Today, roughly half of the vehicle volume – from bumpers to dashboards – is already composed of automotive plastic parts. These components can reduce weight, promote safety, and are absolutely ready for the next generation of EV designs. The metal-to-plastic transition represents an obvious major trend.

In this article, you will learn about the key plastics for automotive usage and the reasons why the plastic is superior to traditional metal. This includes rules for design, tips for matching properties, and effective manufacturer selections.

Types of Plastics Used in the Automotive Industry

The automotive world relies on many specific plastic types. Understanding their unique properties is the first critical step.

Polypropylene (PP) – The Volume King

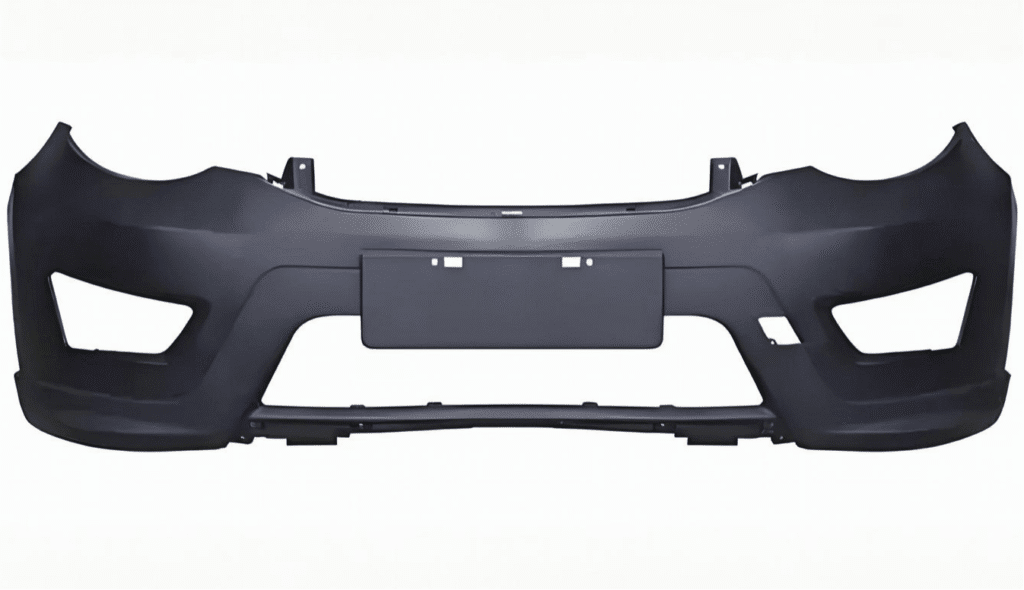

Polypropylene (PP) is, by far, the most common automotive plastic. It has low density, is extremely fatigue resistant, and is priced very competitively, which provides economic value as well. You’ll find it everywhere, like in bumper fascia, battery trays, and cable insulation. It truly is the volume king.

Polyurethane (PUR) – Foam & Skin in One

Polyurethane (PUR) is surprisingly versatile, and its micro-cellular foam can save several kilograms per seat. This directly improves fuel efficiency. Special reaction injection molding (RIM) variants are often used to create those soft-touch, luxurious skins you feel on the dashboard.

ABS – Dyeable Impact Shield

ABS is a tough, versatile plastic. Its heat deflection is suitable for the high temperatures found inside a car’s cabin. Plus, it can be easily dyed and accepts chrome plating well. Look for it in your dashboards, wheel covers, and various sensor housings.

Polycarbonate (PC) – Glass Clear & Bullet-Tough

Polycarbonate (PC) is as clear as glass and unbelievably strong. It handles impacts much better than traditional glass surfaces. This strength works well for thermoformed plastic automotive parts like headlight covers and large panoramic roofs.

Polyamide (PA/Nylon 6) – Under-Hood Metal Replacement

Polyamide (PA/Nylon 6) works well for under-hood parts that normally use metal. Its glass-filled grades handle hot oil and high temperatures without issue. It is frequently used in cam covers, timing gears, and protective fuse boxes.

PBT & PET – Electrical Twins

PBT and PET are the go-to plastics for electrical applications. They both offer outstanding arc resistance and great dielectric strength. You will find them in connector housings, plug bridges, and small but critical LED retainer clips.

PVC – Cost-Cutting Generalist

PVC (Polyvinyl Chloride) is a general-purpose, cost-effective plastic. It is often used to make vinyl leather for door cards and sheaths for wiring harnesses. The plasticized grades are specifically engineered to pass important FMVSS fire tests.

POM – Precision Slider

POM (Polyoxymethylene) is the go-to plastic for precision parts and moving components. It has low friction and resists moisture, which keeps performance stable. This makes it ideal for moving parts like window lift mechanisms and precision fuel-pump inserts.

ASA & PMMA – UV-Proof Glass Alternatives

ASA and PMMA are excellent UV-proof alternatives to glass. You’ll see them in tail-lamp lenses and shark-fin antennas. PMMA allows for laser-weld clarity, while ASA adds superior heat-warp resistance for external parts.

Why Use Plastics in the Automotive Industry

You might be asking why modern vehicles are moving towards plastics for automotive parts. The reasons for this move are compelling.

Weight Reduction Boosts EV Range

One of the biggest reasons to use plastic is mass reduction. A notable drop in vehicle weight directly raises the range of an electric vehicle (EV). For instance, a PP bumper beam can save several kilos compared to an equivalent steel part.

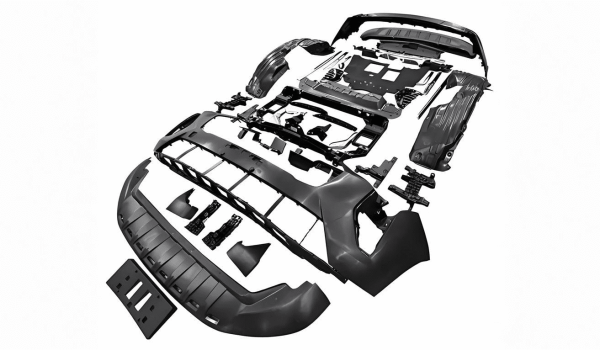

Parts Consolidation Cuts Assembly Time

Plastics allow for incredible parts consolidation. An injection-molded front-end module, for example, can merge numerous separate metal pieces into one simple snap-fit shell. This drastically cuts down on the overall vehicle assembly time.

Corrosion Immunity

Plastics offer total corrosion immunity. Rigorous salt-spray testing clearly shows that a PC/ABS housing stays completely rust-free. This is a huge advantage over coated aluminum or steel parts that will eventually degrade over time.

NVH Comfort Boost

Plastics are a key contributor to NVH (Noise, Vibration, and Harshness) comfort. Polyurethane foam often blocks road noise better than traditional rubber seals. Plus, a PC windshield can even cut down on the drumming sound of rain.

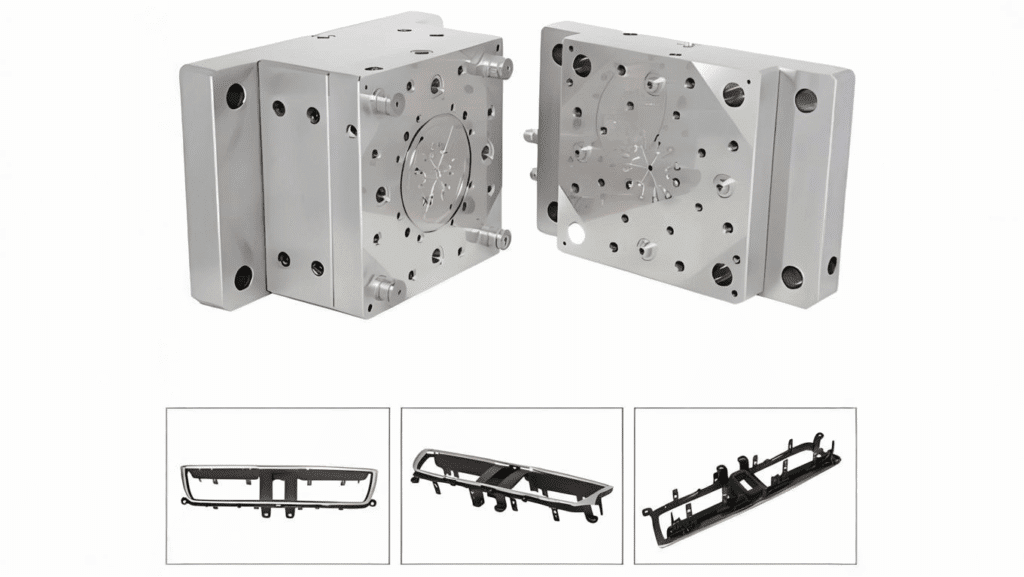

Lower Energy, Lower Cost

The manufacturing process for plastics is highly efficient. Creating plastic injection molding automotive parts generally consumes less process energy compared to the intensive stamping required for equivalent steel components. This leads to both energy and cost savings.

Key Considerations in Automotive Plastic Part Design

It’s not just about material selection when designing great plastic injection molding automotive parts. You must follow strict engineering rules for success.

Functional Requirements

Always define your functional requirements before you even sketch the part. This means setting clear targets for crash performance, thermal cycling limits, and chemical splash resistance. These requirements will directly dictate your wall thickness and rib depth.

Strategic Material Selection

You need a reliable material selection matrix. Map out all critical factors: heat resistance, impact strength, UV exposure, and the final cost. This comprehensive analysis helps you narrow down your choices, for example, deciding between PP+GF or PBT for a thermostat housing.

Uniform Wall Doctrine

Follow the uniform wall doctrine diligently. Try to keep nominal walls near the typical automotive range. Suddenly, thick bosses or ribs can cause visible sink marks on a Class A surface, especially on textured grain.

Draft Angle and Texture

You must include a proper draft for easy part ejection from the mold. A standard draft works for smooth parts, but a deeper-grained leather texture will need an extra angle. This prevents the plastic part from scuffing upon mold release.

Optimizing Gate and Weld Lines

Strategic gate and weld-line placement is essential for part quality. A film-gate placed behind an A-pillar trim can effectively hide the material flow marks. Always move the resulting knit line away from any hole edge to retain maximum weld strength.

Snap-Fits Over Fasteners (DFA)

Embrace Design for Assembly (DFA) by using snap-fits instead of mechanical fasteners. A living hinge can integrate a clip, saving on extra hardware. Remember to calculate the deflection below the yield limit for repeated mating cycles.

Post-Process Compatibility

Think ahead about post-process compatibility. If you are planning how to paint automotive plastic parts later, make sure to leave a proper overspray mask land in your design. This simple step ensures a clean final appearance.

Best Tips on Matching Plastic Properties to Automotive Applications

To maximize performance, you have to balance plastic’s strengths with the application’s needs. Let’s look at some examples.

Bumper Energy Absorbers

For bumper energy absorbers, you absolutely need excellent cold-weather ductility. The part must perform in freezing conditions. Choose TPO (Thermoplastic Olefin), which includes a rubber phase to achieve the high Izod toughness required for impact absorption.

LED Headlamp Heat Zones

In LED headlamp heat zones, the material must withstand concentrated heat. Aluminum-coated PC is ideal as it resists the reflector’s focus. You may also need to add a small heat shield to curb any long-term yellowing of the lens.

Under-Chassis Splash Shields

Under-chassis splash shields require toughness against road debris. Reinforced PP resists gravel impact even at sub-zero temperatures. Critically, the resulting component weight is still well below that of an equivalent steel shield.

Connector Seals

For robust connector seals, minimal moisture uptake is key to performance. PBT-Hydro is an excellent choice because it keeps its required IP rating (Ingress Protection) even after prolonged periods of high humidity exposure.

Interior High-Gloss Trim

Achieving a flawless interior high-gloss trim like piano black is possible with a PMMA/ASA blend. Independent UV-SAE testing conducted on this material consistently reveals minimal color shift, keeping the trim visually great for the life of the car.

How to Select Reliable Automotive Plastic Parts Manufacturers?

To choose the right automotive plastic parts manufacturers, here is an audit checklist that summarizes all key standards and why they are important to your project.

| Audit Standard | Key Questions & Inspection Points | Core Importance |

| Tooling Capacity | Do they have large-tonnage presses for big parts (e.g., lift-gate)? Do they use automated, lights-out robotic operations? | Verifies capacity for large parts and high-volume efficiency. |

| Mandatory Certification | Do they hold IAF 16949 certification and offer PPAP Level 3 capability? | Guarantees consistent part quality via strict Tier-1 process control. |

| Rapid Prototyping | Can they deliver soft-tool T1 samples in a matter of days? | Enables early validation (e.g., crash tests) before costly production tooling. |

| Integrated Finishing | Do they offer in-house painting (Class-rated cell) and laser etching with tight tolerance control? | Streamlines supply chain; ensures tight tolerance and quality finish. |

| Sustainability Focus | Do they provide evidence of regrind usage, a closed-loop water system, and carbon disclosure? | Aligns production with environmental standards and improves the company scorecard. |

Fecision – Your Shortcut to Production

Fecision is your certified Tier-1 partner for automotive plastic parts. We adhere to IAF 16949 certification and offer full PPAP documentation for each of our components. Our rigorous quality emphasis promotes the use of specialized metrology and ongoing in-process inspection to provide you with high-precision parts that meet your quality expectations every time.

Our one-stop service is seamless, offering manufacturing, finishing, and logistics all under one roof. This includes in-house robotic painting and machining to deliver efficient automotive plastic machined parts without secondary handling. Your sourcing process can benefit from our competitive lead times and affordability.

Need a supplier that keeps pace with the EV market’s demands? Partner with Fecision for precision components and reliable lead times from design to delivery.

Conclusion

Automotive plastic parts help make vehicles lighter and more efficient. Their good formability and range of strengths let them replace more expensive metal components. Understanding the key material types, critical design rules, and specialized finishing services available is the foundation for your next generation of vehicle components. Start the process!