electronics, while overmolding excels at creating soft grips or multi-layered plastic products. To ensure success, test prototypes early and consult manufacturers for material compatibility advice.

For businesses seeking reliable injection molding services, Fecision offers solutions that blend precision and efficiency. Here’s why they stand out:

- Certified Quality

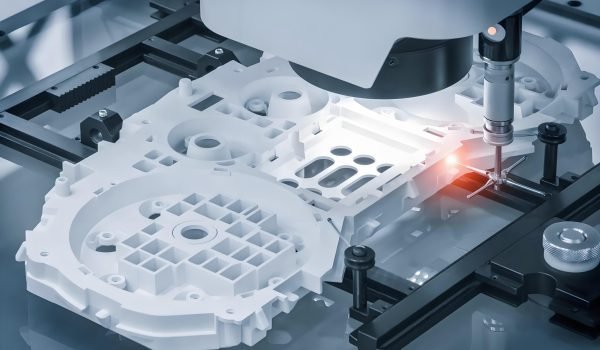

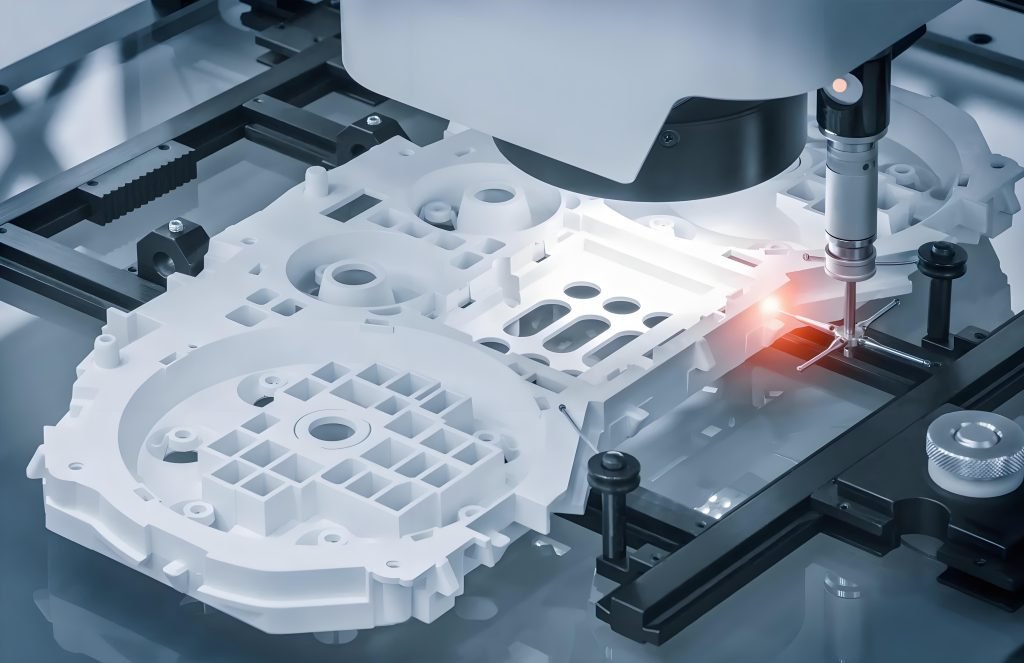

Fecision meets strict industry standards, ensuring parts like automotive dashboards or medical devices are safe and durable. Their in-process inspections with CMM machines catch errors early, reducing waste.

- Material Flexibility

They support plenty of materials, from heat-resistant PPS to flexible TPU. This versatility allows tailored solutions—like rubber-coated USB ports (overmolding) or metal-reinforced chair legs (insert molding).

- Cost-Effective Scaling

Whether producing 10 prototypes or 100,000 units, Fecision’s molds and fast cycle times cut costs.

By combining advanced technology (like gas-assisted molding) with hands-on support, Fecision simplifies complex injection molding projects. Whether you’re in automotive, medical, or consumer goods, their services turn ideas into precision-made products—fast and reliably.