Choosing the right injection molding system can feel tricky. Hot runner or cold runner – which truly optimizes your production for cost and speed? Getting it wrong impacts material waste and cycle times, hitting your bottom line hard.

We simplify the decision. This guide compares both methods directly, helping you choose wisely for your next project. Here’s a peek inside:

- Hot runner mold systems: What they are, pros & cons

- Cold runner mold systems: The essentials, pros & cons

- Key differences you need to know

- Making the right choice for your parts

Let’s get started.

What is Hot Runner Injection Molding?

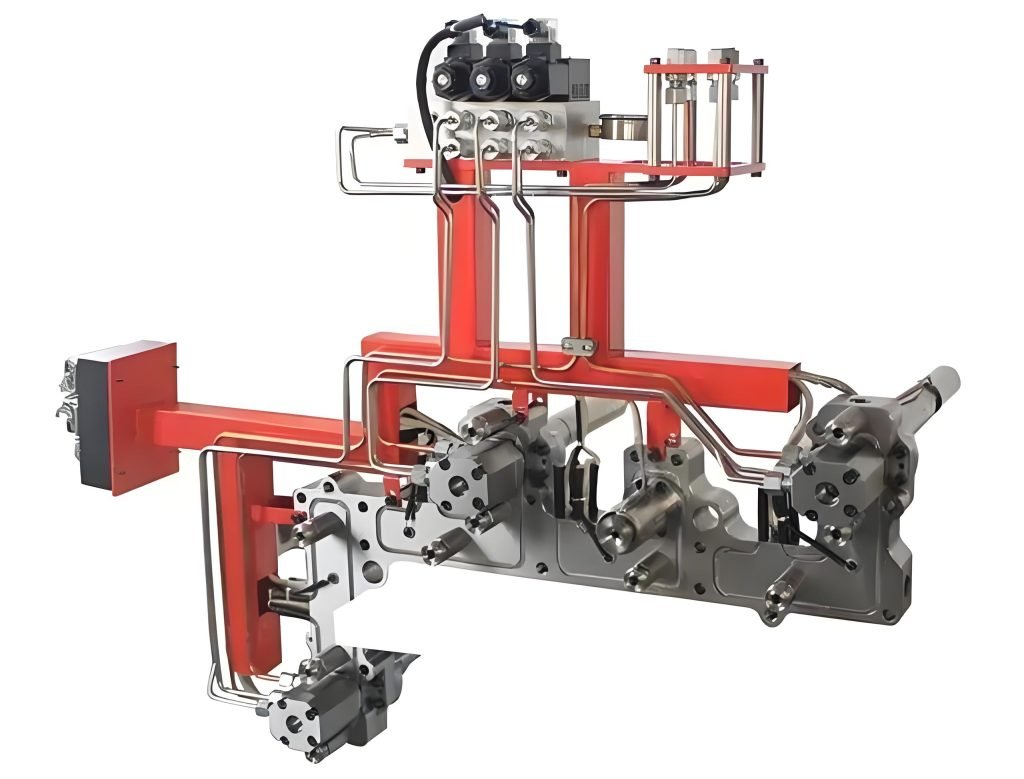

Think of hot runner injection molding as the express lane for molten plastic. Unlike systems where plastic cools and solidifies in the pathway (the runner) before filling the part, hot runners keep things flowing consistently. They achieve this using a heated manifold assembly.

This manifold system maintains the plastic at the optimal melt temperature right up to the point it enters the mold cavity. The big advantage? No solidified runner scrap is created with each shot. This directly reduces your material consumption and can speed up production cycles because there’s no runner to cool or eject.

You’ll encounter different kinds of hot runner systems. The main types usually fall into two categories based on how they apply heat:

- Externally Heated: Heating elements are integrated into the manifold block but sit outside the actual melt channels. The external heat system runner is often mechanically simpler and can be a less costly option initially. They work well for many standard engineering resins.

- Internally Heated: Heating elements or probes are positioned inside the melt channels, directly contacting the molten plastic. This generally provides more precise temperature control, which is beneficial for heat-sensitive materials. These systems often come with a higher price tag and can be more complex.

Beyond the heating method, the gate type is another key difference. Valve gates use mechanical pins to open and close the gate, offering very precise control and clean gate vestiges. Thermal gates (or hot tip gates) rely on a small amount of plastic freezing off at the gate tip between shots, usually leaving a small nub. Valve gates are typically more sophisticated and costly.

So, what are the main upsides and downsides when considering a hot runner?

Pros

- Minimal Material Waste: You’re not producing and then grinding or discarding runner scrap. This is a huge plus with expensive engineering resins.

- Quicker Cycle Times: Eliminating the runner cooling and ejection steps shaves time off each cycle.

- Improved Part Consistency: Direct gating often leads to more uniform filling and packing, reducing variations.

- Design Flexibility: Gate locations can often be placed more optimally on the part itself, not just on the runner edge.

Cons

- Higher Initial Tool Cost: The heated manifold and control system add considerable expense to the mold build.

- System Sophistication: Requires accurate temperature controllers and potentially more skilled personnel for operation and maintenance.

- Not Ideal for All Resins: Very heat-sensitive materials might still experience degradation due to prolonged exposure in the manifold.

- Maintenance Demands: More components (heaters, thermocouples, valve pins if used) mean more potential upkeep is needed compared to simpler cold runners.

What is Cold Runner Injection Molding?

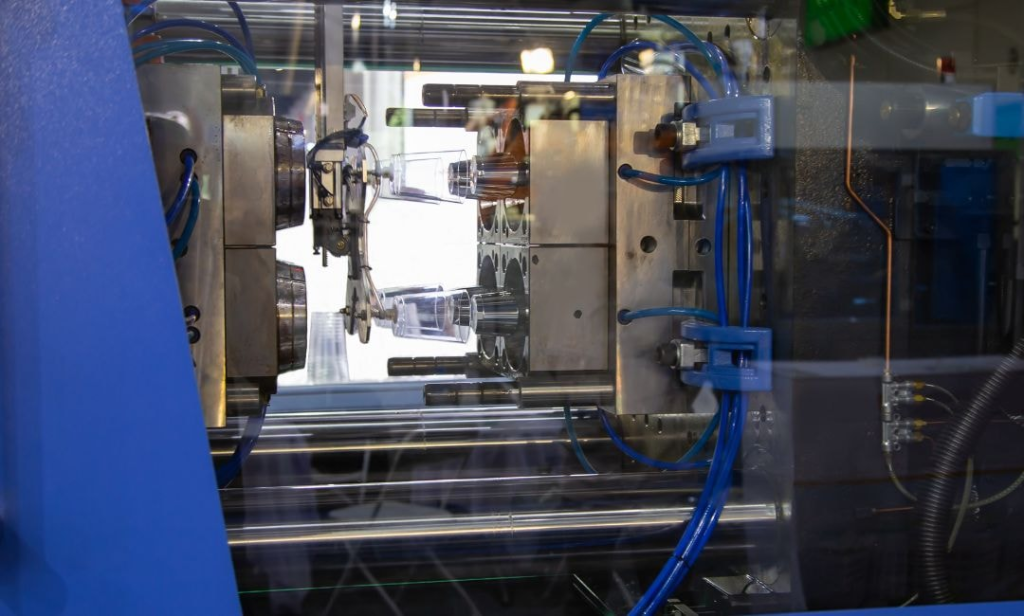

Unlike their hot runner counterparts, these systems operate without a heated manifold. The channels guiding the molten plastic—known as the sprue, runners, and gates—are simply machined directly into the mold plates.

Here’s the defining characteristic: the plastic flowing through these unheated channels cools and solidifies simultaneously with the part forming in the cavity. When the mold opens, this now-solid runner structure is ejected along with the finished part(s). It requires a separate step for removal, done either by hand or through automation.

You’ll primarily encounter two common types of cold runner mold designs:

- Two-Plate Molds: This is the most straightforward configuration. The runner system and the part(s) are located on the same mold parting line and eject together, still attached. It results in simpler, more cost-effective tooling but generally necessitates manual separation of the runner. Gating possibilities are often restricted to the edge of the part.

- Three-Plate Molds: These introduce an additional “runner stripper” plate into the mold structure. This design allows the solidified runner system to detach from the parts automatically as the mold opens, ejecting separately. This configuration enables more gating options, like pin-point gates directly onto the part surface, offering greater design freedom than a two-plate setup but at a higher tooling cost and complexity.

Let’s look at the typical advantages and disadvantages of using cold runners:

Pros

- Lower Initial Tooling Cost: The simpler mold construction translates to a smaller upfront investment compared to hot runner molds.

- Operational Simplicity: Generally easier to design, manufacture, operate, and maintain due to fewer complex components.

- Wide Material Compatibility: Works reliably with almost any thermoplastic resin, including those highly sensitive to heat.

- Faster Color Changes: Less retained material in the feed system allows for quicker and more complete transitions between different colors.

Cons

- Material Waste: The solidified runner is essentially scrap material. It either needs disposal or requires regrinding and reintroduction (which adds cost and can affect process consistency).

- Potentially Longer Cycle Times: Additional cooling time is needed for the runner to solidify properly before ejection.

- Requires Secondary Operation: The runner must be removed from the part, adding an extra step (manual labor or automation cost).

- Gating Limitations: Particularly with two-plate molds, options for gate location are limited, and gate vestiges can be more prominent.

Key Differences You Need to Know

The fundamental split comes down to heat management: hot runners actively keep the plastic pathway molten, while cold runners allow it to cool and solidify with the part. This single difference creates knock-on effects impacting cost, cycle time, material waste, and design possibilities.

Here’s a quick comparison table highlighting the main points:

| Feature | Hot Runner System | Cold Runner System |

| Runner System | Heated manifold keeps plastic molten | Unheated channels; runner solidifies |

| Material Waste | Minimal (no runner scrap) | Significant (runner is scrap/regrind) |

| Cycle Time | Generally faster (no runner cooling) | Generally slower (runner needs cooling) |

| Initial Tooling Cost | High | Low |

| System Complexity | Higher (requires controllers) | Lower (simpler mechanics) |

| Maintenance | More demanding (heaters, etc.) | Less demanding |

| Part Quality | Often better consistency, finer gates | Good, but gate marks can be larger |

| Gate Location | More flexible (can gate on the surface) | More restricted (often edge-gated) |

| Material Suitability | Good, but needs care for sensitive resins | Excellent, handles almost any resin |

| Color Changes | Can be slower, more material purge | Generally faster and cleaner |

Making the Right Choice for Your Parts

The optimal choice emerges when you carefully weigh your project’s unique requirements against the capabilities and costs of each system we’ve reviewed. Think critically about these key factors during your decision process:

- Production Volume is Often Decisive: What’s the scale of your production run? For high-volume, long-term projects, the significant material savings and faster cycle times associated with a hot runner frequently justify the higher initial tooling expense. It’s worth calculating the potential breakeven point. Conversely, for low-volume needs or short prototype runs, the lower upfront cost of a cold runner system is generally more appealing.

- Material Type and Cost: Are you working with a pricey engineering-grade resin or a heavily filled compound? Hot runners minimize waste, offering substantial cost reduction over the life of the tool. If you’re using standard commodity resins like polyethylene or polypropylene, the material savings might be less impactful. For extremely heat-sensitive materials, the simpler thermal journey in a cold runner might be preferable, reducing risk.

- Part Design and Quality Needs: What are the cosmetic requirements? Where must the gate be located? If you need gating directly onto a surface (not the edge) or require an exceptionally clean gate vestige for appearance, hot runners (particularly valve gate types) provide superior flexibility and finish. If an edge gate is acceptable and tooling simplicity is a priority, cold runners are perfectly capable.

- Cycle Time Requirements: Is maximum output speed a critical factor for profitability or meeting market demand? Hot runners typically enable the fastest possible molding cycles. If moderate production speeds are adequate for your goals, cold runners perform reliably.

- Initial Tooling Budget: How much capital is available for the mold investment? If the budget is constrained, cold runners present a clear advantage in lower upfront costs. If a larger initial investment can be tolerated for potential long-term operational savings, hot runners become a viable consideration.

Don’t just rely on gut feelings for the financial aspect. Try to estimate the value of material saved per shot with a hot runner. Multiply this by your projected total production volume. Compare this potential saving against the estimated additional cost of the hot runner system heats mold to gauge the payback period. Always discuss these factors with experienced mold designers and builders – their input is invaluable.

Wrapping Up

Choosing hot runner systems or cold runner systems means balancing upfront cost against long-term efficiency. It’s about matching the tech to your job’s needs – volume, material, and consistent quality goals. You now have the key insights to pick the right path for optimal production results.

Here’s a quick recap of the main takeaways:

- Hot Runners: Offer minimal material waste and faster cycles but come with higher initial tooling costs and complexity. Often best for high volumes or expensive resins.

- Cold Runners: Feature lower tooling costs and simpler operation but generate runner scrap and have slower cycle times. Great for lower volumes, prototypes, or frequent color changes.

- Your Choice Depends On: Production volume, material cost, required part quality, design constraints (like gate location), cycle time needs, and your available tooling budget.