In injection molding, shut-offs are where steel meets steel to lock molten plastic in place. When the mold clamps shut, these precision-machined surfaces create a seal that stops resin from leaking into gaps. Without it, you get defects—flashing around edges or incomplete short shots.

But shut-offs do more than block plastic: they sculpt sharp edges, clean holes, and complex shapes. That’s vital whether sealing syringe barrels against contamination or ensuring automotive connectors take vibration without cracking. It’s the machining accuracy holding back pressure, nothing less.

What Is a Shut Off in Injection Molding?

In plastic injection molding, a shut off injection molding acts like a precision lock inside the mold. Picture this: molten plastic flows into the mold cavity at extreme pressures. Without a reliable injection mold shut off, that plastic would leak into gaps between mold plates or around moving cores. The result? Defective parts with ragged edges are called flash, or worse, incomplete shapes that fail quality checks.

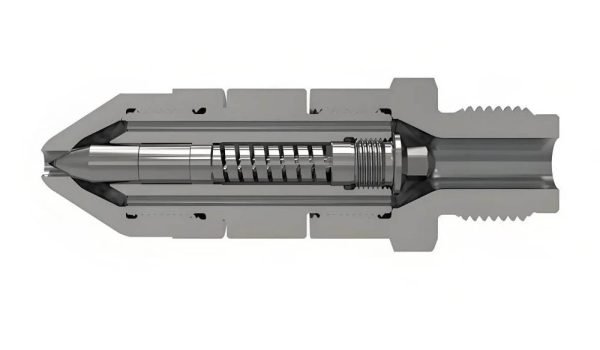

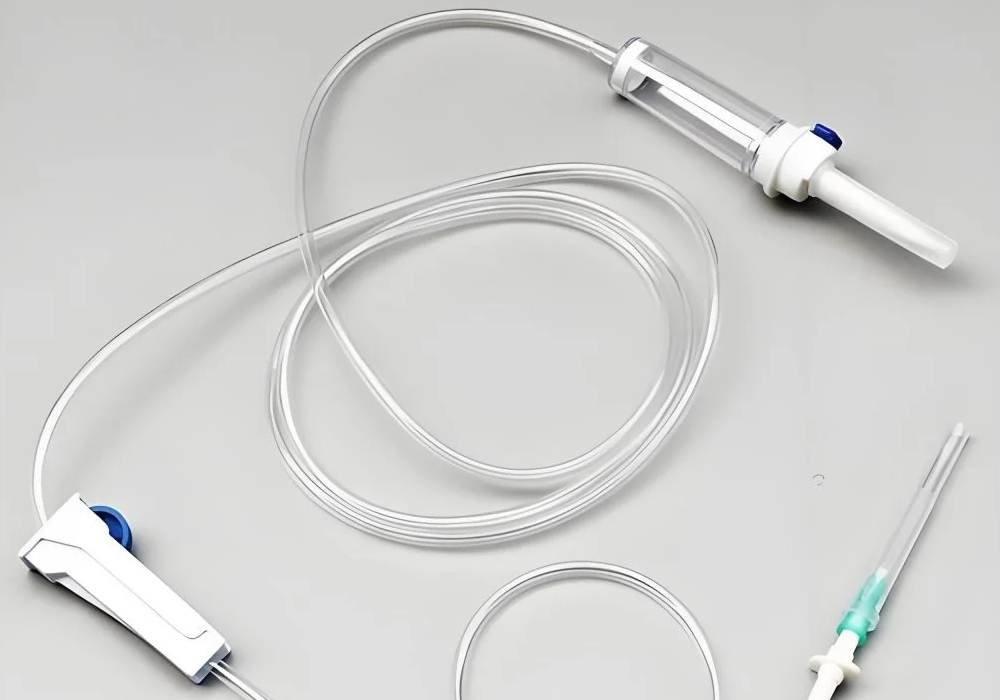

Shut offs achieve this sealing through direct metal-to-metal contact. When the mold clamps shut, two precisely machined surfaces press together, creating a barrier that withstands injection pressure. For instance, in molds for medical syringes, shut offs seal the barrel opening. If plastic seeped into this area, the syringe couldn’t hold liquid—a critical failure in healthcare applications. This sealing isn’t just about blocking plastic; it defines sharp edges, clean holes, and complex geometries impossible to achieve otherwise.

Common mold shut off designs include flat shut offs (simple vertical sealing faces) and angled shut offs (slanted surfaces that slide during mold closure). The angled type is essential for textured parts or undercuts, where a straight seal would jam. However, poor machining or wear causes trouble: tiny gaps allow flash formation, forcing workers to trim excess plastic by hand. Overly tight shut offs might even restrict plastic flow, creating short shots.

Four Essential Shut Off Designs for Injection Molds

Shut offs serve as critical sealing mechanisms in injection molds, physically blocking molten plastic from entering restricted areas. These components directly shape part geometry by defining where material can and cannot flow. Across industries, four primary designs address distinct functional needs — balancing precision, durability, and cost.

Flat Shut Offs

Flat shut offs depend on two smooth metal surfaces pressing squarely against each other when the mold closes. They work well for parts with straight edges, like electrical enclosures or storage containers. Because the sealing force runs perpendicular to the injection pressure, this design handles clamping stresses effectively.

Flat shut offs show sensitivity to wear. Minor scratches or machining imperfections create gaps. Plastic then seeps into those gaps, forming ragged edges called flash. Workers must trim these defects manually, slowing production. For simple parts made in large volumes — automotive trim components, for example — flat shut offs offer reliability if regularly maintained.

Wipes Shut Offs

Wipes shut offs use angled surfaces that slide against each other during mold closure. This sliding action scrapes away dust or debris, helping maintain a clean seal. They suit molds with textured grips or undercuts, like ergonomic tool handles. Consider a toothbrush mold: wipes shut offs around grip patterns prevent plastic leakage into fine ribs.

The sliding motion also reduces friction damage compared to flat designs, making them last longer with abrasive plastics. Still, angled surfaces require careful alignment. If tilted incorrectly during assembly, they bind or wear unevenly.

Saddles Shut Offs

Saddles shut offs curves to match rounded part contours, such as medical syringe barrels or test tubes. Instead of flat contact, they wrap tightly around curves to seal complex shapes. Medical device molds rely on this type because even a tiny plastic leak inside a syringe barrel ruins volume accuracy—a critical failure for drug delivery.

The challenge lies in machining curved surfaces. Producing saddle shut offs demands 5-axis CNC equipment, increasing mold costs. Yet for cylindrical parts, no simpler design ensures complete sealing.

Radiused Saddle Shut Offs

Radiused saddle shut offs add rounded edges to standard saddle designs. These subtle curves spread clamping pressure more evenly. In high-pressure applications like automotive fuel connectors, this prevents stress cracks caused by metal deflection. The radius also helps when molding glass-filled nylons or similar abrasives.

Sharp edges chip after thousands of cycles, but rounded transitions wear more slowly. While machining costs rise, the extended mold life justifies investment in aerospace or medical implant production, where tooling downtime is expensive.

| Shut Off Type | Application | Sealing Mechanism | Consideration |

| Flat Shut Offs | Straight-edge parts (e.g., enclosures, containers) | Vertical metal surfaces compress perpendicular to the injection force | Wear sensitivity – scratches cause flash, requiring manual trimming |

| Wipes Shut Offs | Textured/undercut components (e.g., tool grips, cosmetic cases) | Slanted surfaces slide to scrape debris during closure | Angular alignment – misalignment risks jamming or uneven wear |

| Saddles Shut Offs | Cylindrical shapes (e.g., syringes, test tubes) | Curved contour wrapping around the part’s radius | Machining complexity – requires 5-axis CNC |

| Radiused Saddle Shut Offs | High-pressure/abrasive applications (e.g., fuel connectors, PEEK implants) | Curved edges distribute clamping stress | Initial investment – higher machining cost justifies extended mold life |

Troubleshooting Common Issues with Shut Offs in Injection Molding

Shut-off failures rank among the most disruptive problems in injection molding. When these critical seals malfunction, they allow molten plastic to invade restricted areas. This leakage creates defective parts requiring costly rework or scrap. Understanding why shut offs fail requires examining physical wear, thermal stress, and design mismatches.

Flash Formation at Shut Off Lines

Flash occurs when plastic seeps through micro-gaps between shut off surfaces. With flat shut offs, even very tiny wear can cause thin plastic fins along parting lines. This wear often stems from abrasive fillers like glass fibers eroding steel over thousands of cycles. In medical molding, flash inside syringe barrels ruins sterility, forcing entire batches to be discarded.

To fix this, technicians first measure gap sizes with feeler gauges. If gaps exceed the standard, the mold must be disassembled. Worn shut off areas are then re-machined or welded. For temporary repairs, copper-based anti-seize lubricants reduce friction, but this is only a short-term solution for low-volume production.

Premature Wear in Angled Shut Offs

Wipes shut offs fail differently. Their sliding action generates friction heat, especially with high-viscosity polymers like PVC. Over time, this heat softens hardened steel, accelerating wear. A telltale sign is uneven flash on textured surfaces—plastic leaks deeper into engraved patterns where metal contact weakens.

Mismatch in Curved Shut Off Geometries

Saddle shut offs demand exact curvature matching. If CNC machining tolerances exceed ±0.01mm, plastic infiltrates tube interiors or undercuts. This is catastrophic for medical devices like IV connectors, where internal leaks alter fluid pathways. Troubleshooting starts with blue dye testing: technicians coat shut off surfaces with layout dye, close the mold, and inspect transfer patterns. Uncolored spots indicate poor contact.

Stress Cracking Under High Pressure

Radiused saddle shut offs excel in high-pressure applications but fail if radii are undersized. Sharp edges concentrate clamping stress. These cracks appear as branched lines near shut off corners.

Thermal Expansion Errors

All shut off types suffer from thermal miscalculations. Molds expand when heated during operation. If shut offs were machined at room temperature, thermal growth creates gaps at operating conditions. Compensating requires pre-calculating thermal growth rates during mold design. For existing tools, lowering melt temperatures reduces expansion but risks incomplete part filling—a trade-off demanding careful validation.

Best Practices of Injection Molding Shut Off in Different Industries

Medical Devices: Precision Above All

Injection molding shut offs in medical molding demand zero leakage. Even microscopic gaps risk contaminating sterile devices like syringes or IV connectors. These curved seals wrap tightly around tube geometries, preventing plastic seepage into fluid pathways.

Cooling control proves critical here – mold temperatures must stay to avoid thermal expansion gaps. Materials like tungsten carbide handle repeated sterilization cycles without degrading. Post-molding, helium leak tests verify seal integrity at sensitivity levels beyond standard methods.

Automotive Components: Enduring Stress and Vibration

Automotive shut offs battle constant vibration and thermal swings. Textured dashboard vents or intake manifolds use angled wipe shut offs. The sliding action during closure scrapes debris off surfaces, maintaining clean seals amid dust-prone environments. Laser-hardened steels withstand abrasive glass-filled polymers common in under-hood parts.

Unlike medical designs, automotive shut offs tolerate slightly wider gaps, but compensate with higher clamping forces. Real-time pressure sensors often monitor shut off interfaces during production, auto-adjusting clamps if readings drop below safe thresholds.

Electronics: Keeping Particles at Bay

Electronics molding cannot tolerate even nano-scale flash. Plastic fragments near microchips cause short circuits. Flat shut offs with polished nitride coatings dominate here. The ultra-smooth surfaces minimize friction wear from reinforced plastics like PC/ABS. Designers allocate wide “sealing zones” around shut offs for easier maintenance access.

Crucially, gates avoid placement near shut off lines–molten plastic flowing too close to seal edges increases leakage risk. Piezoelectric sensors embedded in molds detect pressure drops instantly, triggering machine adjustments before defects occur.

Consumer Goods: Balancing Cost and Longevity

High-volume production favors simplicity. Container molds often use standardized saddle shut offs with radii matching common diameters. Pre-hardened steels provide adequate durability for 1 million cycles at lower costs than aerospace alloys. For colored plastics with abrasive pigments, polished shut off surfaces resist wear better than textured finishes.

Maintenance follows fixed intervals: every certain cycle, blue dye tests check contact areas. If dye transfers unevenly, surfaces are re-polished rather than fully replaced–a cost-saving tactic less common in precision industries.

Aerospace: Confronting Extreme Conditions

PEEK or PEI aerospace components withstand great pressures. Radiused shut offs with stress-relieved edges prevent cracks under load. Radii typically exceed part wall thickness to distribute clamping forces evenly.

Unlike consumer goods, sacrificial aluminum inserts surround shut off zones. These inserts absorb wear and get replaced after a certain cycles without dismantling the entire molds. Post-production micro-CT scans validate internal seal integrity, detecting voids invisible to traditional methods.

Conclusion: Match Shut Off Design to Industry Needs

Shut off performance relies on aligning geometry with industry priorities. Medical devices demand radiused seals with near-perfect curvature control. Automotive wipe shut offs focus on angled sliding surfaces to absorb road vibrations, while electronics require polished flat interfaces to block conductive particles. Consumer goods tolerate simpler saddle shut offs, but aerospace needs reinforced edges to handle extreme chamber pressures.

A mold’s shut off design controls part quality and tool longevity. These critical seals balance material behavior, thermal dynamics, and mechanical forces. Selecting the optimal geometry – flat for simplicity, radiused for strength, or angled for complex textures – prevents leakage and premature failure. Success hinges not just on design, but on robust materials that endure repeated use while maintaining tight tolerances. Fecision’s engineers prioritize this functional alignment before selecting materials, avoiding failure seen in generic shut off designs copied between industries.

Fecision’s shut off solutions integrate proven geometries with industrial-grade materials engineered for resilience. For medical applications, we deliver curvature-perfect seals that meet stringent hygiene standards. Automotive shut offs feature hardened surfaces validated through extended operational testing. Every design undergoes rigorous real-world validation to ensure seamless performance under production conditions.

This expertise comes from years of perfecting high-performance molds. We simplify complex sealing challenges across project scales – from prototype tooling to mass production molds. Clients sidestep costly errors through our preventive design review, where engineers optimize shut off interfaces before manufacturing begins.

Why Fecision Stands Apart

- Flexible Order Solutions + Comprehensive Inspection

- Industry-Specific Compliance: Medical, automotive, and quality system certifications

- Accelerated Development: Streamlined workflows from concept to production