Designing plastic parts feels like mixing concrete for a backyard patio—get the proportions wrong, and everything cracks. Wall thickness in injection molding works the same way. It’s not just about making walls “thick enough” or “thin enough.” It’s about threading the needle between what the plastic can handle, how the mold fills, and whether the finished part survives actual use.

Picture squeezing toothpaste through a straw. It is too narrow, and the paste jams halfway. Too wide, and it oozes out uncontrollably. That’s injection molding in a nutshell. Are walls too thin? The plastic freezes before reaching the mold’s corners. Are walls too thick? You’re stuck waiting hours for cooling while money evaporates. The worst offenders are uneven walls—like building a brick wall with random gaps. Thick sections tug at thin neighbors as they cool, warping parts into useless twists.

Smart designers cheat this system. Instead of fattening walls like a winter coat, they add hidden ribs—the plastic equivalent of steel beams in skyscrapers. The taper thickness changes like fading music volume, and not slamming the mute button. And they pick plastics like a chef chooses knives: flexible materials for delicate edges, rigid ones for load-bearing spines.

What is Wall Thickness in Injection Molding?

The wall thickness is simply how thick or thin each section of the part is. But here’s the catch: getting this thickness right isn’t just about making the product strong enough. It’s like walking a tightrope between what the material can do, how the mold fills up, and how fast the whole process works.

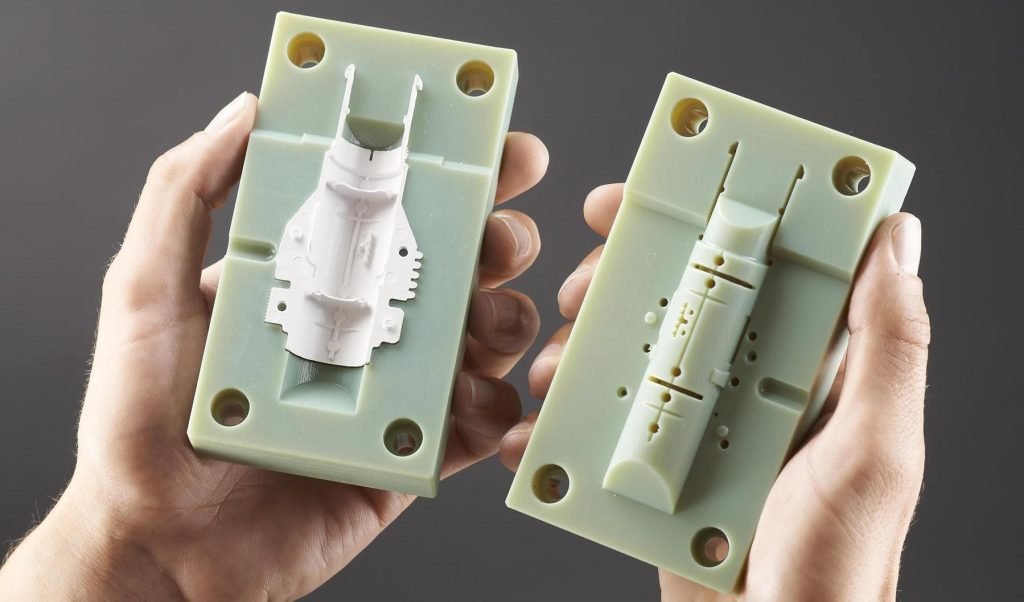

Designers aim for that “just right” thickness that works for both the product and the machine. Uneven thickness is sneaky. One thick section next to a thin area? That’s asking for trouble. As the plastic cools, the thicker part shrinks more, pulling the material unevenly. You’ll end up with warped surfaces or dents called sink marks. Instead of making the whole part thicker (which adds weight and cost), engineers add strategic ribs or gussets. It’s like building support beams inside the part—you get strength without the bulk.

Most everyday plastic items (like bottle caps or appliance housings) stick to 1.5-3mm thickness – enough to hold shape but still cool quickly. When you absolutely need thicker sections, blend them into thinner areas using slopes rather than sudden drops. Think of it like smoothing out a speed bump instead of hitting a pothole. Different plastics behave differently. Nylon flows easily into thin walls, while glass-filled materials need thicker sections to push through. Getting wall thickness right from the start saves headaches later – fewer mold adjustments, less scrap material, and parts that work as intended.

What is Uniform Wall Thickness?

Think of uniform wall thickness like baking a cake—if one side is thick and the other’s paper-thin, it’ll crack or collapse. In injection molding, this principle means keeping plastic parts as evenly thick as possible where it matters. But here’s the twist: it’s not about making every millimeter identical. It’s about avoiding drastic changes that confuse the molten plastic as it flows into the mold.

Imagine driving a car—sudden drops cause crashes. Similarly, walls shouldn’t drop from 3mm to 1mm in a sharp step. Instead, designers use gradual slopes (like merging lanes on a highway) to let the plastic flow smoothly. A good rule? Keep adjacent walls within the proper thickness of each other. Need to strengthen a thin area? Add a rib, but make it properly thinner than the main wall. This avoids ugly sink marks while still adding support. Some plastics, like nylon, flow easily through thin sections. Others, like glass-filled resins, need thicker paths. Uniformity here is about respecting the material’s “personality”.

Ever seen a phone case with weird warping? That’s often uneven walls causing uneven cooling. To fix this, pros tweak thickness in non-critical zones—like thinning the sides of a container while keeping the base sturdy. It’s not perfectly uniform, but it’s strategically balanced. Uniform wall thickness isn’t a strict rulebook—it’s more like traffic laws for melted plastic. Break them, and you’ll get defects; follow them, and your parts roll off the production line smoothly.

Why Uniform Wall Thickness Matters in Injection Molding?

Why does uniformity matter so much? Picture baking a cake: if one side is thick and raw while the other is thin and burnt, the entire slice collapses. Similarly, uneven walls in plastic parts don’t just “look bad”—they trigger hidden problems that sabotage strength, speed, and cost. Let’s break down why skipping this rule risks turning your design into a manufacturing nightmare.

1. Avoids Visible Flaws

Uneven walls create surface problems. Thick areas cool slower than thin ones, leading to marks like dents (sink marks) or wavy lines. These flaws make parts look unprofessional. Thin sections might even show visible seams or color changes from uneven plastic flow.

2. Controls Material Flow

The molten plastic flows better through consistent paths. Thick-to-thin transitions disrupt this flow. Imagine pouring syrup: if a narrow pipe suddenly widens, the syrup slows down and hardens unevenly. Similarly, plastic cools too fast in thin sections, leaving thick areas unfilled or causing air traps.

3. Prevents Warping

Parts bend or twist when sections shrink differently. Thicker walls shrink more as they cool. If one side of a part is thicker than the other, it shrinks unevenly, warping the shape. This makes parts unusable if precision matters, like in medical tools or electronics.

4. Saves Time & Money

Thick walls need extra cooling time. If parts have both thick and thin areas, the whole mold must wait for the thickest section to solidify. This slows production. More material is also wasted in overly thick sections, raising costs.

5. Reduces Stress Points

Sudden thickness changes create weak spots. Think of bending a metal ruler: it snaps easier where it’s thinner. Plastic parts crack or fail faster near abrupt wall changes. Uniform thickness spreads stress evenly, improving durability.

Key Fixes for Designers

• Use gradual transitions between thick and thin areas.

• Add ribs for strength instead of making walls thicker.

• Choose materials that work with your wall thickness needs.

Uniform walls aren’t just a “rule” – they’re a way to make parts faster, cheaper, and more reliable. Even small thickness errors can turn a great design into a failed product.

General Injection Molding Wall Thickness Guidelines

Designing plastic parts requires careful attention to injection molding wall thicknesses—too thin and the part might snap like a dry twig, too thick and it could warp like a wet cardboard box left in the sun. Let’s explore how to navigate these limits without getting lost in technical jargon.

What is the Minimum Injection Molding Wall Thickness?

Imagine trying to pour syrup through a coffee stirrer. That’s what happens when pushing stiff plastic through ultra-thin walls. The injection molding minimum wall thickness depends on three practical factors:

1. Material Behavior

Soft plastics like polypropylene behave like pancake batter—they flow easily into tight spaces, allowing walls as thin as a credit card. Harder materials, such as glass-filled nylon, act more like cold peanut butter. They need thicker paths to move through molds without clogging.

2. Part’s Real-World Job

A disposable coffee cup lid can get away with paper-thin walls because it does not handle heavy loads. However, a car dashboard component holding air vents needs the sturdiness of thicker walls. The rule is simple: if it bends when you breathe on it, it’s probably too thin for anything beyond decorative use.

3. Mold Mechanics

Thin walls demand precision engineering. Injection gates must be positioned like firehoses aiming directly at narrow sections. Cool the mold too quickly, and the plastic hardens mid-flow—leaving unfilled gaps. Solution? Keep molds warmer in thin areas to buy extra flow time.

Common Fixes for Fragile Sections:

• Add tiny reinforcement ribs (like the ridges on a plastic spoon)

• Round all corners—sharp edges crack under stress

• Use “high-flow” plastic grades designed for narrow channels

What is the Maximum Injection Molding Wall Thickness?

Let’s see the maximum wall thickness for injection molding together. Thick walls feel safe—like ordering a triple-layer cake—but create hidden problems:

1. The Shrinkage Surprise

Plastic shrinks as it cools. Thick sections shrink more dramatically, pulling surrounding areas like a too-tight sweater. This causes warping, especially where thick and thin walls meet.

2. The Cost Iceberg

A 5mm wall uses twice as much material as a 2.5mm wall. For 10,000 parts, that’s enough extra plastic to make 5,000 more units. Worse, thick areas take exponentially longer to cool—a 6mm wall might quadruple production time compared to 3mm.

3. Surface Sabotage

Sink marks—those frustrating dents—form when surface plastic hardens over still-molten cores. They’re the plastic equivalent of a soufflé collapsing. Voids hide inside maximum wall thickness injection molding like termites, weakening structures until they suddenly fail.

Smart Alternatives to Bulky Walls:

- Hollow cores – Like a chocolate Easter egg, empty spaces inside maintain shape without material bloat

- Ribbed patterns – A 2mm grid of raised lines provides the strength of 4mm solid walls

- Tapered transitions – Gradually thicken walls over a 3:1 ratio (like a pyramid slope) to ease material flow

| Rule | What to Do | Red Flags |

| Consistency is King | Avoid wild swings in thickness. If one section is thick, nearby areas shouldn’t drop to half that size. Use gradual slopes instead of sharp edges to keep cooling even. | Parts bending where thick and thin meet. Surface defects from uneven cooling. |

| Material Matters | Stiffer plastics need thicker walls to flow properly. Flexible materials handle thinner sections better. Always check your material’s “sweet spot” for thickness. | Cracks in rigid plastics. Sagging in flexible zones. |

| Test Like You Mean It | Don’t skip prototyping. Cheap test molds reveal hidden flaws: thin areas that refuse to fill, thick zones that trap air, or parts warping unpredictably after cooling. | Gaps in finished parts. Dents on surfaces. Twisted shapes. |

| Talk to Mold Nerds | Ask mold engineers early: “Will this ultra-thin edge break during ejection?” “Can we hollow out bulky sections?” “Where can ribs replace extra thickness?” | Broken edges during production. Wasted material in hidden areas. Weak structural points. |

Conclusion

Mastering injection molding wall thickness variation isn’t about memorizing numbers—it’s about understanding how plastic behaves under heat, pressure, and real-world use. Get it right, and your parts look clean, work flawlessly, and cost less to produce. Cut corners, and you’ll face a domino effect of defects, delays, and redesigns.

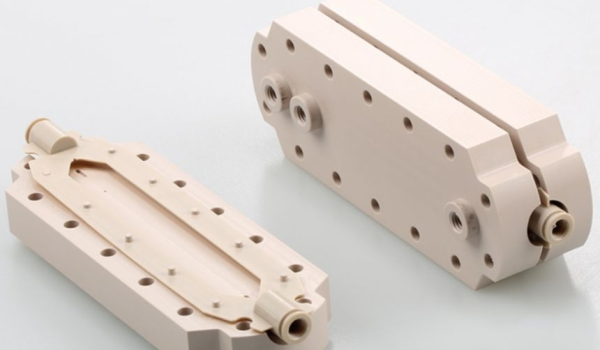

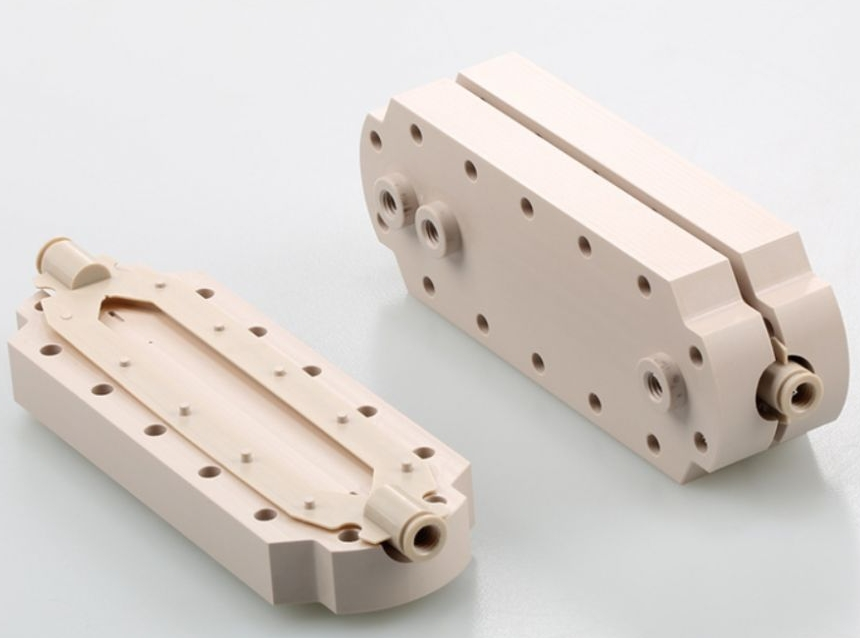

Fecision: Your Partner in Precision Molding

At Fecision, we’ve built our reputation on solving the “wall thickness puzzle” for clients across industries. Our approach blends old-school craftsmanship with cutting-edge technology—like seasoned chefs using modern ovens to bake perfect goods every time. We don’t just follow rulebooks; we adapt to your part’s unique personality, whether it’s a featherlight medical sensor housing or a rugged outdoor gear component.

From prototype tweaks to high-volume runs, our engineers work as an extension of your team. They’ll spot thickness traps you never noticed, suggest smarter material pairings, and tweak molds until even the trickiest walls fill like water into a glass. Need a wall that transitions from razor-thin to rock-solid across three centimeters? We’ve done it for drone frames. Struggling with injection molding uniform wall thickness? We fix that weekly.

Explore Fecision’s Injection Molding Services to see how we turn “good enough” into “bulletproof”.