Polycarbonate is a versatile material known for its high impact resistance and transparency. It’s perfect for many manufacturing processes, like injection molding. Its ability to handle extreme temperatures and flexibility make it great for injection molding.

Using polycarbonate in injection molding has many benefits. It allows for creating complex shapes and designs with high precision. The process involves injecting molten plastic into a mold, where it cools and solidifies, taking the mold’s shape.

This method can produce a wide range of products, from simple components to complex systems. Knowing polycarbonate’s properties and the injection molding process is key to understanding its suitability for different applications.

Introduction to Polycarbonate

Polycarbonate is a versatile material known for its unique combination of properties. It is strong, durable, and transparent. These are key material properties that make it widely used.

The polycarbonate definition includes its chemical structure. It is made to withstand significant impact without breaking. This is because of its flexible molecular chain, which absorbs and distributes force well. So, polycarbonate is often used where safety and durability are important.

What is Polycarbonate?

Polycarbonate is made from bisphenol A and phosgene. This creates a polymer with unique material properties. It has high impact resistance, transparency, and thermal stability. This makes polycarbonate suitable for many uses, from consumer goods to industrial parts.

Key Properties of Polycarbonate

Some key properties of polycarbonate include:

- High impact resistance

- Transparency and optical clarity

- Thermal stability and resistance to heat

- Chemical resistance and stability

- Electrical insulation properties

These properties make polycarbonate attractive for many industries. It is used in construction, automotive, and electronics. Its unique material properties and polycarbonate definition make it versatile and widely adopted.

The Injection Molding Process

The injection molding process is a detailed series of steps. It includes designing, prototyping, and producing a final product. This method has many benefits, like making lots of products quickly and accurately. It also helps in creating complex shapes with precision.

This process starts with designing the product using computer-aided design (CAD) software. Then, a mold is made to shape the final product. The mold is usually made of metal, like steel or aluminum, to handle high pressures and temperatures.

Overview of Injection Molding

The injection molding process starts with designing the product. This is done using CAD software. The design is then used to create a mold, which shapes the final product.

Benefits of Injection Molding

Injection molding has many benefits. It allows for high production volumes, low labor costs, and making complex shapes with precision. It also offers a lot of customization for specific designs and features. Some key benefits include:

- High production volumes

- Low labor costs

- Ability to produce complex shapes with high precision

- High degree of customization

In conclusion, the injection molding process is complex but offers many benefits. It allows for high production volumes, low labor costs, and creating complex shapes with precision. Understanding these benefits helps companies make better decisions about their manufacturing needs.

Polycarbonate’s Compatibility with Injection Molding

Polycarbonate is a versatile material used in many ways, including injection molding. It works well in this process because of its thermal stability and ability to be molded into complex shapes.

Material compatibility is key in polycarbonate molding. The material must handle high temperatures and pressures. Polycarbonate does this well, making it a top choice for many projects.

Why Polycarbonate is Suitable for Molding

Polycarbonate is great for molding because of several reasons:

- High thermal stability

- Good flow characteristics

- Ability to be molded into complex shapes

Limitations When Molding Polycarbonate

While polycarbonate is versatile, there are some molding challenges:

- Risk of warping or cracking

- Need for proper molding techniques and material selection

Understanding polycarbonate’s molding compatibility and its limits helps manufacturers create high-quality products. Its many benefits make material compatibility a key factor in making polycarbonate molded products.

| Material | Thermal Stability | Flow Characteristics |

|---|---|---|

| Polycarbonate | High | Good |

| Acrylic | Medium | Fair |

| ABS | Low | Poor |

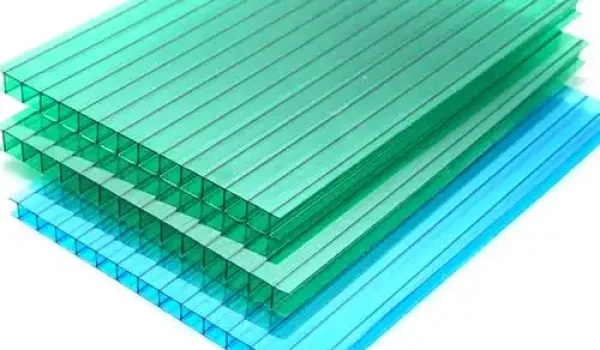

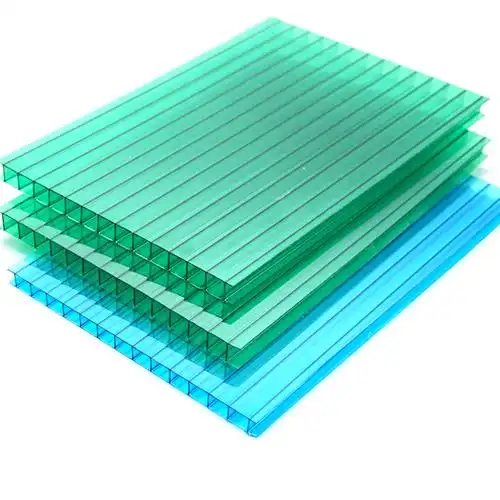

Types of Polycarbonate Used in Molding

Polycarbonate is a versatile material used in many ways. It’s perfect for injection molding because it can be molded into different shapes. This makes it great for lots of applications.

The type of polycarbonate used depends on what the product needs. This includes things like being clear, strong, or fire-resistant. Specialty materials are also added to make polycarbonate products even better.

Clear vs. Solid Polycarbonate

Clear polycarbonate is best for things that need to be clear, like lenses and screens. Solid polycarbonate is better for parts that need to be tough, like car parts and electronic cases.

Specialty Polycarbonates for Molding

Specialty polycarbonates are made for specific needs, like being fireproof, resistant to UV light, or chemicals. These types of polycarbonate are used when regular polycarbonate isn’t enough.

Using specialty materials in molding has led to new designs and products. By picking the right polycarbonate, makers can create products that do exactly what they need to do. And they often do more than expected.

| Type of Polycarbonate | Properties | Applications |

|---|---|---|

| Clear Polycarbonate | Optical clarity, impact resistance | Lenses, displays, medical devices |

| Solid Polycarbonate | High impact resistance, flame retardancy | Automotive components, electronic housings, construction materials |

| Specialty Polycarbonates | Flame retardancy, UV resistance, chemical resistance | Aerospace, medical devices, industrial equipment |

Advantages of Injection Molded Polycarbonate

Injection molded polycarbonate is a top choice for many reasons. It’s strong and light, making it perfect for many uses. Its high strength-to-weight ratio means it’s tough and can handle impacts and chemicals well.

This material is also very light. It can be molded into complex shapes without losing strength. This is great for making car parts, electronic cases, and more where weight matters.

High Strength and Durability

Polycarbonate is very strong and durable. It’s great for places where things need to withstand a lot of impact. It also handles extreme temperatures and chemicals well, making it perfect for outdoor and industrial use.

Lightweight Nature of Polycarbonate

Being light is another big plus for polycarbonate. It’s strong for its weight, allowing for detailed designs. This makes it a top pick for many industries where keeping things light is important.

Considerations for Molding Polycarbonate

Molding polycarbonate requires careful attention to several factors. This ensures the production of high-quality parts. Key considerations include managing temperature and controlling injection speed and pressure. These steps help prevent defects and improve part quality. Optimizing the process also helps reduce costs and increase efficiency.

Manufacturers must evaluate several important factors to achieve the best results. These include:

- Material properties

- Mold design

- Injection molding parameters

Temperature Management

Temperature control is vital in polycarbonate molding. Too much heat can damage the material. The ideal temperature range is between 280°C to 300°C. By managing temperature well, manufacturers can avoid defects and produce quality parts.

Injection Speed and Pressure

Injection speed and pressure are also critical. The right speed and pressure depend on the application and material. By optimizing these, manufacturers can improve part quality and reduce defects.

By focusing on molding considerations and optimizing the process, manufacturers can make high-quality polycarbonate parts. This approach also helps keep costs down and efficiency up.

| Factor | Optimal Range |

|---|---|

| Temperature | 280°C to 300°C |

| Injection Speed | Dependent on application and material properties |

| Injection Pressure | Dependent on application and material properties |

Recommended Molding Techniques for Polycarbonate

To make polycarbonate parts better, using the right molding techniques is key. It’s about making the process cheaper and the product better. Short cycle times help avoid mistakes and make things more efficient.

It’s also important to control moisture to prevent defects. This is vital in making high-quality products, like those for cars and electronics.

Short Cycle Times

Fast cycle times are important in making polycarbonate parts. They help make parts quickly and well. This is done by improving mold design and using new molding tools.

By making things faster, companies can work more efficiently and save money. This makes their products more competitive.

Use of Drying Equipment

Drying equipment is needed to stop moisture problems in polycarbonate parts. It removes moisture before molding. This ensures products are defect-free and meet quality standards.

This is very important for products that need to be top-notch, like in medical and aerospace fields.

Using these molding techniques helps companies make better polycarbonate parts. It improves quality, makes things more efficient, and saves money. This is a big part of making the production process better.

Common Applications for Molded Polycarbonate

Molded polycarbonate is a versatile material used in many industries. It’s strong, durable, and clear, making it perfect for many needs.

In cars, it’s used for dashboards and lights because it can handle big impacts. The tech world also uses it for industry uses like protecting electronics from the environment.

Automotive Components

- Dashboard components

- Lighting fixtures

- Windshields

Electronic Housings

Molded polycarbonate protects electronics from the outside world. It’s clear and lets light through, making it great for many tech needs.

| Industry | Application | Properties |

|---|---|---|

| Automotive | Dashboard components | Impact resistance, transparency |

| Electronics | Electronic housings | Protection from environmental factors, transparency |

In summary, molded polycarbonate is used in many fields, like cars and tech. Its strength, durability, and clarity make it a top choice for many industry uses.

Challenges in Molding Polycarbonate

Molding polycarbonate is a complex task. Ensuring quality control is a big concern. It’s important to watch temperature, pressure, and injection speed closely. This helps avoid defects and keeps the product consistent.

Warping and cracking are common issues. These problems happen when the material cools unevenly or gets too stressed. To fix this, manufacturers need to manage temperature carefully and use control systems.

To tackle these problems, several strategies can help:

- Implementing rigorous quality control measures to detect and prevent defects

- Optimizing the molding process to minimize stress and prevent warping

- Utilizing advanced materials and technologies to enhance the durability and performance of the final product

By tackling these challenges, manufacturers can make their polycarbonate products better. This leads to happier customers and more loyalty.

| Challenge | Solution |

|---|---|

| Warping and cracking | Precise temperature management and control systems |

| Defects and inconsistencies | Rigorous quality control measures |

Comparing Polycarbonate with Other Materials

Choosing the right material for injection molding is key. Polycarbonate is a favorite, but it’s good to look at other options too. A detailed comparison can guide your choice. We’ll dive into polycarbonate alternatives and their features.

Material comparison involves weighing the good and bad of each. For example, polycarbonate stands out for its toughness and clearness. Yet, materials like acrylic and ABS might match these qualities but cost less. Knowing these differences is critical for picking the right material for your needs.

Important factors in material comparison include:

- Cost: How much will the material cost, and what’s the impact on your budget?

- Durability: How long will the material last, and how well will it handle wear and tear?

- Optical clarity: Is the material clear or semi-clear, and how will it look in your product?

By looking at these points and exploring polycarbonate alternatives, you can choose wisely for your project. Whether you need something affordable or a material with special qualities, a thorough comparison is vital for success.

Maintenance and Care of Molded Polycarbonate Products

Keeping molded polycarbonate products in good shape is key. Regular care helps avoid damage and keeps them looking new. Here are some easy tips to follow.

Cleaning Tips

Cleaning is a must for product upkeep. Here are some cleaning tips for molded polycarbonate products:

- Avoid using abrasive materials that can scratch the surface.

- Use a soft cloth and mild soap solution to clean the product.

- Rinse the product thoroughly with water to remove any soap residue.

UV Protection Strategies

UV rays can harm polycarbonate products, causing them to degrade and lose color. To protect them, try these strategies:

- Applying a UV-resistant coating to the product.

- Using a UV-stabilized polycarbonate material.

- Avoiding exposure to direct sunlight for extended periods.

By cleaning and protecting your products from UV rays, you can keep them looking great. Regular care is vital to prevent damage and keep the product’s quality high.

| Material Care Tips | Benefits |

|---|---|

| Regular cleaning | Prevents damage and maintains appearance |

| UV protection | Prevents degradation and discoloration |

Conclusion

Polycarbonate is a top choice for injection molding in many industries. It’s strong, durable, and light, making it easy to work with. These qualities have made it very popular.

Recap on Injection Molding Polycarbonate

We’ve looked at what’s important for molding polycarbonate well. Things like managing temperature and using the right equipment are key. This ensures products are top-notch and without flaws.

Future Trends in Polycarbonate Molding

New tech will bring big changes to polycarbonate molding. We’ll see greener materials and more focus on eco-friendly making. Also, growing needs in aerospace and healthcare will influence how we use polycarbonate.