Manufacturing is ubiquitous. Think about your cell phone, your vehicle, or even the chair that you are presently occupying. All these things exist because of manufacturing. It’s a huge part of our daily lives, shaping our products.

Today, we will put a common question to rest: Is metal casting the same as metal additive manufacturing? Most get these two terms confused. One process is quite old, and the other is rather modern. We will point out the major differences between the two ways and provide you with information on which process produces the best outcome for your particular project.

Is Casting Additive Manufacturing?

The Answer: No

Let’s get straight to the point: casting is not additive manufacturing. There are fundamentally different ways to make parts.

What is Casting?

Casting is one of the oldest methods of producing a part from metal. The casting process has its roots in melting metal all the way to a liquid state like water. This liquid metal is poured into a specially shaped container: a mold. When the metal cools, it solidifies to take the shape of the mold. This is the basic concept of casting.

There are several types of casting. Die casting, for example, is a method that forces molten metal into a mold cavity at high pressure under injection. Another common type of casting is sand casting, where the mold is made from sand.

Here’s the important part: When you pour liquid metal into a mold, you’re filling a void. You’re not adding material layer by layer. Instead, you’re creating a solid part from a liquid that fills a defined space. This process, often part of casting metalworking, is regarded as subtractive because the mold defines the space where the material will not be present. Casting has been used for many centuries since it produces many identical cast metal parts quickly and efficiently.

What is Additive Manufacturing?

Now, let’s look at additive manufacturing. You might know it better as 3D printing. This is a much newer technology. Instead of pouring liquid metal into a mold, additive manufacturing builds parts from the ground up, layer by tiny layer.

Think of it like a building with many thin slices of material that get stacked one on top of another, layer by layer. Each layer fuses to the layer below it, building slowly to a complete three-dimensional object from a digital design.

Typically, in metal additive manufacturing, the work material will be fine metal powder or wire. Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) machines melt and fuse metal particles using a laser or electron beam. Essentially, this process can be considered ideal for making very complicated parts, especially for small quantities of them.

Key Differences

The primary difference between casting and additive manufacturing is the process of building the component. Casting builds a part with a pour of molten material into a mold to become solid with time. Additive manufacturing, on the other hand, builds a part by adding material layer by layer. One fills a void, the other constructs from scratch.

Casting vs. Additive Manufacturing

Now that we have identified they’re different, let’s address key distinctions between casting and additive manufacturing.

Size and Scale

When it comes to size, casting often wins for very large parts. Imagine making engine blocks or massive structural components; casting is usually the go-to method. The molds can be quite big, allowing for the creation of substantial objects.

Currently, there are limits on additive manufacturing, specifically metal 3D printing, by the size of the build volume of that printer. While printing technology is proliferating, it still cannot produce parts at the scale of production like traditional casting can. But it is so powerful when it comes to smaller intricate parts.

Cost

Cost is always a factor in manufacturing and varies very much depending on volume. For large quantities, casting is generally much cheaper per part. After the initial mold set up (which is always expensive), it is very cheap to produce thousands or millions of identical parts, because of economies of scale. Take automotive parts as an example; die casting is used primarily because of its mass-production efficiency.

Additive manufacturing is much more economically viable for small runs, custom parts or highly intricate designs. The capital investment of an expensive mold is not needed, and there is way less setup time associated with the ability of 3D printing. This makes it an excellent choice for prototypes, or specialized components where you just need a few.

Lead Times

How quickly do you need your parts? This is where additive manufacturing tends to hold an upper hand in low-volume production. With 3D printing as a production method, once the design is complete, you can start printing in good time. The overall pre-production work is reduced, and thus the turnaround time from design to prototype or small-run production is quite short.

Casting, however, requires more steps before you can start producing parts. You have to design and make the mold, which can take a long time. The production run can be quick once you have the mold, but the lead time in general is often longer than that of additive manufacturing.

Complexity

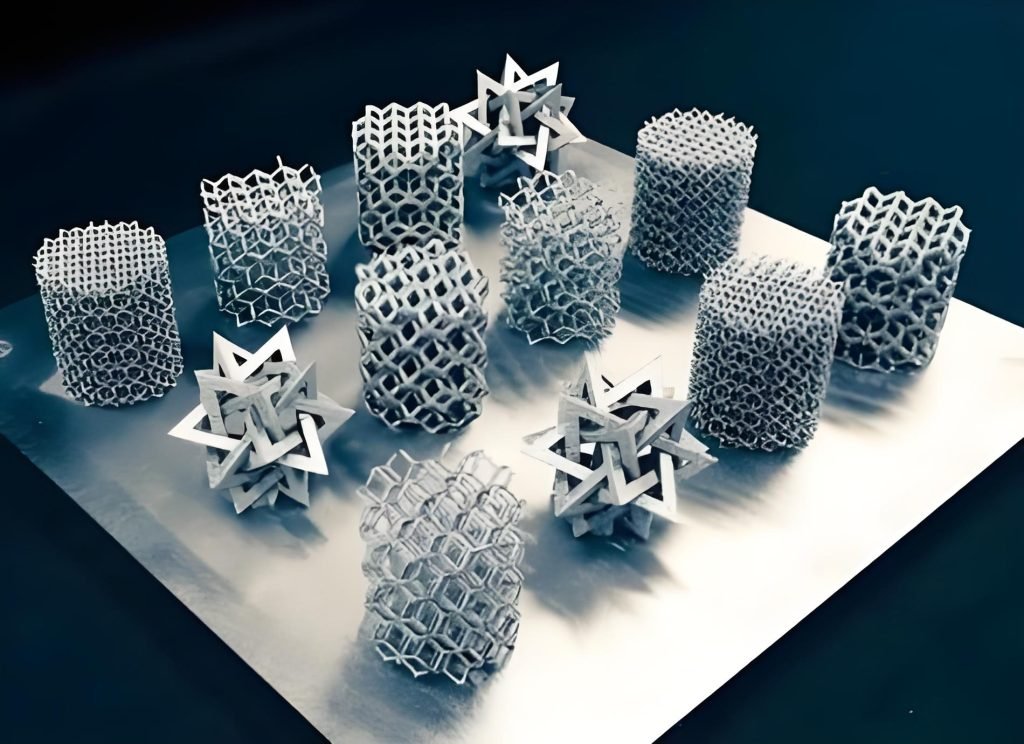

This is where additive manufacturing truly shines. Because it builds parts layer by layer, it can create incredibly intricate geometries, internal channels, and complex designs that would be impossible or extremely difficult with traditional casting. Medical implants, aerospace components with lightweight lattice structures, or parts with internal cooling channels are perfect examples of what additive manufacturing can do.

Casting, while versatile, is better suited for simpler, more robust shapes. While molds can have some complexity, they can’t achieve the same level of fine detail or internal intricacy as additive manufacturing.

Mechanical Properties

The strength and density of parts can vary between the two methods. Cast metal parts will have a consistent microstructure, and can be very strong and durable – specifically in high-volume applications where the material properties are well-understood and controlled.

Parts made by metal additive manufacturing can have great mechanical properties too. However, these properties can be more sensitive to the printing process, the material used, and post-processing. Additive manufacturing can create parts with anisotropic properties (i.e, strength varying in direction) and internal porosity, which may require some added treatments. But in a generalized sense, the mechanical properties of 3D printed parts are ever-increasing along with additive manufacturing. In many unique applications, they tend to outperform traditionally manufactured components.

A Quick Comparison

| Feature | Casting | Additive Manufacturing (3D Printing) |

| Process | Molten metal poured into a mold to solidify | Builds parts layer-by-layer from digital designs |

| Part Creation | Fills a void (subtractive-like) | Adds material (additive) |

| Size & Scale | Ideal for large parts (e.g., engine blocks) | Limited by build volume; best for smaller, detailed parts |

| Cost | Cheaper for large quantities (economies of scale) | More cost-effective for small batches and complex designs |

| Lead Times | Longer initial setup (mold creation); faster production after that | Faster for small batches and prototypes; less pre-production |

| Complexity | Better for simpler, robust shapes | Excels at intricate geometries and internal features |

| Mechanical Properties | Consistent microstructure; strong and durable | Can be excellent, but more process-sensitive; allows for optimized designs |

| Typical Use | High-volume production (e.g., automotive parts) | Small batches, custom parts, prototypes, complex designs |

Making Your Manufacturing Choice: Casting vs. Additive

Choosing between methods of casting and additive manufacturing is strictly dependent on the use case of your particular project. Let’s examine when each method makes the most sense.

When to Choose Casting

Choose casting when:

- You need high-volume production. If you need thousands or millions of parts, casting, especially die casting, is incredibly efficient and cost-effective per unit. Think of the automotive industry where mass production is key.

- Your parts are relatively simple. If your design doesn’t require extreme complexity or intricate internal features, casting is often the more straightforward and economical choice.

- You have budget constraints for large orders. The initial mold cost can be high, but for large quantities, the overall unit cost makes casting very competitive.

When to Choose Additive Manufacturing

Choose additive manufacturing when:

- You need small batch production or custom one-offs. For prototypes, specialized tooling, or limited series of proprietary parts, the high cost and lead time to create molds are avoided with 3D printing.

- Your designs are intricate. Additive manufacturing is the best if you want to create complex geometries, internal channels, lightweight structures, or fine-detail features. Think of a custom medical implant that needs to fit very specific anatomical features.

- You need faster prototyping and reduced lead times. For rapid iteration and quick production of initial designs, additive manufacturing can get parts in your hand much faster than traditional casting with its lengthy mold-making process.

Making the Right Choice

To make the right choice, always think about these key factors:

- Volume: How many parts do you need?

- Complexity: How intricate is your design?

- Budget: What’s your overall cost constraint?

- Lead Time: How quickly do you need the parts?

By matching the processes to the volume, complexity, and budget for your project, it ensures that you can utilize the most efficient and effective production methods.

Fecision – Your Reliable Metal Parts Partner

Recap of Key Points

We’ve covered a lot of information, and the main takeaway is very simple: casting and additive manufacturing are two very different manufacturing processes that each have their own advantages, with casting being better for high-volume simple parts, and additive manufacturing being better for complex parts and low-volume production. It’s important to know the differences to make the correct decision and choose your manufacturing path for your project.

Fecision: Your Go-To for Casting & 3D Printing

At Fecision, we understand that every project is different. That’s why we offer both metal casting and metal additive manufacturing services. We are not just another supplier, but a partner in moving your designs from conception to reality.

With the ability to do die casting, we provide durable cast metal parts in bulk with consistent quality. If you need to mass produce solid and reliable components, our casting services can meet your needs. On the other hand, we can quickly produce precision prototypes and complex patterns with advanced 3D printing services. If your need is a few custom parts, or for rapid prototyping, our additive manufacturing services can support.

Why us? We provide quality, speed, and custom solutions, and will work collaboratively with you to understand your project specifications and advise the best manufacturing method to achieve your purpose.

Need cast metal or 3D printed parts? Contact Fecision today for a quote!