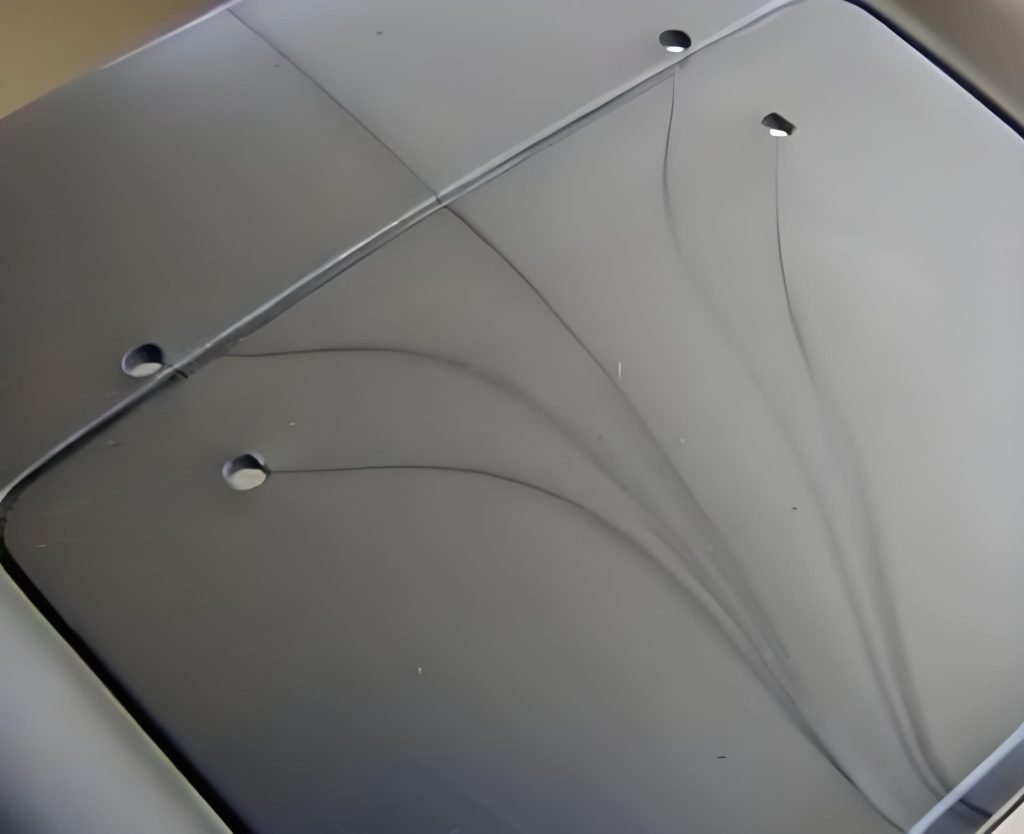

Flow marks are a common problem in injection molding. These are the ripple-like, streaked patterns you sometimes see on the surface of your injection molded plastic parts as a cosmetic defect. But they can seriously impact the perceived aesthetics of what your product looks like, and how the customer experiences enjoyment using your product. Nobody wants to receive a product with an appearance that isn’t perfect, right?

Fortunately, these flow marks are fixable. This guide will explain what flow marks are, what causes them, and more importantly, how you can get rid of them. You will be much better prepared to create better parts!

What is a Flow Mark?

Definition

Flow marks are round, linear, and repeated patterns you may see near the gate of an injection-molded part. They are caused when the molten plastic does not flow consistently and smoothly. It is generally due to temperature differences in the plastic as it fills the mold cavity, or how pigments (colors) are being distributed.

Essentially, flow marks happen because the molten plastic is cooling unevenly while it is filling the mold. This means that some areas are cooling faster than others, resulting in the unsightly surface patterns you see.

Identification

Flow marks are generally easy to identify because they are located near the gate, where the plastic first entered the mold. They may appear as small differences in color from the rest of the part, making them easily identifiable.

Flow marks can occur in various shapes such as circular rings, straight lines, or complex repeating patterns. Because of their distinctive appearance, they can be identified on the surface of a molded part relatively easily.

Impact

Flow marks are an appearance defect, and knowing their impact is important. They do not generally disrupt the structural integrity of the molded part or affect its strength. The part will still function as intended and usually won’t break because of a flow mark.

However, what they impact the most is the aesthetic quality of the part. On many products, especially if the way they look contributes to a certain function (like consumer electronics, automotive interiors, and visible enclosures), flow mark injection molding defects can be a deal breaker. They will give a product the look of being low quality, poorly manufactured, or an expectation that was not delivered, leading to customer dissatisfaction or rejection.

What Causes Flow Marks in Injection Molding?

Flow marks don’t just happen by accident; they have identifiable causes, and the first step in addressing flow marks is to understand what those causes are. In general, the issues can be categorized as related to materials, machines and the molds and mold designs.

Material Causes

Even the properties of the plastic material will have a large impact. Thermoplastics have a Melt Flow Index (MFI), which is a measure of how easily the molten plastic flows. Materials with lower MFI levels tend to be thicker and do not flow well, and therefore, flow marks are more likely to occur.

The process of using the material also plays a role. Inappropriate rates of airflow, or injection speed, can create turbulence or inconsistent filling that manifests as surface flaws in the materials. Also, if you do not keep the material at the proper temperature as it fills the mold, it will not cool evenly, and then it will also have different thickness, which will create flow marks.

Machine Causes

The injection molding machine and its setup are critical. The mold itself is important as well, especially concerning venting for trapped air, uniform wall thickness to allow for cooling, and lubrication to allow for continuous material flow. If there is a problem concerning any of these elements, the plastic’s flow could be interrupted.

The design of the sprue, gate, and runner system is also important in terms of flow marks. Those three components are the channels through which the molten plastic moves before entering the mold cavity. If those flow channels are too small or have flow restrictions, the plastic can very easily start to cool too early or not flow properly, which will cause marks to show. Cold slug wells are also crucial for trapping the initial, cooler plastic.

Mold/Mold Design Causes

The physical design of the mold can directly cause flow marks in injection molding. Mold cavity design features such as sharp edges or corners can affect the smooth flow of molten plastic. The molten plastic will flow and cool unevenly as it goes around sharp angles, which will leave distinct marks that are visible.

Variable wall thickness in the part design is another common cause. Those parts with thicker sections will cool at different rates. When cooling rates differ, there is cooling stress and uneven shrinkage, which often become visible in the form of flow marks. Likewise, the location of the gate, as well as the design of the runner, are important too; if the gate is located poorly, it requires the plastic to travel too far, which could allow it to prematurely cool, and flow marks will develop.

How to Reduce Flow Marks in Injection Molding?

There are several good methods to reduce or even eliminate flow marks in your injection molding process. This will involve adjustments to the machine, working on the mold design, and informing the operators.

Changes to Temperature Parameters

Managing temperature is critical in injection molding. Always check and adjust your barrel temperature based on material specifications. Ideally, the plastic temperature should increase steadily by around 6°C in each successive heating zone.

Increase your nozzle temperature slightly above the melt temperature. This gets the material as liquid as possible when introduced into the mold to aid smoother flow. It is also important to manage the right mold temperature. A cold mold will cool the plastic too quickly, especially on the surface, which can lead to a rapid hardening of the material and flow marks.

Changes to Pressure Parameters

Adjust your pressure settings to improve flow and ultimately surface quality. Increasing back pressure will help make the material melt more uniform by eliminating trapped air and assuring consistent material enters the screw. Better consistency could lead to better flow.

Also, increasing holding pressure once the mold is filled allows the material to be more densely packed in order to compensate for shrinkage, in addition to pushing the plastic against the surface of the mold, which could help eliminate surface flaws. Again, remember not to exert excessive injection pressure because that could lead to other defects like jetting.

Injection Speed

It is critical to maintain a consistent and appropriate injection speed to prevent premature cooling and achieve a more uniform fill rate. If speed is too slow, the plastic will cool and harden before the mold is completely filled, resulting in uneven flow and visible marks.

If the injection speed is too fast (especially in thin areas, or sharp corners), it can cause the molten plastic to create turbulence, resulting in flow marks or worse. In some cases, it may be worthwhile to evaluate materials with proper flow characteristics for your part. It may also help to redesign the gate, if necessary, to ease the flow of plastic into the mold.

Gate, Sprue, & Runner Design

Optimize the design of the gate, sprue, and runner system to produce a higher quality part. They can be thought of as arteries in the molding process. It is beneficial to optimize sizes using simulation tools or experienced designers.

The gate location is important as it should ideally be placed to allow the molten plastic to flow smoothly, and fill the mold evenly from the thickest area to the thinnest areas. Avoiding thin (or small) gates and runners is very important as it reduces flow, and when it’s too restricted, you risk early cooling or too much heat. Both can lead to flow marks.

Venting

Proper venting is critical for allowing the trapped air and gases to leave the mold as the plastic fills it. If air is compressed and trapped, it will produce many problems like burn marks and flow marks in injection molding.

You should vent in all strategic locations, and especially where air will likely become trapped (like the end of its flow path). The depth of the vent is also critical and needs to be adjusted based on which material is being used. When the vent size and location are done correctly, the cavity will fill completely and surface defects from entrapped gases can be avoided.

Mold Design

In addition to gate and runner locations, the type of mold design also plays an important part. It is best to design the molds with fillet edges and rounded corners instead of sharp edges as this helps with material flow. Sharp transitions do not lend themselves to proper transition of the plastic. Rather they lead to turbulence, causing the plastic to change direction and flow unevenly, and then cause flow marks in motion.

Also, where possible, design parts with uniform wall thickness. If you also can’t eliminate varying thickness, then make the varying thickness transition from one to another gradually, rather than suddenly. Gradual changes in thickness allow for more consistent cooling and less uneven shrinkage, which is another typical cause of flow mark in injection molding. Finally, a well-designed cold slug well is crucial to capture the initial, cooler plastic, preventing it from creating defects on the part’s surface.

Operator Knowledge

Even with the best materials, machines, and mold design, the operator makes a difference. It is very important to educate operators about injection molding processes. A knowledgeable operator can see early signs of trouble and make adjustments to ensure the process is optimized and set up for continual quality.

Investigate working with shifts that will monitor production consistently or use robotics for repetitive tasks to limit operator errors, ultimately creating consistency in production. An educated workforce can help eliminate flow mark in injection molding and greatly improve the overall quality of production.

Summary

Flow marks in injection molding are, for the most part, preventable with consideration and the adoption of appropriate modifications. By correcting material temperatures, injection pressures, mold design, and venting, flow related defects can be eliminated, resulting in an enhanced part quality. Process control consistency, proper mold maintenance, and operator training should be taken seriously to minimize flow-related issues.

When things get complicated, and you simply want the best parts possible, there is always the option to get experts for assistance. Fecision’s Injection Molding Services are here to help you reduce flow marks and achieve flawless parts. With cutting-edge machines, a skilled workforce, and quality principles at the forefront of every project, we can promise that your project meets the established timelines, budgets, and best-in-class quality standards.

Here’s what makes Fecision a great choice:

- Custom Injection Molding Experts: We handle complex projects with deep knowledge of materials and designs.

- DFM Feedback Upfront: We will review your design at an early stage to optimize molding, allowing you to potentially avoid flow marks and other defects at the beginning.

- High-Quality Production Guaranteed: We are committed to producing the highest quality parts with the fewest defects with advanced expertise in materials, machine settings, and mold design.

- Intellectual Property Protection: We will protect your intellectual property and keep your project confidential.

Need defect-free injection molded parts? Contact Fecision today for a quote and let our experts handle your project with perfection!