In industries like manufacturing, automotive, aerospace, oil and gas, and heavy machinery, the strength of a metal part can determine whether a machine performs safely or fails unexpectedly. That’s why the debate of forging vs casting is so important.

Both methods shape metal, but they do so in entirely different ways, resulting in major differences in durability, grain flow, and overall performance. The choice between cast vs forged metal can influence everything from product lifespan to resistance against stress and fatigue. This guide explains the key differences to help manufacturers and designers make the best decision for their projects.

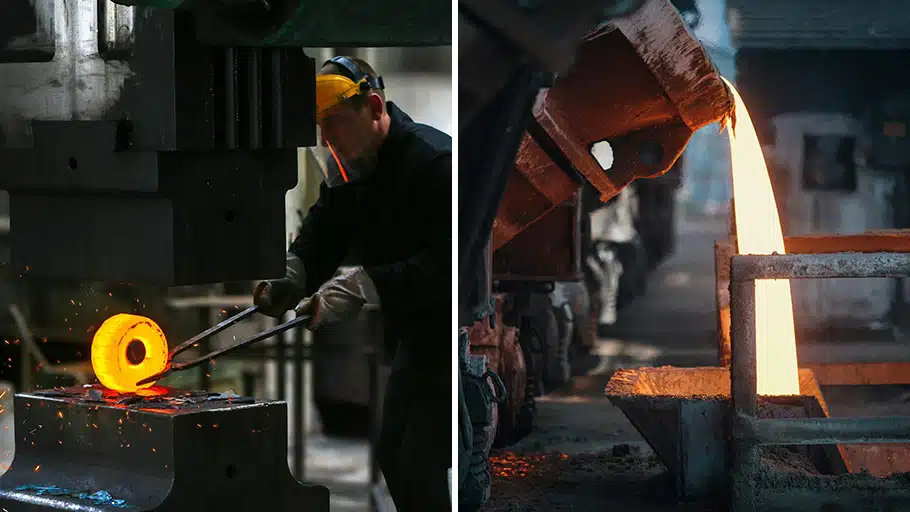

What Is Forging?

Forging is a manufacturing process that shapes solid metal using compressive forces, typically from hammers, presses, or forging machines. Rather than melting the material, forging deforms the metal in its solid state. This mechanical deformation aligns and compresses the internal grain flow, increasing strength and eliminating internal voids.

How Forging Works

- A metal billet or ingot is heated (hot forging) or kept at room temperature (cold forging).

- Compressive force is applied using a hammer or press.

- Metal plastically deforms, and grains elongate along the shape of the part.

- The final product undergoes cooling and optional heat treatment.

This process improves mechanical properties by refining grain flow and removing internal voids.

Common Types of Forging

- Open-Die Forging: Large components shaped between flat dies.

- Closed-Die Forging: High-precision forming using shaped dies. It is ideal for complex but sturdy parts.

- Cold Forging: Produces extremely strong components with tight tolerances.

- Hot Forging: Used for large or complex shapes requiring maximum formability.

Forged parts are commonly used in axles, gears, crankshafts, connecting rods, turbine components, and other safety-critical applications.

What Is Casting?

Metal casting transforms solid materials into a liquid state before shaping them into precise components. This ancient yet still essential manufacturing technique dates back approximately 7,000 years.

Casting is a metal-forming process where metal is fully melted, poured into a mold, cooled, and solidified into a desired shape. Unlike forging, which compresses solid metal, casting relies on the flow properties of molten metal to fill intricate molds.

How Casting Works

- Metal is melted in a furnace.

- Liquid metal is poured into a mold cavity shaped like the final component.

- The metal cools and solidifies.

- The mold is opened, and the part is removed.

- Finishing processes like grinding or machining refine the product.

Because molten metal can flow into complex shapes, casting is ideal for designs that forging cannot easily replicate.

Main Types of Casting

- Sand Casting: Cost-effective, ideal for large parts but less precise.

- Die Casting: High-pressure process for mass production of aluminum, zinc, and magnesium parts.

- Investment Casting: Extremely precise and capable of creating intricate shapes, common in aerospace and medical industries.

Cast parts are used for pump bodies, engine casings, housings, valves, turbine blades, and other intricate shapes.

Forging vs Casting: Key Differences

Choosing between forging and casting depends on mechanical requirements, design complexity, budget, and application environment. The differences between cast vs forged parts are significant, especially when strength matters.

Mechanical Strength and Durability

A fundamental difference exists in the mechanical properties between metal parts that are forged and those cast. These differences have important implications for component performance for critical applications.

1) Tensile Strength

Forged parts consistently show higher tensile strength because of the alignment of their grain structure caused by the forging process. Cast iron and cast steel have a lower strength compared to forged metals because the metal cools without grain alignment and may contain porosity. Cast metals usually have only about two-thirds of the yield strength of forged metals.

2) Fatigue Resistance

The fatigue resistance of forged components is much better. It has been shown that forgings bear up to repeated loading much better, providing as much as 37% greater fatigue strength. In this way, a service life up to six times longer than the life of cast parts can be realized when used under cyclic stress.

3) Toughness

Forged metal can deform so much more before breaking. A forged part can reduce in area by 58% when being stretched to failure, while cast parts only reduce by about 6%. This means that forged parts can absorb more energy, making them much safer in a high-impact situation.

4) Defect Tolerance

Most castings contain a certain amount of porosity that can weaken the part. In general, as porosity increases, the overall strength drops appreciably. For instance, strength might fall from 250 MPa to 120 MPa as porosity increases from 0 to 10%. Forging eliminates internal voids by compressing the metal, which produces a dense and reliable structure with fewer defects.

Design, Size and Material Considerations

The choice between forging and casting often depends on the particular design requirements that are naturally accommodated by each process. These considerations directly influence manufacturing feasibility and final part performance.

1) Shape Complexity

Casting is great for making complex geometries that could never be achieved by forging. Since the molten metal behaves like a liquid, it fills the mold designs completely. More specifically, investment casting can achieve tight tolerances, great detail, and even internal features that cannot be achieved with forging.

2) Size Limitations

Casting is more practical for producing very large components. Forging equipment becomes much more expensive and hard to manage as the part size gets bigger. Casting enables construction of massive parts, even those weighing tens of thousands of pounds.

3) Material Compatibility

Casting provides compatibility with almost all types of metals. More specifically, chrome, nickel, and molybdenum specialty alloys merge more easily in the hot molten metals during the process of casting. On the other hand, some materials, especially with high melting points or work-hardening features, cannot be forged whatsoever.

4) Section Thickness and Internal Cavities

Casting proves ideal for parts requiring thick sections or internal cavities. Since forging requires significant force to shape thick metal sections, casting becomes the obvious choice for complex internal passages. This limitation makes valve and pump bodies primarily suited for casting.

Cost, Production, and Quality Control

In selecting between forging and casting processes, manufacturing economics often proves to be the deciding factor. Both techniques have different cost structures that alter greatly with production volume and part complexity.

1) Tooling and Setup Costs

The cost of casting tools can be very high. Forging dies are also very expensive since they bear the load of extremely high pressure. Although the initial investment in forging tools is large, their per-part cost decreases if you produce big quantities. Even though only about 10% of the budget goes to the design stage, about 70 to 80% of the final production cost will be determined there.

2) When Forging Becomes Cost-Effective

Generally, casting is better for low production runs in the range of 10 to 5,000 pieces. Above that, forging takes over as the more cost-effective process. If you can produce around 10,000 units or more, then closed-die forging becomes more economical compared to sand casting or investment casting. This is because forging uses material more efficiently, often achieving 85–95% material utilization after trimming.

3. Machining and Finishing Requirements

Machining and finishing also influence the overall cost. Generally, forging provides parts with better dimensional accuracy, which requires less machining afterward. Castings, especially sand castings, tend to need much more finishing work. This becomes a huge concern when working with expensive alloys where waste from machining can add to the cost significantly. Forging helps reduce this waste because the produced parts have a near-net shape.

4. Inspection and Defect Detection Methods

Quality control methods vary depending on processes. Cast parts are typically subjected to a large amount of testing for surface and internal flaws, such as liquid penetrant or magnetic particle inspection. Forged parts are ALSO inspected, but generally not to the same degree, as the forging process tends to work out many of the problems associated with casting.

Comparison Table

| Characteristic | Forging | Casting |

| Tensile Strength | 26% higher than casting | 26% lower than forging |

| Fatigue Strength | 37% higher than casting | 37% lower than forging |

| Reduction in Area (When Pulled to Failure) | 58% | 6% |

| Yield Strength | 34% higher than casting | 66% of forged steel strength |

| Material State During Process | Solid (heated to 75% of melting temperature) | Fully melted |

| Formation Method | Compression and deformation | Pouring and solidification |

| Internal Structure | Dense with aligned grain structure | May contain porosity and voids |

| Complex Geometries | Limited capability | Excellent capability |

| Internal Features | Difficult to achieve | Easily achievable |

| Size Limitations | More limited for large parts | Can produce very large parts (up to 200 tons) |

| Material Compatibility | More limited | Compatible with most metals and alloys |

| Cost-Effectiveness | Better for high volume (10,000+ units) | Better for low volume (10-5,000 units) |

| Material Utilization | 85-95% | Not specified |

| Post-Processing Needs | Less machining required | More extensive finishing needed |

| Initial Tooling Costs | High | Lower than forging |

Which Is Stronger: Forged or Cast Metal?

Forged metal is stronger in almost every way. Forged parts have higher tensile strength, higher fatigue strength, better toughness, and greater reliability. Cast metal has its advantages in terms of shape complexity and low-cost production, but it does not match forging when strength is the main concern.

Forging creates a refined and aligned grain structure, removes internal voids, and compresses the metal to make it denser and stronger. This is why forged parts are used in critical applications such as gears, axles, crankshafts, and heavy-load machinery.

If you need reliable and high-performance metal parts, forging remains the best choice.

Forging vs Casting: Which Is Better for Your Project?

Choosing between forging and casting depends on performance requirements:

Choose Forging When:

- Strength is the top priority.

- The component faces high stress, impact, or fatigue.

- It is a safety-critical component (e.g., gears, axles, crankshafts).

- Material reliability is essential.

Choose Casting When:

- The design is highly complex or requires cavities.

- You need lightweight structures.

- Lower cost for intricate shapes is required.

- Production volume is high.

FAQs About Forging vs Casting

1. Is forged steel always stronger than cast steel?

Yes. Forged steel has aligned grain flow and fewer internal defects, making it inherently stronger.

2. Can casting achieve the same strength as forging?

Rarely. Some heat-treated cast steels approach forging strength, but they remain more prone to porosity and fatigue failure.

3. Is forging more expensive than casting?

Tooling cost is higher upfront, but for medium to high production volumes, forging becomes cost-efficient due to lower scrap rates and superior durability.

4. Does investment casting replace forging?

No. Each serves different applications. Investment casting excels for complex geometries with intricate details. Whereas forging remains superior for components requiring maximum strength and fatigue resistance.

5. Why do automotive manufacturers prefer forged components?

Automotive engineers select forged parts for their exceptional reliability under stress. Forged components better withstand impact forces, offer superior fatigue life, and maintain dimensional stability throughout extreme operating conditions.

Conclusion

Forging and casting both play essential roles in modern manufacturing. Forging produces metal parts with superior strength, durability, and reliability thanks to its refined grain structure and dense internal makeup. Casting, on the other hand, is ideal for complex shapes, hollow structures, and cost-effective production, especially at smaller volumes.

Understanding the differences between forging vs casting helps ensure that each part performs safely and efficiently in its intended application. Choosing the right process can boost product lifespan, reduce failures, and improve overall performance.

Are you looking for reliable and high-strength metal components? Visit Fecision to explore advanced forging, casting, and precision machining services.