Not every plastic molding practitioner is familiar with the cause and solution of injection molding burn marks. From a quality standpoint, molders need to resolve the burn marks in injection molding.

A viable solution is only possible when you have detailed knowledge of the issue. Let’s start with the basic introduction to burn marks in injection molding.

What are Burn Marks in Injection Molding?

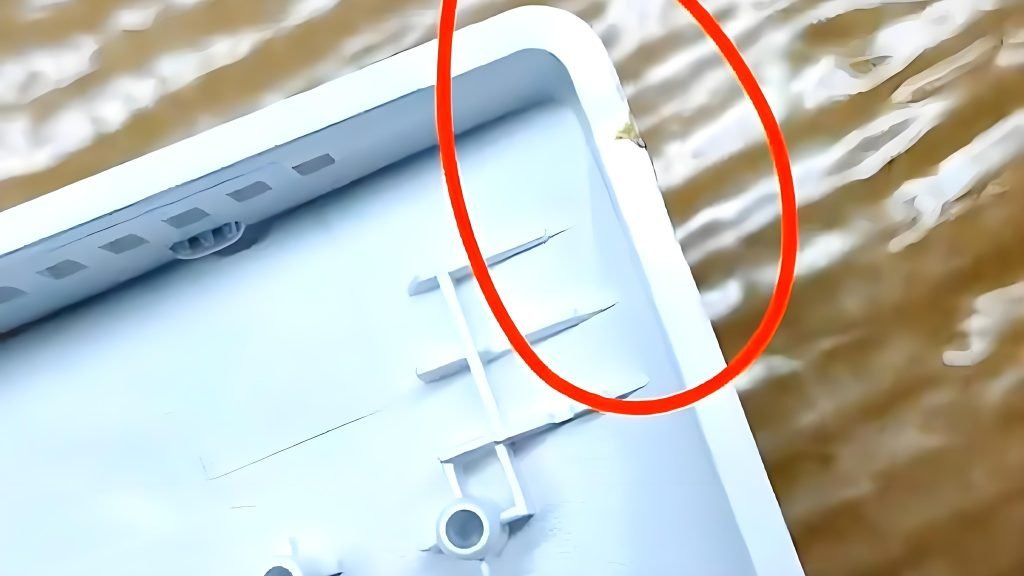

Fast injection and poor mold venting can cause black marks at the end of the flow path. There might be black discoloration at some points of the product due to overheating. These black spots, dark marks, and discoloration are known as burn marks in injection molding.

The gases trapped inside the mold start heating under pressure and start affecting the efficiency of the molding process. With proper venting in the molding equipment, burn marks injection molding can be prevented. The issue is not just about the aesthetics of the final product, but the burn marks also impact the structural integrity of the product.

Impact of Burn Marks on the Product

A few dark spots at the end of the product are not a serious problem. This may be the wrong approach because every little defect eventually affects the appeal and quality of the product. Due to the different textures of the burn marks in molded products, you can easily spot that something is wrong with a specific part.

The altered chemical and physical properties of the burned component affect the usability of the product. You may not get the same level of strength, corrosion resistance, and heat resistance from the burned part.

Make sure to invest in quality molding equipment only. Most of the time, burn marks in injection molding happen due to poorly engineered molding machines. Repetitive burn marks damage the overall molding equipment. Ignoring these issues can cost more in the long run.

Common Causes of Burn Marks in Injection Molding

If you don’t want burn marks to appear on your molded products, first you need to understand the major causes behind this manufacturing fault. Here are some common causes behind injection molding burn marks.

- Mold-related Factors

The presence of oxygen in the molding equipment can be dangerous under high pressure. If air remains trapped inside the mold, it may cause overheating, burning the part that comes in contact with the heat.

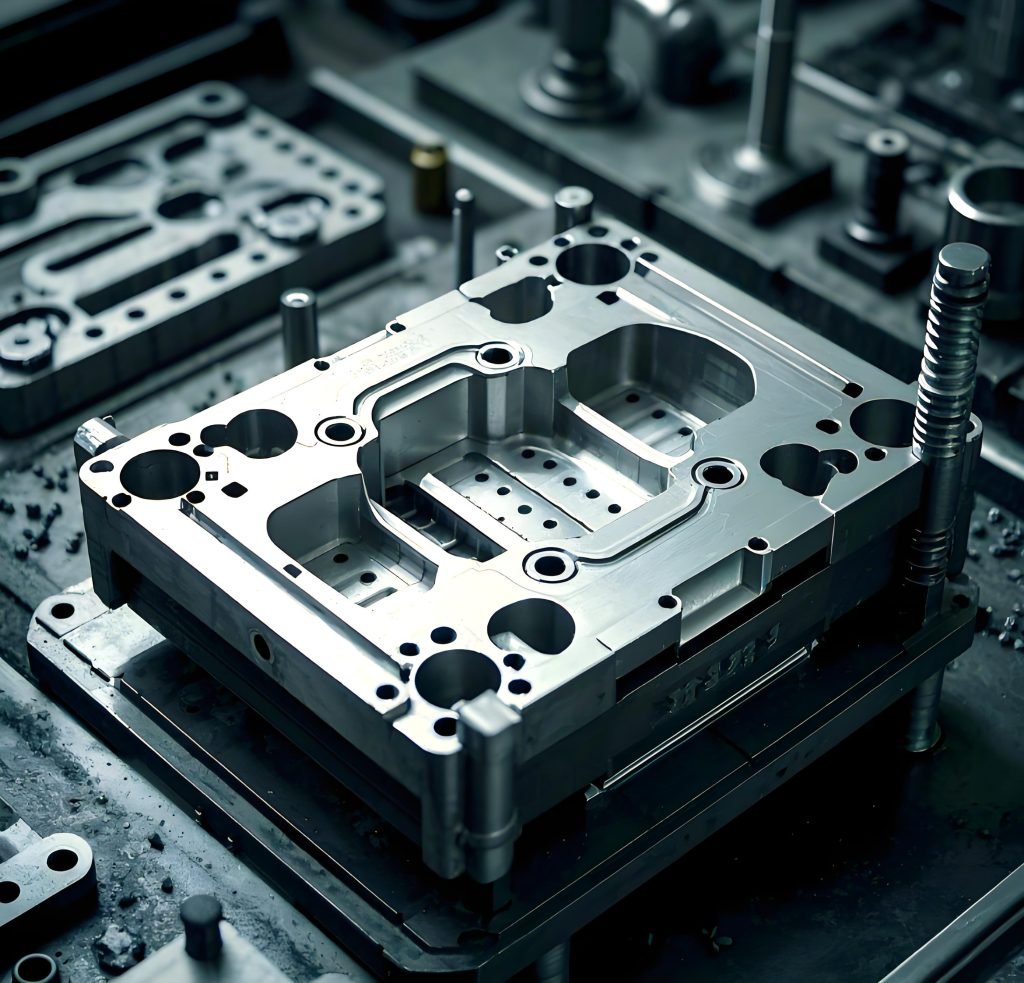

While designing the mold, engineers must ensure efficient venting and the state of the melt flow. Fast injection is also a major reason behind this issue because there is not enough time for air to escape.

The situation becomes even more critical when mold vent holes are blocked by different impurities and mold release agents. Proper care and maintenance of the molding equipment can prevent this issue.

- Equipment Quality or Malfunctions

There are different sensors in the molding equipment to control the heat distribution and other parts of the process. Damaged temperature control systems, sensors, and thermocouples can cause localized overheating.

The gaps between screws and barrel also affect the flow of the melt. Material decomposition or abnormal material ejection alters the desired heating levels and results in excessive heat exposure to certain parts.

- Raw Materials

What type of material are you using for injection molding? If there is excess moisture in the raw material, you might get defective products. While adding plastic additives, make sure to analyze the chemical properties of the material. Poor resistance against heat needs to be addressed immediately.

- Mold Design Issues

Poor venting is not the only issue related to mold design. Injection molding is a sophisticated process and requires highly precise and accurate design. Here are possible mold design issues that might cause dark spots or burn marks on the plastic parts.

Sharp Corners and Edges

These can create areas of high stress and shear. This causes localized heating and potential degradation.

Poor Surface Finish

A rough mold surface can impede gas escape and increase friction, contributing to localized heating.

Tips to Prevent Burn Marks in Injection Molding

A proactive approach to process design, material handling, and mold maintenance can help minimize or eliminate burn marks. Addressing burn marks requires a systematic approach. There are different factors and elements that you need to improve to prevent possible defects during injection molding.

Here are a few tips to reduce the frequency of burn marks and other aesthetic defects in the injection molding process.

- Reduce the injection speed so that the material can evenly settle in the mold.

- Make sure proper venting for the escape of the air trapped inside the mold

- Optimize the melt temperature according to the suggested range of the manufacturer

- Decreasing back pressure also helps with uniform melt quality

- Reduce the clamp force because unnecessarily high clamp force can also be problematic

- Try different levels of hold pressure to determine the best fit

These are a few practical tips to prevent burn marks on your end. These tips only work if the molding equipment is of fine quality. Faulty equipment cannot deliver the desired level of efficiency, so get high-quality molds for your project.

If you are facing this issue, start by inspecting the mold parts to detect any type of malfunctioning sensor or component. Once you are sure that all components are working as required, follow the above-mentioned tips to prevent injection molding burn marks.

Final Words

Having a trusted parts and mold manufacturer can prevent many potential challenges that molders face during injection molding. If challenges happen, customer support can help you navigate the issues. Burn marks are a clear indicator that something is amiss in the injection molding process.

Burn marks in injection molding can be frustrating, but a clear understanding of the cause can help you mitigate the problem easily. Regular maintenance, process monitoring, and the use of simulation tools further ensure a robust and reliable molding operation.